What is Hydraulics Market Size?

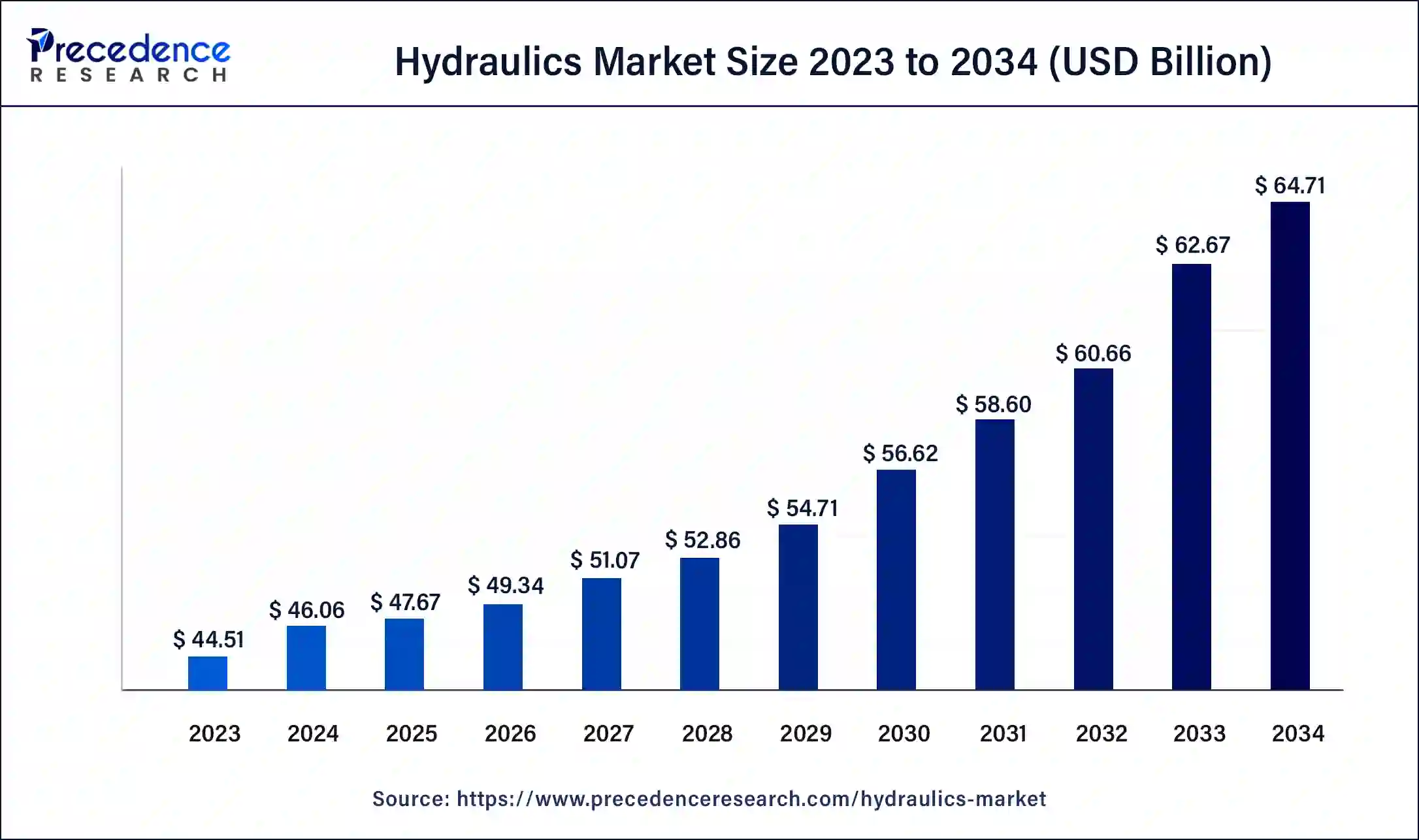

The global hydraulics market size is USD 47.67 billion in 2025, calculated at USD 49.34 billion in 2026, and is expected to reach around USD 66.73 billion by 2035, expanding at a CAGR of 3.42% from 2026 to 2035.

