Industrial Plastic Market Size and Forecast 2025 to 2034

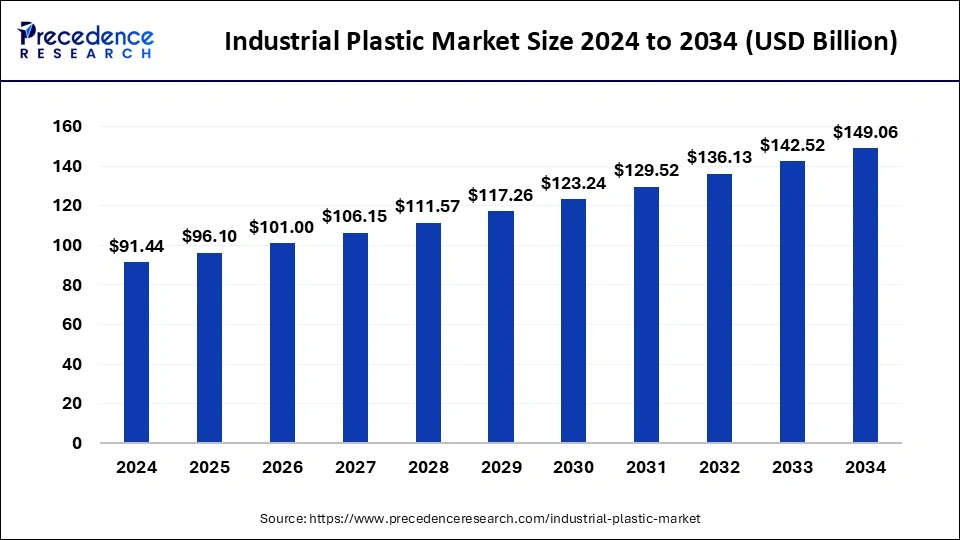

The global industrial plastic market size was estimated at USD 91.44 billion in 2024 and is predicted to increase from USD 96.10 billion in 2025 to approximately USD 149.06 billion by 2034, expanding at a CAGR of 5.01% from 2025 to 2034.

Industrial Plastic Market Key Takeaways

- Asia Pacific dominated the industrial plastic market in 2024.

- By product, the polyamide segment contributed more than 41% of market share in 2024.

- By product, the Polycarbonate segment is anticipated to grow significantly in the market during the forecast period.

- By application, the disposables emerged application segment dominated the market in 2024.

Industrial Plastic Market Growth Factors

Recent advancements in the industrial sector including electrical &electronics and automobile anticipated to propel the demand for lightweight plastic components in these industries. Increasing the application of energy-saving and environment-friendly products is estimated to positively influence market growth.

Further, ongoing Research & development (R&D) for nanotechnology-based plastics mainly for industrial applications is the other prominent factor that boosts the market growth owing to excellent thermal resistance and strength along with improved efficiency and subsequent weight reduction offered by these plastics.

Presently, innovations, technological breakthroughs, and research studies are going on in order to expand the scope of the product's application which is projected to foster the growth of industrial plastics in the upcoming years. Furthermore, the government along with the private institutions invests prominently in the aerospace &defense industry, thereby flourishing the demand for these industrial plastics over the coming years.

Market Scope

| Report Highlights | Details |

| Market Size in 2034 | USD 149.06 Billion |

| Market Size in 2025 | USD 96.10 Billion |

| Market Size by 2024 | USD 91.44 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 5.01% |

| Dominating Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Product Insights

With respect to revenue, polyamide captured the largest segment share in 2024 accounting for nearly 41%. Properties of the product such as dimensional stability, sliding friction, rigidity, and chemical resistance compared to other counterparts make it suitable for application in a wide range of industries. Further, polyamide is lighter in weight compared to others which result in ease of transportation and usage.

Polycarbonate exhibits lucrative growth during the forthcoming years because of its significant demand from the transportation and electrical & electronics sectors. The product is greatly helpful in reducing the weight of the vehicle and hence improving the fuel efficiency which triggers its demand among several automotive Original Equipment Manufacturers (OEMs). Furthermore, polycarbonate is a completely recyclable plastic, thus, favored as a substitute in various applications of plastics; for example, polycarbonate is used as a substitute of PVC mainly in medical devices. Apart from all this, polycarbonate offers high tensile strength and is easily processed and blended with its copolymers such as ABS and polyester. Hence, the aforementioned factors are likely to propel the industry growth for polycarbonate over the analysis period.

Application Insights

Automotive is a major application segment for industrial plastics owing to its notable contribution to the weight reduction of a vehicle. Technological innovations have brought several reforms in the plastic industry with the development of environment-friendly and lightweight plastics this creates a new horizon for its implementation in the automotive sector. Increasing production of electric cars and heavy-duty vehicles is further expected to provide an alluring opportunity for industrial plastics in the automotive sector. Stringent norms for weight reduction and carbon emission are likely to contribute notably to the application segment.

ABS is one of the most prominently used plastics in the automotive application ranging from interior components to engine parts. This type of plastic is also used as a substitute material for engineering plastics and metal components in the automotive industry because of its flexibility as well as excellent mechanical properties.

Regional Insights

The Asia Pacific captured the major market share in the global industrial plastic market in terms of revenue in 2024. The region is expected to continue the same trend over the coming years. The significant growth of the region is mainly because of a well-established manufacturing base, particularly in China, Taiwan, and South Korea. Some of the Asian countries such as India and China have strong manufacturing bases for the chemical industry that strengthen their market in the region. Furthermore, improving economic conditions, rapid urbanization, and increasing infrastructural activities are the key factors that support market growth in the region.

Various factors such as increasing unemployment, stalled industrial output, and debt crisis have negatively impacted the market growth in Europe. However, Eastern Europe is expected to have positive growth owing to rising consumption as well as a manufacturing base in the region. Furthermore, stringent government regulations for chemical industries issued by the European Commission and the European Chemicals Agency (ECHA) are estimated to provide alluring opportunities for renewable and environment-friendly plastic materials in the region.

Key Companies & Market Share Insights

The global industrial plastic market seeks several disruptions owing to the majority of the key market players have integrated their distribution operations and raw material production to maintain their product quality as well as to expand their regional presence. This helps these companies to gain a competitive advantage in terms of cost benefits, thereby increasing their profitability ratio.

Industrial Plastic Market Companies

- SABIC

- BASF SE

- Victrex Plc

- Evonik Industries AG

- EnsingerGmbh

- Lyondellbasell Industries Holdings B.V.

- Eastman Chemical Company

- Arkema S.A.

- Solvay S.A.

- Teijin Limited

- Formosa Plastics Corporation

- Mitsubishi Engineering-Plastics Corporation

- Toray Industries, Inc.

- Covestro AG

- Mitsui & Co., Ltd.

Segments Covered in the Report

This research study comprises a complete assessment of the market by means of far-reaching qualitative and quantitative perceptions, and predictions regarding the market. This report delivers a classification of the marketplace into impending and niche sectors. Further, this research study calculates the market size and its development drift at global, regional, and country from 2020 to 2032. This report contains a market breakdown and its revenue estimation by classifying it on the basis of product, application, and region:

By Product

- Acrylonitrile Butadiene Styrene (ABS)

- Polyphenylene Ether

- Polybutylene Terephthalate (PBT)

- Polyamide

- PEEK

- Polysulfone (PSU)

- Liquid Crystal Polymers

- Polyphenylsulfone (PPSU)

- Polytetrafluoroethylene (PTFE)

- Polyetherimide

- Polycarbonate

- Others

By Application

- Building & Construction

- Packaging

- Electrical & Electronics

- Healthcare

- Automotive & Transportation

- Aerospace

- Others

By Regional Outlook

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting