Navigating the Epoxy Resin Market: Key Developments and Market Analysis

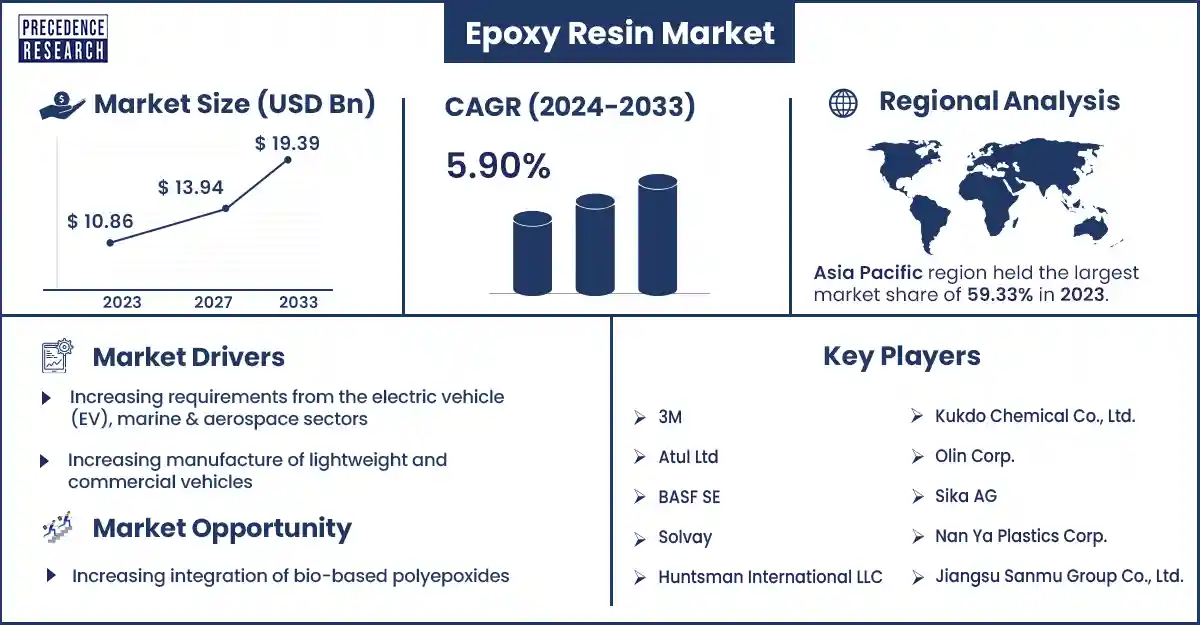

The global epoxy resin market size was evaluated at USD 10.86 billion in 2023 and is expected to attain around USD 19.39 billion by 2033, growing at a CAGR of 5.90% from 2024 to 2033. Rising demand for epoxy resins from several sustainability mandates & stringent regulatory, end-use segments, and rising concerns for the environment are enhancing the growth of the epoxy resin market.

Market Overview

The epoxy resin market produces epoxy resin, which is a raw material-based polymer that is used to coat and chemically paint. In addition, epoxy resin offers high performance with outstanding features, including stability, endurance, corrosion resistance, and temperature stability. They are used in the formation of vegetable oil, sugar, natural rubber, and many more. The rising demand for sealants and adhesives in the automotive industry and the growing construction industry are the major factors enhancing the market growth.

The rising adoption of reformable and recyclable epoxy resin will drive the demand for the market. Due to automotive production surging rapidly, the growing disposable income and demand from middle-class families are increasing quickly and are anticipated to drive the growth of the epoxy resin market.

The application of epoxy resin in various industries drives market growth

When epoxy resin comes in contact with other substances, it holds a good strength. Because epoxy resins have a cohesive bond that balances their resistance for a longer period. Due to the hard epoxy chemical, it's an extra feature that adds to its energy. Epoxy resin has outstanding and impressive use due to its versatility features. It has the surprising and unique effect of getting stuck to various materials, which is why it gets bound with all the materials with the same kind of comfort. So, epoxy resin is called the most pleasing construction material.

The chemistry structure of epoxy resins offers enough stability to make it durable and reliable. Epoxy is resistant to other weather and chemicals. Epoxy resins are very easy to apply over various surfaces, whether it's epoxy flooring or epoxy paints, and they are always swift in the process. Epoxy resins have unique underwater construction features. This chemical is suitable enough for underwater construction. These are the major factors expected to drive the growth of the epoxy resin market.

However, long curing time, messy application, and higher costs may restrain the growth of the market. Epoxy resin glue has a higher curing time and takes a maximum of hours to cure completely. Epoxy resin glue is sticky and thin, which can make it messy and create irritation when applied. It can also be very hard to remove from skin and surfaces. Epoxy resin glue can contain toxic and harmful chemicals, including epichlorohydrin and bisphenol A, which can be harmful if inhaled or ingested. Epoxy resin glue can be more costly compared to other kinds of adhesives, which creates a challenge for applications that need large amounts of glue. These are the hindering factors responsible for the growth of the market.

Epoxy Resin Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 10.86 Billion |

| Projected Forecast Revenue by 2033 | USD 19.39 Billion |

| Growth Rate from 2024 to 2033 | CAGR of 5.9% |

| Largest Market | Asia Pacific |

| Base Year | 2022 |

| Forecast Period | 2024 to 2033 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Epoxy Resin Market Top Companies

- NAGASE & Co., Ltd.

- Westlake Epoxy

- Techstorm

- Kolon Industries, Inc

- Hexion

- Swancor

- China Petrochemical & Chemical Corp.

- Jubail Chemical Industries LLC

- Jiangsu Sanmu Industries LLC

- Nan Ya Plastics Corp.

- Sika AG

- Olin Corp.

- Kukdo Chemical Co., Ltd.

- Huntsman International LLC

- Solvay

- BASF SE

- Atul Ltd

- Aditya Birla Management Corp. Pvt. Ltd.

- 3M

Recent Developments by Westlake Corporation

- In April 2024, at the American Coatings Show, Westlake Corporation announced that Westlake Epoxy launched various new deep pour lower yellowing epoxy resin products to be held in the USA. These new products provide easier use for 4-inch pours in a single application.

Recent Development by Swancor

- In June 2022, Swancor launched two new epoxy resin products, CleaVER and EzCiclo. They provide recycled wind turbine blades and have the capacity to reuse and degrade through CleaVER technology. It turns waste into reclaimed oligomers and carbon or glass fibers, which recycle both resin and reinforcement by closing the loop.

Regional Insights

Asia Pacific dominated the epoxy resin market in 2023. The increasing widespread access to raw materials, increasing prevalence of large-scale manufacturers, and growing favorable end-use industry growth in developing nations are anticipated to drive the growth of the market. India, China, Japan, and South Korea are the emerging countries in North America. China has the world’s largest market.

The increasing demand for electronic devices, growing middle-class disposable incomes, and increasing adoption of electronic devices, including tablets, OLED TVs, and smartphones, are expected to drive the growth of the market in China. China has various leading manufacturers of epoxy resin, such as fiberglass woven roving, fiberglass mesh, fiberglass roving, Chongqing Dujiang, and many more. Zhejiang Ruico Advanced Materials Co. Ltd is a professional water-based epoxy resin supplier and flame-retardant manufacturer in China. India is also showing higher growth and has several epoxy resins manufacturers such as Atul Ltd., Aditya Birla Chemicals, Hexion Chemicals India Pvt. Ltd., KUKDO CHEMICAL CO.LTD, and Huntsman International. These are the major products and key manufacturers of epoxy resin in China and India and are driving the growth of the epoxy resin market in the Asia Pacific.

North America also held a significant share of the market in 2023. The growing non-governmental and governmental infrastructure and rising digitization are boosting higher demand for electronic and electrical products and are anticipated to drive the growth of the epoxy resins market in North America. The U.S. and Canada are the emerging countries in North America. Epoxy resin products are a trustworthy source of high-quality epoxy materials and are proudly situated in the U.S. The U.S. delivers 100% solid epoxy resin materials, accessories, and pearl mica pigments. Ecopoxy is the leading manufacturer in the U.S. They built trust and developed brand awareness, which has helped increase market presence and customer loyalty. Ecopoxy developed trust and provided high-quality epoxy resin products that include high bio-content. These are the major factors and leading manufacturers that are anticipated to drive the growth of the epoxy resin market in North America.

Market Potential and Growth Opportunity

Increasing integration of bio-based polyepoxides

Epoxy resins were generated based on resins to minimize the environmental impact. Biomaterials such as rosins, vegetable oils, lignin, and other biomaterials are utilized to replace a high percentage of petrochemicals. These materials remove the requirement for BPA, which must be handled with care and be hazardous. This type of epoxy resin has a wide range of applications, such as composites, adhesives, and coating materials. Therefore, the rising demand for sustainability in various end-use industries is anticipated to create a lucrative opportunity for the market in the coming years.

Epoxy Resin Market News

- In November 2023, Induron Protective Coatings announced the launch of its innovative product, Novasafe. Novasafe is a modified ceramic-filled novolac epoxy, a thick film, and it can be used to address the environments experienced in treatment plants.

- In June 2023, to mitigate the dangerous condition of corrosion under insulation, Sherwin-Williams Protective & Marine launched ultra-high-solids epoxy mitigation coatings. Sherwin-Williams provides MIO-enhanced Heat-Flex 650 for applications requiring high-temperature epoxy novolac phenolic coatings.

Segments Covered in the Report

By Raw Material

- DGBEA (Bisphenol A and ECH)

- DGBEF (Bisphenol F and ECH)

- Novolac (Formaldehyde and Phenols)

- Aliphatic (Aliphatic Alcohols)

- Glycidylamine (Aromatic Amines and ECH)

- Other

By Application

- Paint & Coatings

- Construction

- Electrical & Electronics

- Wind Turbine & Composites

- Civil Engineering

- Adhesive & Sealants

- Others

By Technology

- Solvent Cut Epoxy

- Liquid Epoxy

- Waterborne Epoxy

- Others

By Sales Channel

- Direct Company Sale

- Direct Import

- Distributors & Traders

- Retailers

By End User

- Building & construction

- Automotive, large & heavy vehicles & railroads

- Aerospace

- Consumer goods (including sporting equipment)

- General industrial

- Wind power

- Marine

Buy this Research Report@ https://www.precedenceresearch.com/checkout/2150

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308