Fused Deposition Modeling 3D Printing Market Size and Forecast 2025 to 2034

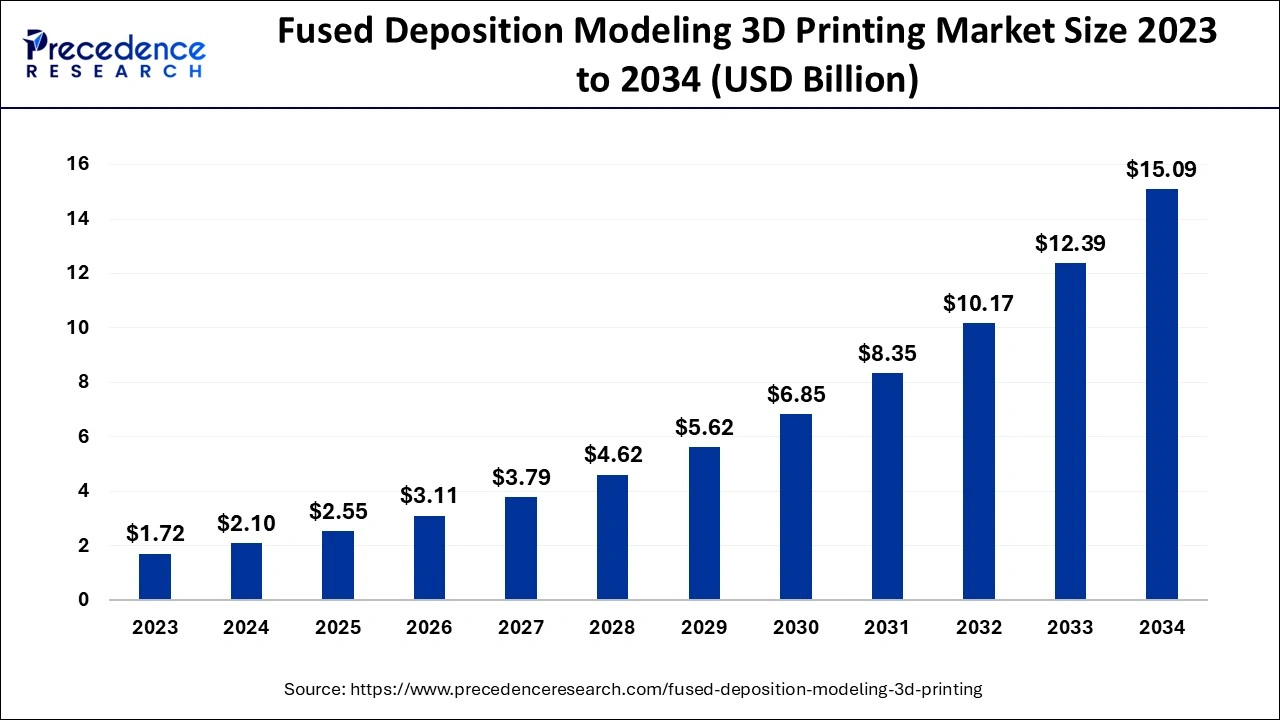

The global fused deposition modeling 3D printing market size was worth around USD 2.10 billion in 2024 and is anticipated to reach around USD 15.09 billion by 2034, growing at a CAGR of 21.80% from 2025 to 2034. The increasing demand for 3D printing technology with sustainable and cost-effective solutions by the different industries is driving the growth of the market.

Fused Deposition Modeling 3D Printing Market Key Takeaways

- The global fused deposition modeling 3D printing market was valued at USD 2.10 billion in 2024.

- It is projected to reach USD 15.09 billion by 2034.

- The fused deposition modeling 3D printing market is expected to grow at a CAGR of 21.80% from 2025 to 2034.

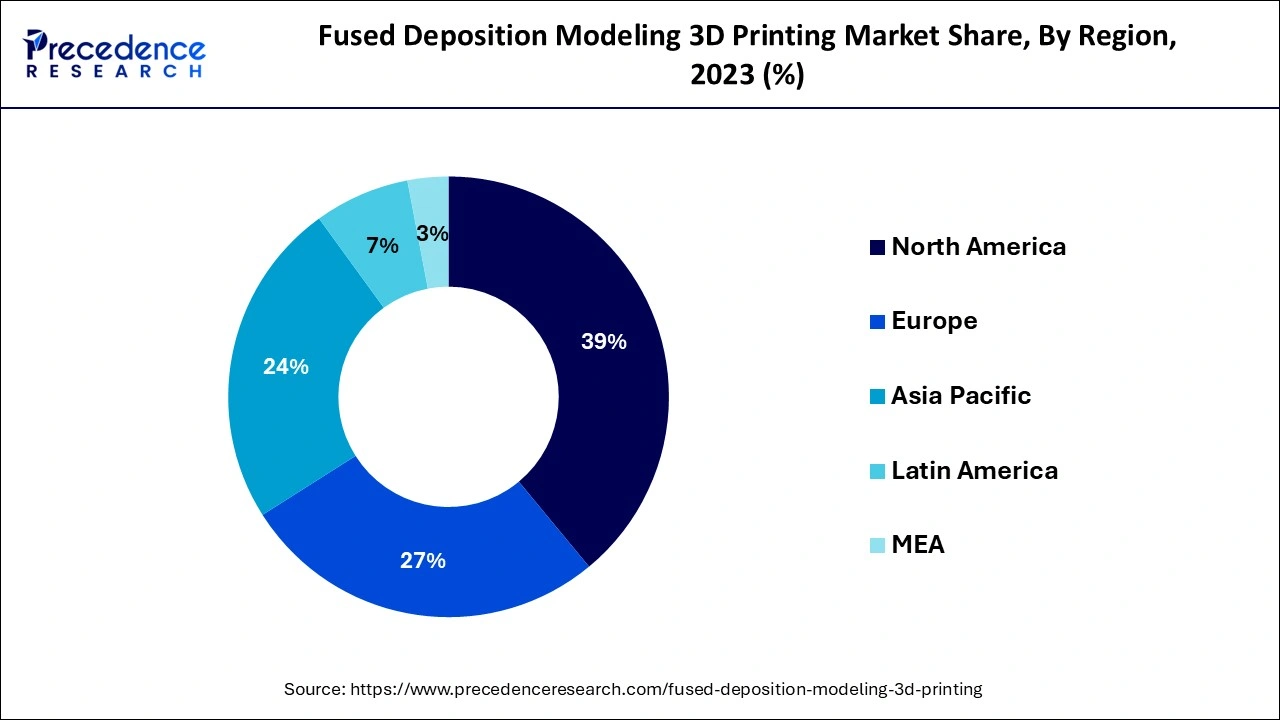

- North America dominated the global market with the largest market share of 39% in 2024.

- Asia Pacific is expected to grow at the fastest CAGR during the forecast period.

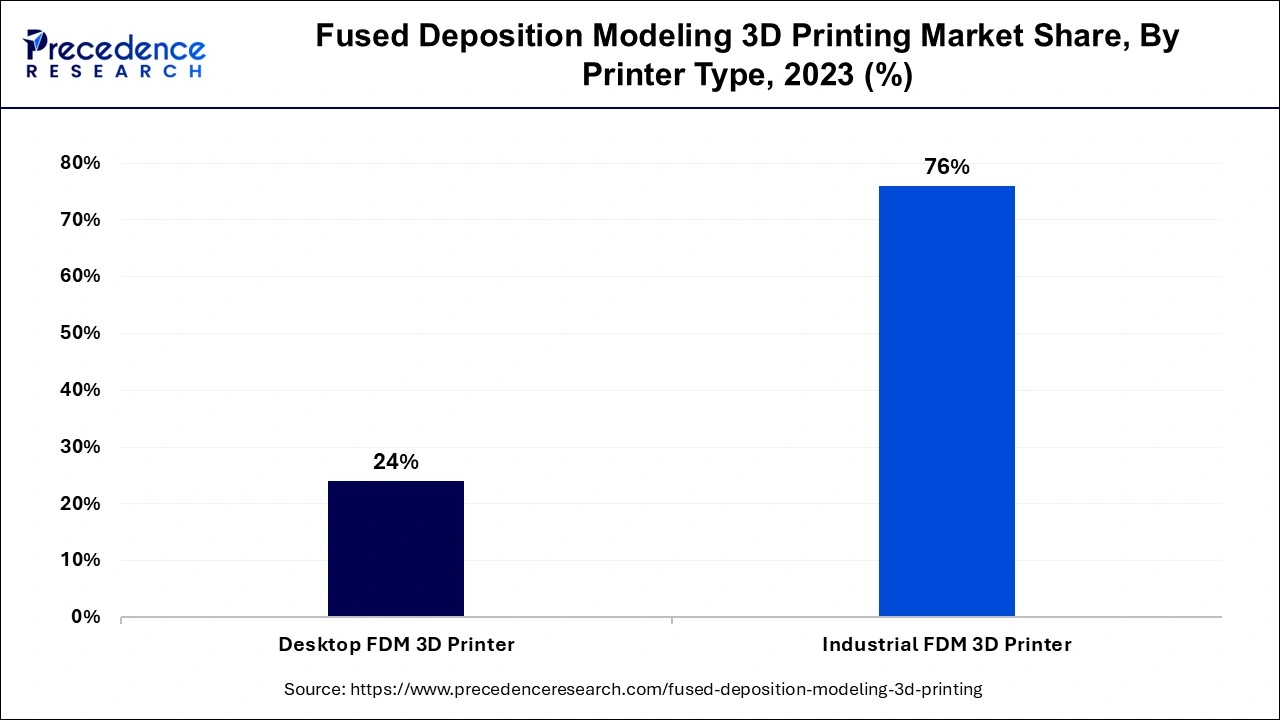

- By printer type, the industrial printer segment contributed the highest market share of 76% in 2024.

- By printer type, the desktop 3D printer segment is expected to grow rapidly during the forecast period.

- By application, the prototyping segment captured the biggest market share in 2024.

- By application, the tooling segment expects significant growth during the forecast period.

- By end-use, the automotive segment held the largest market share in 2024.

- By end-use, the healthcare segment expects significant growth during the forecast period.

How Can AI Impact the Fused Deposition Modeling 3D Printing Market?

The integration of Artificial Intelligence (AI) can significantly contribute to the expansion and process of 3D printing. AI can help increase the efficiency of 3D printing through several processes, including enhancing the designs of products, minimizing human interference and errors in operations, increasing efficiency, helping develop new materials, customization in the manufacturing process, and others.

- In March 2024, the French software startup Spare Parts 3D (SP3D) introduces the beta program for Théia, a new AI-powered 2D-to-3D Model Digitization Tool.

U.S. Fused Deposition Modeling 3D Printing Market Size and Growth 2025 to 2034

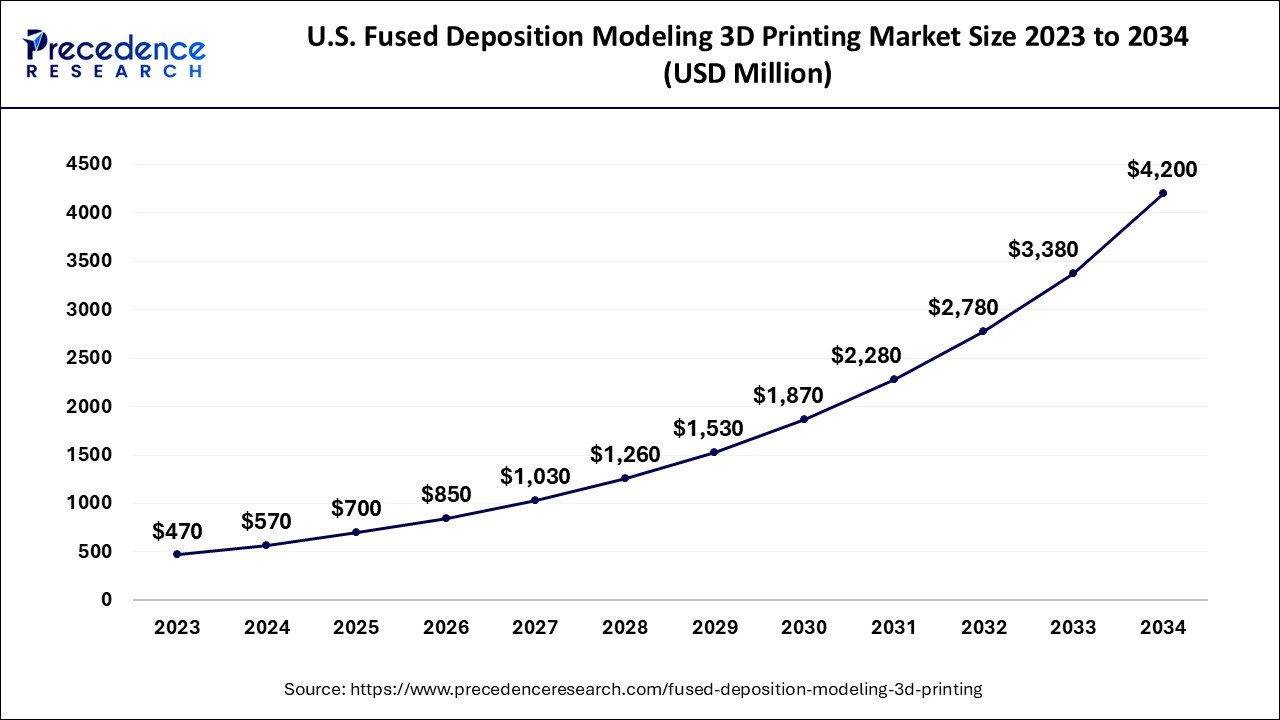

The U.S. fused deposition modeling 3D printing market size was exhibited at USD 570 million in 2024 and is projected to be worth around USD 4,200 million by 2034, growing at a CAGR of 22.11% from 2025 to 2034.

North America dominated the fused deposition modeling 3D printing market in 2024. The growth of the market is attributed to the rising industrialization and the demand for quick and efficient technology that helps in the rapid product development and designing of the prototype. There is a rising use of fused deposition modeling 3D printing in different industries such as automotive, healthcare, consumer goods, manufacturing, and others. The regional countries, including the United States and Canada, are some of the leading contributors to the expansion and acceptance of technologies in several applications, which boosts the growth of the fused deposition modeling 3D printing market in the region.

- The United States manufacturing sector contributed $2.3 trillion to the GDP, amounting to 10.2% of the total U.S. GDP. There are 15.6 million people in the United States who are employed in the manufacturing sector in 2023, representing 9.7% of the overall US population.

- The U.S. accounts for the 2nd largest manufacturing country in the world, and out of 11 subsectors, it ranked 1st in the two subsectors and 2nd in the remaining nine.

Asia Pacific expects the fastest growth in the market during the forecast period. The growth of the market is attributed to the rising manufacturing unit and the adoption of technologies and automation in the manufacturing sector. 3D printing is one of the emerging technologies in the different industries that helps in designing and producing the products with its prototype. It is highly used by the automobile, aerospace, defense, and healthcare industries to make their products more cost-effective and rapid.

- India is one of the fastest-growing economies in terms of industrialization and GDP, and the manufacturing sector is one of the rapidly growing industries, contributing 16-17% of the overall GDP pre-pandemic. India has the capacity to export goods worth US$ 1 trillion by 2030.

- India's manufacturing industry reached US$ 1651.1 billion, with an increase of 69% over the last decade, accelerated by production-linked incentive (PLI) schemes.

Market Overview

The fused deposition modeling (FDM) 3D printing is also known as the material extrusion 3D printing process. It is one of the most common methods of 3d printing; it extrudes the thermoplastics filament in a series of layers, which is built on a flat surface for creating three-dimensional objects. It is the most cost-effective solution for 3D printing and can be used in a wide range of plastic materials, cotton fibers, and other materials. Fused deposition modeling 3D printing is used in different industrial processes, which drives the growth of the fused deposition modeling 3D printing market.

Fused Deposition Modeling 3D Printing Growth Factors

- Increasing industrialization: The rapid growth in economic development and the rise in industrialization are driving the demand for technologically advanced manufacturing equipment for product development and design, which boosts the growth of the market.

- Increasing demand for customization solutions: The rising demand for customized equipment and on-demand manufacturing solutions with the rapid and cost-effective development of the process is contributing to the expansion of the market.

- Rise in manufacturing industries: The rising population and the increasing demand for consumer products involving automobiles, consumer goods, electronics, enhanced medical facilities, and others are driving the demand for the fused deposition modeling 3D printing market.

Market Dynamics

Driver

Increasing adoption of FDM 3D printing by the aerospace and defense industry

The rising adaptation of FDM 3D printing in aerospace industrial applications such as rocket components, interior components, structural components for defense systems, tooling, spare parts, and others is driving the growth of the fused deposition modeling 3D printing market. In the aerospace industry, complex parts are made in low volumes, and 3D printing plays a crucial role in manufacturing. 3D printing helps in designing and manufacturing lightweight parts that help make the airplane lightweight and consume less fuel.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 15.09 Billion |

| Market Size in 2024 | USD 2.10 Billion |

| Market Size in 2025 | USD 2.55 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 21.80% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Printer Type, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Restraint

Maintaining quality standards

There are some limitations associated with FDM 3D printing, such as print quality issues, misalignment of layers, and insufficient availability of materials, and others are collectively restraining the growth of the market.

Opportunity

Inclination towards sustainability in industrialization

The rising concern about environmental challenges, the increasing carbon footprint, and industrial waste on the earth create severe impacts on the environment and human health that drive the demand for sustainable solutions for industries or manufacturing units. FDM 3D printing provides an eco-friendly alternative to traditional manufacturing with the use of biodegradable and recyclable materials that help minimize waste.

Printer Type Insights

The industrial 3D printer segment dominated the fused deposition modeling 3D printing market in 2024. There is a wider demand for industrial FDM 3D printers from a different range of industries, such as automotive, aerospace, medical and dental, consumer goods, industrial goods, and others. 3D printing is an efficient tool in industries that is used in faster prototyping, and it also includes several technologies in it. Industrial FDM 3D printing offers several advantages in operations, including cost savings, customization, and rapid prototyping, and it helps minimize waste, complex geometrics, material versatility, and on-demand production.

- In April 2024, Endless Industries GmbH launched the Endless One, a medium-scale continuous fiber 3D printer that is made to deliver scalability, strength, and customization across industries from automotive, medical, and aerospace.

The desktop 3D printer segment is expecting considerable growth in the market during the forecast period. Desktop FDM 3D printers are generally used in the printing of smaller items as compared to industrial printers. It is mostly used in industrial applications such as education, industrial designing, archeology, animation, lighting, and others. The desktop FDM 3D printing technology is mostly used in the dental industry.

- In November 2024, UpNano, a 3D printing specialist, launched the NanoOne green, a desktop multiphoton laser lithography system enabling layer-by-layer 2-photon polymerization. The NanoOne green integrates the NanoOne 250 and NanoOne 1000 models to enhance transparent material versatility and high resolution.

Application Insights

The prototyping segment led the fused deposition modeling 3D printing market in 2024. FDM 3D printing is the most important technology used in creating a physical visualization prototype. FDM 3D printing allows us to make better decisions, makes product development so much easier, and helps produce multiple iterations before finalizing the product for production. In the prototyping, FDM 3D printing revolutionizes the design of products. FDM 3D printing is the most important technology or tool that is used in prototyping certain products in industries.

The tooling segment expects significant growth in the fused deposition modeling 3D printing market during the forecast period. FDM 3D printing tooling is one of the most efficient types of technology used in manufacturing industries. FDM 3D printing helps in the rapid development of tooling; it provides the manufacturing of tooling on demand. It provides a rapid and sustainable manufacturing option in the manufacturing process. The process is used in the manufacturing of fixtures, tools, templates, dies, molds, jigs, and other equipment. The FDM 3D printing tooling offers several benefits, such as rapid production, faster iterations, improved product quality, reduced CAPA, and others.

End-use Insights

The automotive segment accounted for the largest share of the fused deposition modeling 3D printing market in 2024. Prototyping is one of the important parts of any manufacturing process; it helps in product development, testing, and analysis before it goes into the production line. FDM 3D printing is an efficient technology that provides cost-effectiveness and rapid production and designing of products. The automotive industry is one of the leading manufacturers that accept the FDM 3D printing technology due to its effective and cost-effective way of producing automobile parts.

The healthcare segment expects significant growth in the fused deposition modeling 3D printing market during the forecast period. FDM 3D printing is one of the ideal technologies for designing and producing medical devices. FDM 3D printing helps in prototyping customized patient-centric devices such as implants and prosthetics, which can be produced more affordably and rapidly than traditional manufacturing. In the medical field, FDM 3D printing is highly used in the dental industry. Most of the clear aligners that are used in aligning the teeth and straightening teeth are made with FDM 3D printing techniques. FDM 3D printing is further used in different healthcare applications such as digital dentistry, implant and prosthetics, bioprinting, surgical planning and testing, and others.

Fused Deposition Modeling 3D Printing Market Companies

- Stratasys

- Markforged

- Bambu Lab

- Shenzhen Creality FDM 3D Technology Co., Ltd.

- ELEGOO

- MakerBot

- UltiMaker

- INTAMSYS TECHNOLOGY CO., LTD.

- Prusa Research a.s.

- Flashforge

Latest Announcements by the Industry Leaders

- In October 2024, Bambu Lab postponed the introduction of its new 3D printer to Q1 2025; Bambu Lab, a leading manufacturer of desktop FDM 3D printers, announced on X that the revised timeline enables to refine the new product's “innovative features” to ensure global distribution.

Recent Developments

- In August 2024, Markforged launched the FX10 Metal Kit, a print engine that offers metal printing on its FX10 machine. The FX10 Metal Kit is the 'world's first industrial 3D printer that can print both metal filaments and composites with continuous fiber reinforcement.'

- In June 2024, 3D Systems introduced a new Ext 800 Titan Pellet, which is large by polymer extrusion standards but the smallest in the 3-member Titan family. The newly launched Pellet increased the throughput of up to 14 kilos per hour of material for cheaper parts, faster tools, and molds.

Segments Covered in the Report

By Printer Type

- Desktop FDM 3D Printer

- Industrial FDM 3D Printer

By Application

- Prototyping

- Tooling

- Functional Parts

By End-use

- Automotive

- Aerospace & Defense

- Healthcare

- Consumer Electronics

- Industrial Machines

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting