Reciprocating Compressors Market Size and Forecast 2025 to 2034

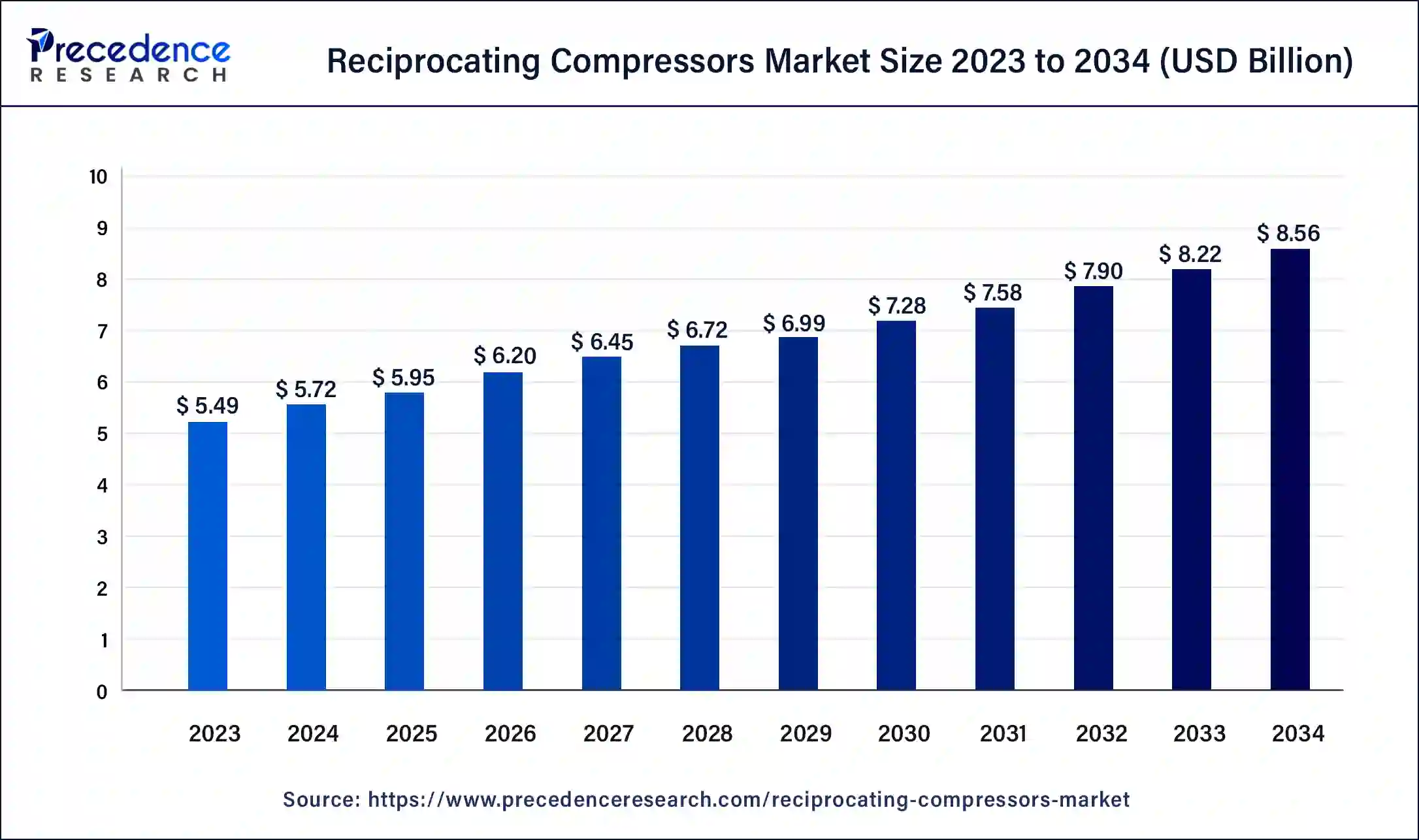

The global reciprocating compressors market size was valued at USD 5.72 billion in 2024 and is anticipated to reach around USD 8.56 billion by 2034, growing at a CAGR of 4.12% over the forecast period 2025 to 2034. The increasing demand for reciprocating compressors by the various end-use industries and their application for energy-efficient solutions boosts the growth of the market.

Reciprocating Compressors Market Key Takeaways

- In terms of revenue, the reciprocating compressors market is valued at $5.95 billion in 2025.

- It is projected to reach $8.56 billion by 2034.

- The reciprocating compressors market is expected to grow at a CAGR of 4.12% from 2025 to 2034.

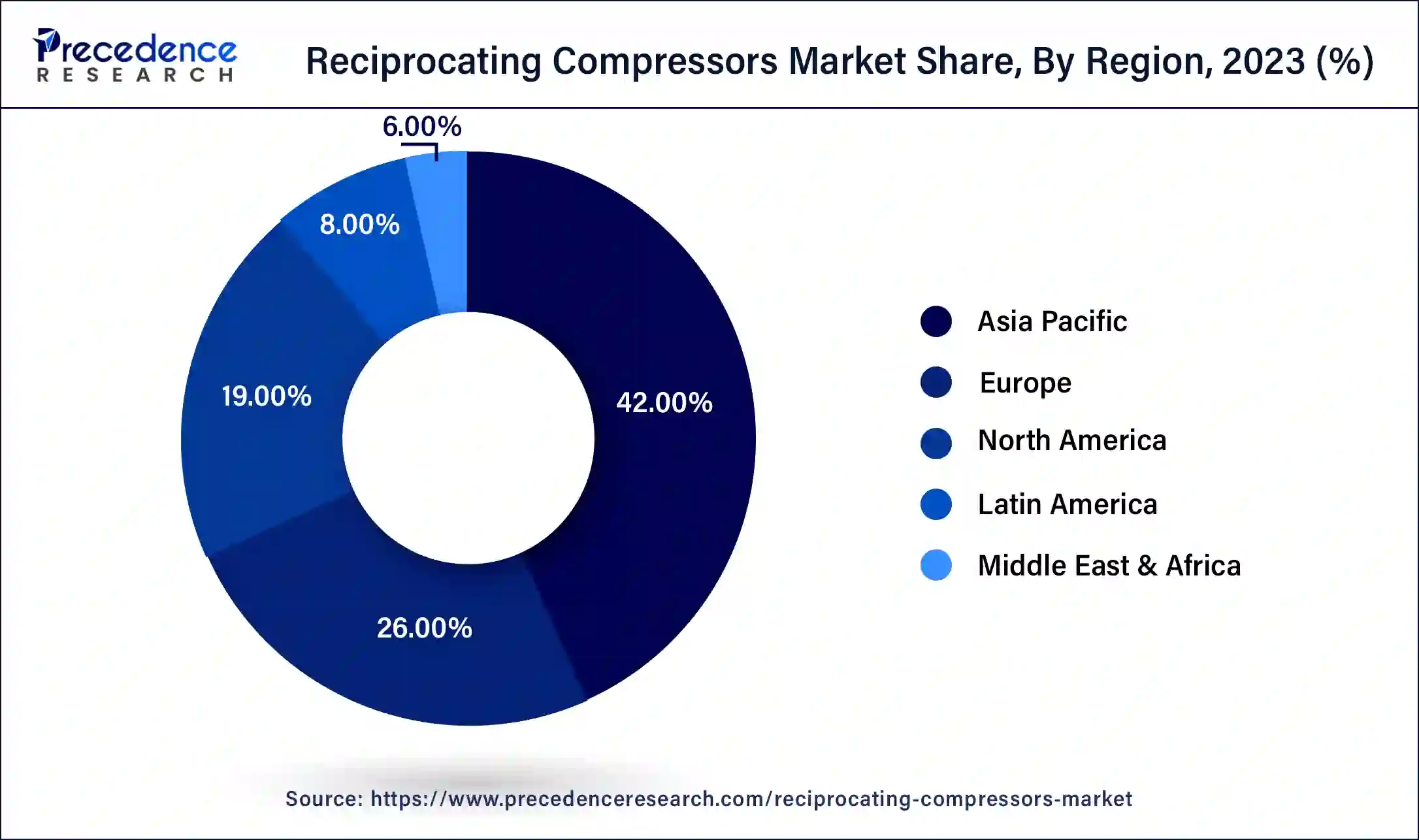

- Asia Pacific dominated the reciprocating compressors market with the highest market share of 42% in 2024.

- North America is predicted to grow at a CAGR of 3.03% during the forecast period.

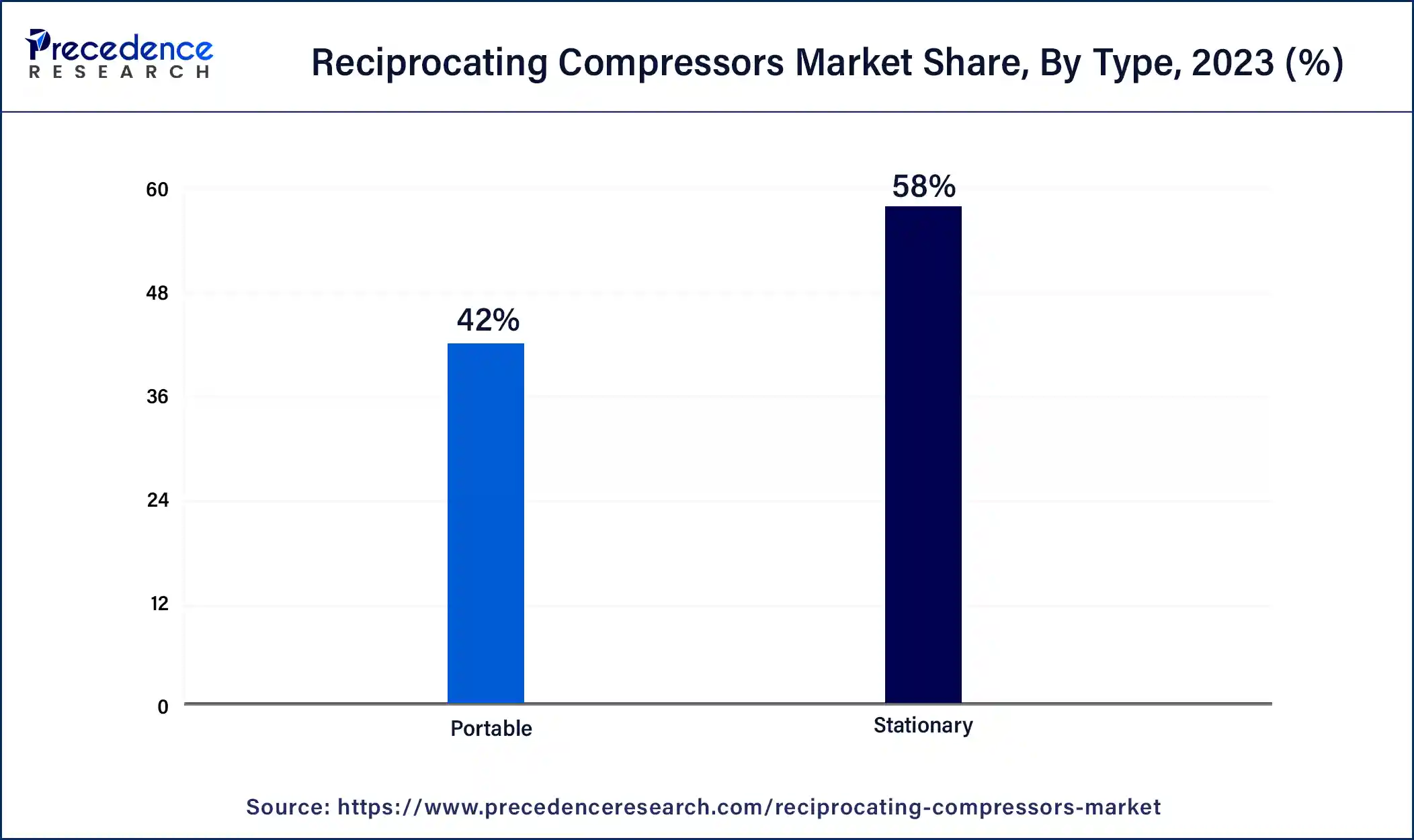

- By type, the stationary segment has held the biggest market share of 58% in 2024.

- By type, the portable segment is anticipated to grow at a CAGR of 4.52% during the coming years.

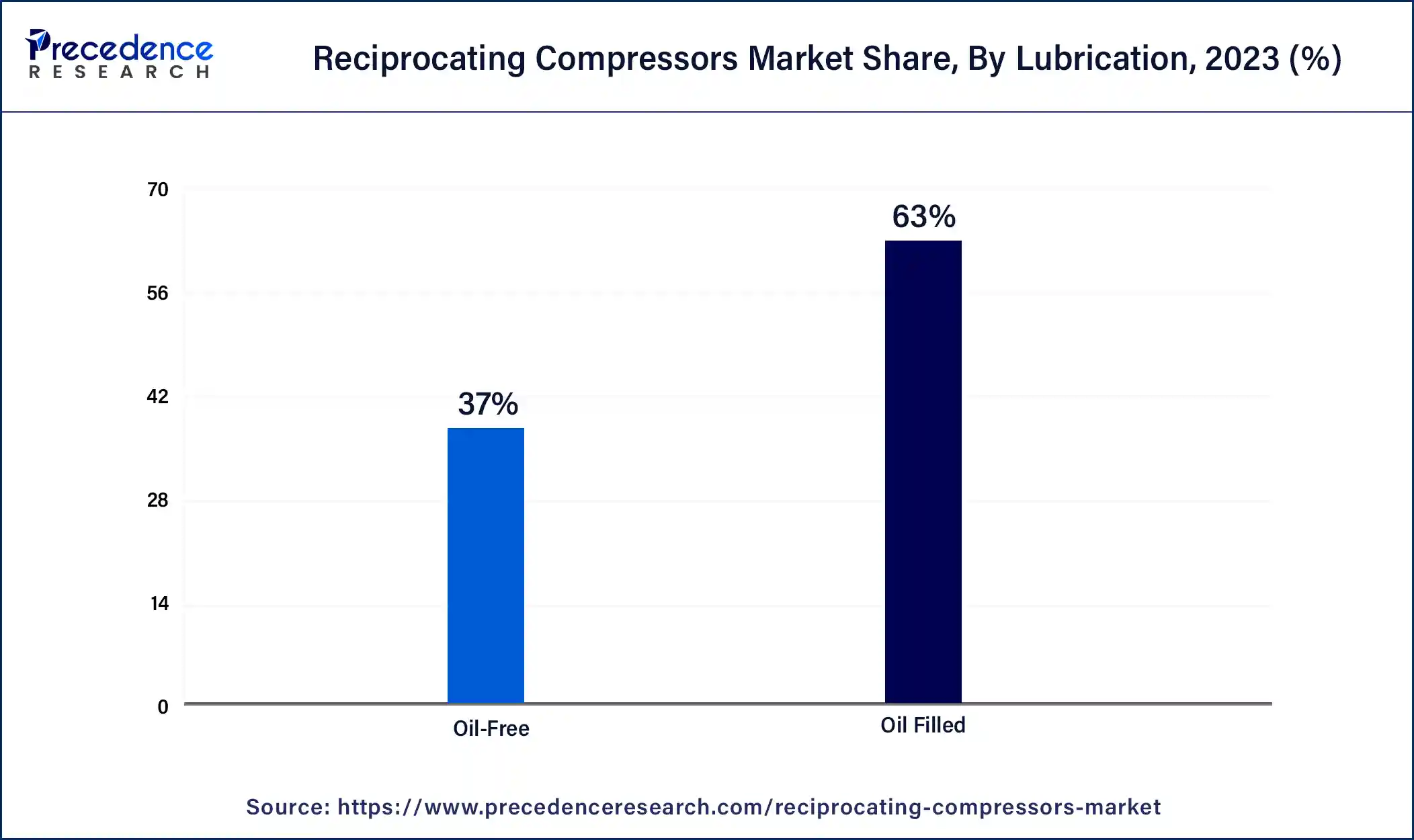

- By lubrication, the oil-free segment contributed the largest market share of 63% in 2024.

- By stage type, the multi-stage segment dominated the market globally in 2024.

- By acting type, the double-acting segment dominated the reciprocating compressors market in 2024.

- By end-user, the manufacturing segment led the market in 2024.

How Can AI Impact the Reciprocating Compressors Market?

The integration of AI revolutionizes end-to-end operations in industries. The adoption of artificial intelligence technologies like machine learning algorithms in the reciprocating compressor's equipment helps in detecting faults in the reciprocating compressors. There are four major machine learning algorithms reviewed in the reciprocating compressors, including support vector machine, artificial neural network, and Bayesian network. There are several machine learning applications in the fault diagnosis of reciprocating compressors based on the process parameters, vibration signals, acoustic emission (AE), and multi-source signals. The integration of artificial intelligence in industrial operations helps in detecting faults in the early stage and increases operational efficiency and productivity.

- In March 2023, TurboTides introduces artificial intelligence/machine learning (AI/ML) optimization in their latest turbomachinery designs, which allows consumers and their product development teams to enhance efficiency. The integrated design system enables users to create 1D and 3D designs and run finite element analysis (FEA), 3D computational fluid dynamics (CFD), and other capabilities.

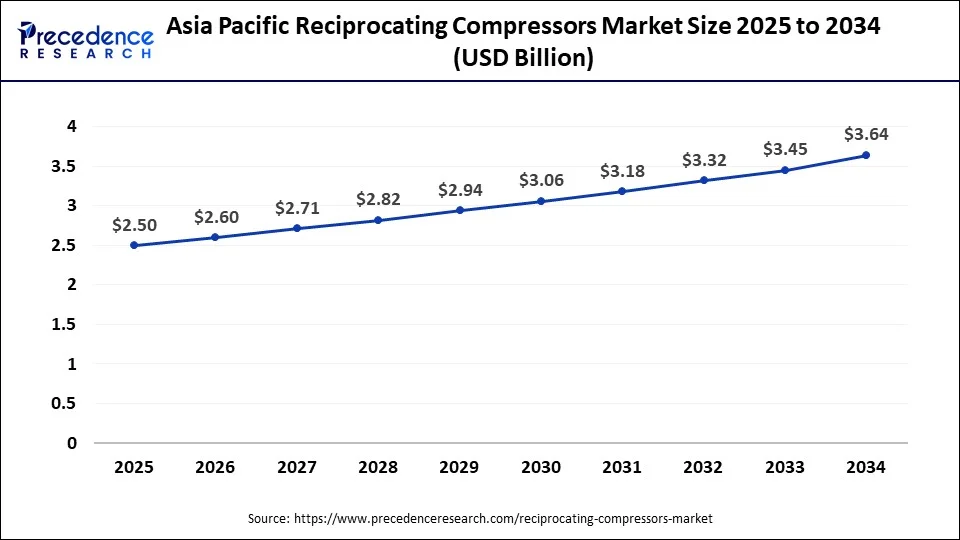

Asia Pacific Reciprocating Compressors Market Size and Growth 2025 to 2034

The Asia Pacific reciprocating compressors market size is exhibited at USD 2.50 billion in 2025 and is projected to be worth around USD 3.64 billion by 2034, poised to grow at a CAGR of 4.32% from 2025 to 2034.

Asia Pacific dominated the reciprocating compressors market in 2024. The growth of the market is attributed to the rising population, and the increase in per capita income in the population drives the demand for consumer goods and results in an increase in industrialization. The increased demand for energy to address consumer demand drives the manufacturing industries, oil and gas industries, and energy generation industries, which are anticipated to drive the growth of the market across the region.

- The Indian manufacturing industry contributed 16-17% of the nation's GDP pre-pandemic and is predicted to be the fastest-growing industry. India will be the major global manufacturing hub with the capacity to export goods worth US$ 1 trillion by 2030.

- India is progressing towards Industry 4.0 with the Government of India's initiatives, such as the National Manufacturing Policy, designed to enhance the share of manufacturing in GDP to 25 percent by 2025, and the PLI scheme for manufacturing launched in 2022 to bring the core manufacturing sector up to global manufacturing standards.

- The manufacturing exports register the highest annual export of US$ 447.46 billion, with a 6.03% growth during FY23, surpassing the prior year FY22 which records the export of US$ 422 billion.

North America anticipates significant growth during the forecast period. The growth of the market is attributed to rising industrialization and the ongoing investment in expansion industries like the oil and gas and energy generation industries, which contribute to the expansion of the market. The rising population and the economic stability in the regional countries result in higher industrialization, and the acceptance of the technologies are accelerating the growth of the reciprocating compressors market in the region.

Europe is expected to grow significantly in the reciprocating compressors market during the forecast period. The advancing industries in Europe are increasing the demand for reciprocating compressors as they serve as a crucial part in machine tools. At the same time, due to strict rules and regulations, the industries are adopting reciprocating compressors. Thus, this promotes the market growth.

UK

The advancing industries in the UK are utilizing reciprocating compressors to promote the use of low-emission compressors. Similarly, their use in the pharmaceutical and food industries is also increasing. Thus, they are focusing on developing and utilizing oil-free compressors along with the use of advanced technologies.

Germany

Germany shows the presence of robust industrial automation along with well-developed food and pharmaceutical sectors, which in turn increases the use of reciprocating compressors. At the same time, with the use of advanced technologies, their performance and maintenance are also being improved.

Market Overview

The reciprocating compressors are specially designed equipment that contain active components that move in an active linear motion. This equipment plays an important role in industries like the oil and gas industry, energy generation, electronics, and others. The reciprocating compressors are known as positive displacement machines, which are used for compressing air and other gases through the pistons.

Reciprocating compressors are considered the most energy-efficient, rapid, and cost-efficient solution in a number of industrial applications. There are different types of reciprocating compressors that are used in the industries as per their operations, including single-acting, double-acting, diaphragm type, single-stage, two-stage, and multi-stage reciprocating compressors.

Reciprocating Compressors Market Growth Factors

- Increasing industrialization: The rising industrialization globally, such as the rise in industries like the automotive, oil and gas industries, healthcare and pharmaceuticals, and others, are driving the demand for reciprocating compressors.

- Usage of industrial gases: The increasing usage of industrial gases in a wide range of industries drives the demand for reciprocating compressors for higher pressure generation, efficiency, and flexibility in usage.

- The rise in the manufacturing sector: The rising availability and development of the manufacturing sector to address the increasing demand for consumer goods and products are driving the growth of the reciprocating compressors market.

- Cost-efficient solution: The increasing demand for cost-efficient solutions in a wide range of industries, including manufacturing, oil and gas industries, healthcare, and others, is driving the demand for energy-efficient reciprocating compressors in their operations.

- Government intervention: The rising government intervention in the further development of industrialization and the adaption of technologically advanced machinery and automation for enhanced productivity and efficiency in operations.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 8.56 Billion |

| Market Size in 2025 | USD 5.95 Billion |

| Market Size in 2024 | USD 5.72 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.12% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Lubrication, Stage Type, Acting Type, End-user, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Driver

The increasing adoption of reciprocating compressors by various end-use applications

The rising industrialization and the adoption of reciprocating compressors by the various end-use applications by the industries for energy-efficient solutions drive the growth of the reciprocating compressors market. There are several advantages associated with reciprocating compressors, including high-pressure generation, flexibility, increased efficiency achieved, and the efficiency of use in intermittent cycling. The reciprocating compressors are used in both oil-flooded and oil-free varieties, though they have flexibility in usage. It can generate high pressure than the other type of compressor, like rotary screw varieties. The pressure ranges up to 30,000 PSI. The reciprocating compressors generate high pressure with the use of less energy.

Restraint

High cost of maintenance

The reciprocating compressors have limits for operating under some specific mechanical rating conditions. When the limit is exceeded one or more times, catastrophic failures can occur, which can result in the high cost of repairs and maintenance, hampering the expansion of the reciprocating compressors market.

Opportunity

Digitization in the industries

The evaluation of industries through time and digitization is driving potential opportunities for the expansion of the reciprocating compressors market. Digitization across industries in a wide range of applications helps in increasing efficiency in production operations. While the integration of digitization in the reciprocating compressors helps in detecting faults by predictive maintenance and real-time monitoring as well the integration of the automation is more likely to increase the efficiency and allow operators to control and monitor reciprocating compressors from the remote location, which helps in faster addressing the challenges, improved efficiency, and minimize downtime.

Type Insights

The portable segment is anticipated to grow at a significant rate in the reciprocating compressors market during the forecast period. The increasing demand for portable reciprocating compressors from a wide range of end-use industries such as construction, automotive, manufacturing, oil and gas, agriculture, pharmaceutical, and others drives the growth of the segment. It is a portable, compact, and transportable compressed air solution attached with wheels and running gear for towing. Its portable design makes it an effective solution for various locations.

Portable reciprocating compressors have several benefits, such as durability, the ability to work in different locations, and the ability to work at any working temperature. It has a long run-time, and it is used in all-day operations. Easy in maintenance due to its portable compressor, which is user-friendly and easy to operate. And multiple engine options with varieties in horsepower, operating needs, and other performance specifications.

- In March 2023, ELGi North America (ELGi) launched the portable compressor at the CONEXPO-CON/AGG 2023. ELGi will introduce the GP35FP, the new portable air compressor and trusted D185T4F model. Additionally, ELGi also introduced nine models in its portable air compressor lineup ranging from 35 CFM to 900 CFM.

Lubrication Insights

The oil-free segment registered its dominance over the reciprocating compressors market in 2024. The increasing use of oil-free lubrication in reciprocating compressors in the healthcare sector is driving the expansion of the segment. The healthcare industry demands uncontaminated and hygienic pressure of air requirements without the intervention of foreign particles. The adoption of the oil-free compressor meets the 100% purity standards for the industries that developed the strict quality standards for ensuring safety in both manufacturing and end-use consumers.

Stage Type Insights

The multi-stage segment dominated the reciprocating compressors market globally in 2024. The increasing demand for temperature control, enhanced pressure, and oil-free application with cost-efficient solutions is contributing to the demand for multi-stage reciprocating compressors. The multi-stage reciprocating compressors are able to make heavy-duty industrial applications and can generate a high volume of pressure (PSI) from medium to high capacities (CFM). The multi-stage reciprocating compressors are able to control the temperature of the machines than any other compressor type.

Acting Type Insights

The double-acting segment dominated the reciprocating compressors market in 2024. The double-acting compressor provides better effectivity than the single-acting reciprocating compressors. It provides air compressors on both backward and forward strokes of the piston. The double-acting compressors are used in a wide range of applications such as pneumatic tools, industrial processes, and manufacturing operations, as well as applications where continuous air pressure is required.

End-user Insights

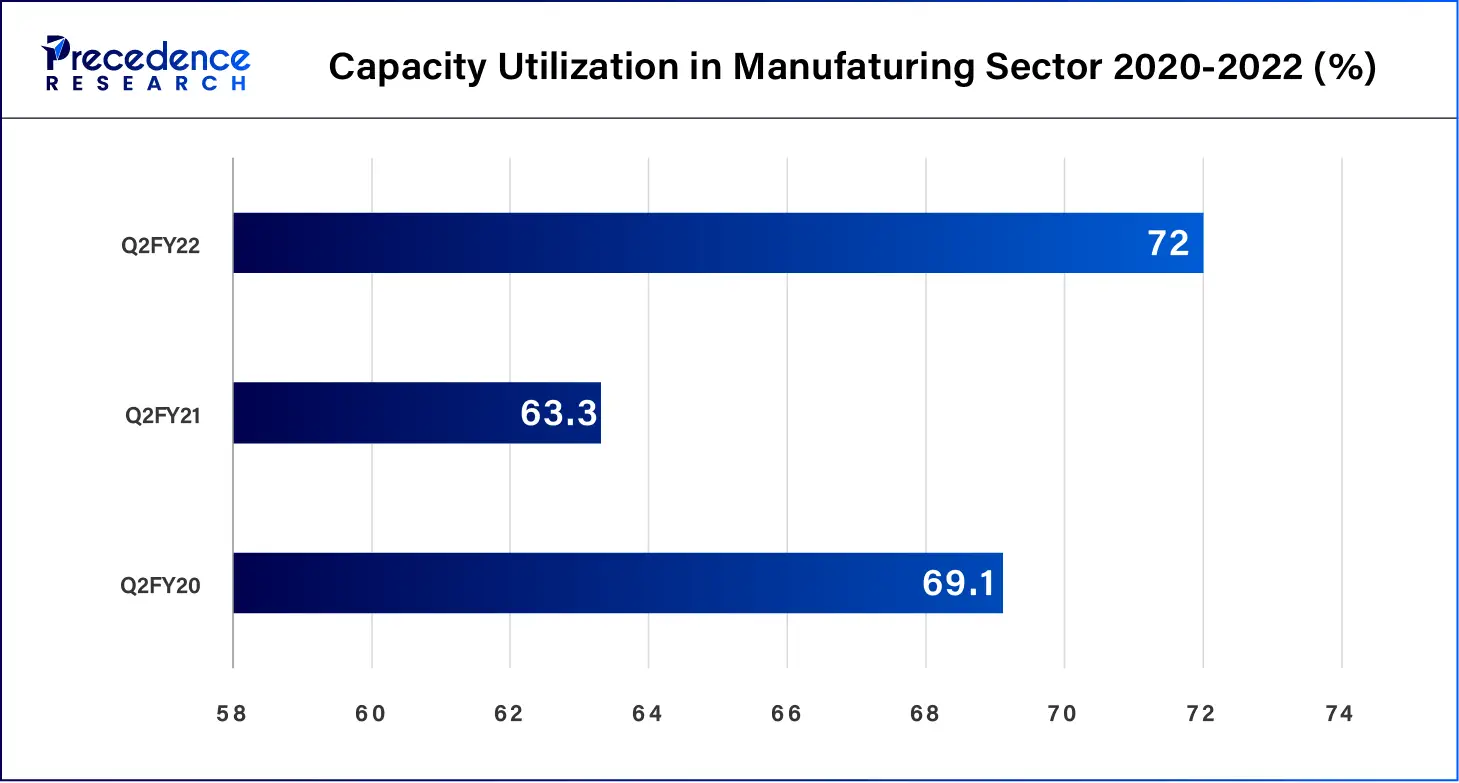

The manufacturing segment led the reciprocating compressors market in 2024. The rising population and the increasing demand for consumer goods products boost the growth of industrialization across the world. The increasing manufacturing industries in economically developing countries are also contributing to the expansion of the market.

The increasing demand for consumer goods and products leads to higher development in the manufacturing sector. There are the leading manufacturing industries are adopting reciprocating compressors in their operation for faster and greater efficiency in productivity and operations.

Reciprocating Compressors Market Companies

- Ariel Corporation

- Atlas Copco

- Burckhardt Compression Ag

- Gardner Denver Holdings Inc.

- GE Company

- IHI Corporation Ltd.

- Siemens AG

- Mitsui E&S Holdings Co., Ltd.

- Howden Group Ltd.

- Mayekawa Mfg. Co, Ltd.

Company revenue

In May 2025, Siemens AG showed a rise of 10% year-over-year to €21.6 billion for second quarter orders as well as 7% to €19.8 billion revenue growth was noted. Moreover, a total of 11% to €2.4 billion rise in net income was observed. At the same time, on a comparable basis, the orders and revenue increased by 9% and 6% respectively. A rise of 29% to €3.2 billion in the Profit Industrial Business was also recorded.

In April 2025, Atlas Copco released its first quarter reports, where it experienced a rise of 2% to MSEK 46,604 for orders. While MSEK 42,730 in revenues was reached. Additionally, the operating profit was noted to be MSEK 8,605. At the same time, adjusted operating profit of MSEK 8,869 was noted, excluding items affecting comparability. Furthermore, profit before tax was MSEK 8,470. Source: Earnings Release and Financial Results Q2 FY 2025 | Press | Company | Siemens 20250429 Quarterly Report Q1 2025

Recent Developments

- In May 2024, SIAD Group company's SIAD Macchine Impianti launched the 550-bar, oil-free, high-pressure hydrogen compressor, specially produced for the transportation and hydrogen refueling station industries. The company said it is a sustainable mobility supply chain.

- In April 2024, Frascold, an Italian compressor manufacturer, launched the TK HD series, the latest product in the transcritical CO2 (R744) semi-hermetic reciprocating compressors. The new product is available in 34 models and offers refrigeration capacities between 3.7 and 72kW with the selection of one or two motors with a power range from 3 to 50HP.

- In June 2024, Hitachi Industrial Equipment Systems Co., Ltd. announced the launch of the "Predictive Diagnosis Service" for the factory equipment. The equipment uses machine learning algorithms for detecting and analyzing the data through remote monitoring and combines the knowledge accumulated by the Hitachi Industrial Equipment Systems maintenance staff to prevent and detect abnormalities in the system that may result in equipment stoppages in advance.

Segments Covered in the Report

By Type

- Portable

- Stationary

By Lubrication

- Oil-free

- Oil Filled

By Stage Type

- Single Stage

- Multi-stage

By Acting Type

- Single Acting

- Double Acting

- Diaphragm

By End-user

- Oil & Gas

- Pharmaceutical

- Chemical Plants

- Refrigeration Plants

- Manufacturing

- Automotive

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting