Copper Sputtering Target Market Size and Forecast 2025 to 2034

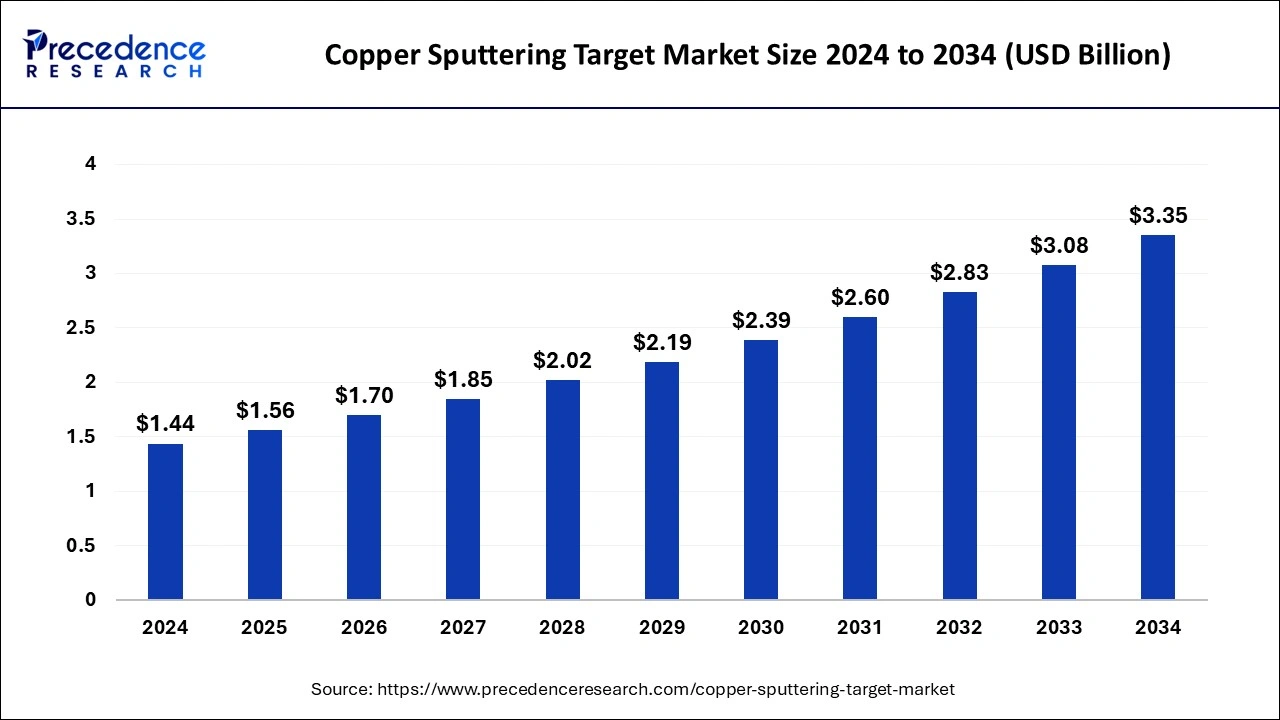

The global copper sputtering target market size was estimated at USD 1.44 billion in 2024 and is anticipated to reach around USD 3.35 billion by 2034, expanding at a CAGR of 7.83% from 2025 to 2034.

Copper Sputtering Target Market Key Takeaways

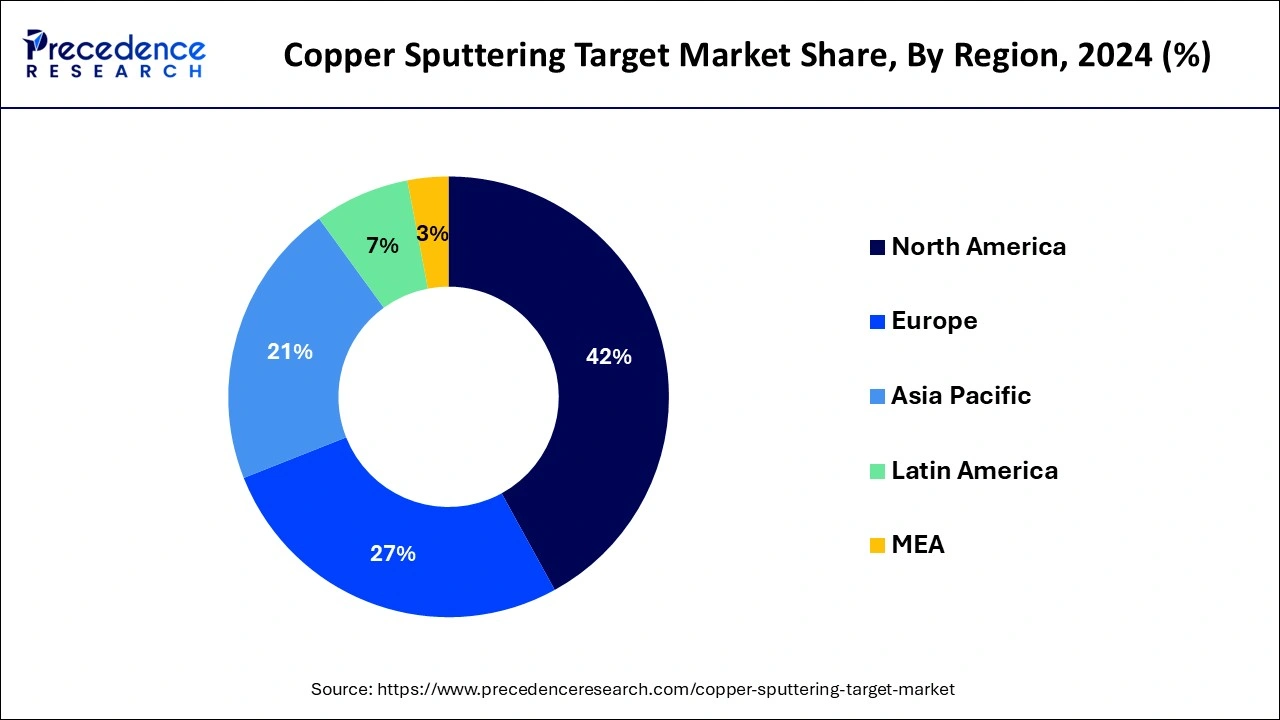

- North America dominated the global copper sputtering target marketwith the largest market share of 42% in 2024.

- Asia Pacific is projected to expand at the notable CAGR during the forecast period.

AI impact on Copper Sputtering Target Market

AI is significantly impacting the copper industry across various operational facets. Integration of AI in copper sputtering enhances efficiency and safety along with environmental compliance. AI algorithms detect trends in major copper using sectors like semiconductor industry, construction and electronics industry. This allows the producer to foresee demand for the copper and its market value which further affects the production schedules proactively.

Such strategic approach about deployment of AI fix that, the copper industry can meet the global demand effectively while ensuring sustainability by avoiding unnecessary production and utilization of resources.

U.S. Copper Sputtering Target Market Size and Growth 2025 to 2034

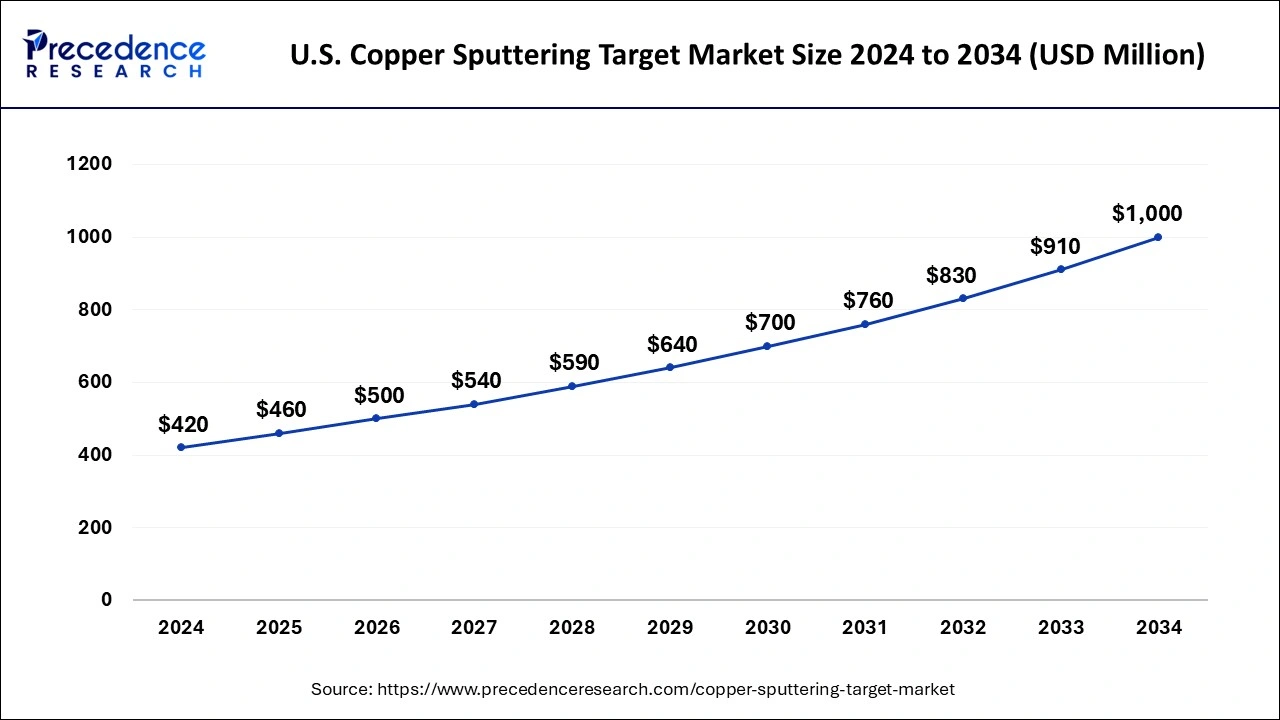

The U.S. copper sputtering target market size was evaluated at USD 420 million in 2024 and is predicted to be worth around USD 1000 million by 2034, rising at a CAGR of 9.06% from 2025 to 2034.

Given the rising demand for semiconductors, solar cells, and LCDs, dominated the global copper sputtering target market with the largest market share of 42% in 2024.

The market is expanding in Europe as a result of rising demand for high-purity items such as copper sputtering targets with ultra-high purity. Due to the rising demand for copper sputtering targets across a range of industries, including semiconductors, LCDs, solar cells, and others, the Asia Pacific is anticipated to experience considerable expansion over the course of the projected period.

Copper Sputtering Target Market Overview

Sputtering targets are materials that are subjected to physical vapor deposition (PVD), a process that involves the high-velocity ejection of atoms from solids. The atoms that are ejected after depositing on the workpiece produce a thin film coating with beneficial properties. There is a transfer of momentum that occurs when high-energy ions collide with the atoms of the target substance. Multiple collisions can occur at times. Due to long-distance flight, the ions occasionally lose energy. If the energy of the ions travelling to the target is higher than the energy of the bonds holding the atoms of the target material together, the colliding atoms will detach from the target material, a process known as sputtering. And the production of thin coatings on the target that range in thickness from a few nanometers to a few micrometres occurs during copper sputtering, a sort of deposition technique.

Gaseous atoms are released when the target materials split apart. These thermodynamically unstable atoms often live on a surface in a vacuum. The thin film is a coating of atoms that is formed on the target and is a micrometre thick. Using copper sputtering targets, the semiconductor and solar industries manufacture solar cells and other electrical devices. Using the sputtering method, a thin layer of an ultra-pure metallic or oxide substance can be deposited on another solid material. A component capable of high-speed computer operation is now being developed using copper sputtering targets with low electric resistance. The copper sputtering target's normal grain size is around 30 m, and 17% of the heterogeneities are formed by annealing at a temperature of 0.4 Tm in order to achieve uniformity in the thin layer that is created. Gases including krypton, xenon, neon, and argon are used in the copper sputtering procedure. Copper sputtering targets can be set up from projects in research and development to production teams, covering medium to large substrate regions, for effective energy directed to the target mass.

Copper Sputtering Target Market Growth factors

- Rising usage of copper material as a prime sputtering target material for manufacturing of semiconductor chips, propelling the copper sputtering target market globally.

- Growing demand for 5G technology across the globe along with AI is fueling the markets growth further.

- The quality of sputtering target material directly affects the uniformity and performance of conductive layer and barrier layer thus playing crucial role in the manufacturing of the electronics material.

- Increasing demand for enhanced chip performance and energy efficiency are the major driving factors for the market's growth globally.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 1.56 Billion |

| Market Size By 2034 | USD 3.35 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 7.83% |

| Base Year |

2024 |

| Forecast Period |

2025 to 2034 |

| Largest Market | North America |

| Segments Covered | Product, Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Increased use of copper as a sputtering target for semiconductor chips will fuel industry expansion.

The use of copper-sputtering targets for semiconductor devices is predicted to rise during the time of the projection, fueling expansion in the global market for copper-sputtering targets. The sputtering target is used to create the barrier layer and the packaging metal wiring layer. The metal grid, barrier layer, and conductive layer of the wafer are produced largely using the target material throughout the wafer manufacturing process. Using the sputtering target material, the chip packaging method produces the wiring layer, the metal layer behind the bump, and other metal parts. Despite the small number of target materials used in wafer manufacturing and chip packaging, according to SEMI figures, their cost accounts for around 3% of the total cost of the wafer manufacturing and packaging process. Sputtering target materials are one of the primary raw materials used in the production of semiconductors because they directly affect the uniformity and performance of the conductive layer and barrier layer as well as chip transmission speed and stability.

Restraint

The market's growth is hampered by the challenge of uniformly setting targets for complicated structures.

Two of the major obstacles for the worldwide copper sputtering business are the inability to reliably place targets with complex geometries and the sluggish deposition rate for specific materials in the sputtering target technology. The technological advancements and innovations produced by both established and upcoming producers in the copper-sputtering target market are also expected to hasten the resolution of these issues.

Opportunity

Consumer electronics semiconductor advancements offer a significant prospect for market expansion.

The development of semiconductors for consumer devices like smartphones, tablets, and laptops is likely to assist the growth of the global copper-sputtering target market during the forecasted period. For instance, IBM introduced strides in the design and manufacturing of semiconductors in May 2021 when it unveiled the first chip in the world to use 2 nm Nano sheet technology. Almost every area of modern life uses semiconductors, including computing, appliances, communications, transportation, and essential infrastructure. Improved chip performance and energy efficiency are in high demand, especially in the era of hybrid clouds, AI, and the Internet of Things. IBM has created cutting-edge 2-nanometer chip technology to help the semiconductor industry keep up with this growing demand. It is projected to perform 45% better or consume 75% less energy than the most recent 7 nm node products. As a result, these improvements in the business offer a lucrative opportunity for market expansion.

Product Insights

Based on techniques copper sputtering is divided into copper sputtering with low purity, copper sputtering with high purity, and ultra-high-copper sputtering.

- Copper sputtering target with low purity - When low-purity copper is sputtered, the target, a sturdy metal disc, is coated with the substance to be settled. As the target gets bombarded by ions to produce electrons, which are eventually released as one electrode of an electronic circuit, it is kept in place by the vacuum chamber of the apparatus of sputter deposition. By delivering a potential that is high voltage between the anode and cathode (the target), a field of electricity is created, accelerating the electrons toward the target (the substrate holder). When these electrons hit the gas molecules in the vacuum chamber, ions of one or both species can be created. The positively charged ions ionise the material on the cathode's surface and sputter it into plasma which condenses on the surface of the substrate when the negatively charged cathode is pulled to them.

- Copper sputtering Target with high-purity - Using a substance known as a copper-sputtering target, thin films are produced. The process of depositing layers of one or more materials onto a substrate to produce a thin film is known as sputter deposition. Sputtered targets are made using vacuum deposition processes, which bombard atoms on substrates with ion beams and impale them with high kinetic energy. The process is also known as sputtering, which is how the phrase "Sputtering Target" came to be. During deposition, ion beams expel target atoms onto surfaces, causing accumulation and the development of thin films with uniform thickness.

- Ultra-high copper sputtering Target -To create copper sputtering targets with ultra-high purity, copper that is 99.999% pure or greater is employed. The performance and quality requirements are quite stringent because it is the highest grade copper sputtering target. The bulk of applications for copper sputtering targets with ultra-high purity include ICs, photovoltaics, transistors, and other semiconductor devices.

Application Insights

This market is divided into Solar cells, LCD displays, semiconductors, Solar Cells, LCD Displays and others.

- Semiconductors -Due to its excellent conductivity and availability in pure form, copper is commonly used as a sputtering target in semiconductor devices. Reduced transistor size and increased need for metal-insulator-metal capacitors that are necessary to power portable electronics have led to an increase in its utilization throughout time. When used in semiconductor devices, copper's reactivity with oxygen and other ambient elements could reduce the lifetime of the device. As a result, attempts are being conducted to develop innovative defences against copper's air degradation.

- Solar Cells -Solar cells capture sunlight and turn it into electrical energy using a copper-sputtering target. It aids in the creation of photovoltaic (PV) technology, which uses sunlight to produce electricity. Because it effectively converts electrical energy from sunlight, copper is a good conductor of electricity. A copper sputtering target is also employed in the production of semiconductors and LCD screens.

- LCD Displays -LCD panels use copper sputtering targets for coating purposes. It is also known as a cathode ray tube (CRT). Copper sputtering targets are used to remove rust and prevent corrosion from metals. It acts as a barrier to prevent chemical reactions between other substances and the metal surface. Additionally, used in semiconductors, solar cells, and other items is the copper sputtering target.

Copper Sputtering Target Market Companies

- KFMI

- Honeywell Electronic Materials

- JX Nippon

- Praxair

- KJLC

- Tosoh

- China New Metal Materials

- KJLC

- Sumitomo Chemical Com-pang

- KJLC

- Plansee

- CXMET

Recent developments

- In June 2024, a global leader in high-performance connectivity, Valens semiconductor has announced the acquisition of Acroname, which is a foundational company in advanced automation and control technologies. This collaboration between two leaders will allow consumers to explore innovative products in the market.

- In April 2024, Vizsla Copper Corp. and universal copper Ltd successfully merged into the business corporation act. This consolidation significantly impacted the market driven by rising demand for infrastructure supporting EVs, AI and cloud storage, highlighting its major role in the market.

Segments Covered in the Report

By Technique

- Copper sputtering target with low purity

- Copper sputtering target with high purity

- Ultra-high copper sputtering

By Application

- Semiconductors

- Solar Cells

- LCD Displays

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting