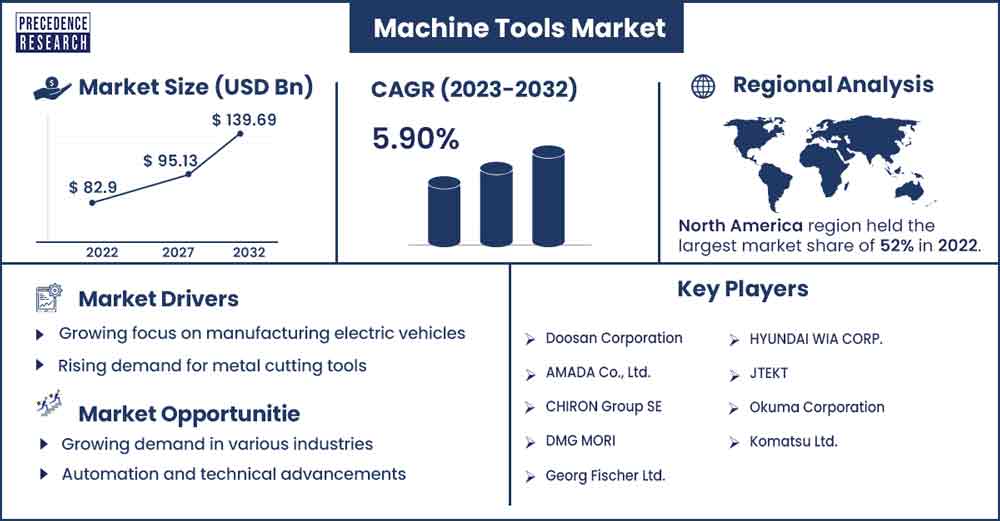

Machine Tools Market Size To Rise USD 139.69 Bn By 2032

The global machine tools market size exceeded USD 82.9 billion in 2022 and is expected to rise to USD 139.69 billion by 2032, poised to grow at a CAGR of 5.9% from 2023 to 2032.

Market Overview

Machine tools encompass a variety of power-driven devices designed for cutting, shaping, and finishing materials. Among these tools are grinders, lathes, and other specialized tools. Lathes, for instance, are versatile machines that play a crucial role in shaping metal and wood. These machine tools are essential in various industries, providing the means to manipulate and refine materials with accuracy and efficiency.

Efficiency and differentiation play a crucial role in the manufacturing sector. A shorter lead time signifies better organizational efficiency, setting it apart. In machine tools, operational efficiency is swiftly achieved with computers. Automation, driven by technology, has enhanced part quality and consistency. It contributes to increased utilization, reduced cycle time, lead time, and labor costs, fostering sectoral growth. The connection between machine tools and the manufacturing sector is significant.

Single-purpose machines focus on doing one task very precisely and quickly. They're used for specific operations like packaging, leak control, function control, and finishing tasks. These machines, such as gear-cutting or gear-grinding machines, are mainly for production. A milling machine can perform various operations like turning, chamfering, cutting gears, and filleting. The growing metalworking industry worldwide has increased demand for milling machines, contributing to expanding the global machine tool market. The manufacturing sector's growth has further boosted the need for automated machine tools, particularly CNC machines, indicating a positive impact on the market.

The automotive industry heavily relies on machine tools, using them extensively for machining various components of internal combustion engine (ICE) vehicles. These components include exhaust systems, pistons, valves, crankshafts, engine blocks, and manifolds. Machine tools are essential in automotive OEMs (Original Equipment Manufacturers) and auto parts manufacturing, playing a crucial role in production. Many well-known car manufacturers have incorporated hybrid technology into their vehicles, combining an internal combustion engine with an electric drive.

This hybrid technology demands intricate machining processes, as hybrid cars need durable components to seamlessly switch between electric and internal combustion modes, especially at high speeds. Despite the rise of electric vehicles, traditional internal combustion engine-based vehicles are anticipated to maintain dominance, fueling the growth of the machine tools market in India shortly.

Regional Snapshot

Asia Pacific is set to lead the global machine tools market due to the growing number of industries involved in metal-cutting processes in the region. China, a significant user and market leader, contributes significantly to this dominance. The Asia Pacific region has witnessed substantial expansion and investment in the automobile, oil, gas, and rail sectors. Key players in this region include Yamazaki Mazak Corporation, DMG Mori, and OKUMA Corporation.

As a country's manufacturing sector grows, it boosts the prospects for the machine tools industry. The lead time between placing an order and its delivery is crucial in manufacturing. When multiple countries focus on manufacturing, it creates competition among them. This competition further drives the machine tools industry.

The region is witnessing growth due to increased government initiatives supporting various industries. Initiatives like the 'Make in India' campaign offer tax benefits and attract foreign direct investments (FDI) to boost the manufacturing sector. China is anticipated to experience significant growth driven by the expansion of its manufacturing industry.

- The Indian government expects substantial domestic and foreign investments in the automotive sector, amounting to 8-10 billion USD, by 2023. Globally, 79.1 million automobiles were produced in 2021. Furthermore, the use of 3D printing technology in the Indian machine tool market is projected to rise due to its ability to meet diverse customer specifications. Leading market players are actively creating machine tools integrated with 3D printing technology; the advancement of 3D printing stands out as a significant trend expected to propel market growth in the foreseeable future.

- In December 2023, Doosan Group revealed planned to showcase its cutting-edge technologies at CES 2024. The featured innovations, presented by various Doosan companies such as Doosan Bobcat, Doosan Enerbility, Doosan Robotics, and HyAxiom, aim to contribute to a cleaner and safer future.

- In October 2023, Supernal, Hyundai Motor Group's Advanced Air Mobility (AAM), joined forces with Hyundai WIA, a global automotive and aerospace parts manufacturer, and Mecaer Aviation Group, an Italian aeronautical company. Together, they announced a collaboration to develop and produce landing gear systems for electric vertical takeoff and landing (eVTOL) vehicles.

Machine Tools Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 83.56 Billion |

| Projected Forecast Revenue by 2032 | USD 139.69 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 5.9% |

| Largest Market | Asia Pacific |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

3D printing technology

Additive manufacturing, commonly known as 3D printing, is gaining popularity in manufacturing industries, including machine tool manufacturing. The key drivers for the widespread adoption of 3D printing include cost-effectiveness, swift manufacturing processes, ease of upgrades, minimal energy consumption, and reduced waste. As a result, several global machine tool manufacturers are incorporating 3D printing technology into their machines.

Electric vehicles industry

The growing focus on manufacturing electric vehicles (EVs) is anticipated to drive the global machine tools industry in the coming years. Substantial investments from global EV manufacturers and automakers, along with rising environmental concerns, are expected to boost the adoption of electric vehicles. Additionally, advancements in both software and hardware are anticipated in the machine tool industry in the coming years.

Restraint

Fluctuations in economic conditions

The market expansion faces challenges due to uncertainties in social and economic conditions. Global economic changes directly affect the industrial sector, influencing the sales of machine tools. A slowdown in the global economy is expected to impact the income derived from machine tools. Given the significant reliance on machinery in various industries, changes in the automotive sector can profoundly affect the machine tools market. Furthermore, unexpected shifts in a nation's political, social, or economic landscape can also impact the market's revenue growth.

Opportunities

Growing demand in various industries

The machine tools market is set for substantial opportunities, propelled by various factors. A major opportunity arises from the growing demand for advanced machining solutions in the aerospace and automotive industries. As these sectors prioritize precision engineering and efficient manufacturing, there's an increasing need for cutting-edge machine tools. Moreover, the shift towards smart factories and Industry 4.0 opens doors for the integration of innovative technologies like IoT-enabled machine tools, providing real-time data insights and optimizing processes.

Automation and technical advancements

Fully automatic CNC machine tools come equipped with tool changers, allowing them to perform multiple tasks with a single machine. The desirable characteristics of CNC machine tools contribute to increased demand, positively influencing the expansion of the global machine tools market. Anticipated growth factors include expanding production facilities and establishing new factories across various automotive, railroad, aerospace, and defence industries. This trend is expected to drive market growth for machine tools throughout the assessment period.

Additionally, opportunities lie in the maintenance, repair, and operations (MRO) of fixed and heavy-duty machine tools, providing increased sales revenue for machine tool vendors.

Recent Developments

- In April 2023, Mitsubishi Electric India unveiled a new manufacturing facility and technology centre called "CNC eXPerience Park" in the Peenya industrial area of Bengaluru.

- In April 2023, Brother, the Japanese manufacturer of 30-taper machining centres, introduced the third version of its machine with a one-meter X-axis. The updated model has improvements in various areas to enhance its capacity and versatility.

Market Key Players

- Doosan Corporation

- AMADA Co., Ltd.

- CHIRON Group SE

- DMG MORI

- Georg Fischer Ltd.

- HYUNDAI WIA CORP.

- JTEKT

- Okuma Corporation

- Komatsu Ltd.

Market Segmentation

By Type

- Laser Machines

- Lathe Machines

- Milling Machines

- Grinding Machines

- Welding Machines

- Winding Machines

- Others

By Application

- Construction Equipment

- Automotive

- Aerospace & Defense

- Power & Energy

- Industrial

- Others

By Technology

- Computer Numerical Control (CNC)

- Conventional

Buy this Research Report@ https://www.precedenceresearch.com/checkout/1242

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308