What is the Metal Powder Market Size?

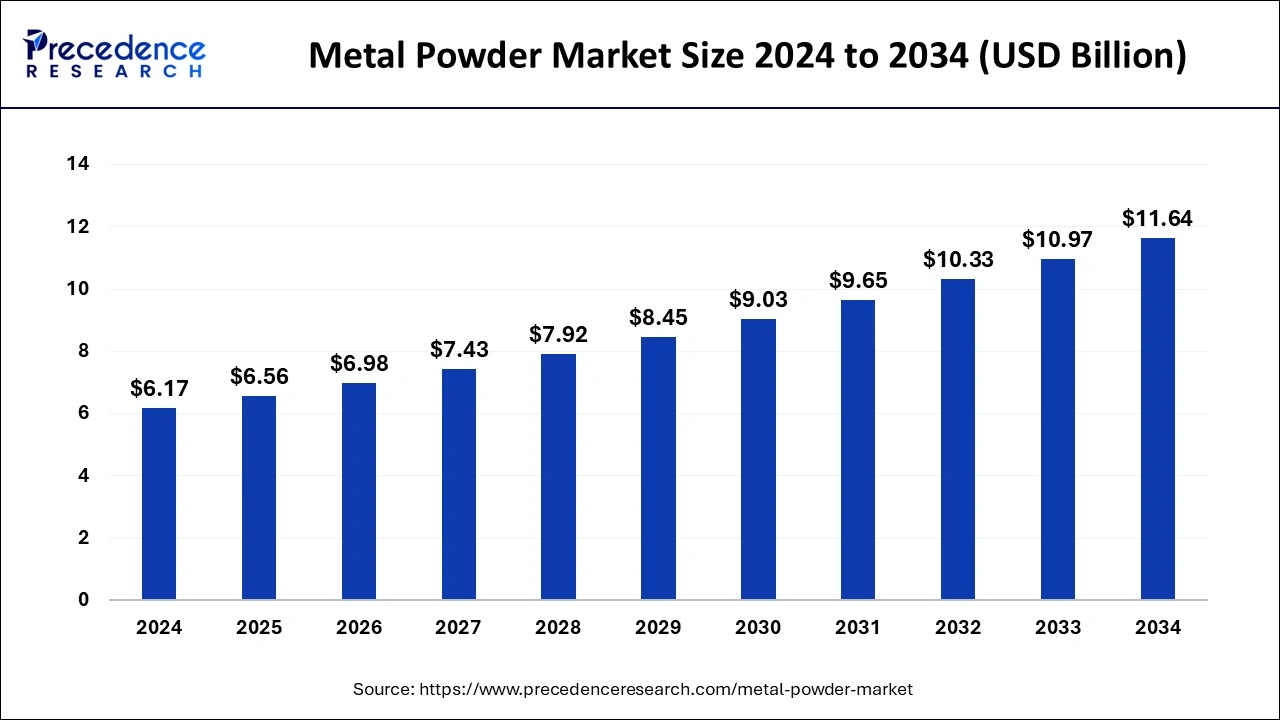

The global metal powder market size is calculated at USD 6.56 billion in 2025 and is predicted to increase from USD 6.98 billion in 2026 to approximately USD 12.29 billion by 2035, expanding at a CAGR of 6.48% from 2026 to 2035.

Metal Powder Market Key Takeaways

- In terms of revenue, the metal powder market is valued at 6.56 billion in 2025.

- It is projected to reach 12.29 billion by 2035.

- The market is expected to grow at a CAGR of 6.48% from 2026 to 2035.

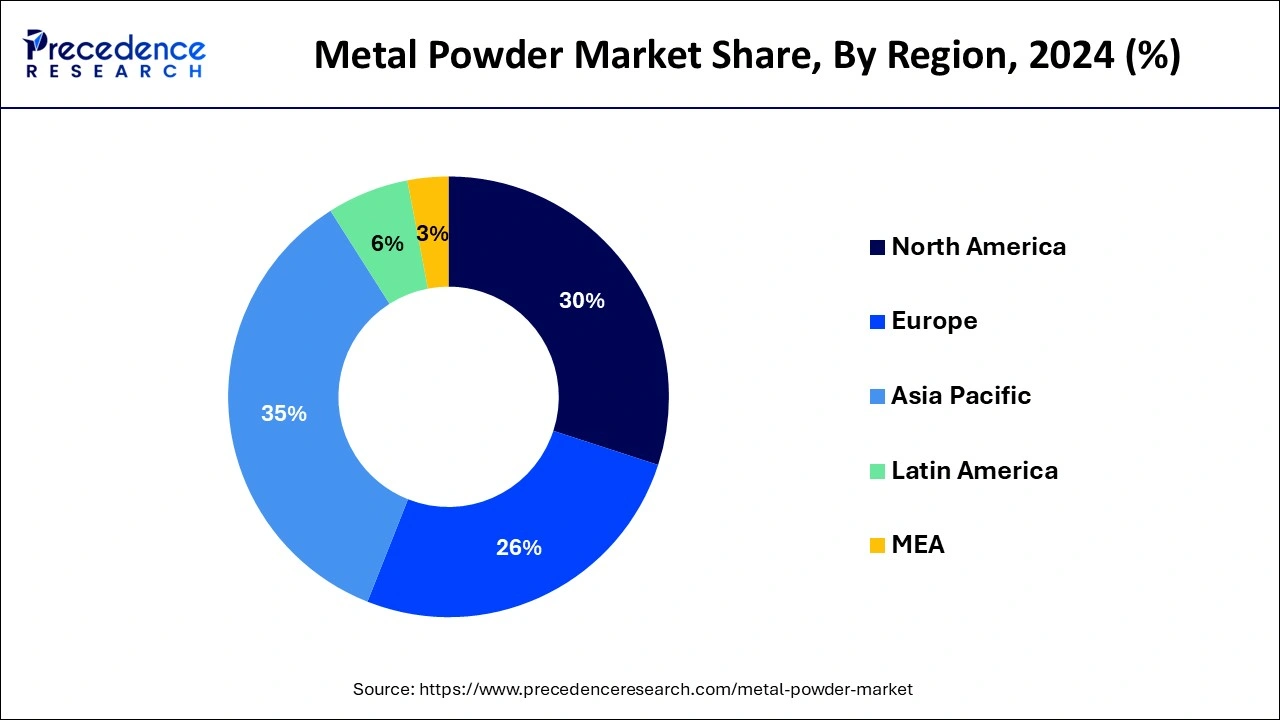

- Asia Pacific led the global market with the highest market share of 35% in 2025.

- By Type, the ferrous segment has held the largest market share in 2025.

- By Application, the aerospace and defense segment captured the biggest revenue share in 2025.

- By Technology, the press and sinter segment registered the maximum market share in 2025.

Market Overview

The metal powder market is growing significantly, driven by the rising applications of metal powders in sectors like automotive, aerospace, electronics, industrial machinery, energy, and additive manufacturing. Metal powders made of iron, aluminum, copper, nickel, steel, and specialty alloys are broadly used in powder metallurgy, metal injection molding, and 3D printing. The demand is rising due to the need for lightweight components, highly precise parts, material savings, and environmentally friendly manufacturing processes. Additionally, vehicle electrification, energy-efficient production methods, and advancements in manufacturing technologies are further driving robust market growth.

Key market Insights

Metal powders are effectively employed in a broad spectrum of applications such as welding, chemical, metallurgical processes, iron fortification, and friction among others. Augmented output in numerous crucial industries such as batteries, motor vehicles, electrical equipment, and machinery manufacturing will remain the key driving force for the growth of this market.

The substantial growth of the metal powders market across the globe is mainly attributed to the noteworthy growth of the manufacturing sector in established and emerging nations. Growing R&D expenditure, technological progressions, and a substantial upsurge in aerospace and automotive production capacities also have caused an augmented need for metal powder worldwide.

Metal Powder Market Growth Factors

- A rise in the manufacturing output of industrial and automotive components is estimated to generate demand for metal in these industries.

- Intensifying need for lightweight components in the automotive industry has offered stimulus for the growth of the global metal powder market.

- Augmented efficiency of metal is probable to emphasize the requirement for metal powder within the automotive component manufacturing sector

Market Outlook

- Industry Growth Overview: The metal powder market is growing due to increasing demand for lightweight, precise, and sustainable components, particularly in automotive, aerospace, and additive manufacturing industries. Advancements in manufacturing technologies, vehicle electrification, and energy-efficient production methods are further fueling market expansion.

- Global expansion: The market is expanding worldwide due to increasing demand for lightweight, precise, and sustainable components, particularly in automotive, aerospace, and additive manufacturing industries. Advancements in manufacturing technologies, vehicle electrification, and energy-efficient production methods are further fueling market expansion.

- Major Investors: Major investors in the market include industrial manufacturers, aerospace and automotive companies, and specialty material suppliers, who fund research, production, and supply chain expansion. Their investments drive the development of high-quality powders, support advanced manufacturing technologies, and enable the adoption of sustainable and precise production processes, boosting overall market growth.

- Sustainability Trend: There is a rising adoption of sustainable practices by taking into consideration some green material sources to produce the metal powder. This focus on green manufacturing is encouraging companies to adopt energy-efficient technologies and develop lightweight, high-performance components that reduce overall environmental impact.

Market Scope

| Report Highlights | Details |

| Market Size in 2025 | USD 6.56 Billion |

| Market Size in 2026 | USD 6.98 Billion |

| Market Size by 2035 | USD 12.29 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.48% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Type, Technology, Application, Region |

Segment Insights

Type Insights

Ferrous Emerged as The Largest Segment and Accounted for a Major Market Share In 2024. The ferrous segment involves metal powders encompassing of all kinds of steel and their alloys, iron, and alloying elements including molybdenum, nickel, and chromium. Steel is one of the inexpensive types of metal in additive manufacturing and finds application in a mixture with other metals like bronze. The non-ferrous product segment comprises metal powders made of copper, zinc, aluminum, tungsten, titanium, magnesium, and others

ApplicationInsights

Aerospace and Defense Application Sector Dominated Metal Powder Market Revenue. The aerospace and defense sector reported for significant revenue stake in the total metal powder market. Players involved in the metal powder market are rapidly undertaking expansion activities via numerous partnerships and joint ventures. In July 2020, MDA Corporation collaborated with BurloakTechnologies with the help of 5 years agreement to develop space applications with the help of additive manufacturing. This contract is projected to benefit both companies and improve design and manufacturing competencies in years to come.

Technology Insights

Press and Sinter Technology Segment Occupied a Major Volume Share in 2024. Press and sinter is a traditional powder metallurgy process. It is cheap and yields near-net-shape components. It encompasses thermal treatment or compaction at a temperature lesser than the melting point of metal to harvest a green compact.

Huge capital investments and continuing technological progressions in the metal powder market are projected to lower the risk of new entrants in the market. There is forceful competition amongst metal powder manufacturers in North America and Europe on account of the occurrence of a large number of local and international companies. Metal powder producers are concentrating on the development of their production competencies to furnish to the increasing demand for metal powder and to augment their footmarks in the worldwide market. Leading competitors contending in the global metal powder market.

Regional Insights

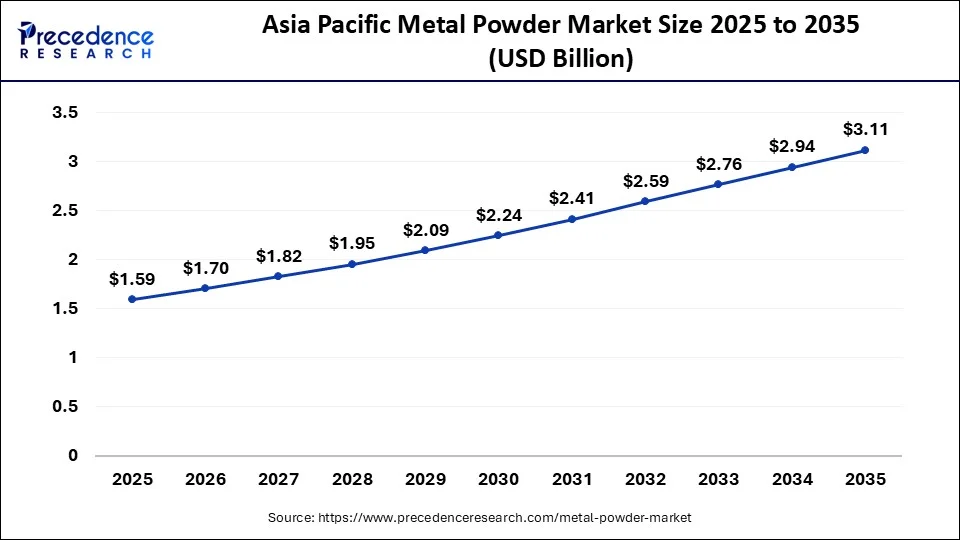

Asia Pacific Metal Powder Market Size and Growth 2026 to 2035

The Asia Pacific metal powder market size is evaluated at USD 1.59 billion in 2025 and is predicted to be worth around USD 3.11 billion by 2035, rising at a CAGR of 6.94% from 2026 to 2035.

Asia Pacific led the global metal powder market in 2024 with a substantial market share. This growth is credited to the intensification in population, an upsurge in disposable income, and development in spending in the electrical & electronics sector. India, China, and Japan are key contributors to the metal powder market in this region.Asia Pacific's dominance in the market is also attributed to its strong manufacturing base, high adoption of additive manufacturing technologies, and significant demand from the automotive, aerospace, and electronics industries. Additionally, rapid industrialization, supportive government initiatives, and investments in advanced production infrastructure further strengthen the region's market leadership.

China and India are major contributors to the Asia Pacific metal powder market due to their large-scale manufacturing sectors, rapid industrialization, and growing adoption of additive manufacturing technologies. China leads with strong automotive, aerospace, and electronics production, while India is expanding its demand for lightweight, high-performance components in automotive and industrial applications.

What Makes Europe the Fastest-Growing Market for Metal Powder?

Europe is the fastest-growing region, driven by strong foreign demand in its established automotive and aerospace sectors. Germany leads the European metal powder market, fueled by a focus on high-precision components, sustainable manufacturing, and rising demand for eco-friendly, energy-efficient technologies.

Europe is a major metal powder market, supported by a well-developed manufacturing ecosystem and strong automotive and aerospace sectors with an increasing focus on eco-friendly production. Strict environmental regulations, recycling initiatives, and energy-efficient manufacturing are driving sustainable metal powder usage, while additive manufacturing benefits from this trend in both prototyping and end-use applications.

Germany is a major contributor to the European metal powder market, driven by its energy-intensive automotive, aerospace, and precision engineering industries, along with strong adoption of additive manufacturing technologies. France also plays an active role, with demand largely driven by the need to enhance material performance in automotive and aerospace applications.

What Opportunities Exist in the Middle East & Africa?

The Middle East & Africa (MEA) offers immense opportunities in the metal powder market due to increasing industrialization, infrastructure development projects, and the introduction of advanced manufacturing technologies. There is increasing demand for corrosion and wear-resistant powders in oil & gas applications, contributing to the market growth. Saudi Arabia is the focal point of the regional metal powder market, driven by industrial growth fueled through economic diversification initiatives and increased investments in automotive, aerospace, defense, and industrial manufacturing sectors.

How is the Opportunistic Rise of Latin America in the Market?

Latin America is experiencing an opportunistic rise in the metal powder market, driven by the recovery of automotive manufacturing and increased adoption of modern production technologies. Brazil leads the regional market, fueled by its large automotive industry, mining activities, and expanding use of additive manufacturing for industrial components. Additionally, investments in infrastructure modernization and rising demand for lightweight, high-performance, and energy-efficient components are creating new growth opportunities in the region.

What Potentiates the Market in North America?

The metal powder market in North America is potentiated by the region's strong automotive, aerospace, and industrial manufacturing sectors, coupled with the rapid adoption of additive manufacturing technologies. Additionally, investments in energy-efficient production, lightweight components, and advanced material innovations are driving sustained market growth. The U.S. is the major contributor to the market due to its large-scale automotive, aerospace, and industrial manufacturing industries, as well as strong adoption of additive manufacturing technologies.

Metal Powder Market Comapnies

- Advanced Technology & Materials Co., Ltd

- MolyWorks Materials Corporation

- GKN PLC

- Rio Tinto Metal Powders

- Hoganas AB

- POLEMA

- Rusal

- Liberty House Group

- Sandvik AB

Recent Developments

- In May 2025, Oerlikon Metco, headquartered in Winterthur, Switzerland, has launched its new MetcoMed brand with metal powders the release of two materials tailored for the Additive Manufacturing of medical components and implants. The powder exhibits a particle size distribution that enables its use on most PBF-LB AM platforms. (Source: metal-am.com)

- In March 2024, SSAB is launching the world's first emission-free steel powder for commercial deliveries, made of recycled SSAB Zero[] steel. The product will create opportunities for customers to 3D-print their unique designs in steel produced without fossil carbon dioxide emissions.

(Source:ssab.com)

Major Market Segments Covered

By Type

- Ferrous

- Non-ferrous

By Technology

- Press & Sinter

- Additive Manufacturing

- Metal Injection Molding

- Others

By Application

- Healthcare

- Automotive

- Aerospace & Defense

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting