What is the Manufacturing Execution Systems Market Size?

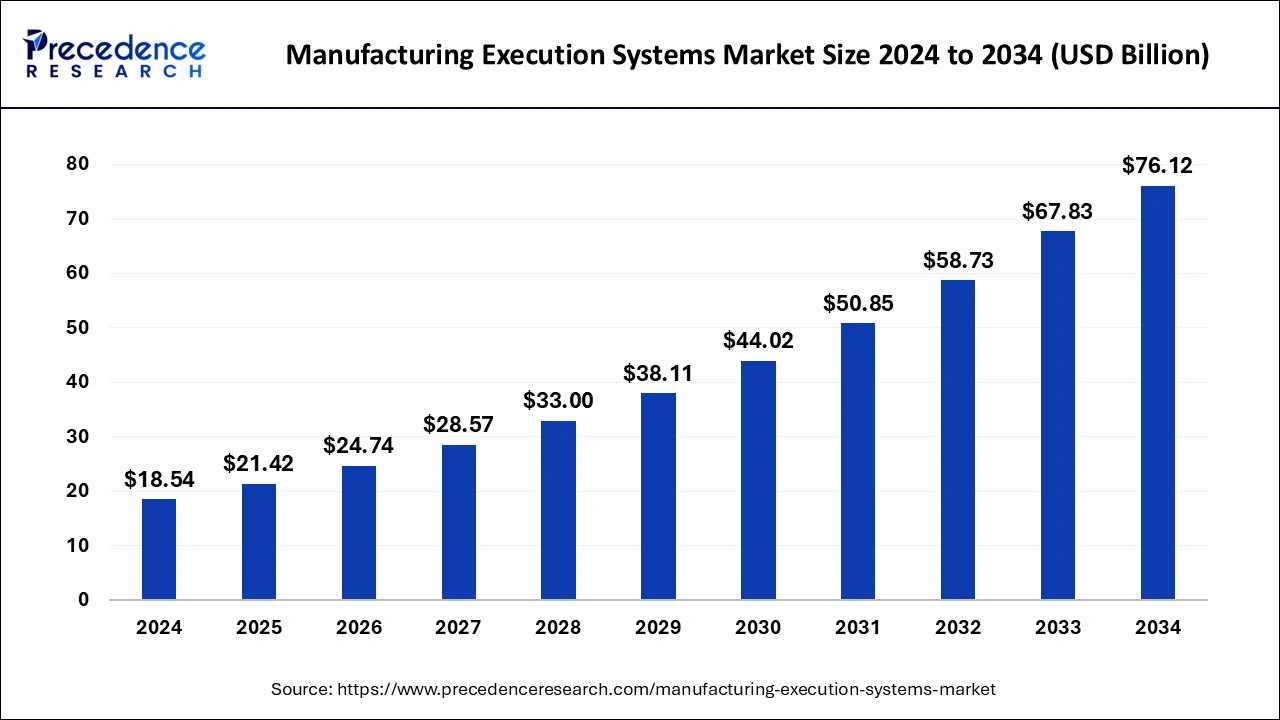

The global manufacturing execution systems market size is calculated at USD 21.42 billion in 2025 and is predicted to increase from USD 24.74 billion in 2026 to approximately USD 84.95 billion by 2035, expanding at a CAGR of 14.77% from 2026 to 2035.

Market Highlights

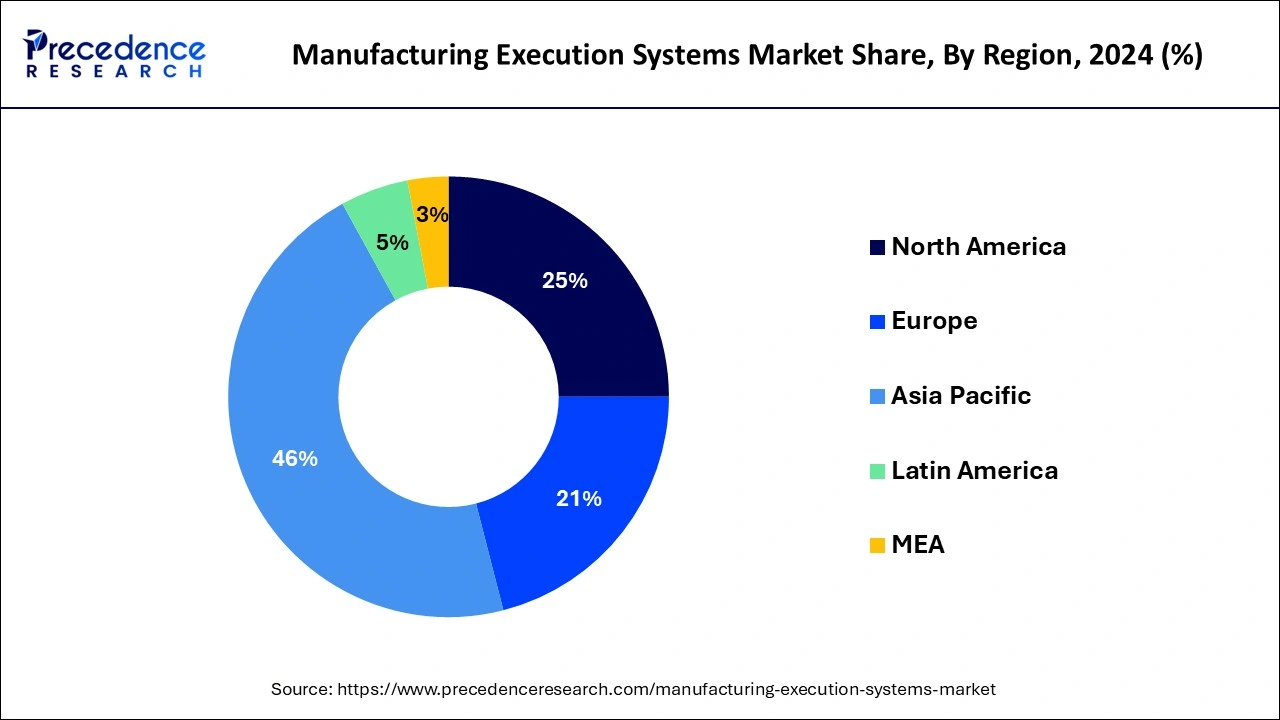

- Asia Pacific led the global market with the highest market share of 46% in 2025.

- By deployment, the hybrid deployment segment has held the largest market share in 2025.

- By offering, the services segment captured the biggest revenue share of 72% in 2025.

- By end user, the drug and life sciences industry segment registered the maximum market share in 2025.

Market Size and Forecast

- Market Size in 2025: USD 21.42 Billion

- Market Size in 2026: USD 24.74 Billion

- Forecasted Market Size by 2034: USD 76.12 Billion

- CAGR (2025-2035): 14.77%

- Largest Market in 2025: Asia Pacific

Market Overview

A Manufacturing Execution System is frequently characterized as IT-empowered frameworks that give answers for enhancing and consequently further developing the assembling system for creation floor designers and chiefs. The framework's essential associates control complex assembling frameworks to screens on the industrial facility floor. The objective of the execution of creating is to ensure the powerful execution of the assembling tasks and further develop creation yield.

The assembling execution framework (MES) market is arranged into the cycle business, capability, discrete industry, and different districts. Different capabilities regulated by the MES framework are archive control, investigation, stock administration, creation following, creation execution examination, asset allotment, and so forth. At the point when the data and information assortment is computerized, MES timetables, tracks, and changes creation exercises additionally screens and controls the exhibition of the pack.

Manufacturing Execution Systems Market Growth Factors

The essential factors, for example, the developing utilization of modern mechanization in process ventures combined with low sending costs are supporting the development of the assembling execution framework market. Besides, the assembling execution framework's market size experienced consistent development because of the popularity from the water and wastewater treatment, food, and drink, power businesses. Likewise, the need to follow continuous information, improve information perceivability, and control off-site advancement activity essentially affects the development of the MES market size. Besides, the infiltration of the IoT innovation across assembling businesses to showcase robotization is powering open doors for the overall assembling execution framework market. Besides, IoT empowers correspondence and communication between modern gadgets to supply enterprises with better adaptability and ideal execution. These have decidedly expected in moving the development of the worldwide assembling execution framework market.

There are sure difficulties confronted that will prevent the general market development. The variables, for example, absence of mindfulness in regards to the advantages of MES arrangements among SMEs are restricting the market development. Likewise, high venture and running costs associated with the execution and overhaul of assembling execution frameworks for limited scope creation is assessed to languid development during the conjecture time frame. In any case, the headways in advances, Integration with arrangements like ERP and PLM, expanding extent of assembling execution frameworks in raising energy effectiveness and feasible creation, and potential application base in the drugs and life sciences industry offer positive learning experiences.

Manufacturing Execution Systems Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 21.42 Billion |

| Market Size in 2026 | USD 24.74 Billion |

| Market Size by 2035 | USD 84.95 Billion |

| Growth Rate from 2025 to 2035 | CAGR of 14.77% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Offering, Deployment Type, Process Industry, Discrete Industry, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Key Market Drivers

Requirement for large scale manufacturing and associated store network to serve developing populace

- The requirement for an associated production network in assembling businesses is a vital driver for the MES market. Effective data stream across the processing plant is a significant element for empowering proficient creation exercises. IoT frameworks can be involved by makers for area following, checking stock, and announcing of made items going through the inventory network process. Associated producing arrangements additionally assist in the simple progression of data all through the whole stockpile with fastening, which makes it simple for organizations to answer the changing economic situations.

- Ongoing data helps makers in bringing down stock expenses, distinguishing risk issues, and accomplishing creation as per market needs. The expansion in assembling exercises worldwide for large scale manufacturing, alongside quality improvement, is driving the requirement for cutting edge devices and programming frameworks. This need can be taken care of with cutting edge creation frameworks and techniques presented by assembling execution frameworks.

Market Opportunity

Growing extent of assembling execution frameworks in raising energy effectiveness and maintainable creation

- Fabricating execution frameworks are being carried out by different huge organizations and SMEs as they assist with improving assembling processes. The capacity of these frameworks to increment creation, lessen cost, work on quality, and empower item following and information assortment continuously helps increment creation effectiveness. This component is supposed to support the reception of these frameworks to increment benefits.

- The execution of assembling execution frameworks likewise prompts decreases in energy utilization and waste during the assembling system. For instance, while utilizing a MES arrangement on a shop floor, extra IT assets are not needed, and the requirement for desk work and actual extra room is wiped out.

Market Challenge

Complexities in sending of MES in different businesses

The sending of MES is intricate on the grounds that each such framework is different as per the singular business necessities. Additionally, the cycle engaged with assembling and creation exercises likewise contrast from one industry to another. Various stages like Implementation, organizing, and moving to the creation floor are associated with the assembling system. Execution at these various stages gets confounded because of the intricacy of the equipment foundation of creation or shop floor. Hence, it is extreme for the assembling execution framework to adjust to various circumstance at various stages and perform effectively, as it needs different alterations during establishments.

- The execution cycle of an assembling execution framework requires roughly four years. The primary year centers around making assembling and business processes appropriate for the framework.

- The second-year explicitly centers around the venture for arrangements like DCS, PLM, or ERP that would help with controlling and observing the natural substances in the creation region.

- In the third year, the organization is prepared for execution to keep up with electronic records rather than paper clump.

- The last year centers around the joining of assembling execution frameworks with arrangements like ERP. The intricacy of the cycles engaged with the execution of assembling execution frameworks with each arrangement of a creation floor and the tedious course of execution are the significant difficulties for the MES market.

Manufacturing Execution Systems Market Segment Insights

Deployment Insights

Hybrid Deployment is supposed to have most elevated CAGR of the assembling execution frameworks market during the figure time frame. The use of mixture sending of assembling execution frameworks has expanded in the oil and gas area because of the developing significance of following ongoing data about the activities in oil and gas fields. Likewise, a cross breed producing execution framework gives additional capacity limit, in this manner guaranteeing the wellbeing of information. Subsequently, the market for hybrid arrangement in oil and gas industry is supposed to develop at the most elevated CAGR during 2025 and 2034.

Offering Insights

The services section is growing faster CAGR during the gauge time frame. The variables that can be credited to further developing effectiveness as well as the creation interaction by diminishing wastage and creation time.

