What is the Packaging Primer Market Size?

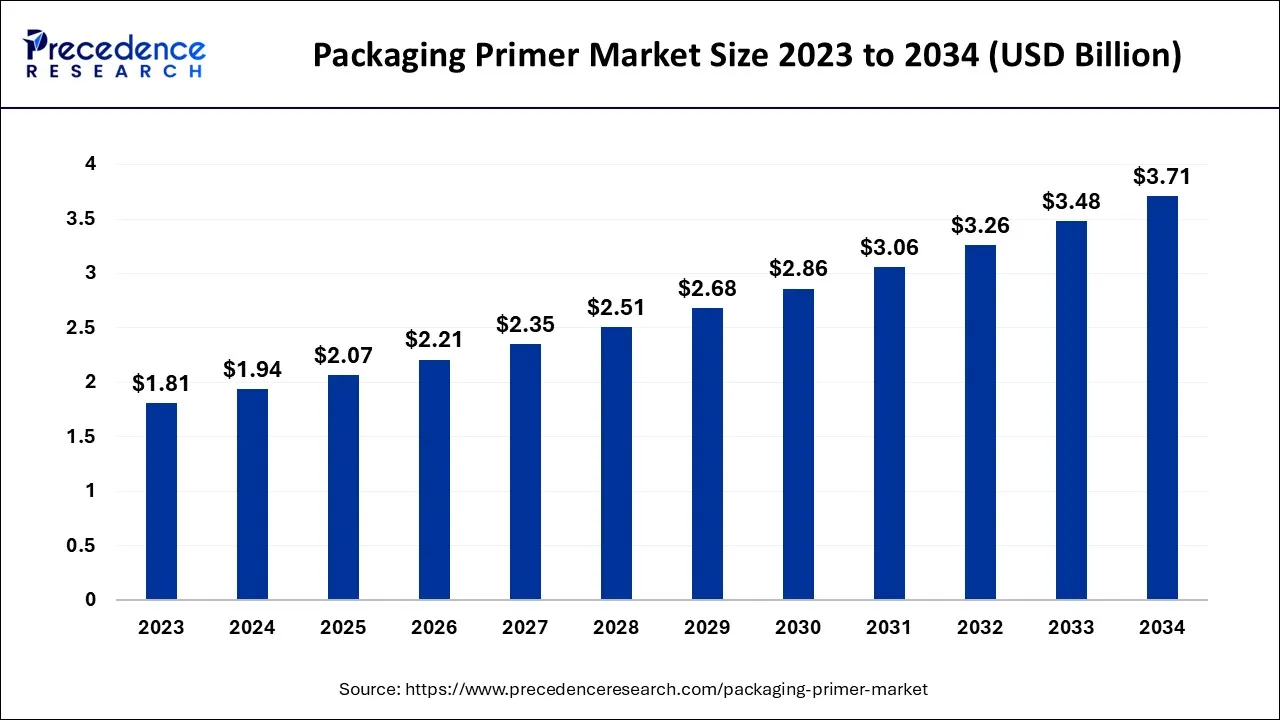

The global packaging primer market size is calculated at USD 2.07 billion in 2025 and is predicted to increase from USD 2.21 billion in 2026 to approximately USD 3.93 billion by 2035, expanding at a CAGR of 6.62% from 2026 to 2035.

Packaging Primer Market Key Takeaways

- By primer, the solvent-based primer segment dominated the primer packaging market and will show significant growth in the predicted period.

- By application, the aluminum segment will grow the most during the forecast period.

- By region, the packaging primers market is dominated by Asia-Pacific as a result of the slow rise of developing nations. The packaging primer market will also grow significantly in North America.

Market Overview

The packaging primer market is the global industry that produces and supplies primers or coating materials specifically for the packaging industry. These primers are adhesives that are applied to various packaging materials to enhance their performance. Packaging primers are typically used to increase the effectiveness of high-end printing, providing anti-blocking, slip control, moisture resistance, and release. They can be water-based, solvent-based, or wax and poly coatings based. Poly and solvent-based coatings offer reliable, high-quality print finishes and protection for various applications. Nearly all end uses in the beverage, food, personal care and cosmetic, and pharmaceutical sectors, among others, are provided by manufacturers of packaging primer solutions.

Such primers for packaging purposes serve multiple benefits in packaging applications while adding a subsequent layer to the packaging material to improve its durability along with print quality.

The market for packaging primers is growing globally with industry leaders such as the Sherwin-Williams company seeing substantial growth in revenue. For instance, the annual revenue for Sherwin-Williams was $22.149B in 2022, which was an increase of 11.05% from 2021.

Packaging Primer Market Growth Factors

The rise in construction-related needs and activities due to commercial structures, such as warehouses, offices, manufacturing facilities, and so forth, are significant factors anticipated to propel the expansion of the packaging primers market over the estimated time frame. Additionally, the building and construction industries make extensive use of primers. The packaging primers market is expected to rise quickly because it is used as a base coat before paint is applied to many surfaces, including walls. Another factor expected to temper the expansion of the packaging primers market is the water-based coatings' relative cost-effectiveness in contrast to their solvent-based equivalents. However, it is also anticipated that the pandemic's effects will restrain the demand for packaging primers during that time.

Market Outlook

- Industry Growth Overview: The packaging primer market has begun to increase as companies strive for improved adhesion, barrier performance, and compatibility with coatings on multiple types of substrates. This is a strong result of the rapid growth of e-commerce and the specialized nature of pharmaceutical and food & beverage packaging.

- Sustainability Trends: Sustainability initiatives are becoming more than just a mention of "green" products. There is a large amount of research taking place on products such as low-VOC, biodegradable, and solvent-free primers, which help achieve recyclable and circular packaging goals and more stringent international sustainability regulations.

- Global Expansion: The potential for expansion in North America and the Asia Pacific regions will be tremendous in terms of industrial development, urbanization, and the growing demand for premium coatings for packaging, thus encouraging/creating numerous corporations to pursue mergers, acquisitions, and strategic alliances to expand their footprints across other countries.

- Startup Ecosystem: While the traditional chemical companies are leading the growth of the packaging industry, there is still a great deal of activity from small start-up companies and material developers that are developing products with bio-based coatings, digital printing primers, and enhanced performance formulations to create interest from venture capitalists for sustainable technology in the packaging industry.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 2.07Billion |

| Market Size in 2026 | USD 2.21 Billion |

| Market Size by 2035 | USD 3.93Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.62% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | By Primer and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Growing demand for sustainable packaging solutions

Multiple key players are focused on the development of the products that are in demand and consumers prefer the most. Sustainable packaging meets these important industrial drivers by being resource and material-efficient, extending product shelf life to decrease food waste, increasing product to package ratio, improving transportation owing to lightweight, and reducing waste to landfill. The rising demand for sustainable packaging solutions has boosted the emphasis on the production of eco-friendly primers that release zero volatile organic compounds (VOCs) during the application. Moreover, such production of chemical-free primers is expected to boost the growth of the market during the forecast period.

For instance, Michelman professionals prioritize recyclability and health & safety when using innovative materials and coatings, using a "sustainability first" strategy. With chances to decrease waste, improve product protection, and utilize fewer natural resources, their next-generation primers, topcoats, barrier coatings, and heat seal coatings provide greater functionality in sustainable packaging.

Restraint

Limitations in advancements

Primers for packaging provide a significant recycling issue, at least for multilayer systems used today. Due to the numerous layers of various materials utilized to achieve package performance, recycling flexible packaging is currently problematic. Most recent regulation changes are motivated by a goal to increase package sustainability. Several new restrictions on using materials, many of which target single-use plastics. Flexible packaging must employ recycled material following other programs. These initiatives range from aspirations for the years to formal restrictions or regulations.

Opportunity

Introduction of water-based coating

A chemical primer is typically required in multilayer flexible packaging designs to strengthen bindings between a coating and a substrate, such as ink or an extrudate. The barrier qualities, appearance, and general performance of the completed construction can all be improved by primers. Water-based primers are a popular option since they operate well on a wide range of substrates. When compared to materials made from solvents, they are also a more secure and sustainable option. Packaging industry players can protect a surface against minor stains like pencil, ink, water stains, scuff marks, and rust, as well as more prominent stains like soot, fire damage, and charring with a water-based primer. Water-based primers are thereby contributing to the expansion of the packaging primer industry.

Segment Insights

Primer Insights

By primer, the solvent-based primer segment dominated the primer packaging market and will show significant growth in the predicted period. The solvent-based segment is in high demand due to its advantageous properties over the other application segments. It offers durability, ensures the integrity of packaging material, and has a faster drying time. It is compatible with different primers and has barrier properties for packaging materials such as aluminum and rigid plastic. Water based segment is expected to witness notable growth in the forecast period. It is eco-friendly and doesn't release VOCs like solvent-based primers. It is growing in popularity because of the rising environmental concerns; it is safer to handle and has better adhesion. It is versatile and can be used with multiple materials.

Application Insights

By application, the aluminum segment will grow the most during the forecast period. This is because of its valuable properties, such as offering a protective layer against air, temperature, light, micro-organisms, moisture, and odor. It is also recyclable and lightweight. The packaging primers are applied on multiple aluminum packaging solutions widely as the application is comparatively easy and helps in enhancing the durability of the product inside. Aluminum is a material that is prone to get affected by sun exposure, air and even humidity in some cases. Protecting aluminum packaging material, especially used in pharmaceuticals and food & beverages industries becomes crucial. The rising demand for aluminum packaging with the expanding end-users also gains the requirement of primer coating, this element is observed to promote the growth of the segment.

Regional Insights

What is the Remarkable Position of the Asia Pacific in the Packaging Primer Market in 2025?

Asia-Pacific dominates the packaging primers market due to the slow rise of developing nations. The demand for more packaging primers and the region's strong economic growth is also driving regional firms to expand their businesses in the sector, which will help the market grow during the estimated time frame. The need for packaging primers is expected to expand significantly in North America due to the presence of several important key players.

Several governments in Asia Pacific are implementing stringent regulations on packaging materials to ensure consumer safety. These regulations are expected to boost the production as well as innovation of sustainable primers for the packaging industry, which promotes the development of the market in the Asia Pacific.

India Packaging Primer Market Trends

India is experiencing a massive growth in the market due to advanced printing and smart packaging, and the growth of pharmaceuticals and healthcare. The FSSAI of India revised food packaging regulations to accelerate the growth of the food industry towards a sustainable future. Overall, demand for functional, sustainable, and high-performance packaging primers is projected to grow in line with India's packaging industry expansion.

How is the Significant Growth of North America in the Packaging Primer Market?

The packaging primer market will also grow significantly in North America. The presence of multiple key layers in the nation and potential of investing in product development, the United States is expected to be the largest contributor to the market's growth in North America. For instance, Michelman, a packaging primer manufacturer based in the USA, is one of the leading producers. Significant advancements in the primer formulations as well as the development of low-VOC and UV curable primers in the region are highlighting the growth of the market in North America.

U.S. Packaging Primer Market Analysis

The U.S. government ensures regulatory compliance of advanced primer solutions and the integration of Industry 4.0 and automation. Meanwhile, pressure to reduce costs and raw material volatility remains a challenge, pushing formulators to optimize performance while controlling expenses. Overall, the US packaging primer market is driven by performance demands, sustainability objectives, and ongoing innovation in coating technologies.

- In November 2025, the U.S. Plastics Pact launched the second phase of the reuse in retail initiative, which aims to support retailers, brands, and reuse providers in identifying reasonable applications for reuse in retail. This launch is designed to scale the reusable packaging system in retail stores across America.

(linkedin.com )

How is Europe Dominating the Packaging Primer Market?

Europe dominated the market in 2025, owing to sustainability, eco-friendly formulations, and stringent regulatory mandates. The European Union announced the enforcement of packaging and recycling rules in the new Packaging and Packaging Waste Regulation. The rising trends like the recycled content, reusable packaging, and bio-based materials will reshape the packaging industry by 2028. Overall, performance optimization, environmental stewardship, and regulatory alignment are shaping steady market growth across Europe's packaging primary segment.

The UK Packaging Primer Market Trends

In the UK market, growth is being shaped by a strong shift towards sustainable, low-VOC, and water-based primers as brands and regulators push for eco-friendly packaging that supports recyclability and reduced environmental impact. Demand is also rising with e-commerce and high-speed printing technologies, driving the need for primers that deliver enhanced adhesion, durability, and fast drying for robust packaged products.

What are the Major Factors Contributing to the Packaging Primer Market within South America?

South America is expected to experience notable growth during the forecast period due to the e-commerce boom, sustainability, and regulatory shifts. Still, challenges such as raw material price fluctuation, supply chain constraints, and variable regulatory landscapes across countries influence market dynamics. Overall, demand for functional, sustainable, and cost-effective primer solutions is expected to support steady growth in South America's packaging primer market.

What Opportunities Exist in the Middle East and Africa in the Packaging Primer Market?

MEA is expected to grow at a lucrative rate in the market in the coming years, driven by the rapid expansion of major end-user industries such as food and beverage, pharmaceuticals, and personal care and cosmetics. Overall, MEA's packaging primer market is poised for gradual growth as manufacturers focus on sustainability, performance optimization, and meeting the needs of a diversifying industrial base.

Exploring the Latin American Packaging Market

Brazil Packaging Primer Market Trends

The Brazilian packaging market is one of the largest in Latin America, with continued strong growth in rigid and flexible packaging due to the continued demand for food, beverage, and other consumer goods, leading to opportunities for improved primers to produce better print quality and durability. Brazil is the leading market for regional expansion, supported by a diverse industrial base and a growing investment in sustainable packaging technologies.

Packaging Primer Market - Value Chain Analysis

- Raw Material Sourcing (Plastic, Paper, Glass, etc.): This stage is driven by post-consumer recycled content, mono-material transition, and bioplastics.

Key Players: Amcor, Uflex Ltd., Smurfit WestRock, International Paper, Mondi Group, BASF SE, Verallia. - Logistics and Distribution: The potential trends that are driving this stage are AI and hyper-automation, sustainability, circularity, smart and connected packaging, and supply chain resilience.

Key Players: UPS Supply Chain Solutions, DHL Supply Chain, Smurfit WestRock, International Paper, Mondi Group. - Recycling and Waste Management: This stage is surging in demand due to regulatory frameworks, including QR codes, recycled content mandates, and EU packaging regulations.

Key Players: Waste Management, Inc., Veolia Environnement S.A., Tetra Pak, Ball Corporation, Mondi Group.

Packaging Primer Market Companies

- The Sherwin-Williams Company

- Axalta Coating Systems

- PPG Industries, Inc.

- ACTEGA Terra GmbH

- DIC Corporation

- Akzo Nobel N.V.

- BASF SE

- National Paints Factories Co. Ltd.

- Aqua Based Technologies

- KANGNAM JEVISCO CO., LTD.

- Michelman, Inc.

- Paramelt B.V.

- Mica Corporation

- Coim Group

- S-One Holdings Corporation

Recent Developments

- In March 2025, PPG Industries, Inc. launched a waterborne automotive coatings plant in Thailand. The plant is designed to enhance the company's local production capacity of primers and waterborne basecoats.

(Source: investor.ppg.com) - In November 2025, DIC Corporation and Sun Chemical planned to showcase their latest innovations in color and resin materials at CHINACOAT 2025. CHINACOAT is an essential platform for the industry learning way of DIC, and Sun Chemical drives the future for color and coatings performance.

(Source: dic-global.com ) - In June 2022, the most prominent global supplier of packaging labels and coatings, Siegwerk announced an important improvement in deinking. The improvement has been made especially for rigid plastic packaging materials. The invention aims to enhance mechanical recycling in the industry. As a result of this improvement, Siegwerk is aiming to offer a UV-curing primer that can work with pressure-sensitive materials.

- In February 2021,Ashland revealed a brand-new primer. Ashland's Purekote coater-ready 29100 primer line is made for on-demand water-based inkjet printing and provides a variety of matte, high gloss, and satin finishes for the packaging, label, and graphic arts sectors. Water-based inkjet technology has significantly improved performance and costs compared to other digital platforms. It has the greatest expected growth rate over the next five years as digital print spreads into the traditional printing industry. Adding the Purekote 29100 series to Ashland's electrophotographic and UV inkjet product lines significantly improves their selection of digital primers.

- In April 2023,INX International Ink, Co., a major supplier of coating solutions announced the launch of a GB-XA oxygen barrier coating solution, EcoStage, especially designed for mono-material packaging and food preservation purposes. The new coating solution is expected to enhance the shelf life of food products while maintaining the color and clarity of external packaging material.

Segment Covered in the Report

By Primer

- Water-Based Coatings

- Solvent-Based Coatings

- Other Coatings

By Application

- Film Makers

- Aluminium Makers

- Paper And Aluminium Converting

- Paper Coaters And Makers

- Film

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting