What is the Vacuum Pumps Market Size?

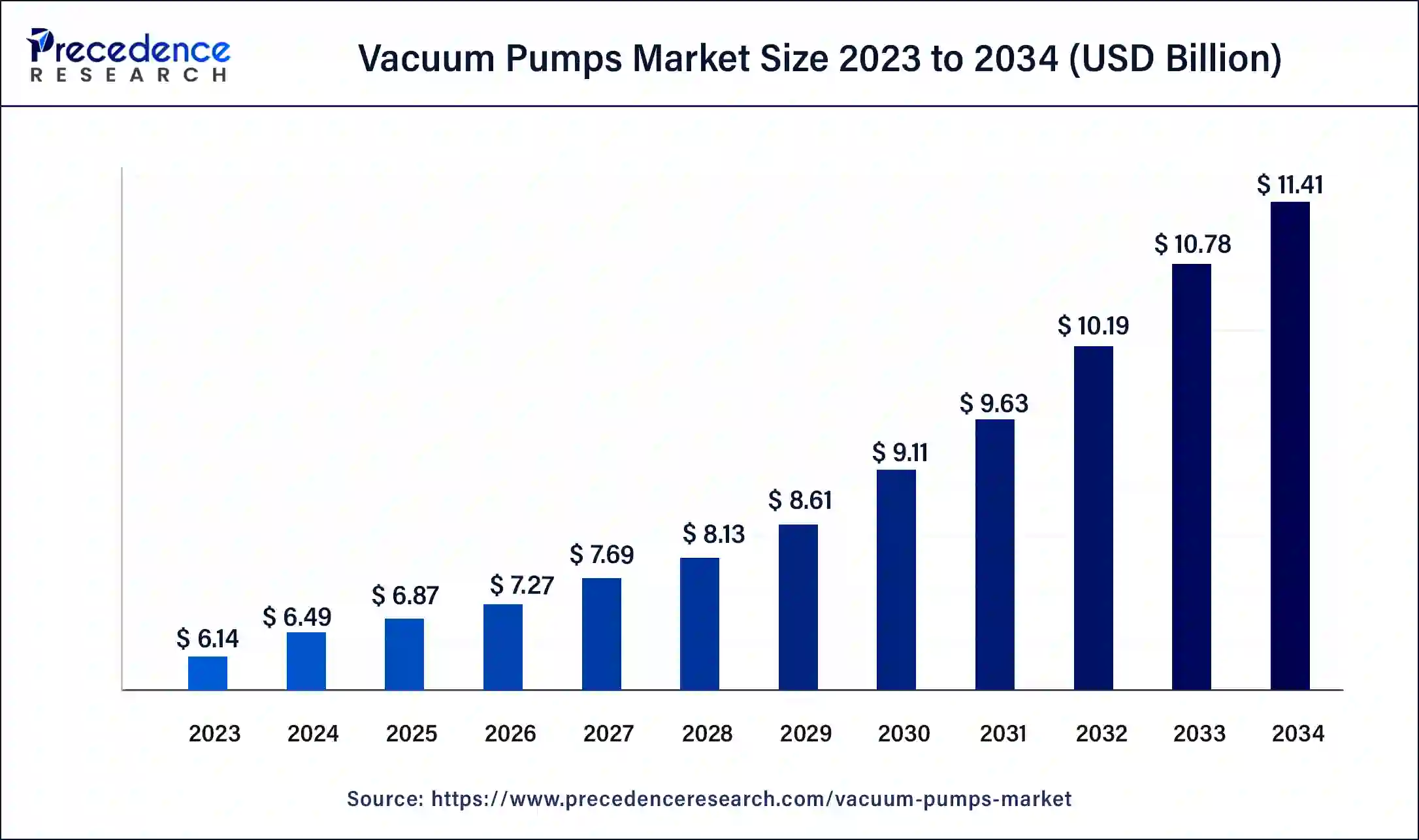

The global vacuum pumps market size was estimated at USD 6.87 billion in 2025 and is predicted to increase from USD 7.27 billion in 2026 to approximately USD 12.01 billion by 2035, expanding at a CAGR of 5.74% from 2026 to 2035.

Market Highlights

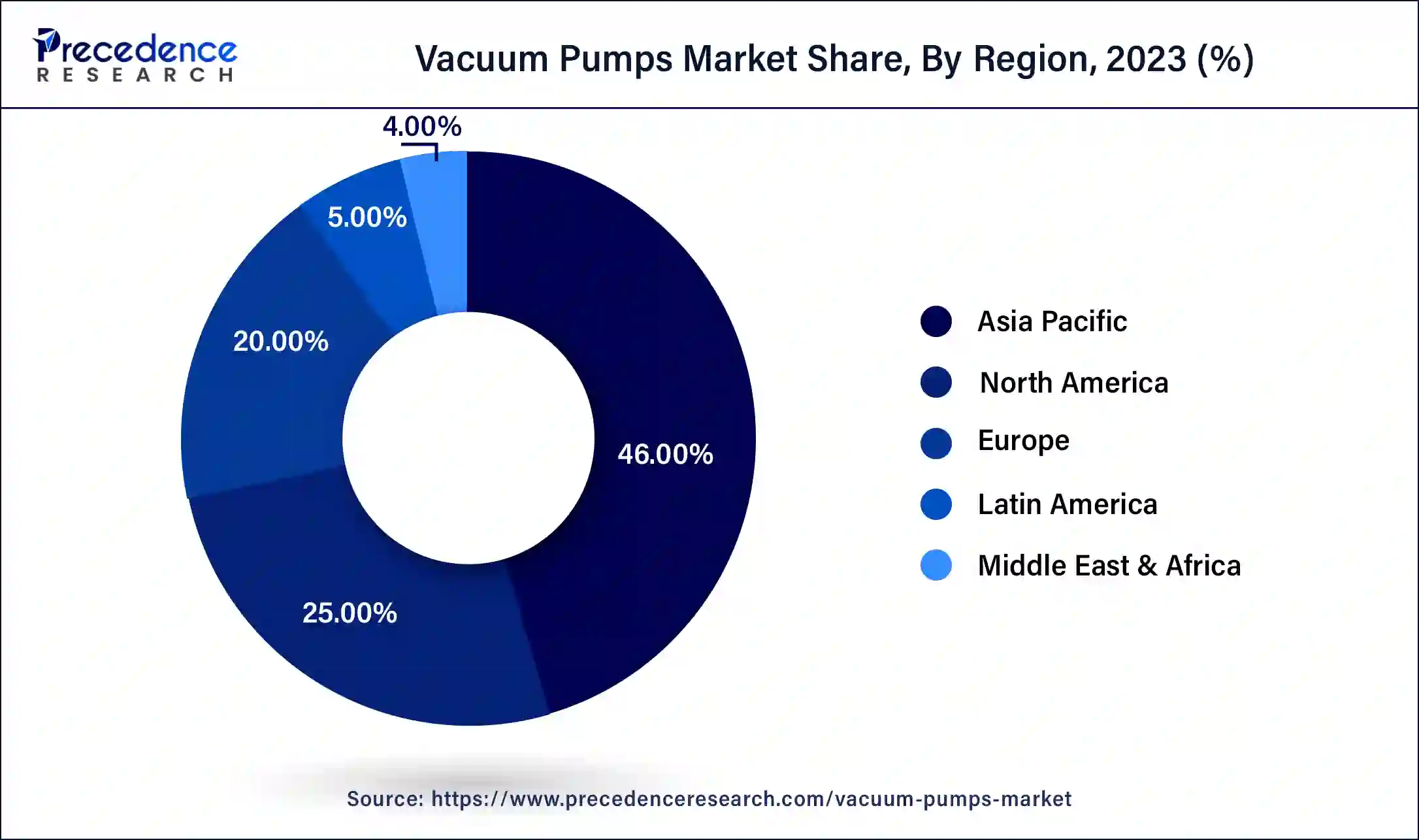

- Asia Pacific contributed more than 46% of revenue share in 2025.

- North America is estimated to expand the fastest CAGR between 2026 and 2035.

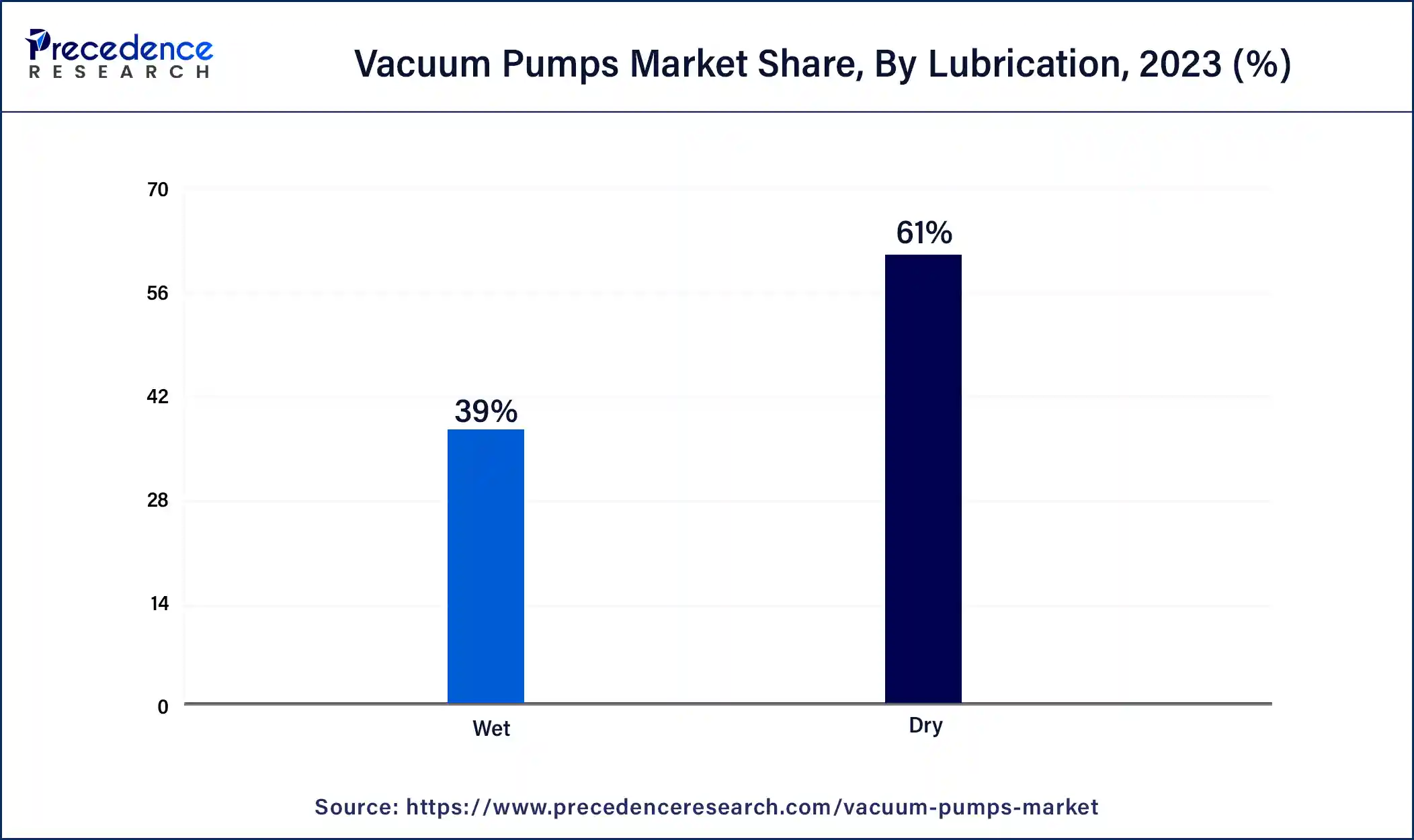

- By lubrication, the dry lubrication segment has held the largest market share of 61% in 2025.

- By lubrication, the wet lubrication segment is anticipated to grow at a remarkable CAGR of 5.9% between 2026 and 2035.

- By vacuum level, the low vacuum level segment generated over 53% of revenue share in 2025.

- By vacuum level, the high vacuum level segment is expected to expand at the fastest CAGR over the projected period.

- By end-use, the manufacturing segment generated over 30% of revenue share in 2025.

- By end-use, the semiconductor & electronics segment is expected to expand at the fastest CAGR over the projected period.

Market Size and Forecast

- Market Size in 2025: USD 6.87 Billion

- Market Size in 2026: USD 7.27 Billion

- Forecasted Market Size by 2035: USD 12.01Billion

- CAGR (2026-2035): 5.74%

- Largest Market in 2025: Asia Pacific

- Fastest Growing Market: North America

Market Overview

A vacuum pump is a sophisticated mechanical apparatus designed to eliminate air and various gases from a confined space, thereby creating a controlled vacuum or low-pressure environment. This is achieved through the pump's ability to manipulate the pressure within a chamber, effectively extracting gases, moisture, and contaminants. Vacuum pumps are indispensable tools utilized across a spectrum of industries, serving vital roles in industrial, scientific, and commercial settings.

These pumps are particularly valuable in fields such as manufacturing, pharmaceuticals, and electronics, where precise vacuum conditions are imperative for processes like degassing, desiccation, or molding. A variety of vacuum pump types are available, including rotary vane pumps, diaphragm pumps, and turbomolecular pumps, each tailored to specific applications. Vacuum pumps are pivotal in upholding the integrity of vacuum systems, facilitating experiments, industrial procedures, and the efficient operation of an array of devices reliant on a controlled vacuum environment.

Artificial Intelligence: The Next Growth Catalyst in Vacuum Pumps

AI is primarily impacting the vacuum pumps industry by enabling smarter, more efficient, and reliable systems, a trend driven largely by the demands of advanced semiconductor manufacturing. Through the integration of sensors and Internet of Things technology, AI algorithms facilitate predictive maintenance, which minimizes the need for maintenance before it occurs.

Vacuum Pumps Market Growth Factors

- Increasing industrial activities worldwide drive the demand for vacuum pumps in applications such as manufacturing and processing.

- The semiconductor industry relies heavily on vacuum pumps for various processes, leading to sustained market expansion.

- Stricter environmental regulations are pushing industries to adopt vacuum pumps for emissions control and pollution prevention.

- Growing research in fields like nanotechnology and materials science creates a need for specialized vacuum equipment.

- Medical and pharmaceutical sectors require vacuum pumps for research, diagnostics, and treatment equipment, fostering market growth.

- Vacuum pumps are used in oil and gas extraction, contributing to market expansion in the energy sector.

- These industries require vacuum pumps for various applications, including space exploration and military equipment.

- Developing economies are adopting vacuum pump technology for industrial growth, providing new market opportunities.

- Innovations in pump efficiency and durability fuel market growth.

- The shift toward sustainability encourages the use of vacuum pumps in waste management and recycling.

- The chemical industry relies on vacuum pumps for critical processes like distillation and evaporation.

- Vacuum pumps aid in food packaging, preservation, and processing, driving market growth.

- Vacuum pumps are essential for pharmaceutical manufacturing, ensuring product quality and safety.

- Vacuum pumps are used in automotive production, benefiting from the expansion of this sector.

- Building services and heating, ventilation, and air conditioning (HVAC) systems require vacuum pumps.

- Scientific research and experimentation create steady demand for vacuum pump technology.

- Vacuum pumps are integral to the development of renewable energy technologies, such as solar and wind power.

Major Key Trends in Vacuum Pumps Market

- Shift Toward Oil-Free Pumps: Sectors like food and healthcare are progressively embracing oil-free vacuum pumps to comply with hygiene and contamination-free standards mandated by regulatory agencies in various regions.

- Integration with IoT Technologies: Vacuum pumps are being fitted with IoT-enabled sensors and controls to facilitate real-time diagnostics, predictive maintenance, and greater operational efficiency within industrial environments.

- Expansion in Semiconductor Manufacturing: The growth of semiconductor production is propelling the necessity for precise vacuum technologies employed in chip fabrication stages, such as chemical vapor deposition and ion implantation.

Market Outlook

- Market Growth Overview: The vacuum pumps market is expected to grow significantly between 2025 and 2034, driven by the rising need for semiconductors and electronics, the shift towards compact, energy-saving pumps with lower operating costs, and growing adoption to eliminate hydrocarbon contamination.

- Sustainability Trends: Sustainability trends involve rising dry and oil-free pumps, integration of smart and digitalization, and sustainable materials and lifecycle.

- Major Investors: Major investors in the market include Atlas Copco, Pfeiffer Vacuum, Busch Vacuum Solutions, Ingersoll Rand, Ebara Corporation, and Tsurumi.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 6.87 Billion |

| Market Size in 2026 | USD 7.27 Billion |

| Market Size by 2035 | USD 12.01 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 5.74% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Lubrication, Vacuum Level, End-Use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Semiconductor industry and healthcare advancements

The semiconductor industry acts as a primary catalyst for the heightened demand in the vacuum pump market. Vacuum pumps serve as indispensable tools in semiconductor manufacturing, particularly in the production of ever-smaller and more powerful integrated circuits.

As the semiconductor sector progresses, necessitating the creation of increasingly compact and advanced chips, the demand for precision vacuum pumps escalates. These pumps are instrumental in maintaining a clean and controlled environment, ensuring contamination-free processes during key stages like lithography, etching, and deposition. The relentless drive for technological innovation within the semiconductor industry consistently propels the growth of the vacuum pumps market.

On the other hand, healthcare advancements have significantly surged the demand for vacuum pumps. These pumps are integral to various healthcare applications, such as vacuum-assisted wound closure, blood analysis, and medical sterilization processes. As medical research and innovation progress, vacuum pump technologies are continually adapted to ensure the highest levels of precision, safety, and performance in these critical healthcare applications. Therefore, the healthcare sector's continuous pursuit of technological advancements and improved patient care fuels the ever-growing need for vacuum pumps in this domain.

Restraint

Energy consumption and economic cycles

Energy consumption serves as a significant restraint on the growth of the vacuum pumps market. Vacuum pumps are known to be energy-intensive devices, consuming substantial amounts of power during their operation. This high energy demand results in increased operating costs for businesses, particularly in industries that require continuous vacuum operations.

Rising energy prices and a growing emphasis on environmental sustainability further exacerbate this issue, compelling users to seek more energy-efficient alternatives or to optimize their existing vacuum systems. Consequently, the high energy consumption of vacuum pumps can discourage potential users and pose a financial burden on existing users, thus restraining the market's growth. Economic cycles also have a notable impact on the vacuum pumps market.

The demand for vacuum pumps is closely tied to industrial activities and capital investments. During economic downturns or periods of economic uncertainty, businesses may curtail capital expenditures, affecting the adoption of vacuum pump systems. Conversely, in times of economic growth, industries may be more inclined to invest in these systems. Economic fluctuations, therefore, introduce a level of volatility into the vacuum pumps market, making it sensitive to broader economic conditions and potentially limiting its sustained growth in uncertain economic environments.

Opportunity

Green technology adoption and customization & specialization

Green technology adoption is a significant opportunity in the vacuum pumps market. As environmental sustainability becomes a top priority, there is a growing demand for energy-efficient and eco-friendly vacuum pump technologies. Manufacturers can capitalize on this by developing pumps that minimize energy consumption and reduce emissions. Additionally, the use of clean and environmentally friendly lubricants, like dry pumps, can align with green technology principles.

This trend not only caters to environmentally conscious industries but also attracts incentives and favorable regulations, further boosting market growth. Customization and Specialization present another avenue for market expansion. The ability to provide tailored vacuum solutions for niche applications is a valuable opportunity. Industries such as 3D printing, aerospace, and research laboratories require highly specialized vacuum systems to meet their unique requirements. Manufacturers that offer customization services or design pumps specifically for these applications can gain a competitive edge and tap into previously unaddressed markets. This specialization allows for higher product differentiation and increased demand for vacuum pump systems in various sectors.

Segments Insights

Lubrication Insights

The dry lubrication segment had the highest market share of 61% in 2025. Dry lubrication in the vacuum pumps market refers to a lubrication method that doesn't rely on liquid or oil-based lubricants. Instead, it employs solid or dry film lubricants to reduce friction and wear between moving parts within the pump. This approach offers several advantages, including lower maintenance requirements, reduced contamination risk, and improved efficiency.

A notable trend in the vacuum pumps market is the increasing adoption of dry lubrication systems. This trend is driven by the desire to minimize environmental impact, enhance operational cleanliness, and reduce downtime for maintenance. Dry lubrication not only improves the performance and lifespan of vacuum pumps but also aligns with the industry's sustainability goals and regulatory compliance.

The wet lubrication segment is anticipated to expand at a significant CAGR of 5.9% during the projected period. In the vacuum pumps market, "wet lubrication" refers to a lubrication method where a liquid, typically oil, is used to reduce friction and maintain the sealing between moving parts within the pump. Wet lubrication helps extend the pump's lifespan and enhances its performance by reducing wear and heat generation.

This segment has witnessed a growing trend towards the development of environmentally friendly lubricants that aim to minimize oil emissions and enhance the sustainability of vacuum pump operations. Additionally, manufacturers are focusing on designing pumps with improved oil management systems to reduce maintenance requirements and overall operating costs.

Vacuum Level Insights

The low vacuum level segment has held a 53% revenue share in 2025. In the vacuum pumps market, the low vacuum level segment refers to the range of vacuum pressures typically between 1 and 1,000 Torr. This segment finds applications in areas such as food packaging, laboratory equipment, and HVAC systems where moderate vacuum levels are required. Recent trends in the low vacuum level segment include a focus on energy-efficient pump designs, improved reliability, and quieter operation. Additionally, the integration of smart technologies and digital controls to enhance monitoring and maintenance has gained prominence. Manufacturers are also emphasizing eco-friendly features and materials to align with sustainability initiatives, further driving the demand for low vacuum level pumps.

The high vacuum level segment is anticipated to expand fastest over the projected period. The high vacuum level segment in the vacuum pumps market typically refers to vacuum levels below 10^-3 Torr. In this category, precision and efficiency are paramount, making it crucial for industries like semiconductor manufacturing, research, and space exploration. Trends in the high vacuum level segment include a growing demand for oil-free and dry vacuum pump technologies to meet stringent cleanliness requirements.

Additionally, there is a focus on the integration of digital monitoring and control systems to enhance precision and ensure consistent performance, aligning with Industry 4.0 principles. High vacuum level applications continue to advance, with an emphasis on achieving cleaner, more efficient, and technologically sophisticated vacuum environments.

End-use Insights

The manufacturing segment had the highest market share of 30% in 2025. In the vacuum pumps market, the manufacturing segment encompasses a wide range of industries, including automotive, electronics, pharmaceuticals, and more. This segment primarily utilizes vacuum pumps for various manufacturing processes, such as degassing, forming, and packaging. Trends in this sector involve an increasing emphasis on energy-efficient and sustainable manufacturing practices.

Manufacturers are adopting vacuum pump technologies that reduce energy consumption and environmental impact. Additionally, there's a growing demand for smart and connected vacuum systems that can be monitored and controlled remotely, enhancing efficiency and reducing downtime in manufacturing operations.

The semiconductor & electronics segment is anticipated to expand fastest over the projected period. The semiconductor and electronics segment in the vacuum pumps market is defined by its extensive use of vacuum pumps for critical manufacturing processes. These pumps are indispensable for creating clean, controlled environments during semiconductor fabrication, ensuring high precision and low contamination levels. Recent trends in this segment include the growing demand for dry and oil-free vacuum pumps to minimize contamination risks and improve process efficiency.

Moreover, the development of advanced materials and technologies in the semiconductor industry is driving the need for specialized vacuum solutions, aligning with the increasing focus on miniaturization and precision in electronics manufacturing.

Regional Insights

What is the Asia Pacific Vacuum Pumps Market Size?

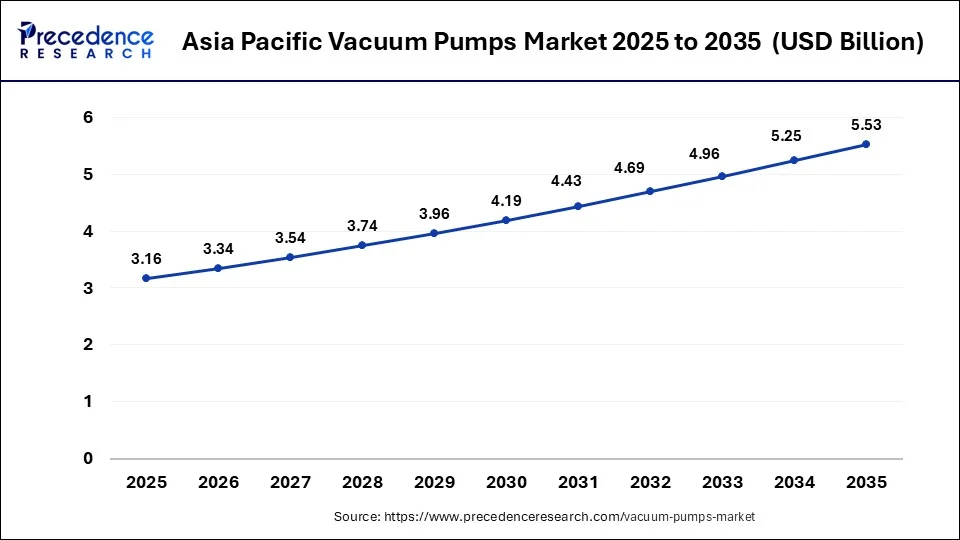

The Asia Pacific vacuum pumps market size is estimated at USD 3.16 billion in 2025 and is predicted to be worth around USD 5.53 billion by 2035, at a CAGR of 5.76% from 2026 to 2035.

Asia Pacific has held the largest revenue share of 46% in 2025. Asia Pacific dominates the vacuum pumps market due to several key factors. The region's robust industrialization, particularly in electronics, semiconductor manufacturing, and automotive sectors, drives substantial demand for vacuum pumps. Additionally, the expanding healthcare and pharmaceutical industries further contribute to the market's growth.

Favorable government policies and investments in manufacturing infrastructure also bolster Asia Pacific's vacuum pumps market. Moreover, the presence of key manufacturers and suppliers in countries like China, Japan, and South Korea, combined with a vast consumer base, makes this region a major player in the global vacuum pump market.

China Vacuum Pumps Market Trends

China's integration of digital control systems and smart automation has turned these pumps into intelligent assets capable of real-time energy optimization and predictive diagnostics. While international leaders maintain a strong presence, the rise of specialized domestic manufacturers in sectors like cryogenics and molecular pumping is diversifying the supply chain for precision engineering.

North America is estimated to observe the fastest expansion. North America's prominent growth in the vacuum pump market is primarily attributed to its thriving semiconductor and electronics sector, a substantial user of vacuum pump technology.

U.S. Vacuum Pumps Market Trends

The U.S.'s pharmaceutical sector's demand for contamination-free manufacturing and a broader industrial shift toward energy-efficient, EPA-compliant systems. Government initiatives prioritizing local production of critical technologies further accelerate the adoption of advanced, automated vacuum solutions.

The region's robust presence in key industries such as healthcare, aerospace, and automotive manufacturing, all of which depend significantly on vacuum pumps, also plays a pivotal role. North America's dedication to research and innovation, coupled with its commitment to environmentally responsible practices, fosters the adoption of energy-efficient vacuum pump solutions. These factors collectively establish North America as a major player in the vacuum pump industry.

Europe is observed to grow at a considerable growth rate in the upcoming?period, largely fueled by advancements in industrial automation, cleanroom practices, and rising demand within the pharmaceutical and semiconductor industries. Stringent environmental regulations are driving manufacturers to adopt oil-free and energy-efficient vacuum pump technologies. The region is also seeing a growing integration of smart vacuum systems with IoT technology for predictive maintenance purposes. Countries like Germany, France, and the UK are bolstering research and development initiatives due to their robust industrial infrastructure. Additionally, the increase in food processing and packaging applications throughout Europe is driving the demand for sophisticated vacuum pump solutions.

Germany Vacuum Pumps Market Trends

Germany holds a crucial position in the European vacuum pumps market, because of its solid manufacturing foundation and focus on precision engineering. The nation is recognized for creating technologically advanced and high-performance vacuum solutions utilized in the automotive, pharmaceutical, and electronics industries. Adhering to regulatory requirements and promoting sustainable manufacturing are central to its operations. Germany's dedication to innovation and automation continues to boost the demand for vacuum pumps across various industrial sectors.

Value Chain Analysis of the Vacuum Pumps Market

- Research & Development (R&D) and Technology Innovation

This initial stage involves designing new, more efficient, and specialized vacuum pump technologies, such as dry screw or turbomolecular pumps, to meet specific industry needs.

Key Players: Pfeiffer Vacuum, ULVAC, Inc., and Edwards Vacuum - Inbound Logistics & Raw Material Sourcing

This stage focuses on arranging the timely and cost-effective inbound movement of specialized materials and components, such as high-grade metals, seals, and electronic controls, from suppliers to manufacturing plants.

Key Players: Atlas Copco and Busch Vacuum Solutions - Manufacturing and Assembly

Operations in this stage involve the precise transformation of raw materials and components into finished vacuum pumps, including machining, assembly, quality control, and testing.

Key Players: Atlas Copco, Busch Vacuum Solutions, Gebr. Becker GmbH and Ingersoll Rand.

Vacuum Pumps Market Companies

- Atlas Copco provides a wide range of vacuum solutions, from rough to ultra-high vacuum, applied across diverse industries including semiconductors, chemicals, and general manufacturing, focusing on energy efficiency and low lifecycle costs.

- Gardner Denver, part of the Ingersoll Rand portfolio, offers a comprehensive line of industrial vacuum pumps known for their durability and reliable performance in applications like food processing, packaging, and environmental technology.

- Pfeiffer Vacuum specializes in high-tech vacuum products and systems for analytical instruments, R&D, and semiconductor production, notably contributing with turbomolecular pumps and extensive leak detection technology.

- Busch Vacuum Solutions is a major player offering a vast selection of vacuum pumps, blowers, and compressors for nearly all industries, renowned for their robust rotary vane pumps and commitment to sustainable vacuum generation.

- ULVAC leverages its expertise in materials and processing technology to provide innovative vacuum solutions, particularly playing a significant role in semiconductor manufacturing and flat-panel display production with a broad range of vacuum equipment.

- Edwards Vacuum, now part of Atlas Copco, is a leader in vacuum technology for the demanding semiconductor and flat-panel display markets, while also offering robust general-purpose vacuum pumps for industrial and scientific applications.

Other Major Key Players

- Leybold

- Ebara Corporation

- Agilent Technologies

- KNF Neuberger

- Becker Pumps

- Tuthill Corporation

- Graham Corporation

- VACUUBRAND

- DEKKER Vacuum Technologies

Recent Developments

- In March 2025, Honeywell announced its acquisition of Sundyne, a leading manufacturer of pumps and compressors. This strategic move aims to enhance Honeywell's position in advanced industrial solutions and broaden its product offerings for process industries, encompassing vacuum technologies.

- In June 2024, Ingersoll Rand finalized the acquisition of Fruvac, a Canadian firm specializing in mobile and truck-mounted vacuum systems. This acquisition aligns with Ingersoll Rand's strategy to diversify its vacuum product portfolio and extend its geographical reach.

- In July 2024, Pfeiffer Vacuum has entered into a strategic partnership with CryoDry to improve the integration of vacuum technology within pharmaceutical freeze-drying processes. The collaboration focuses on merging high-efficiency pumps with specialized drying systems for enhanced performance.

- In March 2023, Kaishan USA introduced the KRSV series of industrial vacuum pumps, known for their exceptional energy efficiency with a combination of variable speed drive and variable discharge port airend. These pumps come fully assembled and ready for immediate use, making them highly convenient for various applications.

- In March 2022, Ingersoll Rand launched the SVT Series of oil-lubricated rotary screw vacuum pumps designed for industries like electronics and food and beverage. These pumps operate intelligently, adjusting pump speed to match actual demand, resulting in substantial energy savings ranging from 30 to 50% compared to fixed-speed technologies.

- In January 2022, Atlas Copco expanded its presence in the Asia-Pacific region by acquiring HHV Pumps Pvt. Ltd., a company specializing in vacuum pumps and systems used across multiple industries. This strategic move reinforces Atlas Copco's position in the vacuum pump market and enhances its ability to serve a broader range of customers in the region.

Segments Covered in the Report

By Lubrication

- Dry

- Wet

By Vacuum Level

- Low

- Medium

- High

By End-Use

- Chemical & Petrochemical

- Semiconductor & Electronics

- Manufacturing

- Pharmaceutical

- Food & Beverage

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting