What is the Induction Heating Roller Market Size?

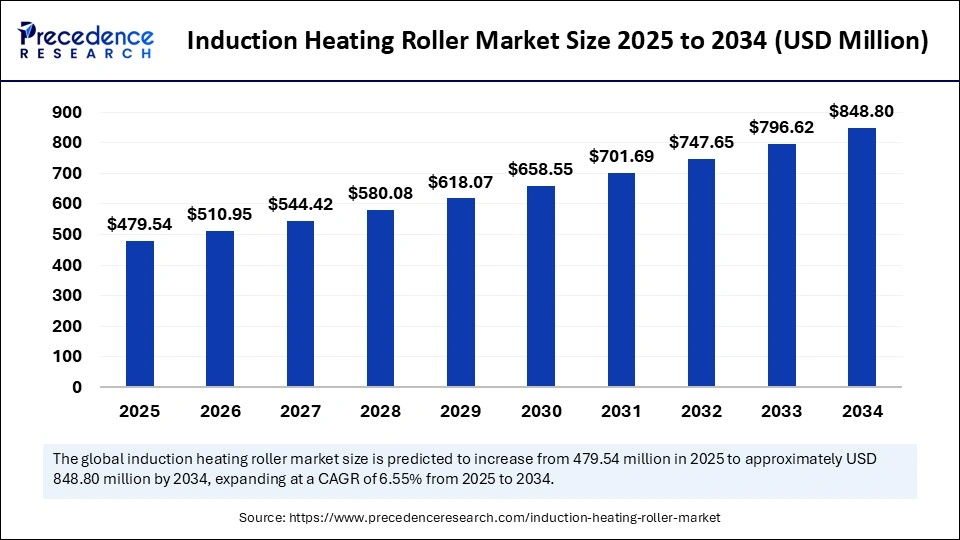

The global induction heating roller market size accounted for USD 450.06 million in 2024 and is predicted to increase from USD 479.54 million in 2025 to approximately USD 848.8 million by 2034, expanding at a CAGR of 6.55% from 2025 to 2034. The rising demand for energy-efficient solutions, rapid technological innovation, rapid industrialization, and the growing demand for efficient heating technologies are expected to propel the growth of the global market for induction heating rollers over the forecast period. Additionally, the market is rapidly expanding in various developing and developed regions, particularly the Asia Pacific, fuelled by a supportive regulatory environment and rising sustainable initiatives.

Market Highlights

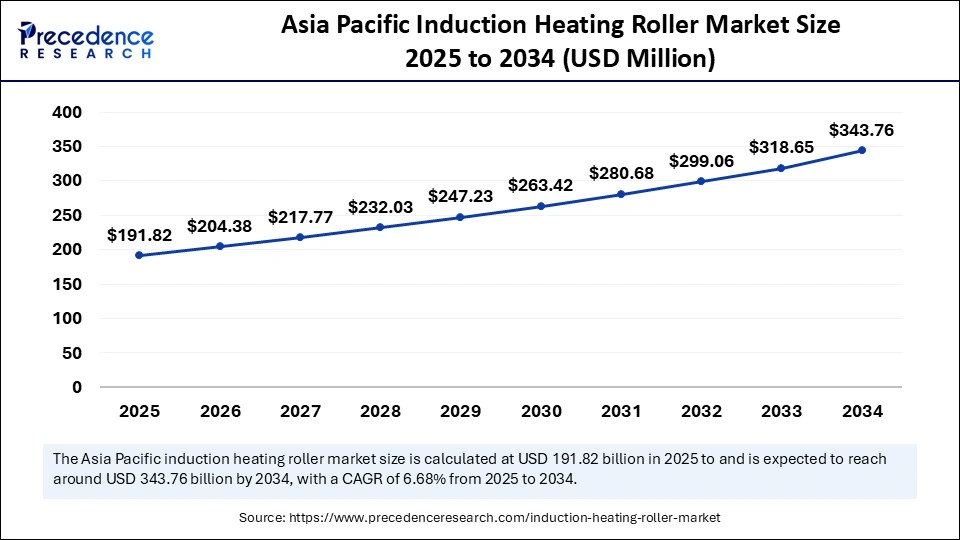

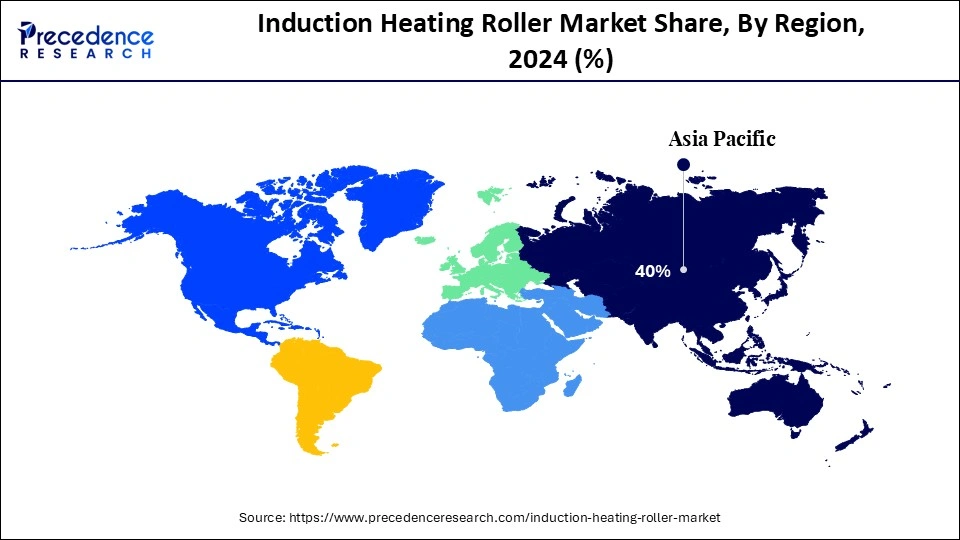

- Asia Pacific dominated the induction heating roller market with the largest market share of 40% and is expected to grow further at the fastest CAGR during the forecast period.

- By product design, the hollow (jacket) induction rollers segment accounted for the significant market share of 45% in 2024.

- By product design, the segmented induction rollers (modular) segment is expected to witness a significant growth CAGR during the forecast period.

- By frequency range, the medium-frequency induction (10–100 kHz) segment held the biggest market share 55% in 2024.

- By frequency range, the high-frequency induction (>100 kHz) segment accounted for considerable growth over the forecast period.

- By roller material, the stainless-steel rollers segment generated the major market share of 40% in 2024.

- By roller material, the ceramic-coated rollers segment is expected to grow significantly during the forecast period.

Market Size and Forecast

- Market Size in 2024: USD 450.06 Million

- Market Size in 2025: USD 479.54 Million

- Forecasted Market Size by 2034: USD 848.80 Million

- CAGR (2025-2034): 6.55%

- Largest Market in 2024: Asia Pacific

Market Overview

An induction heating roller is a rotating industrial roller whose surface or shell is heated by electromagnetic induction (via internal coils or external inductors) to deliver precise, rapid, contactless, and controllable process heat. This technology is widely employed in web and strip handling, laminating, calendering, drying, embossing, preheating, and thermal processing applications. Unlike conventional heating methods, induction heating rollers provide uniform temperature distribution, high energy efficiency, and faster response times, making them an attractive choice for industries that demand high-quality surface finishing and controlled thermal treatment.

The adoption of induction heating rollers is gaining momentum across industries such as packaging, textiles, paper, plastics, rubber, metal processing, and electronics manufacturing is giving a huge boost to the induction heating roller market. In these sectors, the need for improved process reliability, reduced downtime, and enhanced product quality is driving the replacement of conventional heating rollers with induction-based systems. Furthermore, their ability to deliver consistent heat without direct contact reduces wear-and-tear, minimizes contamination risks, and extends equipment life, offering operational advantages to end users.

How Artificial Intelligence Integration Improve the Induction Heating Roller Market?

As technology continues to advance, artificial intelligence integration holds great potential for growth and innovation in the induction heating roller market by offering predictive maintenance, improving quality assurance, enhancing energy efficiency, and reducing equipment downtime. AI-powered solutions and machine learning assist in effectively monitoring equipment performance, identifying early signs of degradation, and integrating the rollers into smart manufacturing systems for making data-driven decisions and a more streamlined process. AI-driven analytics rapidly analyze the data from sensors to optimize heating parameters in real-time, which ensures precise temperature control and consistent heating profiles. The incorporation of Artificial Intelligence can predict potential equipment failures before they occur, enabling the significant reduction of unexpected downtime and proactive maintenance.

What Are the Latest Trends in the Induction Heating Roller Market?

- The stringent energy efficiency regulations and the rising expansion of manufacturing bases in emerging economies are anticipated to accelerate the market's revenue during the forecast period.

- The expanding applications of induction heating rollers across various industries, such as packaging, automotive, textiles, rubber manufacturing, and others, are expected to significantly contribute to the overall growth of the induction heating roller market during the forecast period.

- The increasing industrial automation and adoption of 4.0 principles are expected to propel the expansion of the market in the coming years.

- The rapid technological advancements in roller technology, which lead to improved durability and control, are driving the market's growth during the forecast period.

- The growing demand for sustainable manufacturing practices is expected to promote the growth of the market for induction heating rollers during the forecast period.

- The rising focus of key players to develop more advanced Induction heating rollers through technological innovation and strategic partnerships is anticipated to boost the growth of the induction heating roller market in the coming years.

Market Scope

| Report Coverage | Details |

| Market Size in 2024 | USD 450.06 Million |

| Market Size in 2025 | USD 479.54 Million |

| Market Size by 2034 | USD 848.80 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 14.77% |

| Dominating Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Design, Frequency Range, Roller Material, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Rapid Pace Of Industrialization

The rising industrialization is expected to boost the growth of the induction heating roller market during the forecast period. Several industries are increasingly adopting energy-efficient alternatives over conventional heating methods to reduce overall operational costs and environmental impact, which increases the demand for induction heating rollers. Induction heating rollers are a cutting-edge technology crucial for various industrial processes that require precise, uniform, and efficient heating. Industries such as automotive, printing, packaging, metal forging, pulp and paper, textiles, non-woven fabrics, and rubber are increasingly relying on the technology to minimize downtime, improve process speed and consistency, and enhance efficiency. The versatility and performance benefits offered by induction heating rollers increase their significance in modern manufacturing techniques. Additionally, the incorporation with automation and Industry 4.0 enables Internet of Things (IoT)-enabled rollers for accurate real-time monitoring, improving operational efficiency, and predictive maintenance.

Restraint

High Initial Investment Costs

The high implementation cost is anticipated to hamper the market's growth. The high upfront capital investment is required for purchase and maintenance, which often acts as a barrier for small and medium-sized companies (SMEs) due to budget constraints. In addition, a lack of awareness among smaller businesses and a shortage of specialized technical expertise are likely to limit the expansion of the induction heating roller market in price-sensitive regions or sectors.

Opportunity

How Are the Supportive Government Regulations Impacting the Market's Growth?

The supportive government regulations and supportive initiatives are projected to offer lucrative growth opportunities to the induction heating roller market during the forecast period. Several government regulations and incentives around the world are increasingly focusing on promoting energy efficiency and modernizing industrial processes. The adoption of sustainable manufacturing practices significantly reduces the carbon footprint, which further fuels the adoption of induction heating roles as energy-saving technologies. Additionally, several players are increasingly focusing on developing more durable, efficient, and eco-friendly solutions to expand their market presence, particularly in developing nations due to their expanding industrial bases. Therefore, the shift towards sustainable manufacturing is fuelled by the increasing demand for energy-efficient induction heating solutions, replacing conventional methods.

Segments Insights

Product Design Insights

What Has Led the Hollow (Jacket) Induction Rollers to Dominate the Induction Heating Roller Market?

The hollow (jacket) induction rollers segment accounted for the largest market share of the global induction heating roller market in 2024. A hollow (jacket) induction roller uses a magnetic field to heat its surface with uniformity and precision. Hollow (jacket) induction rollers are widely used in industries that require highly precise thermal processing, such as converting, laminating, printing, and others. The segment growth is mainly driven by the increasing demand from various key industries such as textiles and plastics, owing to the rapid heating, uniform temperature distribution, energy efficiency, and minimal contamination risk.

On the other hand, the induction rollers (modular) segment is anticipated to grow at a CAGR during the forecast period. The segment's growth is driven by the increasing demand for high-performance modular induction heating rollers across a wide range of industries, including plastics, rubber, textiles, paper and printing, metallurgy, packaging, and others. Modular induction heating rollers offer enhanced flexibility and scalability as well as and can be easily adapted to different production needs.

Frequency Range Insights

What Causes the Medium-Frequency Induction (10–100 kHz) to Dominate the Induction Heating Roller Market?

The medium-frequency induction (10–100 kHz) held a dominant presence in the market for induction heating rollers in 2024. The 10–100 kHz frequency range of the induction heating roller is primarily considered ideal for several tasks involving rollers owing to its ability to achieve a controlled and medium-depth heating. The 10–100 kHz frequency range finds application in surface hardening, shrink fitting, forming and bending, drying and curing, pipeline coating, and various other local heating applications. Moreover, the introduction of more efficient power devices, like IGBTs, is likely to boost the growth of the medium-frequency induction heating technology.

On the other hand, the high-frequency induction (>100 kHz) segment is expected to grow at a notable rate, owing to the high demand from industries automotive, aerospace, and others, which rely on the high-frequency range for manufacturing and component production. High-frequency induction heating rollers, operating at higher frequencies (>100 kHz), are a key segment in the market. High-frequency induction heating is favoured for rapid, efficient, and precise applications.

Roller Material Insights

Which Segment Is Dominating the Market by Roller Material in the Induction Heating Roller Market?

The stainless-steel rollers segment dominated the global induction heating roller market in 2024. Stainless steel is a key material used in induction heating rollers owing to its corrosion resistance, durability, and suitability for numerous industrial applications. Stainless steel is a preferred material for induction-heated rollers due to its specific properties, such as induction heating compatibility, corrosion resistance and durability, high-temperature applications, and hygienic properties. Induction-heated stainless-steel rollers are widely used in a wide range of industrial processes nonwovens and textiles, plastics and lamination, hot rolling, printing, converting and packaging, and others.

On the other hand, the ceramic-coated rollers segment is expected to witness remarkable growth during the forecast period. Ceramic coatings significantly enhance the performance of induction heating rollers. Ceramic coatings are widely used to provide thermal and electrical insulation, non-conductivity, hardness, and corrosion protection properties to a surface. There are various benefits offered by ceramic-coated induction rollers, such as enhanced durability, precision, and efficiency, lower maintenance, high-temperature resistance, and others. The longer lifespan and reduced downtime of ceramic-coated rollers provide greater cost-effectiveness over time compared to several conventional rollers.

Regional Insights

Asia Pacific Induction Heating Roller Market Size and Growth 2025 to 2034

The Asia Pacific induction heating roller market size was evaluated at USD 180.02 million in 2024 and is projected to be worth around USD 343.76 million by 2034, growing at a CAGR of 6.68% from 2025 to 2034.

Asia Pacific Is Dominating the Induction Heating Roller Market With the Highest Growth Prospects in the Forecasted Period

Asia Pacific accounted for the majority of the market share and is expected to further grow at the fastest CAGR. The region's rapid growth is driven by the rising industrialization and rapid infrastructure development in various Asia-Pacific countries, such as China, India, Japan, and South Korea, which propels the demand for high-performance heating rollers to support large-scale production. The market for induction heating roller is propelled by the increasing adoption of industrial automation and the growing demand for energy-efficient, clean, and high-precision heating solutions across various industries such as automotive, packaging, textiles, rubber, metal forging, steel, pulp and paper, plastics, and others.

Induction heating rollers offer numerous benefits over conventional heating solutions, which rely heavily on oil, steam, or resistance heating elements. The growing regulatory pressure on various industries and the push for sustainable manufacturing practices by government regulations and mandates for energy conservation encourage the adoption of induction heating technologies, and significantly reduce the carbon footprint. Industries in the region are increasingly preferring energy-saving technologies as an attractive alternative to conventional heating methods. Such combination of factors is expected to drive the expansion of the induction heating roller market in the coming years.

Induction Heating Roller Market Companies

- Tokuden

- Kendrion

- MagComp AB

- ISGEV

- Comaintel

- SenTek

- Huatao Group

- Inductotherm Group

- Ajax TOCCO Magnethermic

- Ambrell Corporation

- Fives

- Miller Electric

- Radyne

- Thermatool

- SEIT Elettronica

- Teknel Induction

- Leifert Induction

- BALTECH GmbH

- Andritz

- Voith

Recent Developments

- In March 2025, Simatec AG launched Simatherm IH 125, bringing bearing heating technology into the digital era. Through the user-friendly app, users can intuitively control the device, store heating data, and access it directly. This connectivity not only enhances efficiency but also supports quality assurance in bearing installation processes.(Source: https://www.bearing-news.com)

- In December 2024, Ino Trident introduced plasmics, which represent a significant advancement in 3D printing as the first commercially available inductive hotend. Unlike traditional hotends that rely on resistive heating elements, this innovative design uses electromagnetic induction for faster, more precise, and energy-efficient temperature control.(Source: https://www.geeky-gadgets.com)

SegmentsCovered in the Report

By Product Design

- Hollow (jacket) induction rollers

- Solid-shaft induction rollers

- Segmented induction rollers (modular)

- Sleeve-based induction rollers (replaceable)

By Frequency Range

- Low-frequency induction (<10 kHz)

- Medium-frequency induction (10–100 kHz)

- High-frequency induction (>100 kHz)

By Roller Material

- Stainless steel rollers

- Carbon/alloy steel rollers

- Aluminum rollers

- Copper-surfaced rollers

- Ceramic-coated rollers

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting