What is the Industrial Wireless Vibration Monitoring Market Size?

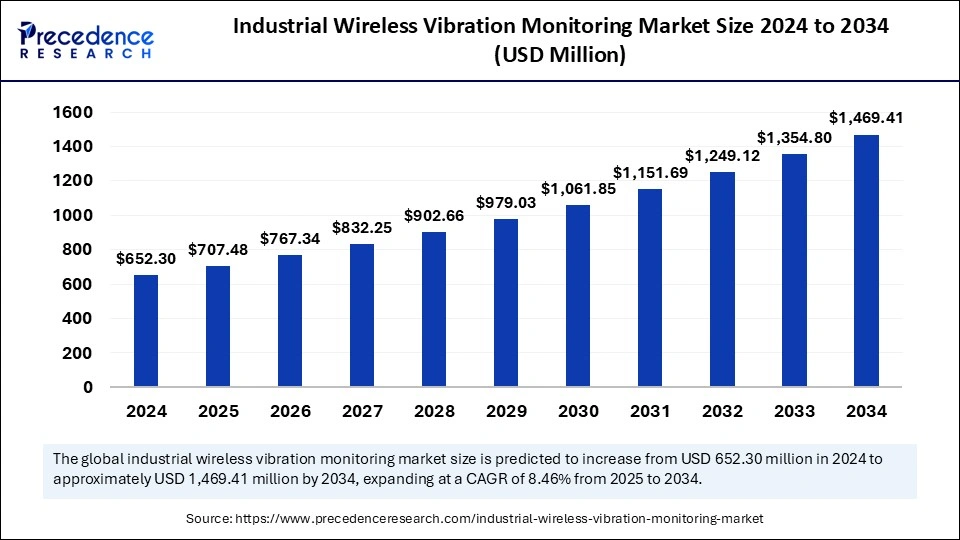

The global industrial wireless vibration monitoring market size is calculated at USD 707.48 million in 2025 and is predicted to increase from USD 767.34 million in 2026 to approximately USD 1,578.07 million by 2035, expanding at a CAGR of 8.35% from 2026 to 2035.The growth of the market is driven by the increasing adoption of smart technologies and rise of industry 4.0. Furthermore, advancements in technology contribute to the growth of the market.

Industrial Wireless Vibration Monitoring Market Key Takeaways

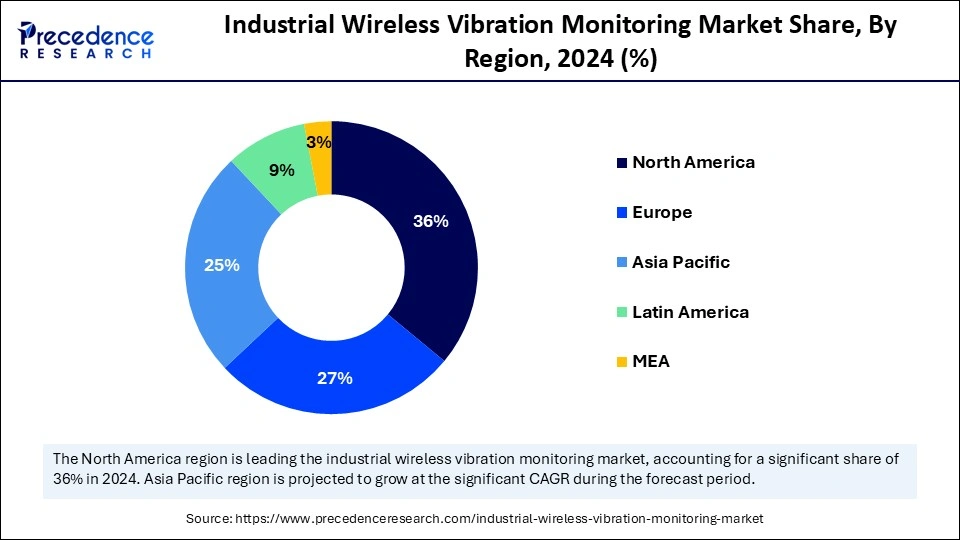

- North America dominated the market by holding 36% of market share in 2025.

- Europe is expected to witness the fastest growth in the coming years.

- By type, the wireless sensors segment held the biggest market share of 37% in 2025.

- By type, the data acquisition systems segment is projected to grow at the fastest rate during the forecast period.

- By application, the condition monitoring segment contributed the highest market share of 42% in 2025.

- By application, the predictive maintenance segment is anticipated to grow rapidly during the projection period.

What are Industrial Wireless Vibration Monitoring Systems?

Industrial wireless vibration monitoring systems are embedded with sensors that efficiently analyze vibration in industrial machinery to identify potential problems and reduce downtime. The industrial wireless vibration monitoring market is experiencing significant growth due to the increasing focus on improving operational efficiency and growing concerns about worker safety. These systems stand out as ideal solutions to improve the efficiency of industrial operations since they eliminate equipment failures and downtime. They detect failures in rotating machinery, such as pumps, motors, agitators, gearboxes, centrifuges, fans, conveyor systems, and compressors. This, in turn, allows for timely maintenance, reducing downtime, enhancing the equipment's reliability, and creating a safe environment for workers.

Wireless vibration monitoring is a simple, effective, alarm-based system that detects major faults in industrial equipment without compromising safety. These systems allow monitoring more machinery with fewer resources, particularly suitable for machines in limited spaces, harsh surroundings, and hard-to-reach areas. They also enhance worker safety.

How is AI Impacting the Industrial Wireless Vibration Monitoring Market?

Artificial Intelligence emerged as a powerful analytical tool in various industries, opening new avenues for monitoring machinery conditions. It analyzes vibrations in machinery to ensure peak performance and avoid failures. Integrating AI algorithms in industrial wireless vibration monitoring systems enhances efficiency by identifying areas of improvement. AI algorithms analyze vibration data to identify anomalies and predict equipment failure, allowing for timely maintenance and reducing downtime. AI-driven vibration monitoring systems are ideal for condition monitoring. AI enables these systems to analyze vast amounts of data in real-time, detecting subtle changes in machine behavior that may indicate potential failures.

Industrial Wireless Vibration Monitoring Market Growth Factors

- The rise of Industry 4.0 is a major factor boosting the adoption of advanced technologies, including industrial wireless vibration monitoring systems, boosting the growth of the market.

- Industrial wireless vibration monitoring systems are the preferred choice in various industries where worker safety is the utmost priority. These systems create a safe working environment for workers by identifying malfunctions in equipment.

- Advancements in technologies like WiFi-Direct, 5G, RFID, 6LoWPAN, and Li-Fi greatly increase the capabilities of wireless vibration monitoring systems.

Market Outlook

The industrial wireless vibration monitoring market is expected to witness robust growth from 2025 to 2034 due to increasing demand for predictive maintenance, operational efficiency, and reduced downtime across manufacturing and heavy industries. Adoption of IoT-enabled sensors and real-time analytics is driving innovation and providing cost-effective solutions for equipment monitoring and maintenance.

The market is growing globally due to rising industrial automation, the need for predictive maintenance, and the push to reduce unplanned equipment failures. Emerging regions offer significant opportunities as industries adopt smart manufacturing practices, upgrade legacy machinery, and invest in IoT-enabled monitoring solutions to enhance operational efficiency.

Major investors in the market include industrial automation companies, private equity firms, and technology integrators who fund R&D, manufacturing, and deployment of advanced wireless monitoring systems. Their investments accelerate the development of IoT-enabled devices, improve sensor accuracy, and expand the adoption of predictive maintenance solutions across industries worldwide.

Market Scope

| Report Coverage | Details |

| Market Size by 2035 | USD 1,578.07 Million |

| Market Size in 2025 | USD 707.48 Million |

| Market Size in 2026 | USD 767.34 Million |

| Market Growth Rate from 2026 to 2035 | CAGR of 8.35% |

| Dominating Region | North America |

| Fastest Growing Region | Europe |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Type, Application and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Rising Adoption of Vibration Sensors

There is a high adoption of vibration sensors in various sectors, like oil & gas, manufacturing, aerospace, and automotive, which is a major factor driving the growth of the market. These sensors play an important role in proactive and predictive maintenance approaches, enabling industries to monitor the conditions of complex systems, improve operational efficiency, and reduce downtime and associated maintenance costs. The oil & gas and manufacturing sectors are especially at the forefront of adopting vibration sensors to enhance asset performance and comply with stringent safety regulations.

Emphasis on Industrial Automation

The increasing emphasis on industrial automation is another key factor driving the growth of the industrial wireless vibration monitoring market. As industries continue to boost operational efficiency through automation, the adoption of wireless vibration monitoring systems increases. These systems enable remote monitoring of equipment, reducing the need for on-site inspection and supporting automation.

Restraint

High Cost and Skilled Personnel Requirement

High costs associated with wireless vibration monitoring systems hamper the market's growth. These systems require additional hardware to work efficiently, which adds to the overall cost. This cost factor discourages small-scale businesses, especially those with budget constraints, from adopting such systems. Moreover, installing these systems and analyzing data generated by these systems require skilled personnel, creating challenges for some businesses. Thus, a lack of trained personnel or expertise limits the adoption of these systems, thus restraining the growth of the industrial wireless vibration monitoring market.

Opportunity

Growing Need to Enhance Operational Efficiency with Predictive Maintenance

With the growing need to enhance the efficiency of industrial operations, the demand for predictive maintenance solutions is increasing in various industries, creating immense opportunities in the market. By implementing industrial wireless vibration monitoring systems, industries can monitor and track parameters like sound and vibrations to assess machine conditions and predict potential failures. This proactive method enables timely equipment maintenance and addresses safety challenges, significantly enhancing operational efficiency.

Segment Insights

Type Insights

The wireless sensors segment dominated the industrial wireless vibration monitoring market with the largest share in 2025 since wireless sensors are crucial in wireless vibration monitoring systems. They require low maintenance and a small amount of power to function. These sensors are compatible with many systems. They enable continuous monitoring of machine health, reducing failures and downtime.

The data acquisition systems segment is expected to grow at the fastest rate over the studied period as they enhance the reliability and efficiency of machinery. This type of system automates data entry processes, reducing human intervention. Data acquisition systems are the foundations of industrial vibration monitoring systems that reduce errors. These systems analyze and process equipment data in real-time, predicting potential failures.

Application Insights

The condition monitoring segment held the largest share of the industrial wireless vibration monitoring market in 2025. This is mainly due to the key role of wireless vibration monitoring systems in condition monitoring. These systems continuously measure industrial equipment's vital parameters like temperature, vibration, and pressure. They detect anomalies in equipment function and predict potential failures. They also evaluate machine conditions remotely through wireless sensors.

The predictive maintenance segment is projected to grow at a rapid pace in the coming years. This is mainly due to the increasing adoption of predictive maintenance strategies to boost operational efficiency. Wireless vibration monitoring systems are crucial in predicting equipment failures by monitoring vital parameters. This enables timely maintenance, reducing downtime and maintenance costs. Moreover, the rising need to reduce maintenance costs and increase equipment lifespan is expected to drive segmental growth.

Regional insights

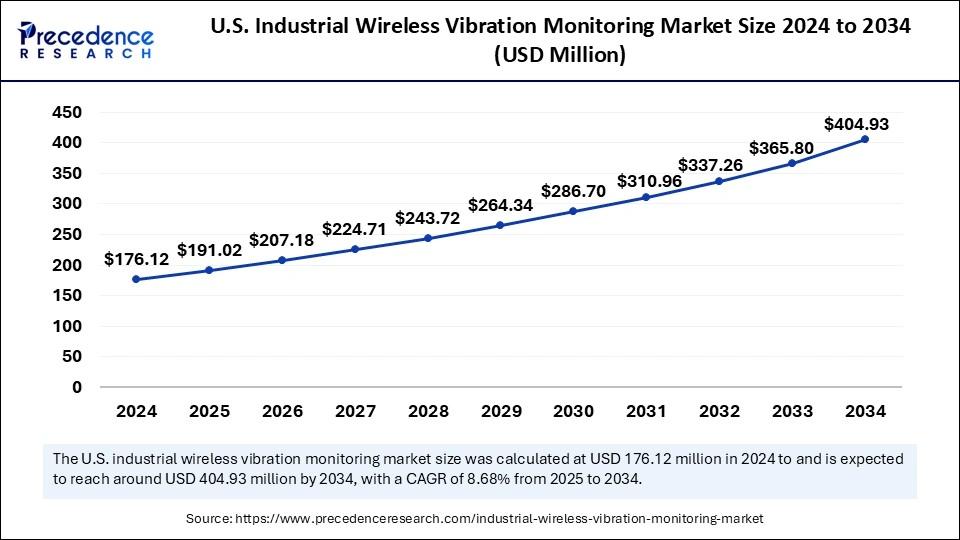

The U.S. industrial wireless vibration monitoring market size is exhibited at USD 191.02 million in 2025 and is projected to be worth around USD 437 million by 2035, growing at a CAGR of 8.63% from 2026 to 2035.

North America's Sustained Dominance in the Market

North America registered dominance in the industrial wireless vibration monitoring market by capturing the largest share in 2024. This is mainly due to its strong industrial base. The region is the early adopter of modern technologies like artificial intelligence and automation solutions. There is a heightened adoption of wireless vibration monitoring systems in the manufacturing sector to support automation. Moreover, the region is at the forefront of technological innovations, leading to the rapid development of advanced sensors and sophisticated vibration monitoring systems, supporting regional market growth.

The U.S. is the major contributor to the North American industrial wireless vibration monitoring market. The rising adoption of automation solutions in the U.S. is contributing to market expansion. There is a strong focus on enhancing the efficiency of industrial operations, boosting the acceptance of wireless vibration monitoring systems. Moreover, stringent regulations regarding asset safety and management are supporting market growth.

Europe is expected to emerge as the fastest-growing region in the coming years. This is mainly due to the rising trend of automation and the rise of Industry 4.0. There is a strong focus on smart manufacturing, boosting the demand for vibration monitoring systems to ensure assets' functionality. The European Green Deal is transforming the power sector in the region by increasing the deployment of solar and wind power energy systems. Wireless vibration monitoring systems play a crucial role in the predictive maintenance of wind turbines, which extends the lifespan of the turbine and reduces operational costs.

The UK and Germany are expected to lead the European industrial wireless vibration monitoring market. Increasing government initiatives to support digital transformation and industrial automation is a major factor contributing to market expansion. A well-established manufacturing sector in these countries is seeking solutions to increase operational efficiency and worker safety. Moreover, the increasing focus on sustainable practices and energy efficiency is encouraging industries to adopt wireless vibration monitoring systems to optimize equipment performance and reduce energy consumption.

Asia Pacific is observed to grow at a notable growth rate in the upcoming period. This is mainly due to the rapid industrialization and rising manufacturing activities. There is a strong emphasis on industrial automation. Governments of various Asian countries are providing incentives to promote the adoption of automation solutions and support Industry 4.0. With the growing industrialization, there is a strong focus on predictive maintenance strategies to improve operational efficiency, boosting the demand for wireless vibration monitoring systems. These systems enable various industries to lower equipment downtime.

Industrial Wireless Vibration Monitoring Market Companies

Provides advanced wireless vibration sensors and analytics platforms for predictive maintenance in industrial equipment and energy assets.

Offers industrial IoT-enabled vibration monitoring solutions integrated with real-time diagnostics and automated alerts for operational efficiency.

Supplies wireless vibration monitoring systems as part of its digital industrial portfolio, enabling predictive maintenance and smart factory integration.

Delivers portable and wireless vibration measurement tools with real-time data logging and analysis for machinery health monitoring.

Provides wireless vibration sensors, condition monitoring systems, and predictive maintenance software for industrial machinery and rotating equipment.

Recent Developments in the Market

Recent Developments in the Market

- In March 2025, Salunda's Latch Hawk 2 fingerboard latch monitoring device improves offshore drilling safety by providing real-time data on latch status, preventing dropped objects during pipe handling without the need for a spotter or camera.

(Soure: worldoil.com/news) - In January 2025, Swedish tech company pureSignal of Sweden AB introduced pureALUBE, a wireless system with app monitoring and AI decision support, marking a breakthrough in proactive maintenance and gaining significant international attention and distributor agreements.

(Soure: news.cision.com) - In April 2024, the Timken Company launched a new wireless sensor and condition monitoring solution. This novel sensor and solution help users detect equipment failure by monitoring temperature and vibration.

- In November 2023, Worldsensing announced the launch of its novel wireless sensor, the Vibration Meter. This sensor measures vibrations in long-term, continuous vibration monitoring projects. The novel product uses a tri-axial MEMS accelerometer along with longer battery life, a broader communications range, and a hugely competitive price point than existing vibration-related technologies on the market, while complying with key regulatory standards.

- In September 2023, Energous Corporation, an industry leader in RF-based wireless power network solutions, partnered with InPlay Inc., a fabless semiconductor company dedicated to engineering advanced low-power wireless communication technologies for the Industrial IoT market, to demonstrate a battery-free temperature and humidity IoT sensor solution.

Segments Covered in the Report

By Type

- Wireless Sensors

- Wireless Controllers

- Vibration Transmitters

- Data Acquisition Systems

- Vibration Analysis Software

By Application

- Condition Monitoring

- Asset Management

- Predictive Maintenance

- Machine Health

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa (MEA)

Get a Sample

Get a Sample

Table Of Content

Table Of Content