Croom Medical Debuts Biofuse: Revolutionizing Orthopaedic Implants with 3D Printing

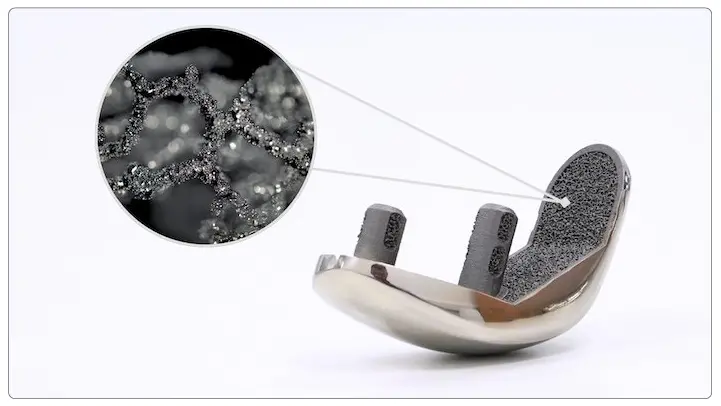

Croom Medical has unveiled Biofuse, a cutting-edge porous ingrowth platform powered by advanced Laser-Powder-Bed-Fusion (L-PBF) technology. Biofuse, which will dramatically change the design of orthopedic implants, provides OEMs with an unprecedented ability to design porous structures. This innovation gives OEMs exact control of pore size, porosity, and lattice gradients, allowing them to achieve better implant integration and patient outcomes.

Biofuse combines dense and porous regions within a single build to provide customized ingrowth conditions and also simplify the production. The method eliminates coating or machining procedures, reduces delamination hazards, and enhances the overall structural strength, even in highly intricate structures. Biofuse enables manufacturers to have a more predictable route between design transfer and proven production, giving them a faster time to market and ensuring they comply with the strict regulatory requirements.

Biofuse will assume a leading role in the uptake of additive manufacturing in orthopedics, which will lead to a new implant geometry, greater biological integration, and improved patient recovery outcomes. Biofuse can help to extend the life of an implant and potentially revolutionise standards in surgical practice and patient care. It has the capability of providing porous ingrowth structures that more closely mimic the behaviour of natural bone than existing methods. Furthermore, Biofuse, in an industry where accuracy and dependability are of the utmost importance, can be viewed as a solution of this kind that allows the convergence of technology innovation and clinical outcome.

Executives’ Statements:

Sean McConnell, Engineering & NPI Manager, Croom Medical:

“Biofuse draws on our additive experience, where we’ve seen firsthand how components can be both faster and more cost-effective to print than to machine. Embedding lattice structures directly into the build removes coating and machining steps. The result is a more predictable manufacturing process that consolidates production, preserves structural integrity, and helps OEMs bring implants to market faster.”

Dr. Bryan Naab, Additive Lead, Croom Medical:

“With Biofuse, customers can design lattices to their exact equirements. That might mean replicating a porous structure previously produced through coating methods, or proposing lattice characteristics. The flexibility of the platform gives OEMs confidence that their design intent can be realised consistently and in line with regulatory expectations.