Additive Manufacturing Market Revenue, Top Companies, Report 2033

Additive Manufacturing Market Revenue and Trends

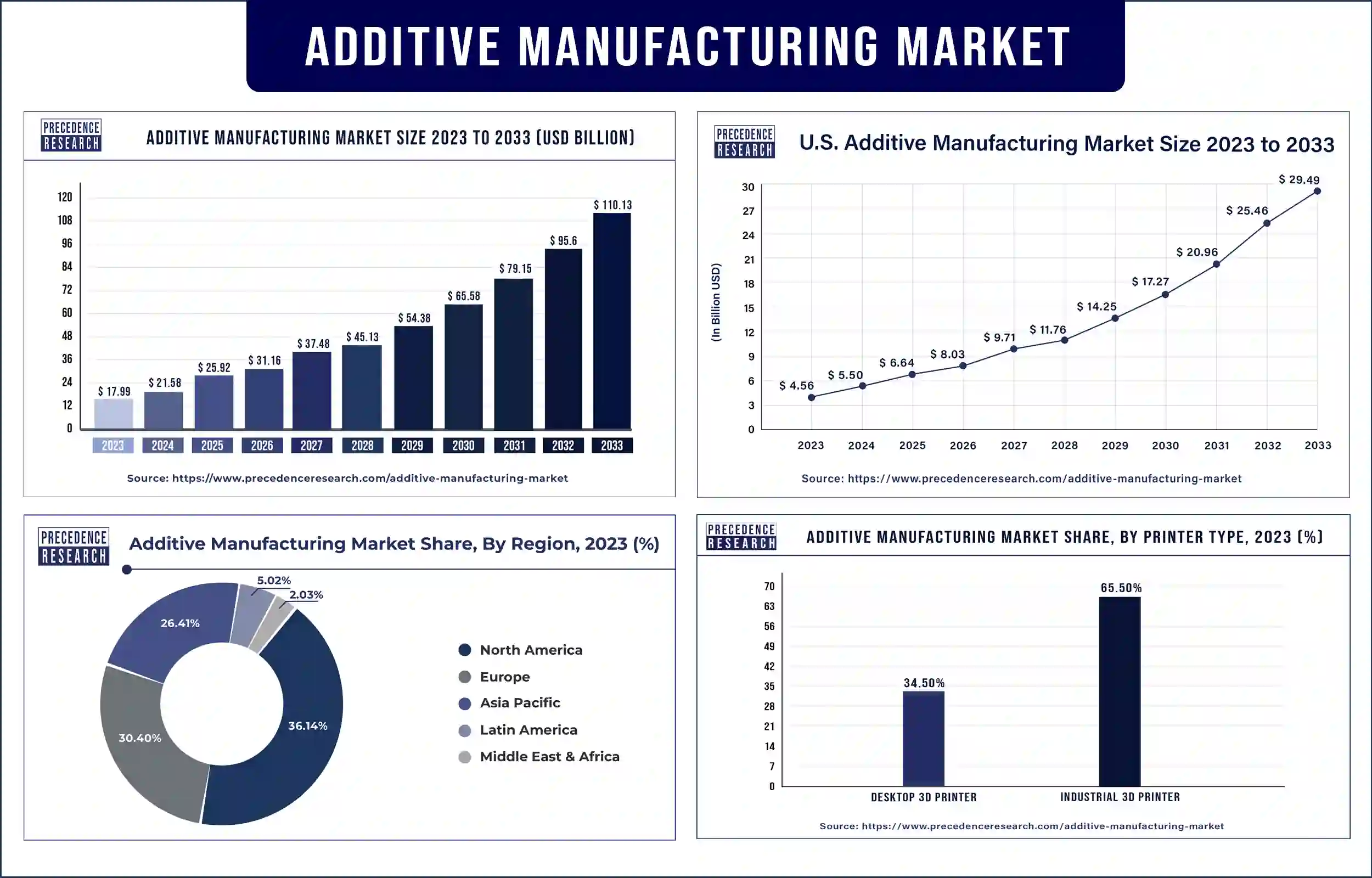

The global additive manufacturing market revenue was valued at USD 17.99 billion in 2023 and is poised to grow from USD 21.58 billion in 2024 to USD 110.13 billion by 2033, at a CAGR of 19.85% during the forecast period 2024 - 2033. The additive manufacturing market is focused on designing, distributing, and producing cloth, yarn, garments, and clothing. The raw materials used may be ceramic, alloys, metal, and plastic. Additive manufacturing companies deliver remarkably to the economy of various countries.

Market Overview

Additive manufacturing also called additive layer manufacturing (ALM) or 3D printing is a technology primarily used for manufacturing 3 dimensional objects by depositing layers over layers. The worldwide additive manufacturing market statement offers facts of market stake, new progress, and the influence of national and localized market companies, studies chance in terms of developing income pockets, variations in market guidelines, product endorsements, planned choices, product inaugurations, geographic extensions, and technological inventions in the market.

The additive manufacturing market can be split based on substantial type, vertical, and technology. Material categories comprise plastics, ceramics, metals, and others, each contributing exclusive assets and submissions. Technologies like fuse deposition modeling, stereolithography, and discriminating laser sintering supply varied manufacturing requirements. Upright division covers automotive, aerospace, consumer products, healthcare, defense, government, and others, showing the extensive acceptance of additive manufacturing across the market.

Additive Manufacturing Market Trends

- Additive manufacturing machinery and start-up costs are low in comparison to other manufacturing. There are multiple trainings available over the internet to learn how to use additive manufacturing machinery or 3D printers.

- It reduces the wastage of raw materials whereas other traditional methods of manufacturing require large metal blocks to start.

- Computer Aided Designs (CAD) showed the shift from 2D print to 3D print. It also takes less time to manufacture in comparison to others.

Growing demand for lightweight substances from the aerospace and automotive industries

The aerospace and automotive sector needs several cooperating technical and economic purposes of practical presentation, lead time decrease, light in weight, cost managing, and distribution of protection essential machinery. To encounter the request and to recompense for the fuel expenditure and cost control to improve the technical presentation and permissible to make a light construction which directly connected to improving economic and technical presentation and which will assist the airlines market to transmit more load, which will directly enhance their income. Additive manufacturing machinery, distinct from usual old-style manufacturing, practices layer-by-layer manufacturing rely on distinctive materials like plastic polymer, and powder or wire which is lightweight.

Trades like aerospace were few of the markets that used additive manufacturing goods for their presentation, and airplane parts are made up of additive manufacturing goods that are light in weight and can endure severe atmospheric situations, due to fewer substantial needed and by the procedure of making resources layers by layers, aerospace market utilizes it as the benefit for heaviness drop and waste decrease, which are very significant for the industries of aerospace fragments for main companies.

The advantage that additive manufacturing gives has unlocked wide prospects for generating absolutely any 3-dimensional figures and components. However, not every occupation can inexpensively mix this type of movement into their commercial procedures. Some of the most public reasons that hamper the forthcoming period of additive manufacturing are the high price of apparatus and the lack of experts in this additive manufacturing market. However, the final charge relies on the selected material, like plastic, which is measured as the most pocket-friendly choice among all other supplies existing. The time mandatory is also pretty high as it requires more than one hour to print just a 40cm object.

Additive Manufacturing Market Highlights

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 17.99 Billion |

| Market Revenue by 2033 | USD 110.13 Billion |

| Market CAGR | 19.85% from 2024 to 2033 |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Top Companies in the Additive Manufacturing Market

- Desktop Metal

- Formlabs

- EOS

- SLM Solutions Group AG

- ExOne

- Organovo

- Stratasys

- Markforged

- Materialise

- Voxeljet AG

- Nano Dimension

- Addup Limited

- 3D Systems

- Aconity 3D

- HP

- Additive Industries

- Citrine Informatics

- Carbon

- Glowforge

- DMG Mori

- Hybrid Manufacturing Technologies

- Autodesk

- Elementum 3D, Inc

- Seurat Technologies

Recent Development by Nano Dimension

- Nano Dimension is the global provider of Additively Manufactured Electronics (AME) technology which is an alternative in-house method of fabricating printed circuit boards (PCBs) and various other electronic devices. In May 2024, Nano Dimension showcased developments for micro and industrial flagship manufacturing systems at the TCT3Sixty exhibition.

Recent Development by Elementum 3D, Inc

- Elementum 3D, Inc. is a leading developer of enhanced metal additive manufacturing company. It offers the most advanced technology and materials in the world and turns ground-breaking concepts into reality. In January 2024, Elementum 3D, Inc. received 2,875,000 USD from America to develop material property datasets with high statistical power for industrially relevant aluminum and nickel alloys.

Regional Insights

North America dominated the worldwide additive manufacturing market in 2023. The U.S. leads in the North American area due to progressive expansion in technologies. Regional markets such as the European market also have a well-known share in the worldwide additive manufacturing market, tracked by Asia Pacific, Middle East, and Africa, and the lowermost market of South America.

The Europe Additive Manufacturing Market is witnessing significant growth, driven by advancements in technology and increasing adoption across various industries such as aerospace, automotive, healthcare, and consumer goods. The region benefits from a strong industrial base, a highly skilled workforce, and substantial investments in research and development. Key players in the market are continuously innovating to enhance the efficiency and capabilities of additive manufacturing technologies, including 3D printing. The market is also supported by favorable government policies and funding initiatives aimed at promoting digital manufacturing and Industry 4.0. Additionally, the presence of leading academic and research institutions in Europe is fostering innovation and collaboration, further propelling the market. However, challenges such as high initial costs and the need for standardization in processes and materials may hinder the market's growth to some extent. Overall, the Europe Additive Manufacturing Market is poised for robust expansion, leveraging technological advancements and strategic investments.

Asia Pacific is expected to grow at the fastest CAGR during the forecast period because of the occurrence of emerging financial prudence and the accessibility of huge populations in India and China that need cutting-edge medical services. Furthermore, the request for dental 3D printing because of the growth in people experiencing tooth replacement operations will boost the market development. Likewise, the growing cases of arthritis and the fast-growing healthcare organizations are predicted to boost the development of the healthcare additive manufacturing market in the Asia Pacific region.

Market Potential and Growth Opportunity

Digitalization of the additive manufacturing market

Additive manufacturing has enormous potential to transform the manufacturing and industrial invention scenery through digital procedures, imaging, and communication. Additive manufacturing is a sheering commercial that has huge demand from several industries such as automotive, medical sector, aerospace, fashion, electronics, etc. observing the potential option of this sector's influence on the nation's budget, governments of various countries are forthcoming with a diverse plan to support and endorse this industry.

The growth of digitizing medical imaging that digitalization permits for the reform of 3-dimensional replicas from patients' anatomy. The distinctive roadmap of the tailored medical equipment starts with imaging or seizing the geometry of the patient and the anatomy using computed three-dimensional scanning approaches. Such information can be used to print 3-dimensional models of the anatomy of the patient or can be utilized to generate modified devices or implantations.

Additive Manufacturing Market News

- In May 2024, Fonon Corporation which is a multi-market holding company and manufacturer of advanced laser material processing systems for subtractive and additive components. They have announced to development of additive manufacturing technology to transform the construction industry.

- In April 2024, Metal Injection Molding (MIM) company Indo-MIM partnered with HP for metal 3D parts production in India. MIM company has announced that it will operationalize HP’s two metal jet binder 3D printers in India.

- In June 2024, Carpenter Additive which once launched engineered metal powders announced to shut down its UK facility but will continue to serve AM customers.

Market Segmentation

By Component

- Hardware

- Software

- Services

By Printer Type

- Desktop 3D Printer

- Industrial 3D Printer

By Technology

- Stereolithography

- Fuse Deposition Modeling

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Polyjet Printing

- Inkjet Printing

- Electron Beam Melting

- Laser Metal Deposition

- Digital Light Processing

- Laminated Object Manufacturing

- Others

By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

By Application

- Prototyping

- Tooling

- Functional Parts

By Vertical

- Industrial Additive Manufacturing

- Automotive

- Aerospace & Defense

- Healthcare

- Consumer Electronics

- Power & Energy

- Others

- Desktop Additive Manufacturing

- Educational Purpose

- Fashion & Jewelry

- Objects

- Dental

- Food

- Others

By Material

- Polymer

- Metal

- Ceramic

Buy this Research Report@ https://www.precedenceresearch.com/checkout/3332

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308