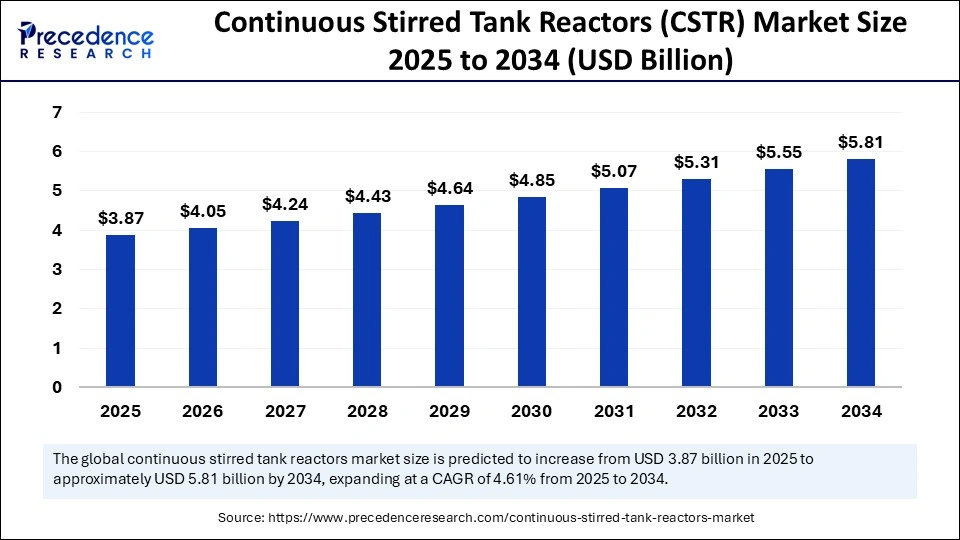

The global continuous stirred tank reactors (CSTR) market size is calculated at USD 3.87 billion in 2025 and is forecasted to reach around USD 5.81 billion by 2034, accelerating at a CAGR of 4.61% from 2025 to 2034. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global continuous stirred tank reactors (CSTR) market size accounted for USD 3.70 billion in 2024 and is predicted to increase from USD 3.87 billion in 2025 to approximately USD 5.81 billion by 2034, expanding at a CAGR of 4.61% from 2025 to 2034. The growth of the market is attributed to the increasing demand for efficient and scalable chemical processing solutions across industries such as pharmaceuticals, petrochemicals, and wastewater treatment.

Artificial Intelligence-driven process control systems are increasingly being implemented in continuous stirred tank reactor (CSTR) operations to enhance safety and efficiency. Temperature pressure and flow rates are just a few of the reactor parameters that these sophisticated systems monitor and control by analyzing real-time data. AI algorithms can anticipate possible problems before they arise, lowering the possibility of hazardous situations and interruptions to operations. AI algorithms reduce human errors and detect anomalies in operations, enhancing decision-making and operation safety.

AI-driven process control systems are essential for increasing efficiency in addition to enhancing safety. Through the automation of repetitive control tasks and the provision of actionable insights to operators, they guarantee optimal reactor performance. As a result, there is less waste, less energy use, and better resource utilization. Moreover, AI-driven process control systems can boost the throughput of CSTR operations and maintain consistent product quality by dynamically modifying parameters in response to real-time requirements.

The continuous stirred tank reactors (CSTR) market is experiencing significant growth due to its widespread application across various industries. CSTRs are crucial in operations like wastewater treatment, chemical manufacturing, and pharmaceutical production that call for constant mixing and reaction. They are adopted in both large-scale industrial operations and research settings due to their high efficiency and cost-effectiveness, which enable continuous production and maintain uniform reaction conditions. The demand for CSTRs is rising across a variety of industries due to their adaptability in managing a broad range of chemical reactions.

Ongoing technological innovations and a growing focus on environmentally friendly production methods are likely to drive market growth. The performance and dependability of CSTRs have been improved by advancements in reactor design, automation, and real-time monitoring systems that allow for exact control over reaction parameters and raise the quality of produce. Industries are also encouraged to adopt CSTRs by the move toward continuous manufacturing processes, which are more efficient and produce less water than traditional batch methods. As industries look for more sustainable and efficient production methods, the demand for CSTRs is expected to rise.

| Report Coverage | Details |

| Market Size by 2034 | USD 5.81 Billion |

| Market Size in 2025 | USD 3.87 Billion |

| Market Size in 2024 | USD 3.70 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.61% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type of Operation, Application, Material of Construction, Size, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Consistent and Reliable Mixing Performance

CSTRs ensure uniformity in temperature concentration and other reaction parameters across the vessel. They are perfect for delicate and intricate reactions where reliability is essential. In addition to improving batch-to-batch reproducibility, steady-state operation lowers the risk of process variability. Industries like chemicals and pharmaceuticals rely heavily on CSTRs. By distributing heat, CSTRs enable uniform mixing, making it possible to handle exothermic reactions more effectively.

Rising Use in Water and Wastewater Treatment

The rising use of CSTRs in water and wastewater treatment is driving the growth of the continuous stirred tank reactors (CSTR) market. In biological treatment procedures, especially anaerobic digestion and activated sludge systems, CSTRs are essential. Sustainable wastewater management solutions are becoming more and more popular among the municipal and industrial sectors. By aiding in the breakdown of organic waste and producing biogas as a byproduct, CSTRs support the objectives of the circular economy. Their sturdy construction enables them to handle a range of sludge compositions and load conditions. The adoption of CSTRs is being aided by governments around the world enforcing stricter environmental regulations.

Complex Process Control

To ensure steady state operation and prevent deviations, CSTRs require strict control over several parameters. CSTRs require sophisticated control systems and software to ensure the monitoring of temperature, pressure, and pH changes in real time. This further increases complexities in operations. Reactions are frequently nonlinear and sensitive to small changes, making manual intervention dangerous. Operators need to be highly trained to interpret data and make quick corrections, and this talent isn't always easily accessible. Batch failures, compliance risks, and quality problems can result from inconsistent process control.

Risk of Contamination in Bioprocesses

CSTRs are frequently utilized in procedures requiring strict sterility, such as fermentation and cell culture. Continuous operation raises the possibility of microbial contamination from air vents, inlet valves, or raw materials. When a bioreactor gets contaminated, cleaning it without shutting it down completely becomes challenging and costly. This can lead to product recalls and regulatory noncompliance in food or pharmaceutical applications. Sterilization in place (SIP) system installation raises the complexity and cost of the equipment. Frequent cycles of microbial testing and cleaning also disrupt production and use more resources. Because of this, CSTRs are a dangerous choice for important biotech applications unless strict controls are implemented.

Innovation in Materials and Sustainable Reactor Designs

Innovation in materials creates immense opportunities in the continuous stirred tank reactors (CSTR) market. Developments are improving the robustness and adaptability of CSTRs in reactor materials, such as corrosion-resistant alloys, high-performance coatings, and sustainable composites. These advancements increase The scope of CSTR applications, making them appropriate for corrosive reactants and harsh operating conditions. Transportation and installation expenses are also being decreased by lightweight recyclable materials. Reactors that support low carbon and low waste objectives are sought after by industries as circular economic ideas gain traction. Manufacturers can stand out by emphasizing recyclable materials and environmentally friendly designs. In the current green economy, providing reactors or energy-efficient models that run on renewable energy adds even more value.

The continuous CSTR segment held a significant share of the continuous stirred tank reactors (CSTR) market in 2024. This is mainly because of its effectiveness, reliability, and scalability in production processes with large volumes. To minimize downtime and preserve steady state conditions, industries like chemicals, pharmaceuticals, and food processing increasingly prefer continuous operation models. Reaction kinetics, heat transfer, and product homogeneity are all crucial elements in maintaining constant quality in large-scale production and can be better controlled with CSTRs. Continuous system is a preferred option for facilities adopting Industry 40 principles because they are becoming more and more popular in a variety of industrial sectors. The capacity of these CSTRs to operate processes continuously also reduces labor costs and increases throughput.

The chemical production segment dominated the continuous stirred tank reactors (CSTR) market with the largest share in 2024 due to its widespread application in large-scale processes like neutralization, oxidation, hydrolysis, and polymerization. CSTRs are a crucial part of the synthesis of bulk chemicals where constant and continuous mixing is necessary. Processes requiring exact temperature and concentration control benefit greatly from CSTRs' capacity to maintain consistent reaction conditions. These systems' robustness and scalability also play a crucial role in the chemical industry's broad adoption. To maximize throughput and lower operating costs, chemical manufacturers continue to invest in medium and large-scale CSTR systems.

The pharmaceutical manufacturing segment is expected to grow at the fastest rate in the coming years. The growth of the segment can be attributed to strict regulatory compliance and the growing need for continuous processing. CSTRs are being incorporated into contemporary drug development and production lines as the industry moves from batch to continuous manufacturing to increase quality and shorten production times. CSTRs are perfect for pharmaceutical applications because of their capacity to produce consistent product quality and facilitate quick scale-up from lab to plant. To better control critical parameters, lower the risk of contamination, and guarantee consistent product output, all of which are top priorities for pharmaceutical companies, continuous stirred tank reactors aid in meeting good manufacturing practice (GMP) standards.

The stainless steel CSTR segment dominated the continuous stirred tank reactors (CSTR) market with the largest share in 2024 because of its superior characteristics such as resistance to corrosion and ability to tolerate high temperatures and pressures. These reactors are extensively utilized in the food processing, petrochemical, and chemical industries where long service life and high mechanical strength are crucial. In continuous production setups, stainless steel CSTRs are preferred due to their ease of cleaning and maintenance. They are also a flexible option for large-scale industrial applications due to their compatibility with a wide variety of reactants and solvents.

The glass-lined CSTR segment is expected to grow at the fastest rate during the forecast period, driven by the growing demand from the specialty chemicals, pharmaceutical, and cosmetic industries where non-reactive surfaces and product purity are essential. Because of their exceptional chemical resistance, glass linings are perfect for handling highly reactive or corrosive materials without contaminating the final product. These reactors are appropriate for procedures that need to follow stringent standards of cleanliness. These reactors also reduce the risk of cross-contamination. Developments in glass lining technology have expanded applications in high-precision manufacturing settings by improving durability and lowering maintenance needs. The use of glass-lined reactors is expanding quickly in sensitive applications due to the growing emphasis on high-purity production and regulatory compliance.

The medium scale CSTR segment held the largest share of the continuous stirred tank reactors (CSTR) market in 2024. This is mainly due to its broad applications in a variety of sectors, including wastewater treatment, chemicals, pharmaceuticals, and food processing. Medium-scale reactors are preferred for established processing units because they balance cost-effectiveness and operational capacity. Their adaptability to batch and continuous processes increases their usefulness in a variety of mid-sized manufacturing environments. Furthermore, medium-scale reactors frequently incorporate semi-automated control scalable operations without the expense or complexity of large-scale industrial systems. The increased need for these reactors, particularly in developing industrial zones, for consistent output quality and process optimization also bolstered the segmental growth.

The small scale CSTR segment is expected to expand at the fastest rate during the projection period. The growth of the segment can be attributed to the growing demand from pilot scale applications, research institutions, and startups. Small-scale CATRs are flexible and simple to use, making them perfect for early-stage product development, laboratory-scale experiments, and educational applications. Their demand is being further fueled by the rise in R&D investments in industries like biotechnology and specialty chemicals. Furthermore, small-scale units have become more advanced and economical due to developments in portable systems and modular reactor design. Their ability to adjust to new technologies like IoT integration and AI-based control is promoting wider adoption even in non-industrial settings.

The manually operated CSTR segment dominated the continuous stirred tank reactors (CSTR) market with the largest share in 2024. Manually operated CSTRs are inexpensive and easy to use in small to medium-sized businesses. These reactors are widely utilized in industries and academic settings where budgetary restrictions and more straightforward process requirements are prevalent. Manual systems are easy to maintain and give operators direct control over process parameters without requiring complex integration or advanced training. These reactors remain a preferred option, particularly in areas where customization and direct process control are crucial.

The automated CSTR segment is expected to grow at the fastest rate in the upcoming period, driven by the growing need for continuous processing that is precise, safe, and monitored in real-time. High levels of accuracy and operational efficiency have been made possible by the sophisticated sensor control units and software interfaces that these systems have. To satisfy stringent quality and regulatory requirements, industries like specialty chemicals, biotechnology, and pharmaceuticals are quickly adopting automated reactors. Incorporating smart technologies like AI and IoT also makes remote control process optimization and predictive maintenance possible, all of which are essential for contemporary manufacturing. Automated CSTR adoption is growing rapidly as industries strive for digital transformation and lessen human intervention in crucial operations.

Asia Pacific dominated the continuous stirred tank reactors (CSTR) market in 2024. This is mainly due to the rapid industrialization and increased investment in the bioprocessing, chemical, and pharmaceutical industries. The region has a robust manufacturing base. Increased government initiatives to promote sustainable practices and a strong emphasis on process automation across industries further boosted the demand for scalable and efficient reactor systems. Next-generation process technologies are also being adopted more quickly as a result of an increase in the accessibility and adaptability of equipment. The increased production of pharmaceuticals and chemicals further bolstered the growth of the market in the region.

North America is expected to witness the fastest growth in the upcoming years. The market is growing quickly in this region, thanks to a progressive shift toward high-tech solutions and strong R&D investments. North America has an advantage due to its top technology developers and substantial investment in pilot-scale innovations. Investments in continuous reactor systems are also being fueled by a focus on sustainable processing and energy efficiency. The region boasts well-established pharmaceuticals and chemicals manufacturing industries, which heavily rely on CSTRs.

Europe is observed to witness considerable growth in the coming years. The growth of the continuous stirred tank reactors (CSTR) market in the region can be attributed to the rising government initiatives to promote sustainable manufacturing processes. Continuous processing systems that satisfy performance and regulatory requirements are in high demand in the region due to its established industrial base. CSTRs are being used more often in a variety of applications, thanks to advancements in clean energy and green chemistry technologies. Furthermore, the incorporation of advanced reactor systems is supported by government funding for carbon-neutral and circular economy projects. Europe's focus on safety, quality, and compliance further influences the market

By Type of Operation

By Application

By Material of Construction

By Size

By Control Technique

By Region

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client