What is the Mineral Wool Market Size?

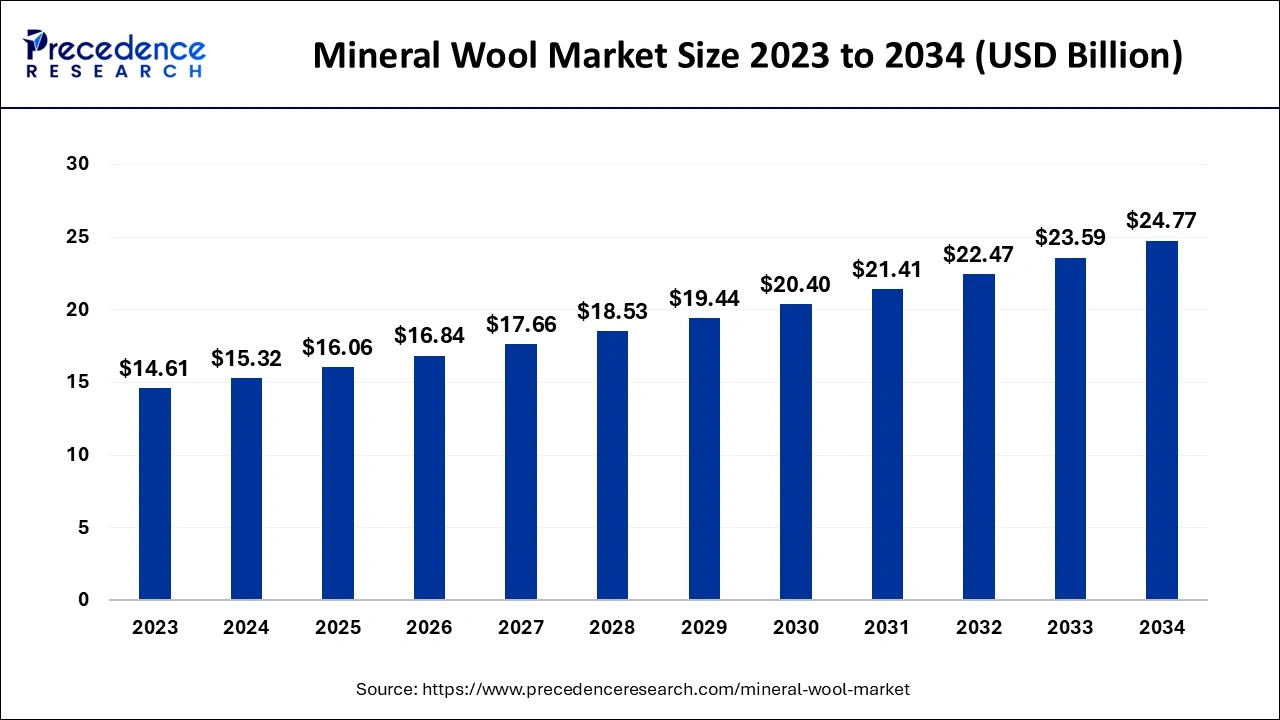

The global mineral wool market size is calculated at USD 16.06 billion in 2025 and is predicted to increase from USD 16.84 billion in 2026 to approximately USD 25.91 billion by 2035, expanding at a CAGR of 4.09% from 2026 to 2035.

Mineral Wool Market Key Takeaways

- The global mineral wool market was valued at USD 15.32 billion in 2025.

- It is projected to reach USD 25.91billion by 2035.

- The mineral wool market is expected to grow at a CAGR of 4.09% from 2026 to 2035.

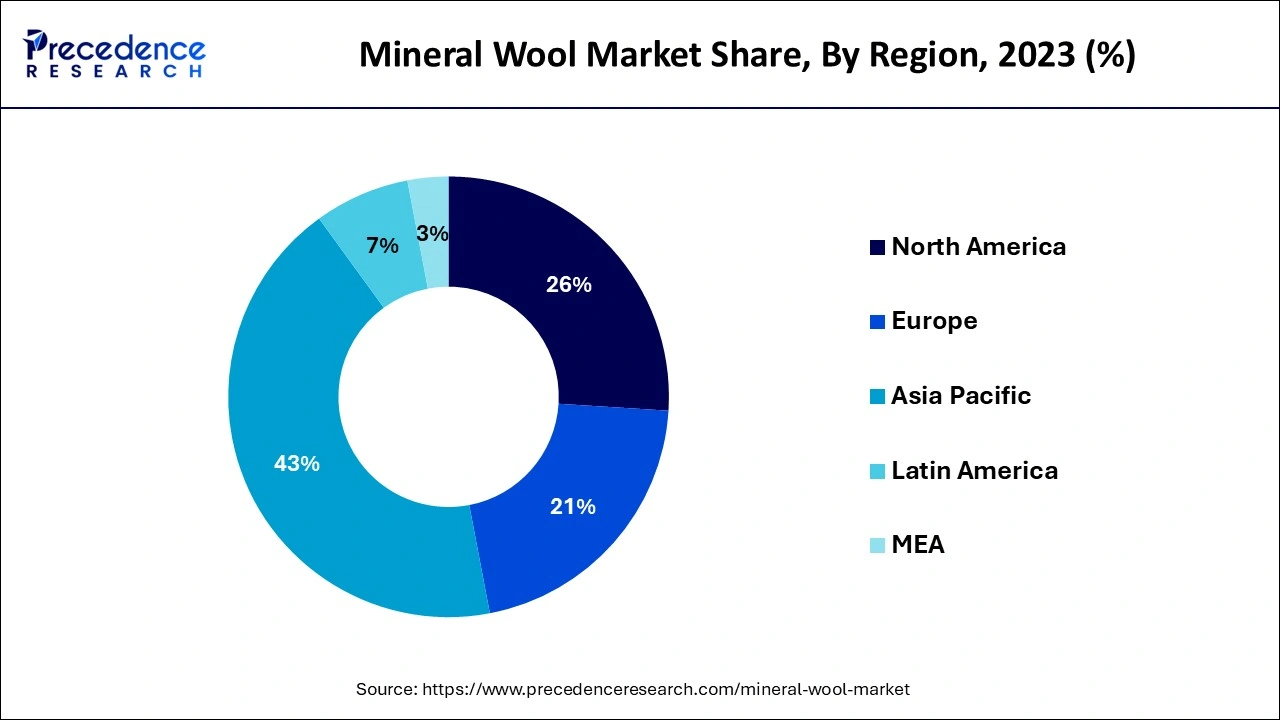

- Asia Pacific dominated the global market with the largest market share of 43% in 2025.

- North America is anticipated to grow at a high CAGR during the forecast period.

- By product, the mineral wool boards segment contributed the highest market share in 2025.

- By product, the mineral wool blankets segment is expected to expand at the fastest CAGR in the forecast period.

- By fiber type, the glass wool segment held the highest market share in 2025.

- By fiber type, the stone wool segment is anticipated to grow at the fastest CAGR from 2026 to 2035.

- By density, the low-density mineral wool segment captured the biggest market share in 2025.

- By density, the medium-density mineral wool segment is anticipated to grow at the fastest CAGR during the forecast period.

- By processing method, the wet process segment generated the major market share in 2025.

- By processing method, the dry method segment is expected to grow rapidly in the market during the forecast period.

- By application, the insulation for buildings segment registered the largest market share in 2025.

- By application, the insulation for the industrial application segment is anticipated to grow at the fastest CAGR during the forecast period.

What is the Use of Mineral Wool?

Mineral wool is a universal and effective insulating material. It is demanding for its durability, thermal performance, and fire safety characteristics. Along with that, it is environmentally friendly as it is made from abundant and recyclable material. They are available in stone, silica, and other materials that are extremely heat resistant. The making process includes heating the material to high temperature and, once molten, spun into fibers. These fibers are then formed into the finished insulation products such as rolls, slabs, pipe sections, and loose wool or granulation. The application of mineral wool is commonly noticed on walls, floors, ceilings, roofs, attics, pipes, and ducts.

What is the Role of AI in the Mineral Wool Industry?

Artificial Intelligence (AI) has the ability to transform the mineral wool market by automating production processes. Automation enhances operational efficiency and reduces labor as well as production costs. AI systems monitor production processes, identify defects, and reduce waste generation, leading to high-quality final products. In addition, AI also helps in supply chain management by optimizing inventory levels.