The MES processes are conveyed in two ways for example during and after execution.

End User Insights

The drug and life sciences industry holds the biggest piece of the pie during the gauge time frame. Life sciences organizations give arrangements that assistance in normalizing fabricating processes across various destinations situated in various areas worldwide. Producing execution frameworks help makers in overseeing information, which is subsequently utilized for administrative consistence.

With the persistently advancing patterns in the drug business, producers are encountering expanded strain to keep pace and alter their tasks to address evolving issues. Fabricating Execution Systems (MES) empower the drug business to lessen creation costs and further develop consistence with administrative necessities fundamentally.

MES has been effectively carried out inside the drug and life sciences industry since the Food and Drug Administration (FDA) proclaimed the last 21 Part 11 guidelines on 21 March 1997. These have given models to the acknowledgment by the FDA, under particular conditions, of electronic marks, electronic records, and transcribed marks executed to electronic records as comparable to paper records and written by hand marks executed on paper.

Besides, the developing worry towards fake medications entering the store network has brought about the reception of worldwide track and follow guidelines to safeguard patient wellbeing and guarantee item trustworthiness. The EU Falsified Medicine Directive (EUFMD), the US Drug Supply Chain Act (DSCSA), and other worldwide guidelines imply that producers are currently attempting to guarantee consistence and add imaginative advancements and increment the assets to deal with the extra authoritative weight. The utilization of standardized identifications and serialization numbers, as well as the consolidation of RFID labels inside the bundling gear, are all actions that are being required to work on the nature of recognizability and following.

Manufacturing Execution Systems Market Regional Insights

The Asia Pacific manufacturing execution systems market size is estimated at USD 9.85 billion in 2025 and is predicted to be worth around USD 39.57 billion by 2035, at a CAGR of 14.92% from 2026 to 2035.

India Manufacturing Execution Systems Market Analysis

India is emerging as a global manufacturing leader through strong performance and supportive policies. In November 2025, the country approved 17 new electronics manufacturing projects worth INR 71.72 billion. The Production Linked Incentive (PLI) Scheme serves as the government's strategy to position India as a global manufacturing powerhouse, promoting innovation, efficiency, and competitiveness across key industries. All these factors contribute to the market growth in India.

- The assembling execution frameworks market in Asia Pacific to develop at the most noteworthy CAGR during the gauge time frame. The interest for assembling execution frameworks is exceptionally high in Asia Pacific because of nations like China, Japan, South Korea and India. It is the quickest developing business sector for assembling execution frameworks.

- China and India are the quickest developing economies on the planet because of fast industrialization as well as spotlight on assembling exercises in businesses, for example, auto, buyer gadgets, etc. China is supposed to develop at the most noteworthy rate because of flooding interest for assembling units in the country. This is at last expected to give gigantic open doors to MES programming. Besides, alongside car and shopper gadgets, there has been a rising spotlight on laying out various assembling plants in enterprises like materials, power, and drugs where fabricating execution frameworks have preeminent interest. China and India are the development motors for the MES market in Asia Pacific.

- North America is supposed to keep on holding the huge portion of the MES market over the conjecture period, significantly because of the presence of a few critical MES merchants.

- Besides, North America's solid monetary position empowers it to put vigorously in cutting edge arrangements and advancements that have given an upper hand on the lookout. Likewise, the district is seeing a few organizations by market players, which is assisting them with consolidating their answers and contributions to expand their market presence.

- The continuous consistent developments and speculations toward digitization across the ventures in the district are one of the expected open doors for the market. Development in the quantity of SMEs and the rising digitization in the assembling capabilities by enormous associations, like IBM and General Electric, are supporting the development of the IoT market in the local assembling fragment. SMEs are turning out to be progressively adaptable to consolidate new advances with their current frameworks, while huge producers have significant spending plans for digitization. This is empowering the reception of EMS.

U.S. Manufacturing Execution Systems Market Analysis

The U.S. government has implemented supportive programs and regulatory frameworks to encourage the adoption of advanced manufacturing technologies. Targeted funding in sectors such as semiconductors promotes the adoption of sophisticated systems, including manufacturing execution systems (MES). Industry standards are being developed to ensure MES integration, enabling seamless information flow across manufacturing operations. These factors drive the market in the U.S.

Europe is expected to grow at a significant rate in the market in the upcoming period. The European Union actively promotes the adoption of advanced manufacturing through funding programs and wide-ranging initiatives. The Made in Europe partnership drives sustainability, innovation, and digital transformation across the sector, while the European Institute of Innovation & Technology Manufacturing supports the implementation of innovative technologies, pilot projects, and automation and digitalization efforts in manufacturing.

The French government encourages the adoption of digital technologies such as manufacturing execution systems through the ‘France 2030' investment plan and the ‘Team France Industry of the Future' program. It provides substantial funding to large industrial sites to implement low-carbon solutions and support decarbonization initiatives. Many French manufacturers are increasingly integrating artificial intelligence (AI) and machine learning (ML) into MES platforms to enable predictive maintenance, quality control, and optimized production scheduling, moving from reactive to proactive operations, thereby boosting market growth.

The market in Latin America is driven by rising Industry 4.0 adoption as manufacturers across automotive, food & beverages, and other sectors increasingly embrace automation, IoT, and AI to enhance efficiency and production transparency. Latin America is emphasizing digitalization and smart manufacturing practices to strengthen competitiveness. Government incentives promoting digital transformation and automation are accelerating the adoption of Manufacturing Execution Systems (MES), which enable real-time production monitoring and data-driven decision-making.

Brazil is leading the market in Latin America, driven by widespread adoption of Industry 4.0 technologies. There is a rising demand for operational efficiency, improved production capabilities, and regulatory compliance. The country is further benefiting from significant investments in data centers and cloud computing infrastructure. Additionally, multi-stakeholder support to advance Brazil's renewable energy sector is boosting the adoption of digital and automated manufacturing solutions.

The manufacturing execution systems market in the Middle East & Africa (MEA) is driven by various factors. Firstly, governments across MEA, particularly in GCC countries, are supporting Industry 4.0 initiatives, encouraging manufacturers to adopt automation, IoT, cloud, and data‑driven control systems. Secondly, the rising adoption of advanced technologies like AI, digital twins, and collaborative robotics. Finally, widespread digitalization initiatives and government-led automation efforts are driving the adoption of advanced industrial technologies.

Manufacturing Execution Systems Market Companies

- ABB LTD (Switzerland)

- Tebis Technische Informations syteme AG (US)

- Werum IT Solutions Gmbh (Germany)

- Dassault Systems (France)

- Rockwell Automation Inc. (US)

- Honeywell International Inc. (US)

- Emerson Electric CO. (US)

- General Electric Company (US)

- Siemens AG (Germany)

- Andea Solutions (Sweden)

- Oracle Group (US)

- Siemens AG (Germany)

- Samsung Group of Companies (South Korea)

Recent Developments

- In May 2021, Siemens sent off another Opcenter Execution Discrete 4.1, which gives strong MES capacities, complete reconciliation of administrative and quality prerequisites, synchronized creation processes for ideal store network the board, and supported decreases in upkeep and activity costs.

- In November 2021, Rockwell Automation sent off new remote access arrangement which contains strong security abilities including multifaceted confirmation along with encoded conventions. The remote access arrangement can situate OEMs to satisfy current and future remote help prerequisites.

- In April 2021, SAP executed DMC in collaboration with the TU Vienna Pilot Factory in its creation and sequential construction systems, which have previously been digitalized by SAP organization utilizing SAP S4 and SAP ME.

- In November 2020, Rockwell refreshed a bunch of new usefulness for Factory Talk Innovation Suite, empowered by PTC, to simplicity, scale, and lift digitalization for modern associations.

Segments Covered in the Report

By Offering

- Software

- Services

By Deployment Type

- On-Premise

- On-Demand

- Hybrid

By Process Industry

- Food & Beverages

- Oil & Gas

- Chemicals

- Pulp & Paper

- Pharmaceuticals & Life Sciences

- Energy & Power

- Water & Wastewater Management

- Others

By Discrete Industry

- Automotive

- Aerospace

- Medical devices

- Consumer packaged goods

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting