Light-powered Catalyst Revenue to Attain USD 13.68 Bn by 2033

Light-powered Catalyst Revenue and Trends

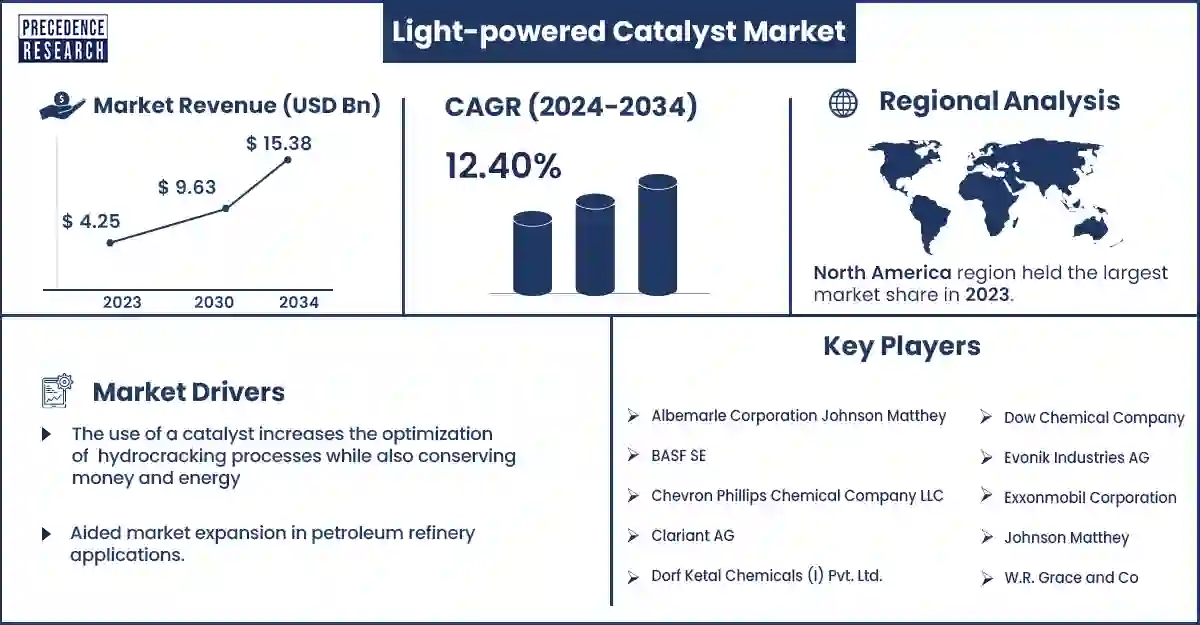

The global light-powered catalyst market size was USD 4.78 billion in 2024 and is projected to surpass around USD 13.68 billion by 2033, expanding at a CAGR of 12.40% during the forecast period 2024 to 2033. The demand for light-powered catalysts is rising across various applications, such as chemical synthesis and petroleum refining. The light-powered catalyst market is driven by the growing demand for photocatalysts and the increasing focus toward cutting-edge materials and nanostructures.

Market Overview

Light-powered catalysts accelerate chemical reactions when exposed to light. In the realm of additive manufacturing, these catalysts are utilized to cure photopolymer resins. Biohybrid photocatalyst, a novel form of catalyst, comprises a light-harvesting protein that absorbs light and transmits the energy to a metal-containing catalyst. This catalyst then converts the energy into reactions that can be used to synthesize medications or transform trash into biofuels or other valuable molecules. Furthermore, environmental catalysts help manufacturers fulfill all NOx, SOx, and CO2 emission criteria.

With the rising shift toward alternative fuels such as shale gas fuel and biodiesel, the demand for catalysts has increased in the energy sector. Companies strive to add value to their feedstock by producing value-added chemicals and petrochemicals, such as methanol and polyolefins. Moreover, market players are improving the design of their light-powered catalysts to enhance performance.

- For instance, in July 2022, a team of chemical engineers at Rice University improved their design for a light-powered catalyst that rapidly breaks down perfluorooctanoic acid (PFOA), one of the world’s most problematic “forever chemical” pollutants.

Highlights of the Light-powered Catalyst Market

Based on raw materials, the chemical compounds segment dominated the market in 2023. Chemical compounds like titanium dioxide and calcium carbonate are extensively used photocatalyst due to their excellent oxidizing power, non-toxicity, and chemical stability. Zinc oxide and graphene-based catalysts are known for their high photoactivity, strong mechanical properties, and excellent electrical conductivity. On the other hand, the metals segment is projected to expand at a rapid pace in the coming years. Noble metals, such as palladium, platinum, ruthenium, copper, rhodium, and gold, and non-noble metals, such as tungsten and molybdenum, are used as essential catalyst raw materials due to their chemical inertness.

On the basis of product, the heterogeneous catalyst segment led the market in 2023. This is mainly due to the rising adoption of heterogeneous catalysts for biodiesel production due to their low cost. Homogeneous catalysts are transformed into heterogeneous catalysts using solid supports to reduce toxicity. Suffocated carbon materials, sulfonated silica materials, Sulphated zirconia, and sulfonated MOF materials are all examples of heterogeneous catalysts.

- Based on application, the chemical synthesis held the largest share of the market in 2023. This is mainly due to the rising adoption of light-powered catalysts in the chemical synthesis process. These catalysts are used to accelerate reactions and boost product yields.

Market Trends

- Shifting focus toward cutting-edge materials and nanostructures: The abrupt shift toward cutting-edge materials and nanostructures due to their ability to enhance the performance and efficiency of light-powered catalysts has revolutionized the light-powered catalyst market. As a result, many prominent companies are making efforts to develop catalysts made with cutting-edge materials like graphene and MOFs. Moreover, incorporating nanotechnology has resulted in improved features such as intensified reaction speed, durability, etc.

- Increasing demand for photocatalysts: With the growing environmental concerns across the world, the demand for photocatalysts has increased in environmental applications like pollution control and air purification due to their sustainable nature and cost-effectiveness.

Regional Snapshot

Asia Pacific dominated the light-powered catalyst market with the largest share in 2023. This is mainly due to the rapid expansion of polymer, chemicals, and petrochemicals production facilities. China has a large number of polymer and chemical production companies. Moreover, rising investments in green energy technologies and rapid industrialization contribute to regional dominance. On the other hand, North America is expected to witness rapid growth in the market due to the rising environmental regulations, which require the use of environmental catalysts. The rising use of gasoline in the US is expected to increase demand for catalysts for converting heavy crude oil into light fractions such as diesel, kerosene, and gasoline.

Light-powered Catalyst Market Coverage

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 4.78 Billion |

| Market Revenue by 2033 | USD 13.68 Billion |

| CAGR | 12.40% from 2024 to 2033 |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market News

- In October 2024, Catalyst Power, an independent, integrated retail energy and distributed energy solutions provider, unveiled energy management services for generators and retail energy suppliers.

Segments covered in the report

By Raw Material

- Chemical compounds

- Metals

- Zeolites

- Others

By Product

- Heterogeneous Catalyst

- Chemical synthesis

- Chemical catalysts

- Adsorbents

- Syngas production

- Others

- Petroleum refining

- FCC

- Alkylation

- Hydrotreating

- Catalytic Reforming

- Purification

- Bed grading

- Others

- Polymers and petrochemicals

- Ziegler Natta

- Reaction Initiator

- Chromium

- Urethane

- Solid Phosphorous Acid catalyst

- Others

- Environmental

- Light-duty vehicles

- Motorcycles

- Heavy-duty vehicles

- Others

Get this report to explore global market size, share, CAGR and trends, featuring detailed segmental analysis and an insightful competitive landscape overview@ https://www.precedenceresearch.com/checkout/2032

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 804 441 9344