Mineral Wool Market Growth Factors

- Fire resistance: Mineral wool is non-combustible and has to ability to withstand extremely high temperatures, unlike other insulation materials. This is an ideal choice for improving the fire safety of buildings, providing occupants with more time to evacuate in case of fire, and reducing property damage to some extent.

- Soundproofing qualities: The dense and fibrous structure of mineral wool effectively dampens sound waves, reducing noise transmission between rooms and floors. It is gaining popularity in walls, ceilings, and floors, especially in joint-family, office buildings, and other noise-restricted environments such as hospitals.

- Thermal insulation: Mineral wool helps to maintain the indoor temperature by reducing heat loss in winters and heat gain in summers, it leads to an energy-efficient building while lowering the utility bills.

- Sustainability: As the mineral wools are made from abundant natural resources and contain recycled content, they are considered environmentally friendly. The production process does not consume large energy compared to other insulating materials which contributes to lowering carbon footprints.

- Longevity: The mineral wool does not degrade with time which means it does not need to be replaced. Hence, turns out to be a durable material, which creates less waste and a more sustainable building lifecycle.

Mineral Wool MarketMarket Outlook

Between 2025 and 2030, this market is expected to rise significantly due to the rapid investment by the government for strengthening the construction sector along with technological advancements in sound-proofing materials.

Numerous market players are actively entering this market, drawn by partnerships, R&D and business expansions. Several mineral wool companies, such as Shandong Wiskind Architectural Steel Co., Ltd, Panelcok, China Iking Industrial Group Co and some others have started investing rapidly for manufacturing mineral wool in different parts of the world.

Various startup brands are engaged in manufacturing mineral wool across the globe. The prominent startup companies dealing in the production of mineral wool consist of Fenx, Nanoplume, Fiberwood and some others.

Market Scope

| Report Coverage | Details |

| Market Size by 2035 | USD 25.91Billion |

| Market Size in 2025 | USD 16.06 Billion |

| Market Size in 2026 | USD 16.84 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 5.04% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Product, Application, Fiber Type, Density, Processing Method, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Market Dynamics

Driver

Energy efficiency

The adoption of the mineral wool market services saves energy and reduces emissions. It acts as a heat barrier. When mineral wools are properly installed by a professional, it cost-effectively reduces heating and cooling, leading to increased overall energy efficiency and reduced carbon emissions over the lifetime of buildings. The integration of mineral wool fabricated pipe insulation reduces energy consumption, which results in conserving non-renewable fuel and reducing air pollution and greenhouse gas emissions. Moreover, it is made from natural products and waste byproducts, which helps conserve resources and eliminate waste to keep the environment clean.

Restraint

Potential concerns of health and environment

There are legitimate concerns about health risks related to the mineral wool market. While mineral wools are considered safe to handle, they consist of some potential health risks. Several studies show that inhalation of these fibers causes respiratory health effects and that the material of the fiber can irritate the skin and eyes. The spread of fiber into the body has the potential to cause long-term problems such as dermatitis, asthma, and lung cancer. Additionally, some concerns have been raised about environmental impact, particularly regarding disposal and waste management. To avoid this issue from occurring, make sure to wear protective gear during the installation of mineral wool, such as gloves, a respiratory mask, and safety goggles.

Opportunity

Counteract climate shift

The mineral wool market is expected to play a crucial role in combatting climate change in the future. This will be achieved by creating products that help to improve the environmental performance of buildings, as well as social and economic aspects. This approach to sustainability covers both handprint and footprint. The innovative manufacturers are working towards developing a product that ensures a positive impact on buildings and their occupants.

Mineral Wool Market Segment Insights

Product Insights

The mineral wool boards segment accounted for the highest share of the mineral wool market in 2025. The thickness of the mineral wool insulation board ranges from 1” to 5” thick. They are commonly used on the exterior wall where continuous insulation is required. They are widely preferred in building construction due to their natural fire- resistance, high sound absorbance, and R-value of 4.2 per inch. It is a building material used in construction to insulate walls and attic spaces. The fibers of mineral wool insulation are derived from minerals in volcanic rock and slag waste from steel production.

The mineral wool blankets segment is expected to expand at the fastest CAGR in the mineral wool market during the forecast period of 2024 to 2034. The mineral wool blanket is an insulation material made from natural or synthetic minerals such as rock wool or glass wool. It is widely used in construction and industrial applications to provide thermal and acoustic insulation. It is available in a variety of thicknesses and densities, tailored according to a specific insulation requirement. The mineral wool blanket has the best durability, fire resistance, and energy-save properties, which make it a popular choice for builders and engineers.

Application Insights

The insulation for buildings segment registered the largest share of the mineral wool market in 2025. In commercial settings such as offices, hotels, hospitals, and educational institutes, mineral wool is installed for reliable fire protection, and sound attenuation is invaluable in these premises. In the residential setting, it is commonly observed in walls, attics, and floors to enhance fire safety and soundproofing. Homeowners prefer mineral wool for its ability to create a quitter and safer living space.

The insulation for industrial application segment is anticipated to grow at the fastest CAGR in the mineral wool market during the forecast period of 2024 to 2034. The expansion of this segment is due to the increasing demand for the application of mineral wool insulation in pipes, ducts, and equipment. The high-temperature resistance and soundproofing quality create a safe and noise-free environment for industrial facilities.

Fiber Type Insights

The glass wool segment held the highest share of the mineral wool market in 2025. The dominance of this segment is due to its light, thin, and environmentally friendly properties. Glass wool is also known as fiberglass; it has excellent thermal properties, which help save energy and lower environmental impact. The application of glass wool insulation or fiberglass has a broad utility in both residential and industrial buildings, such as household applications, train insulation, marine and offshore insulation, automotive insulation, and HVAC and air-conditioning system insulation.

- In September 2025, Knauf Insulation Romania finalized the construction of a mineral glass wool factory worth around USD 154.6 million in the central city of Tarnaveni. The plant has an annual production capacity of around 75000 tonnes of mineral glass wool.

The stone wool segment is anticipated to grow at the fastest CAGR in the mineral wool market from 2024 to 2034. The growth of this segment is observed due to its highly effective insulating properties. Stone wool is an exceptionally versatile product with a variety of contributing characteristics that make it a suitable material for the indoor environment without compromising installation ease and performance. Stone wool is commonly used for insulation and fire protection; therefore, it is ideal for industrial use because of its high-temperature resistance and non-combustibility.

- In August 2025, Rockwool Group invested INR 550 crore to build a new factory in Cheyyar to meet the increasing demand for non-combustible stone wool insulation in the South Asia market.

Density Insights

The low-density mineral wool segment stood dominant in the global mineral wool market in 2025. The dominance of this segment is experienced due to its lightweight and adequate thermal insulation characteristics that are suitable for residential and commercial buildings. Commonly used material is glass mineral wool, which offers great performance and energy efficiency.

The medium-density mineral wool segment is anticipated to grow at the fastest CAGR in the mineral wool market during the forecast period of 2025 to 2035. The segment deals with the increasing requirement for industrial and construction fields. The fibrous structure has a medium density ranging from 40 to 100 kg/m2, this is an ideal material for acoustic insulation with a great ability to absorb airborne and impact noise.

Processing Method Insights

The wet process segment held the highest share of the mineral wool market in 2025. The wet processing method of mineral wool consists of melting, fiberization, curing, cutting, and packaging. The natural materials are precisely measured such as basalt, diabase dolomite sand, limestone, and soda ash are sent to a melting furnace. The primary raw materials are derived from internal production, external construction, and installation cut-offs. Secondary raw materials require less energy and are a natural incentive for recycling.

The dry method segment is anticipated to register the fastest growth in the mineral wool market during the forecast period of 2024 to 2034. In the dry processing method, the melt flows from the furnace and is applied to the spinning wheels, from which the fibers are drawn with a powerful air stream that blows into the shipping chamber. This process consumes less energy and results in a coarser fiber structure.

Mineral Wool Market Regional Insights

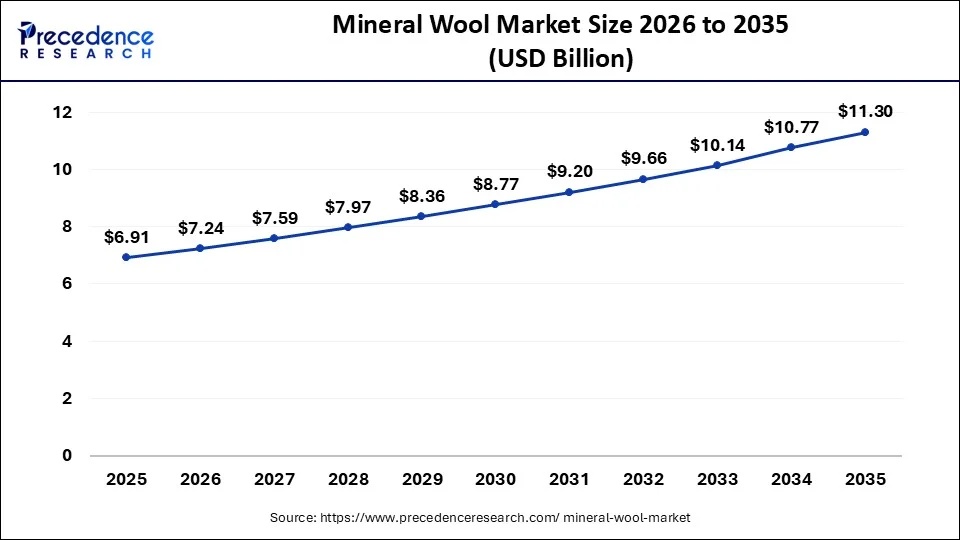

The Asia Pacific mineral wool market size is exhibited at USD 6.91 billion in 2025 and is projected to be worth around USD 11.30 billion by 2035, growing at a CAGR of 5.04% from 2026 to 2035.

Asia Pacific dominated the mineral wool market in 2025. The dominance of the region in the market is observed due to the increasing number of construction activities happening in the region, particularly in countries such as China and India. The notable growth is perceived due to the presence of top construction companies in the region, such as Larsen & Turbo (USD 59.77 billion). The increasing development of urbanization, economic expansion, and substantial government investment are propelling the region to the top.

- China State Construction Engineering (USD 29.3 billion) and Daiwa House (USD 19.94 billion).

North America is observed to grow at the fastest rate in the mineral wool market during the forecast period. The growth of this region is expected to due to the presence of construction and insulation industries. The most common type of insulation is fiberglass, which is noticed in the United States. The construction field required insulation in the building walls, ceiling, floors, and roofs.

- The United States consists of about 27,241 businesses that are insulation contractors in the U.S. industry.

- The U.S. holds a prominent position in the construction industry. In 2023, the total construction spending reached about USD 1.98 trillion.

Europe held a significant share of the market. The rise in the number of residential constructions in several nations, including Germany, France, Italy, the UK and some others, has boosted the market expansion. Additionally, rapid investment by market players for opening up new production centers in different parts of the world is expected to accelerate the growth of the mineral wool market in this region.

Latin America held a considerable share of the industry. The growing demand for glass wool from the horticulture sector in numerous countries such as Argentina, Brazil, Peru, Venezuela and some others has boosted the market growth. Also, numerous government initiatives aimed at developing the advanced materials industry are expected to drive the growth of the mineral wool market in this region.

The Middle East and Africa held a notable share of the market. The rising sales of acoustic insulation solutions in various nations, including the UAE, Saudi Arabia, South Africa, Qatar and some others, has driven the industrial expansion. Additionally, the growing use of high-temperature insulation solutions in the automotive sector is expected to propel the growth of the mineral wool market in this region.

Value Chain Analysis

The raw materials used for mineral wool production are rock (like basalt) and slag (a byproduct of metal smelting), along with additives such as limestone, sand, and clay.

Key Companies: Carmeuse, Holcim, Lhoist, and others.

Mineral wool is manufactured by melting raw materials like rock, slag, or glass in a furnace at high temperatures, then spinning the molten material into fine fibers.

Key Companies: Saint-Gobain, Luyang Energy-Saving Materials Co., Ltd, Shandong Wiskind Architectural Steel Co., Ltd, and others.

The distribution channel for mineral wool primarily involves manufacturers selling to large distributors who then supply to retailers and contractors that delivers products to numerous end-users such as builders, homeowners, and industrial clients.

Key Companies: ROCKWOOL International, Knauf Insulation, Sheth Insulation Pvt Ltd, and others.

Mineral Wool Market Companies

ROCKWOOL International is a global leader in stone wool solutions, manufacturing and supplying products for insulation, acoustics, and horticulture. This company is headquartered in Denmark and provides a diverse range of products for building insulation, industrial applications, marine environments, and acoustic ceilings through brands including Rockfon, Rockpanel, and Grodan.

Knauf Insulation is a global manufacturer of insulation products, part of the larger Knauf Group, with a focus on creating energy-efficient and sustainable building solutions. The company produces a range of products, including glass mineral wool and other mineral wool.

Sheth Insulation Pvt Ltd is an Ahmedabad-based company founded in 2011 that specializes in distributing high-quality insulation and waterproofing materials. They are a key channel partner and supplier for various industrial products, with a mission to provide solutions that improve energy efficiency, safety, and performance.

Johns Manville is a manufacturing company based in Denver, Colorado, that produces insulation, commercial roofing, and engineered products, such as fibreglass and nonwovens. It serves various industries, including building, industrial, and residential, with products used in applications such as construction to automotive and wind energy.

Owens Corning is a global building materials company based in Toledo, Ohio, specializing in insulation, roofing, and fibreglass composites. The company develops and manufactures products that enhance the energy efficiency, comfort, and durability of commercial and residential buildings.

Saint-Gobain is a French multinational corporation founded in 1665, now a global leader in the design, manufacturing, and distribution of materials and services for the construction and industrial markets. The company provides innovative and sustainable solutions for buildings, transportation, infrastructure, and more, operating in 80 countries with a focus on light and sustainable construction and decarbonization.

Other Major Key Players

- Luyang Energy-Saving Materials Co., Ltd

- Shandong Wiskind Architectural Steel Co., Ltd

- Panelcok

- China Iking Industrial Group Co., Ltd

- Bredeco

- Polybond Insulation Private Limited

Latest Announcements by Industry Leaders

- In May 2024, Will Wigfield, Product Manager HVAC & Fire Protection at ROCKWOOL, said: “Fire Barrier EN will replace our existing fire barrier products. With the two options now available, we are underlining our commitment to ensuring that ROCKWOOL products are tested to EN standards wherever possible while simplifying specifications by streamlining the range. Depending on the application and fixing method, Fire Barrier EN offers fire resistance of up to two hours.”

- In May 2024, Neil Hargreaves, Knauf Insulation's managing director for Northern Europe, said: “The investment represents a step change in the capacity, capability, and sustainability of our UK rock mineral wool solutions, while significantly contributing towards Knauf Group's ambitious sustainability goals.”

Recent Developments

- In November 2025, TimberHP launched TimberBoard. TimberBoard is a dry process wood fibre board designed for high-performance building envelopes.

(Source: www.prnewswire.com) - In July 2025, Knauf Insulation inaugurated a mineral wool production plant in Tashkent. This manufacturing unit is expected to produce around 30,000 tons of mineral wool for the consumers of Uzbekistan.

(Source: www.uzdaily.uz) - In May 2025, Saint-Gobain opened a new low-carbon stone wool insulation plant in the UK. This plant is expected to manufacture around 50,000 tons of high-performance stone wool insulation per year.

(Source: www.saint-gobain.com)

Segments Covered in the Report

By Product

- Mineral Wool Blankets

- Mineral Wool Boards

- Mineral Wool Rolls

- Mineral Wool Loose Fills

By Application

- Insulation For Buildings

- Insulation For Industrial Applications

- Acoustic Insulation

- Fire Protection

By Fiber Type

- Glass Wool

- Stone Wool

- Slag Wool

By Density

- Low-Density Mineral Wool

- Medium-Density Mineral Wool

- High-Density Mineral Wool

By Processing Method

- Wet Process Mineral Wool

- Dry Process Mineral Wool

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting