Accelerating Aerospace Innovation: GKN Enhances Additive Fabrication of Engine Components

GKN Aerospace has taken a major step by making a few changes in its additive fabrication. The Additive Fabrication (AF) with Fan Case Mount Ring (FCMR) will now progress towards full-rate production by the end of 2025. The company is already delivering its duties from its Sweden facility in Trollhattan. The output at the Sweden facility ramps up to 30 units per month, with the goal of reaching 40 units per month by the end of 2025.

GKN Aerospace’s President Engines, Mr. Joakim Andersson, quoted, “This is a turning point for aerospace manufacturing. With the FCMR program at industrial scale, we are proving not just the technical capabilities of additive fabrication, but its real-world impact on sustainability, lead time, and cost, as well as bringing predictability to our supply chain. Our recent achievements underline GKN Aerospace’s leadership in developing and certifying advanced fabrication technologies for next-generation engines – and this is just the start for this transformative technology.”

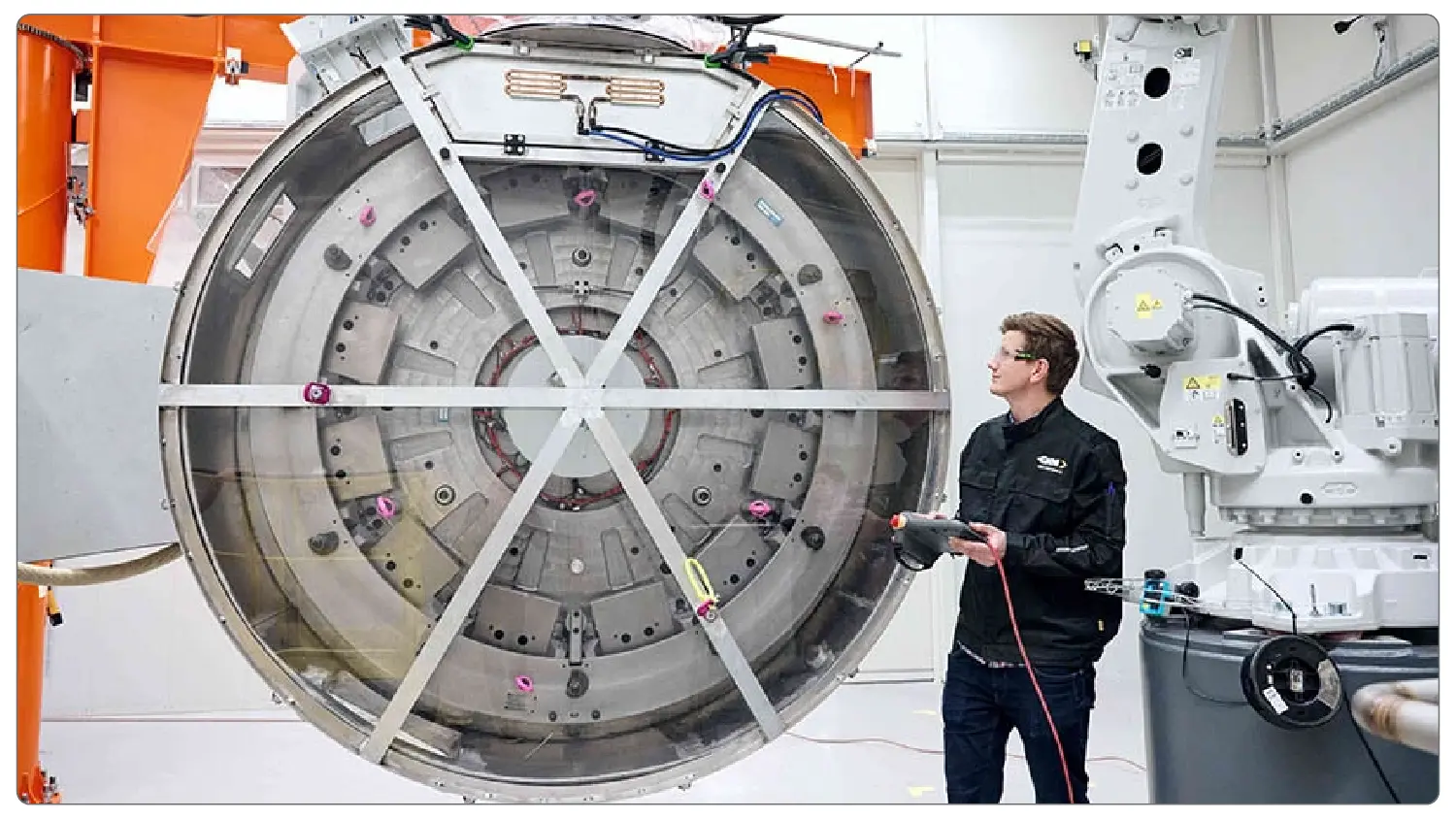

GKN Aerospace marked its 200th delivery of an additively fabricated ‘hot size ring’, the core structure of the FCMR, earlier this year. The delivery was for its Newington, Connecticut, facility for final machining. The major additive fabrication industrialization changes the company has noted a 40% reduction in material waste per part compared to traditional manufacturing methods. GKN Aerospace targets 70% material savings in the forecasted period, along with reducing end-to-end lead times from 9 months to as little as 1 month.

GKN Aerospace’s ramp-up follows $50 million investment in 2024 to expand its sustainable additive fabrication capability, which is focused on increasing its capacity across civil and military engine platforms. The work will begin in 2026, leveraging the additive fabrication production concept, which enables the rapid deployment of technology at other sites worldwide.

The year 2024 was marked by numerous achievements for GKN Aerospace, including the receipt of several certifications. The queue of achieved milestones includes FAA approval for its first additively fabricated critical structural component, along with the successful delivery of its largest all-additive component, a large titanium engine case for the CFMI RISE technology demonstrator.