Conveyor System Market Revenue To Attain USD 13.21 Bn By 2032

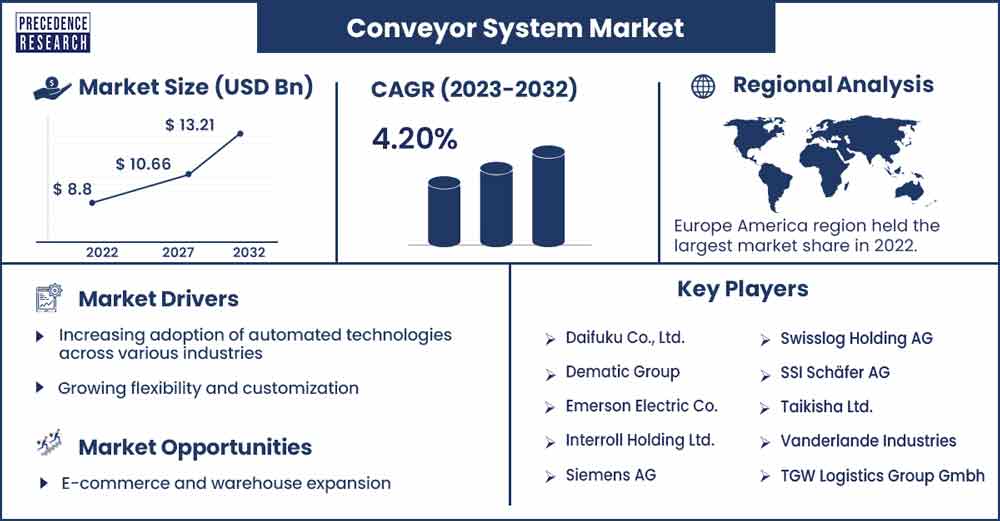

The global conveyor system market revenue surpassed USD 8.80 billion in 2022 and is projected to attain around USD 13.21 billion by 2032, growing at a CAGR of 4.20% from 2023 to 2032.

Market Overview

The industry that deals with the design, production, and distribution of conveyor systems is called the conveyor system market. Conveyor systems are mechanical handling devices used to move products, materials, and other items throughout a facility or between separate sites. These systems are widely used to automate material flow and improve operational efficiency in manufacturing logistics, warehousing, and transportation. The market for conveyor systems includes a broad range of goods and services, including several kinds of conveyor like screw, roller, overhead, and belt conveyor, among others. Maximizing the handling and transportation of commodities also entails the integration of automation and control technologies.

The need to reduce human labor in industrial operations, higher productivity, cost-effectiveness, and the necessity for efficient material handling are some of the factors driving the demand for conveyor systems. Conveyor systems are essential for optimizing production processes, cutting down on human error, and raising throughout levels. Changes in industry trends, technology developments, and the particular needs of various industries impact the market for conveyor systems. Conveyor equipment makers, system integrators, and solution providers that serve a variety of sectors seeking to improve their material handling procedures are among the businesses in this market. Further developments in the market to enhance the productivity and functionality of conveyor systems include robotics, IoT, and sophisticated sensors.

- In June 2022, Conveyor belts for offshore rescue were launched by UK firms. The rescue vessel's construction is being handled by the UK-based shipyard Manor Marine. The ship may operate both with and without people.

Regional Snapshot

Europe holds the largest share of the conveyor system market. It is observed that the growth of e-commerce has dramatically impacted the market in the region. Conveyor systems are essential for the growing need for quicker and more effective material handling and transportation solutions. They are widely utilized in automotive, food and beverage, pharmaceutical, and other industries. Europe has a broad manufacturing industry; thus, the demand for automated and effective production operations has propelled the use of conveyor systems.

Ongoing technological developments, such as sensors, IoT, and artificial intelligence, have improved the capabilities of conveyor systems. These facilitate predictive maintenance, real-time monitoring, and increased efficiency. Several key players are making significant strides in the European conveyor system market. These include Continental AG, Siemens AG, and Fives Group, whose contributions are shaping the industry's landscape and providing valuable insights for businesses.

Germany is leading the way in industrial automation. Conveyor system adoption is frequently a component of a more significant movement toward automated manufacturing processes to boost productivity, lower labor costs, and increase overall efficiency. Germany's economy is strongly related to the state of the world economy. Global economic trends, trade dynamics, and geopolitical developments can all impact manufacturing and, in turn, the market for conveyor systems. Continuous technological developments like IoT, data analytics, and sensor integration will likely impact the conveyor system market.

In the United Kingdom, the market is significantly influenced by the industrial sector's success. Conveyor systems and automated procedures are used in manufacturing facilities to increase productivity and lower labor expenses. The market is growing due to advancements in conveyor technology, such as incorporating automation, industry 4.0 principles, and sensors. Conveyor systems that possess the ability to interact with other machinery to ensure smooth functioning are becoming more and more common. Businesses must follow standards to guarantee both ecological sustainability and worker safety.

Conveyor System Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 9.13 Billion |

| Projected Forecast Revenue by 2032 | USD 13.21 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 4.20% |

| Largest Market | Europe |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Flexibility and customization

Users can readily modify the length, design, and layout of conveyor lines to meet their unique space and operating needs by choosing conveyor systems that are modular and reconfigurable. Businesses may adjust the conveyor system to different the conveyor system to different production rates with customizable speed controls and variable speed options, which lowers the possibility of bottlenecks or inefficiencies. Conveyor systems that can handle several product kinds within a single system are versatile because they support various materials, sizes, and weights. Options that can easily interface with other material handling and production systems, like robotics, sorting systems, and packing gear, are more flexible.

Restraint

Labor displacement

Numerous sectors have adopted sophisticated conveyor systems with sensors, actuators, and control systems due to the growing trend toward automation and industry 4.0 conveyor systems, which offer a more dependable and efficient workaround for physical labor because of their continuous and steady operation. High material volumes can be handled by automated conveyors quickly and precisely, increasing total productivity. Conveyors decrease the need for manual handling of bulky or dangerous products, which enhances workplace safety. This reduces the possibility of accidents at work and rids us of the necessity for hard work in complex settings. Today's Conveyor systems are made to be readily and flexibly adjusted to changing production needs.

Opportunity

E-commerce and warehouse expansion

Warehouses and e-commerce businesses use automated solutions more frequently to improve workflow and handle rising order quantities. Conveyor systems are essential to automation because they make it easier to transport things through a facility quickly and effectively. In the e-commerce industry, meeting client expectations requires faster and more precise order fulfillment, made possible by conveyor systems. Demand fluctuations are common for e-commerce enterprises, particularly during high season. Scalable and flexible conveyor systems are necessary to handle different workloads. Conveyor systems handle inventory more efficiently when integrated with technology like RFID, barcode scanners, and warehouse management systems.

Recent Developments

- In April 2022, A conveyor and roller chain automatic lubrication system was introduced by FB Chain. Cement plant operators can maintain their chains optimally for longer replacement intervals and reduce oil and energy usage using RotaLube, an automated lubrication system for roller and conveyor chains.

- In December 2023, Getinge unveiled its modular, fully automated load-handling system that seamlessly integrates with the company's GEV terminal sterilizers. The new Getinge roller conveyor system improves operator safety and maximizes throughput performance in pharmaceutical production.

Key Market Players

- Daifuku Co., Ltd.

- Dematic Group

- Emerson Electric Co.

- Interroll Holding Ltd.

- Siemens AG

- Swisslog Holding AG

- SSI Schäfer AG

- Taikisha Ltd.

- Vanderlande Industries

- TGW Logistics Group Gmbh

Market Segmentation

By Type

- Belt

- Roller

- Overhead

- Pallet

By Industry

- Airport

- Retail

- Automotive

- Food & Beverages

- Supply Chain & Logistics

- Pharmaceuticals

- Mining

- Others

Buy this Research Report@ https://www.precedenceresearch.com/checkout/1317

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308