Food Extrusion Market Size To Rake USD 121.15 Bn By 2032

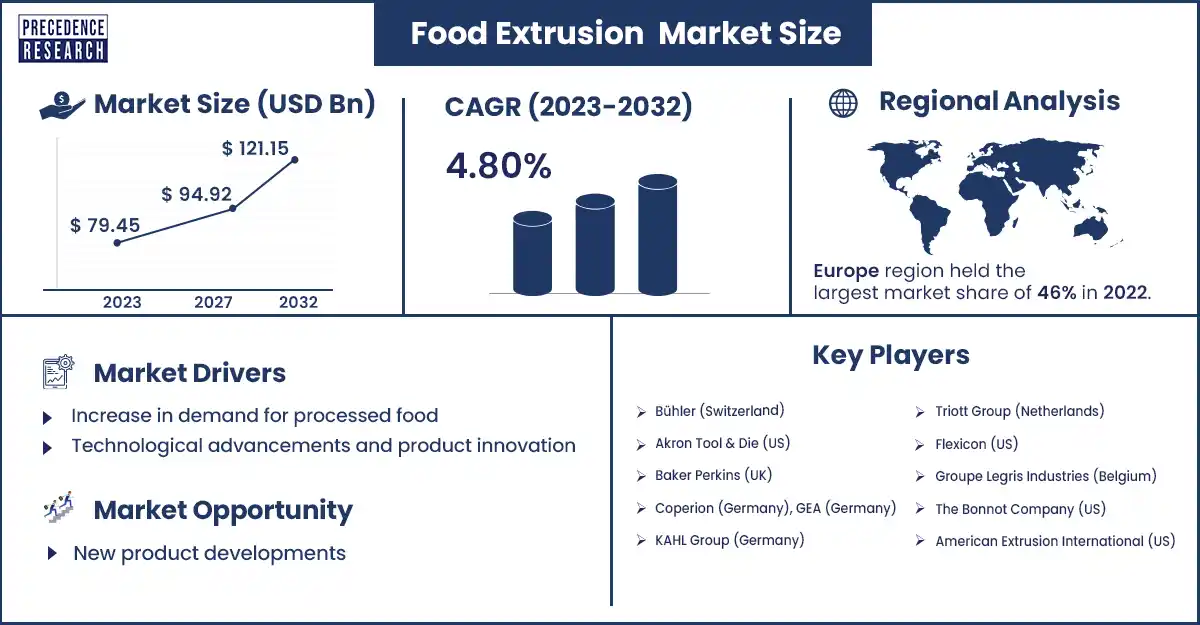

The global food extrusion market size was evaluated at USD 79.45 billion in 2023 and is expected to attain around USD 121.15 billion by 2032, growing at a CAGR of 4.80% from 2023 to 2032.

Market Overview

Food extrusion market with the methods used in food processing. It includes forcing soft mixed substances through an opening in a pierced plate or raw materials to produce the required shape. Generally, the extruded food is cut in different sizes of blades. Extrusion allows the mass manufacture of food by a continuous, efficient system that ensures consistency of the final product. Food products produced using extrusion generally have a large amount of starch content. These include some dry and semi-moist pet food, some beverages, vegetable protein, full-fat soy, several baby foods, premade cookie dough confectionery, and many breakfast bowls of cereal. Food extrusion also helps to cut into the number of microorganisms in food varieties. When it is treated at high heat and removes the regular poisons, it makes the food sources more secure for utilization. It is cutting border food managing creation that includes conveying, texturizing, manipulating, bending, puffing, and cooking.

Food extrusion recognizes the benefits of new consumer snacks and food products. This cycle mainly ends with two cycles: hot food extrusion and cold food extrusion. This cycle uses different extruders, such as contra twin-screw, twin-screw extruders, and single-screw extruders. Extruded Foods is one of the highly preferred ready-made and ready-to-cook items markets due to its specialty as it is easy to make, ready to eat, nutritious, low cost, and tasty, which makes it a high-demand product in the market, with the growth of the economy and fast urbanization.

Regional Snapshot

Europe dominated the food extrusion market in 2023. It has the highest market share due to the increasing growth and customer base in food processing units. In Europe, food companies are targeting salty and tasty snacks more. Food extruder machines and cereal production have high demand in Europe. Due to the increasing consumption of bread, the market in Europe is growing. The European market is in high demand for textured protein from health-conscious customers.

Asia Pacific is estimated to grow fastest in the forecast period. In the global food extrusion market, the Asia Pacific region is ranked due to its Massive Population. Countries like China and India have immense and expanding populations, creating a substantial need for accessible and cost-effective food choices. Rising disposable incomes empower consumers to purchase packaged and processed foods, among which extruded products are prevalent. Urbanization and time constraints, as cities grow and lifestyles become hectic, the demand for speedy and convenient meals surges, which aligns with the ease and convenience offered by extruded foods. In addition, Consumers are becoming increasingly health-conscious, so food manufacturers are creating healthier extruded foods with nutrients, whole grains, and less sugar and fat. These products meet changing consumer demands and boost market growth. The Asia Pacific region has a large and growing consumer base, rising incomes, and shifting market trends, making it a promising future market for extruded foods.

Food Extrusion Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 79.45 Billion |

| Projected Forecast Revenue by 2032 | USD 121.15 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 4.80% |

| Largest Market | Europe |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Increase in demand for processed food

The food extrusion market is principally driven by the growth of the processed food industry. In today's high-speed world, customers want foods that are ready to eat and easy to prepare. Food extrusion technology plays an important role in meeting these requirements by authorizing the innovation of the exhibition of comfort products like instant noodles, cereals for breakfast, and extruded snacks. The capacity to produce long-time storage products with boosted taste and texture allocates position perfectly with exploring the lifestyles and dietary habits of modern customers.

Technological advancements and product innovation

Advancements in food extrusion technology are driving the food extrusion market. They are giving growth to applications and novel products. Industrialists are purchasing extrusion to make textured vegetable proteins, plant-based meat derivatives, and gluten-free snacks. The flexibility of extrusion equipment permitted specific control over factors such as shear, pressure, and temperature, enabling the production of complicated product textures and structures. This technological versatility facilitates the development of products that imitate the existence, taste, and texture of traditional animal-based foods while serving dietary existences and principled considerations.

Restraint

Sustainability and environmental impact

Sometimes, the food extrusion market faces increasing pressure to address sustainability concerns and reduce its environmental footmark. Restraints arise related to the efficient utilization of resources, waste management, and energy consumption throughout the extrusion process. Moreover, the managing of waste generated from extrusion processes is the biggest restraint. Confirming responsible disposal or recycling of by-products and adjusting production processes to decrease waste production is important for sustainability efforts within the food extrusion industry. The production of eco-friendly packaging solutions for extruded food products is also a big restraint.

Opportunity

New product developments

Over the last few years, the food extrusion market has upgraded so many activities, such as the appearance of new players, the enlargement of the snacks portfolio through continuous product creation, moving in consumption patterns with growing demand for comfort food, and the assertive marketing campaigns to establish a supplier-customer relationship. In addition, the growing health awareness of always seating lifestyles and the rising evidence of lifestyle diseases in progress and developing regions have resulted in the demand for healthy and nutritional snacks. This requirement is only expected to rise in the future and presents profitable opportunities for existing and new players.

- In September 2023, the 'THE FILET - Inspired by Salmon' product is the first item created using MassFormer, a proprietary 3D food printing technology from Revo Foods. The business claims that a new generation of real seafood alternatives with the characteristic "flakiness" and juicy fibers of fish filets have been made possible by this innovative extrusion process's smooth integration of fats into a fibrous protein matrix. Revo Foods claims to have invented the first-ever continuous manufacturing method that can produce 3D-printed food in large quantities using its patent-pending 3D-MassFormer technology.

Recent Developments

- In July 2023, ALPLA announced the eant-based meat. Vegan meat manufacturers have encountered "unique obstacles concerning texture optimization," according to the inventors of GreenProtein AI. One of the primary methods for converting plant-based ingredients into fibrous meat, along with low-moisture extrusion and shear-cell technology, is high-moisture extrusion (HME). This is mostly because of the high costs associated with HME.

Key Market Players

- Bühler (Switzerland)

- Akron Tool & Die (US)

- Baker Perkins (UK)

- Coperion (Germany), GEA (Germany)

- KAHL Group (Germany)

- Triott Group (Netherlands)

- Flexicon (US)

- Groupe Legris Industries (Belgium)

- The Bonnot Company (US)

- American Extrusion International (US)

- Shandong Light M&E Co., Ltd (China)

- Snactek (India)

- Doering systems, inc. (US)

Segments Covered in the Report

By Product Type

- Savory snacks

- Breakfast cereals

- Breads

- Flours & Starches

- Textured protein

- Functional ingredients

- Others

By Extruder

- Single screw extruder

- Twin screw extruder

- Contra-twin screw extruder

By Process

- Cold Extrusion

- Hot Extrusion

Buy this Research Report@ https://www.precedenceresearch.com/checkout/1829

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308