StenTech Inc. Launches BluPrint PVD Stencils in the U.S., Revolutionizing SMT Production

The U.S. introduction of the new StenTech BluPrint PVD Stencils from StenTech Inc. is an advanced cutting-edge solution aimed at improved effectiveness, increased exactness, and durability of Surface Mount Technology (SMT) production. These technologies empower advanced Physical Vapor Deposition (PVD) technology to enhance solder paste deposition, productivity, and operational cost reductions to manufacturers across various industries.

The StenTech BluPrint PVD Stencils are designed to have superior high-precision and longevity mechanical features defined in the performance bar for stencil technology for SMT. They have an overall transfer efficiency of 98%, which is the most precise and perfect solder paste deposition ever established. Such features make an excellent environment for producing high-performance PCBs. The technology can be effective for complex PCBs with smaller area ratio designs and demand, rapidly becoming the standard in modern electronics.

Another thing that differentiates the StenTech BluPrint PVD Stencils from the rest is that they can perform substantially and consistently up to 50,000 prints without deterioration, greatly minimizing the need for cleaning cycles. The ultra PVD coating reduction in cleaning cycles by up to 300% is less production disruption, thereby significantly improving overall productivity.

Brent Nolan, President & COO, of StenTech, says: "We are at StenTech committed to promoting SMT technology and delivering solutions that are reliable and economical." The particular characteristics of coating conformity make StenTech BluPrint suitable for stencils optimized for everything from consumer electronics to automotive and industrial electronics applications.

As the electronics industry manufacturing goes on evolving, high-technology innovations such as StenTech BluPrint PVD Stencils meet the growing demands on performance by improved precision, reliability, and productivity requirements for high-speed production volume SMT. Leverage advanced PVD technology with customizability and remarkable durability; StenTech BluPrint opens up that missing piece towards higher productivity, fewer disruptions, and greater reliability in manufacturing electronics.

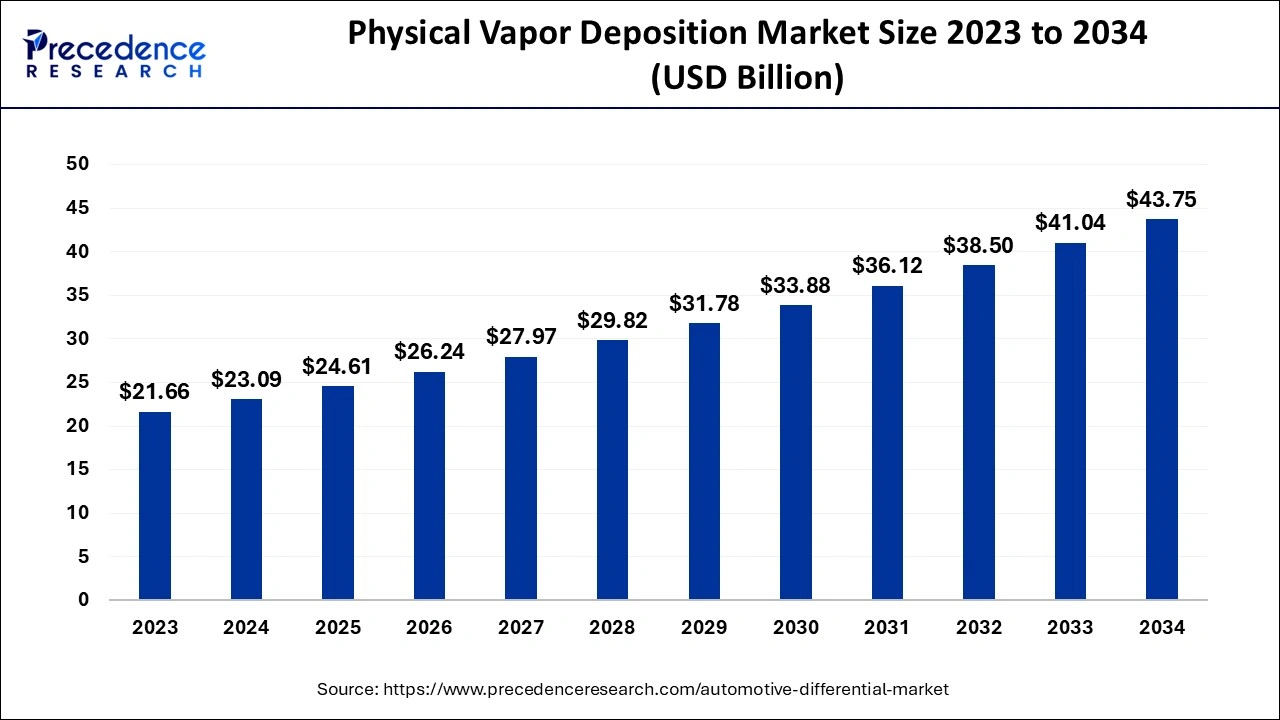

Physical Vapor Deposition Market Size and Forecast 2024 to 2034

The global physical vapor deposition (PVD) market size is accounted for USD 23.09 billion in 2024 and is anticipated to reach around USD 43.75 billion by 2034, growing at a CAGR of 6.60% from 2024 to 2034.

Physical Vapor Deposition Market Top Companies

- Advanced Energy Industries Inc.,

- AJA International, Inc.

- Angstrom Engineering, Inc.

- Applied Materials Inc.

- CHA Industries

- Intevac, Inc.

- Denton Vacuum

- OC Oerlikon Management AG

- IHI HAUZER B.V.

- Impact Coatings AB

Physical Vapor Deposition Market Recent Developments

- In October 2024, Boch developed a cutting-edge coating technology using physical vapor deposition (PVD) coatings in Suzhou, China, to enhance the durability and performance of fuel cell stacks. This breakthrough is expected to drive the adoption of electric vehicles by improving the lifespan and efficiency of critical components like bipolar plates.

- In October 2024, Sandvik Coromant introduces GC1230, a groundbreaking grade for indexable milling, featuring advanced Zertivo® coating technology. The PVD grade enhances strength, durability, and performance, making it the preferred choice for steel milling.

We’ve prepared a service to support you. please feel free to contact us at sales@precedenceresearch.com | +1 804 441 9344