Market Highlights

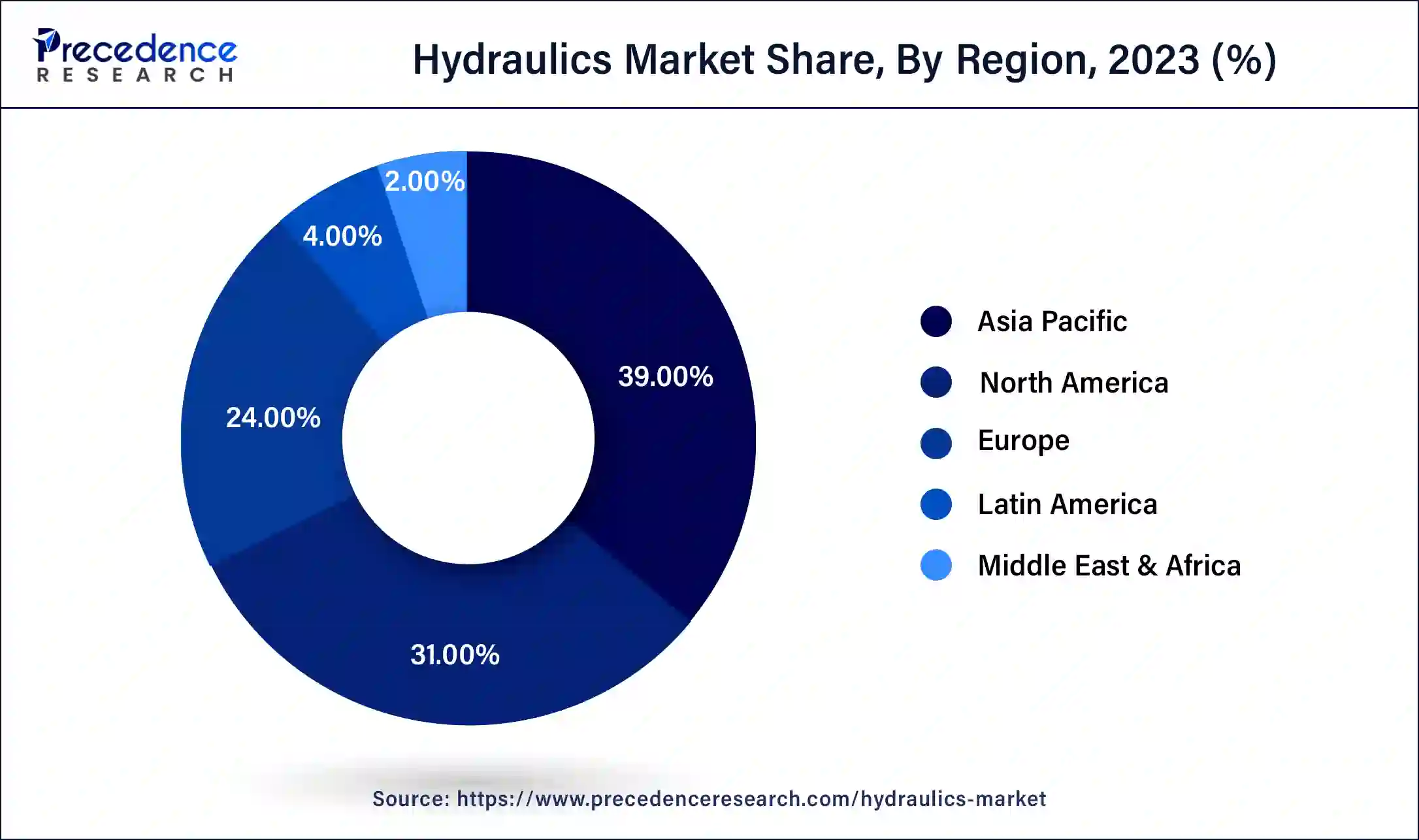

- Asia Pacific led the global market with the highest market share of 39% in 2025.

- North America is expected to witness the fastest CAGR of growth during the forecast period.

- By Component, the cylinders hydraulics segment dominated the market in 2025.

- By Component, the pump segment is expected to grow at a significant rate during the forecast period.

- By Application, the mobile-type segment dominated the market in 2025.

- By Application, the industrial hydraulics segment is expected to grow at a notable rate during the forecast period.

- By End-use, the construction segment dominated the market in 2025.

- By End-use, the agricultural segment is expected to generate a significant revenue share of the market during the forecast period.

What is the Hydraulics Market?

The hydraulics market refers to the industry that manufactures and sells hydraulic systems, components and equipment. Hydraulics is a powerful technology which can be seen in every industry. Hydraulics come in a variety of sizes and shapes. Hydraulics can be used in several industries such as manufacturing, construction, and others and it also works on other applications. There are many types of hydraulics systems or components used in several industries all of which work on the same principle. Hydraulics systems are flexible and can work in different kinds of industries and there are a number of types of hydraulics systems. Higher demand for the hydraulics system in expanding industries is driving the growth of the hydraulics market.

How is AI Contributing to the Hydraulics Market?

AI is the big deal in hydraulics. It does the magic of predictive maintenance, automating processes, and optimizing systems. Besides that, it allows for real-time monitoring to be done with more precision at less energy cost, and it even makes possible the running of digital twin simulations for the purpose of design improvements. Also, AI analytics are the ones reducing time taken to make decisions, consequently leading to less downtime, and thus, green operations. The transition made by the hydraulic industry towards smartness, flexibility, and reliability through AI and IoT integration is not restricted to the industrial and mobile applications alone but spreads across the whole spectrum of these applications.

Hydraulics Market Growth Factors

- Modern agricultural machinery, such as tractors and combine, use hydraulics for precision control and power, increasing the market's size in the agricultural sector.

- The need for more eco-friendly and energy-efficient solutions drives the development of hydraulic systems that reduce energy consumption and environmental impact.

- Growing industrialization in emerging economies increases the adoption of hydraulic systems in various sectors, contributing to market expansion.

- The presence of robust manufacturing bases for hydraulic components and systems in regions like Europe, North America and Asia Pacific fuels market growth.

- Regulations and standards related to safety and emissions drive the adoption of advanced hydraulic technologies to meet compliance requirements.

Market Outlook

- Industry Growth Overview: the steady growth of the market is underlined by the emphasis on electro-hydraulic systems and automation with the support of demand in construction and agriculture.

- Sustainability Trends:The three main areas of focus are eco-friendly fluids development, energy efficiency improvement, and light-weighting with recyclable materials to the overall reduction of environmental impact.

- Global Expansion: The Asia Pacific region is leading the global market growth as a result of fast industrialization, infrastructure projects, and increased farm mechanization.

- Major Investors: The market is ruled by the major manufacturers Bosch Rexroth, Parker Hannifin, Eaton, and Danfoss, who are investing heavily in R&D and taking strategic acquisitions.

- Startup Ecosystem: Startups are engaged in the creation of smart hydraulics using AI and IoT, and they put their efforts in the direction of innovative solutions such as hybrid systems and predictive maintenance capabilities.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 47.67 Billion |

| Market Size in 2026 | USD 49.34 Billion |

| Market Size in 2035 | USD 66.73 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 3.42% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | By Component, By Application, and By End-Use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Requirement of higher efficiency in industrial operations

Hydraulic systems can easily lift huge objects owing to their incredible strength. Hydraulic systems can easily move heavy loads by applying pressure and fluid power, which enables them to complete tasks that would otherwise be difficult. Because they are efficient and portable, hydraulic systems are perfect for many uses. Hydraulic parts can be carefully placed, just like a well-organized toolbox, to conserve space and improve functionality. Their small size makes it possible to build powerful machines that can fit in small locations. Precision control over machinery and equipment is provided by hydraulic systems.

These devices permit fine changes and movements, much like a good artist's brush. Hydraulic systems enable operators to move with greater precision whether controlling heavy machines or guiding a vehicle. Industries such as manufacturing firms, automotive industries and many others require higher efficiency in industrial operations, where hydraulics equipment can be considered an ideal option. Thereby, the factor is observed to act as a driver for the market.

Restraint

Complicated maintenance of hydraulics

Maintaining hydraulic systems often requires specialized knowledge and proficiency. Hiring technicians and professionals for the same can be challenging for manufacturers, especially for small-scale manufacturers. Maintenance activities can lead to downtime, which can be costly for industries where continuous operation is crucial, such as manufacturing and construction. Complex maintenance procedures may prolong downtime. Complex hydraulic systems may require more frequent maintenance, including the replacement of components, fluid changes and troubleshooting. This can deter potential buyers and users. Thus, the element is observed to act as a major restraint for the market.

Opportunity

Advancements in hydraulic pumps

Advanced hydraulic pumps are designed to be more energy-efficient, which can result in substantial cost savings for users. They reduce power consumption while maintaining high performance, making hydraulic systems more attractive to a wider range of industries. More efficient pumps contribute to reduced energy emissions, aligning with environmental regulations and sustainability goals.

Modern hydraulic pumps can offer higher flow rates and better controllability, which enhances the productivity and performance of machinery and overall equipment. Advancements in pump design have led to smaller, more compact pumps with reduced weight. All these advancements are observed to offer a growth opportunity for the market.

Segment Insights

Component Insights

The cylinder segment dominated the market in 2025. The position of the segment is attributed to the rising use of cylinder hydraulics in multiple industry applications. Hydraulic cylinders are mechanical components that can generate linear movement in chemistry by using a piston. The cylinder is used to convert linear movement energy to energy which can be stored and used in the entire hydraulic system.

The hydraulic cylinders are also considered the heart of the hydraulic system due to being the place where the energy is generated. Cylinder hydraulics are placed in the manner in which they are interconnected stored oil in it and fitted with pistons on both sides. It works when the force is given on the smaller side of the piston, the pressure is transmitted throughout the fluid. There are five major types of hydraulic cylinders such as single-acting hydraulic cylinders, double-acting hydraulic cylinders, tie-rod hydraulic cylinders, welded-rod hydraulic cylinders, and telescopic cylinders.

On the other hand, the hydraulic pumps segment is expected to witness a significant rate of growth during the forecast period. Hydraulic pumps can be hydrodynamic or hydrostatic, e pumps are mainly used to drive the hydraulic system in an equipment. Hydraulic pumps are used to convert mechanical energy into hydraulic energy. It creates enough power flow to overpower the pressure induced by the pump. In addition, the emergence of energy-efficient hydraulic pumps with the rising emphasis on reducing the energy consumption in industries creates a significant opportunity for the segment to grow.

Application Insights

The mobile hydraulic segment dominated the market in 2025. Ongoing innovations in hydraulic technology, including the development of electro-hydraulic systems and smart hydraulic components, have further enhanced the appeal of hydraulic systems in mobile applications. With proper maintenance, hydraulic components can have a long service life, which is important for mobile equipment that often has a high upfront cost. Mobile hydraulic systems are designed to withstand harsh operating conditions, including exposure to dust, dirt, extreme temperatures, and heavy vibrations. Their durability and reliability make them suitable for demanding environments.

The industrial hydraulic segment is expected to grow at a notable rate during the forecast period. Industrial hydraulics is used in a variety of industries. There are several varieties of machinery that can be used in the manufacturing process, metal formation, printing, stamping, injection molding, etc.

End-Use Insights

The construction segment dominated the market in 2025. The growth of the segment is attributed to the rising use of hydraulic technology in the industry or construction machinery. The majority of the machinery or equipment in construction sites is propelled by hydraulic power. In this kind of equipment, the hydraulic system drives motors and converts the hydraulic power into torque for pushing the diggers, bulldozers, and backhoes carrying a heavy load.

Construction equipment is subjected to harsh conditions, including extreme temperatures, heavy loads, and rough terrain. Hydraulics are known for their durability and resistance to wear and tear, ensuring that construction machinery can withstand the demands of the job site.

On the other hand, the agriculture industry segment is anticipated to generate a significant revenue share during the forecast period. The growth of the segment is attributed to the use of hydraulic power in agricultural machines and equipment which is driving the growth of the hydraulic market in the agriculture industry. The use of hydraulic power is changing the agriculture industry significantly through the adoption of the latest methods and manner of production. Adopting hydraulic power in the agriculture industry results in the reduction of the manual power amount, lowering the injury risks, limiting the amount and time of agricultural operations, and increasing the overall productivity of the individuals. The use of hydraulics is visible in the domestic and international agricultural systems.

- The heavy equipment outlook of 2022 was received by AEM, 65% of the fall member survey thought demand for agricultural equipment was above the normal level.

Regional Insights

Asia Pacific Hydraulics Market Size and Growth 2026-2035

The Asia Pacific hydraulics market size is valued at USD 18.59 billion in 2025 and is estimated to surpass around USD 26.03 billion by 2035, growing at a CAGR of 3.40% from 2026 to 2035.

How is Asia-Pacific Leading in the Hydraulics Market?

The biggest manufacturer of hydraulics is the Asia-Pacific region. Besides the mandated industrialization, and the subsequent automation of the manufacturing process, the region's demand for hydraulics is also coming from the construction and farming sectors where hydraulics are being increasingly adapted. Besides these factors, the governments through their policies aimed at renewable energy and modern infrastructure are also driving the need for hydraulics significantly. Moreover, the continued investments in advanced machinery and adoption of AI-integrated hydraulics have been making the region's position in the global market as a manufacturing hub even stronger.

China Hydraulics Market Trends:

The world's leading market player in hydraulics is China which is positioned there because of the enormous manufacturing sector, infrastructure development, and the growing use of hydraulics in the industrial sector. The fast pace of urbanization and the commitment to technology as a driving force have resulted in adoption of hydraulic systems in major industries. With its significant local manufacturing and technology cooperation, China is still developing smart hydraulic systems that focus on efficiency, safety, and eco-friendliness.

What are the Driving Factors of the Hydraulics Market in Europe?

The European market is characterized by the steady growth of advanced engineering, innovation driven by sustainability, and the large-scale application of the electro-hydraulic systems. Strong industrial automation and strict environmental regulations support energy-efficient and low-emission design developments. The area's commitment to the circular economy and recycling of materials ensures long-term competitiveness in the hydraulic manufacturing and system integration sector.

How is North America Performing in the Hydraulics Market?

The steady growth in demand for hydraulics in North America is attributed to the existence of cutting-edge industries, the continuous push for automation, and the growing use of smart hydraulic technologies. The construction and aerospace industries are not only growing but also the use of predictive maintenance and IoT technology is making operations more efficient and less costly which is opening new avenues for application across different sectors.

North America held the second-largest share in the hydraulics market, growing at the fastest rate. Hydraulics plays a crucial role in various industries, including construction, agriculture, manufacturing, and mining. An increase in industrial and construction activity typically drives demand for hydraulic equipment and systems. Infrastructure projects, such as road construction, bridges, and buildings, often require hydraulic systems for heavy machinery and equipment. Investments in infrastructure can boost the hydraulics market.

United States Hydraulics Market Trends:

Energy-efficient system and state-of-the-art processing are the forces that drive the U.S. market. The aerospace and defense sectors' high investment in automation and steady hydraulics usage are the major factors in this market.AI and digital control platforms' cooperation lead to even more precise, sustainable, and productive systems, hence making the country a pioneer in hydraulic technology development.

Germany Hydraulics Market Trends:

Germany is an exception among governments bringing about the exceptional quality of its engineering and the early embrace of smart hydraulic solutions. Industrial, automotive, and automation sectors extensively use the most modern hydraulic equipment. Research on fluid dynamics, component design, and hybrid systems leads to the constant performance enhancement which is in line with the goals of sustainability and precision engineering.

What Drives the Hydraulics Market in the Middle East & Africa?

The hydraulics market in the Middle East & Africa is driven by rising infrastructure development, oil and gas manufacturing activities, and ongoing construction projects. Growing demand for heavy-duty hydraulic equipment in energy, mining, and water management further fuels market growth. Additionally, the industrialization and diversification of regional industries are expanding the adoption of hydraulic solutions across multiple sectors.

Saudi Arabia Market Trends

Saudi Arabia is the major contributor to the market within the Middle East & Africa because of its extensive investment in large-scale infrastructure and robust oil and gas operations. As construction investments, industrialization, and the diversification of energy resources continue to grow, the need for dependable hydraulic systems is expected to rise.

How is the Opportunistic Rise of Latin America in the Hydraulics Market?

Latin America is expected to grow at a steady rate in the market, primarily due to increasing industrialization, infrastructure development, and expansion in the mining and energy sectors. Growing investments in agriculture, construction, and oil & gas projects are driving demand for heavy-duty hydraulic equipment. Additionally, the adoption of modern machinery and automation technologies is helping manufacturers expand their presence and capitalize on the region's untapped growth potential.

Brazil Market Trends

Brazil leads the Latin American hydraulics market due to its diverse agricultural economy, extensive mining operations, and major infrastructure investments. Rising mechanization in agriculture and the widespread use of hydraulic equipment in construction machinery have created consistent demand for hydraulic solutions across multiple industries.

Value Chain Analysis

- Raw Material Sourcing (Metals, Electronics): Attaining the basic materials that are necessary for the production of hydraulic systems.

Key Players: - Component Fabrication and Machining: The transformation of raw materials into hydraulic parts of high accuracy and assemblies.

Key players: Bosch Rexroth, Parker Hannifin, Danfoss, Kawasaki Heavy Industries - Testing and Certification: The components are subjected to tests and andcertification proving that the components meet the required performance, safety, and quality standards.

Key players: Bosch Rexroth and Parker Hannifin - Installation and Commissioning: The complete hydraulic systems are set up and employees are trained on the proper usage at the location of the operation.

Key players: Dhanvanthri Engineers Pvt. Ltd. and HYT Engineering - Distribution and Sales of Hydraulics: The final products are sent to industrial and commercial end-users in an efficient way.

Key players: Parker Hannifin, Bosch Rexroth, Danfoss, and Eaton

Hydraulics Market Companies

- Bosch Rexroth (Germany)

- Danfoss (Denmark)

- Parker-Hannifin Corporation (US)

- Enerpac Tool Group (US)

- HYDAC (Germany)

- Kawasaki Heavy Industries (Japan)

- KYB Corporation (Japan)

- SMC Corporation (Japan)

- Wipro Enterprises (India)

- Caterpillar (US)

Recent Developments

- In September 2025, ContiTech has launched production at its new $90 million hydraulics facility in Aguascalientes, Mexico, enhancing local supply chains, regional production capacity, and innovative fluid power solutions for regional customers. (Source: https://www.continental.com)

- In July 2025, Mahindra Tractors launched its mLIFT Precision Hydraulic System in three models: 275 DI XP Plus, 475 DI MS XP Plus, and 575 DI XP Plus, produced at Jaipur facility for Rajasthan farming. (Source: https://www.autocarpro.in)

Segments Covered in the Report

By Component

- Cylinders

- Pumps

- Motors

- Valves

- Filters

- Accumulators

- Transmissions

- Others

By Application

- Mobile Hydraulics

- Industrial Hydraulics

By End-Use

- Construction

- Agriculture

- Aerospace

- Metals & Machinery Manufacturing

- Automotive

- Mining

- Marine

- Oil & Gas

- Material Handling

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting