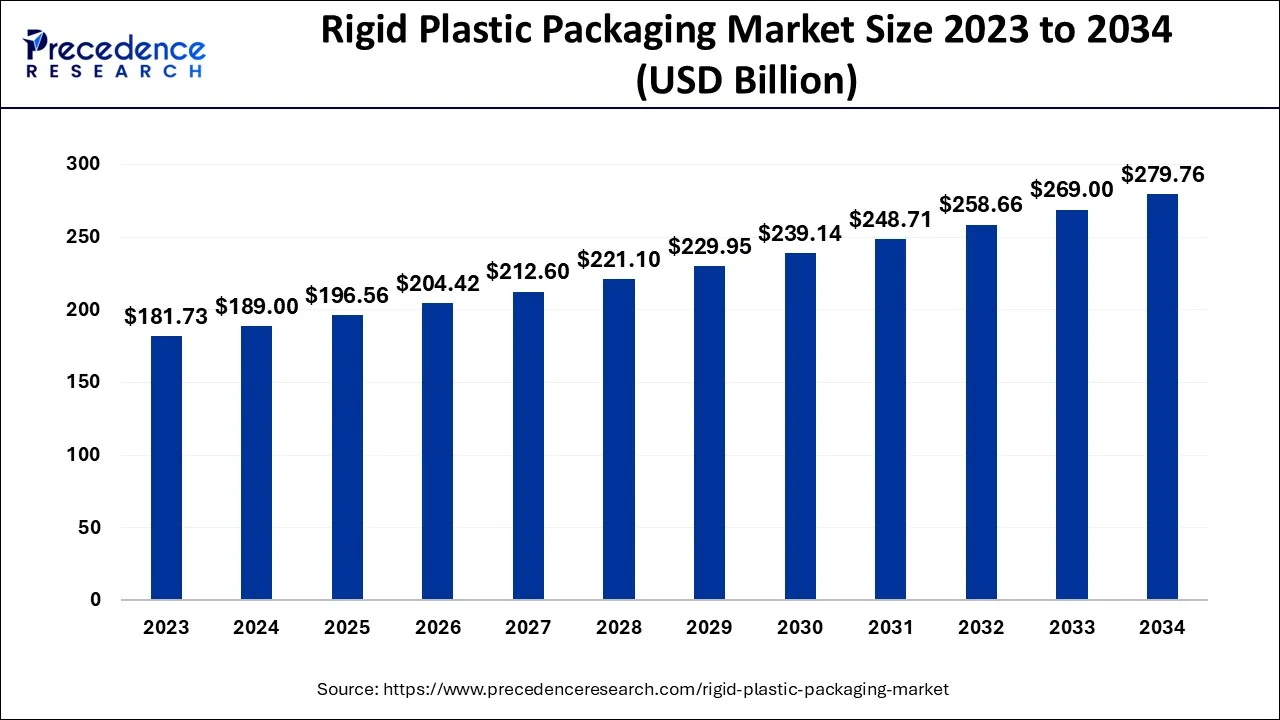

Rigid Plastic Packaging Market Size and Forecast 2024 to 2034

The global rigid plastic packaging market size is estimated at USD 189.00 billion in 2024 and is anticipated to reach around USD 279.76 billion by 2034, expanding at a CAGR of 4% from 2024 to 2034.

Rigid Plastic Packaging Market Key Takeaways

- By material, the polyethylene terephthalate (PET) segment accounted for 61.5% in 2023.

- By production process, the injection molding segment has accounted highest revenue share of over 38% in 2023.

- By end users, the food & beverage segment hit 55% market share in 2023.

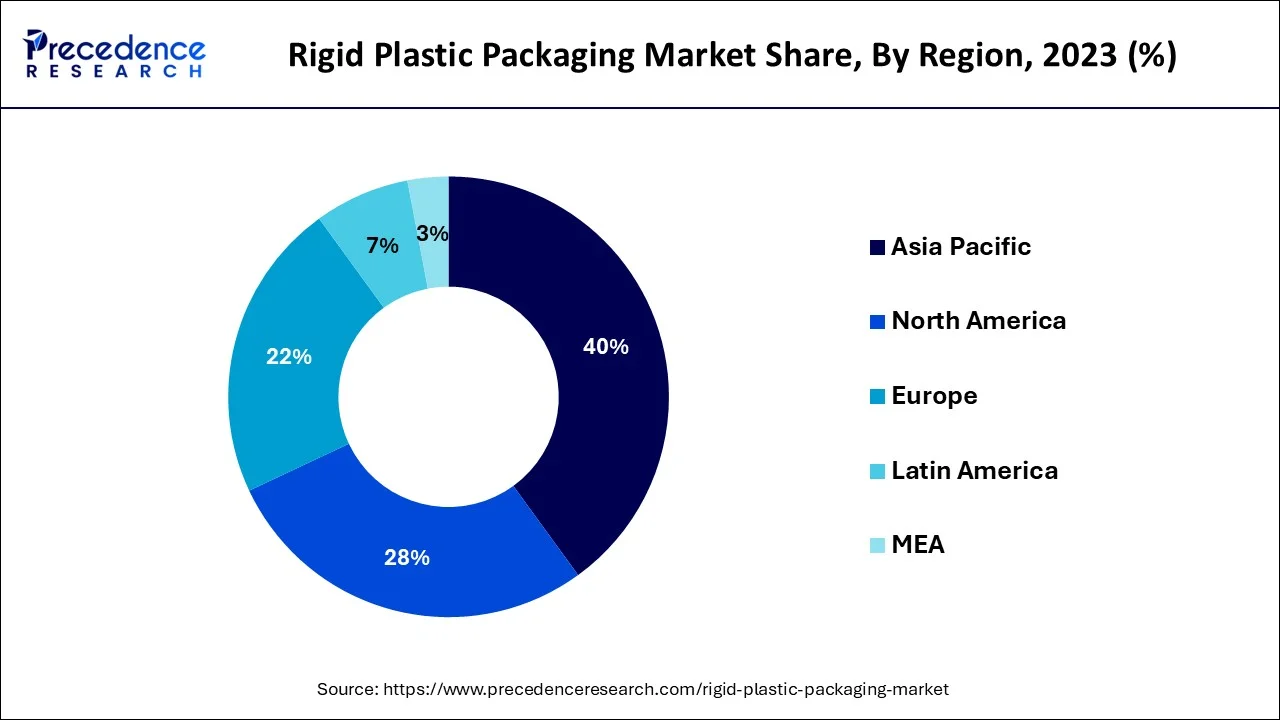

- Asia-Pacific region accounted for 40% of revenue share in 2023.

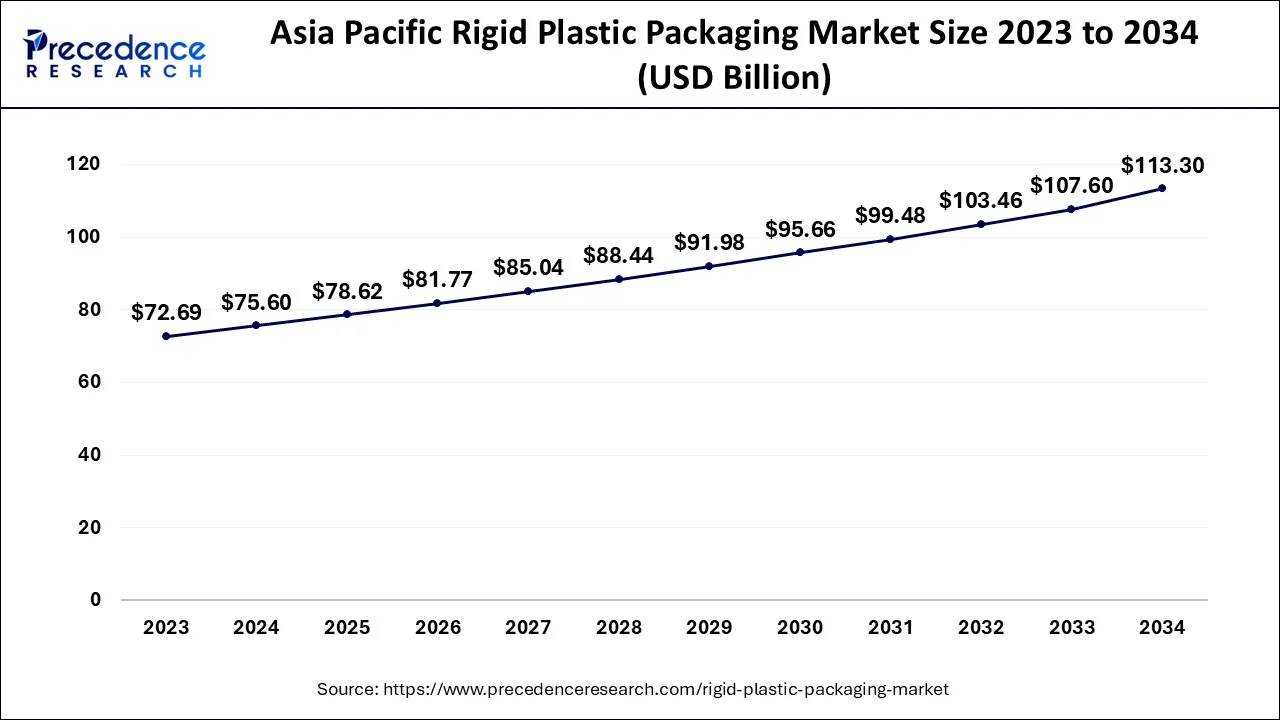

Asia Pacific Rigid Plastic Packaging Market Size and Growth 2024 to 2034

The Asia Pacific rigid plastic packaging market size is evaluated at USD 75.60 billion in 2024 and is predicted to be worth around USD 113.30 billion by 2034, rising at a CAGR of 4.12% from 2024 to 2034.

In 2023, the Asia Pacific area held the greatest share, and it is anticipated that it would continue to hold that position during the projection period. The rigid plastic packaging industry is predicted to grow rapidly in nations like China and India due to their expanding economies and expanding economic activity. In addition, these nations' expanding populations provide a sizable market for FMCG goods and consumer durables, which is anticipated to fuel the expansion of the rigid plastic packaging industry.

The market for rigid plastic packaging has expanded due to important reasons such industrialization, the expansion of the convenience food business, expanding manufacturing activities, rising disposable income, rising consumption levels, and rising e-retail sales during the past several years.

Market Overview

For the packaging of new bottles and containers, rigid plastic packaging uses plastic materials including polypropylene (PP), high-density polyethylene (HDPE), and polyethylene (PET). These materials are lightweight and enduring. Packaging made of polyethylene and polypropylene may be used in a variety of sectors, including food and beverage, agricultural, aerospace, automotive, and medical. The food and beverage industry's explosive growth is a significant factor in the rigid plastic packaging market's rise since it increases demand for bottles, fruit jars, juice containers, food packaging containers, and gastronomic bags. For instance, by 2021, the U.S. hotel market has grown to almost $154.34 billion. Increased demand for electronics switches, containers, and bicycle wheels is further boosting the growth of the global market for rigid plastic packaging. Additionally, market expansion is predicted to be fueled by the expansion of the automotive sector. For instance, Trading Economics predicts that from 2021 to 2023, Mexico's automobile output would increase at a pace of 43.12%. Due to the increased need for plastic packaging systems, rigid plastic packaging solutions are also employed in a variety of industrial verticals, including agriculture, medicine, personal care, and pharmaceuticals.

However, it is projected that strict government restrictions on the use of plastic and fluctuations in the price of raw materials would impede the expansion of the world market for rigid plastic packaging. On the other hand, it is predicted that the increase in e-commerce sales would create profitable chances for the market's expansion.

Rigid Plastic Packaging Market Growth Factors

The growing need for rigid plastic packaging is a result of the expansion of the food and beverage, healthcare, personal care, and other sectors on a global scale. In these businesses, rigid plastic packaging offers qualities including sturdiness, low weight, and flexible packaging. Several processes, including extrusion, injection molding, blow molding, thermoforming, and others are used to create these packing components. To keep the products, secure for a longer period of time, stiff plastic packaging produced from materials like polyethylene, expanded polystyrene, and others is used. Additionally, one of the key factors fueling the expansion of the rigid plastic packaging market is the increase in packaged goods sales, which is a result of changing lifestyles.

Market Scope

| Report Coverage | Details |

| Market Size in 2024 | USD 189 Billion |

| Market Size by 2034 | USD 279.76 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 4% |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Production Process, Material, End User, and Geography |

Market Dynamics

Market Drivers

- Increased package recycling rates: Over the past several years, the reuse and recycling of packaging materials have attracted a lot of attention on a global scale. Recycling is the process of turning garbage into something that may be used again. PET bottles and HDPE milk bottles are frequently seen being recycled. Recycling rigid plastic packaging lowers the need for raw materials, which lessens pollution of the air and water. Hence contributing to the decrease of greenhouse emissions. The CO2 emissions from packaging can also be regulated with recycled materials. Significant recycling rates have been observed for rigid plastic packaging materials. Plans to reduce plastic waste through recycling have been developed by several governments and business stakeholders.

- Growing Demand in the Healthcare Sector - In response to the pandemic, governments are making investments across several continents to improve the healthcare infrastructure of developing countries. Rigid plastic packaging safeguards drugs against infection and is perfect for storing medical items including needles, tablets, syrups, surgical equipment, and others because to its strength, cleanliness, clarity, and light weight. Globally, it is projected that as the healthcare sector grows, so will the demand for rigid plastic packaging. For example, the staff research report on the "US-China Economic and Security Review Commission" projects that by 2030, the Chinese healthcare market would be worth 16 trillion RMB (US$ 2.3 million)." Therefore, it is projected that during the course of the forecast period, the growing healthcare sector would fuel the expansion of the rigid plastic packaging market.

Market Challenges

- Environment-related effects: High density polyethylene (HDPE), expanded polystyrene (EPS), polyethylene terephthalate (PET), and polyvinyl chloride are the polymers that are most commonly used in the packaging industry (PVC). Different industries use rigid plastic packaging to preserve and sustainably store packaged goods including industrial equipment, food, and medical supplies. Recycling, reusing, and segregating plastic garbage is the major issue posed by these polymers. Plastic packaging materials can take up to a thousand years to breakdown in landfills, causing contamination of the land and water. Furthermore, plastics lose mechanical strength when exposed to direct sunshine, while thermoplastics creep and soften at room temperature. Therefore, rigid plastic packaging's negative environmental consequences will restrain market expansion.

Key Market Opportunities

Surging Demand for Rigid Plastic Packaging in Cosmetics & Personal Care

- Rigid plastic packaging is used in the cosmetics and personal care sector for applications such as product packaging for sun care, skin care, oral care, perfume, body care, ornamental cosmetics, and hair care, giving the items frictionless storage and a longer shelf life. The need for rigid plastic packaging is expanding as the cosmetics and personal care sector expands quickly in emerging nations. For instance, the International Trade Administration in Malaysia estimates that the personal care and cosmetics sector would develop at a compound annual growth rate of 4% by 2025. In Thailand, the market for personal care and beauty products generated US$4.2 billion in sales in 2021, and it is projected to increase by 5.5 percent year through 2025. Thus, during the course of the projection period, the market for rigid plastic packaging will expand in tandem with the expansion of the cosmetics and personal care industry.

Use of fiber-based material for packaging

- One of the major rigid plastic packaging market trends driving the market's expansion is the use of fiber-based materials for packaging. One of the best types of sustainable packaging materials is fiber-based material. They may be used to package goods and are recyclable, renewable, or biodegradable. Consumers in the food and beverage, chemical, and construction sectors often favor fiber-based products. As a result, some businesses are selling packaging goods. One such company is Multivac Inc., a German provider of packaging solutions, which sells packaging makers materials made of paper fiber. The product made from components based on paper fibers may be recycled easily, allowing businesses to adhere to international laws. During the anticipated time, these attributes can help the market expand.

Type Insights

In terms of value, the bottles and jars category accounted for the biggest market share in the rigid plastic packaging industry in 2023, and it is anticipated to expand at the second-highest CAGR over the forecast period. Water, juice, carbonated soft drinks, cosmetics, food, personal care, and pharmaceutical goods are just a few of the things that are packaged in rigid plastic bottles. These bottles and jars are mostly constructed out of PET, PE, PP, HDPE, PS, and PVC. The expanding retail sector in addition to customers' rising disposable money. The market is expanding due to the increased demand for drinks and home care goods as well as the growing urbanization and population.

Production Process Insights

During the anticipated period, the extrusion segment is anticipated to dominate the rigid plastic packaging market. The method allows for the creation of components and products with a range of straightforward to extremely complicated continuous cross-sections by accommodating a wide range of die profiles. The extruded rolling stock doesn't need to cure before thermoforming. The overall materials and waste costs for an extrusion operation are cheaper than those of other molding processes because thermoplastics—which may repeatedly go through the melting, moulding, and hardening operations—are frequently used in extrusion processes.

Material Insights

In 2023, the rigid plastic packaging market's greatest share belonged to the polypropylene (PP) material category. In comparison to other plastic materials like polystyrene (PS), polyethylene terephthalate (PET), and others, polypropylene offers superior barrier qualities, improved surface polish, cheap cost, and high tensile strength.

These features make polypropylene an ideal material for a range of packaging applications. Some of the expanding uses for polypropylene include medicine bottles, ketchup and syrup containers, and bottle caps and closures. The market for rigid plastic packaging will thus continue to increase over the projected period as a result of the rising demand for the polypropylene (PP) material.

End User Insights

The market for rigid plastic packaging was dominated by the food and beverage sector in 2022, and it is anticipated to expand at a CAGR of 5.35% from 2024 to 2034. The stiff plastic packaging gives the containers qualities like taste absorption, durability, lifespan, and low weight. Bottles, cans, jars, and other rigid plastic packing containers keep the food item secure and free from contamination. In developing nations including the United States, Canada, China, India, and other nations, the need for rigid plastic packaging is rising quickly. The need for rigid plastic packaging is rising as the food and beverage sector expands.

Rigid Plastic Packaging Market Companies

- ALPLA-Werke Alwin Lehner GmbH & Co KG

- Amcor Limited

- DS Smith Plc

- Berry Plastics Corporation

- Klöckner Pentaplast

- Plastipak Holdings, Inc.

- Pactiv Evergreen Inc

- Sealed Air Corporation

- Silgan Holdings, Inc.

- Sonoco Products Company.

Recent Developments

- ALPLA Group kept up its global expansion of its recycling initiatives as of September 2020. The family-run business from Austria is now constructing an HDPE recycling facility in Mexico. Each year, 15,000 tons of post-consumer recycled material are expected to be produced.

- Amcor created the lightweight 900-ml Polyethylene Terephthalate bottle for edible oil in Brazil in November 2020 by modifying its cutting-edge engineering and design technologies. The specially created container for So Paulo-based agribusiness and food giant Bunge is 22% lighter than comparable bottles while offering higher productivity and more sustainable advantages.

- Sonoco purchased Plastique Holdings, Ltd. and Thermoform Engineered Quality, LLC in January 2020; the combined company is now known as SONOCO TEQ.

- In order to produce its BottleOne integrated handle PET bottle for the market, Practically Impossible Labs created a strategic relationship with Silgan, Krones, and Husky in September 2018.

Segments covered in the report

By Type

- Bottles & Jars

- Rigid Bulk Products

- Trays

- Tubs, Cups, & Pots

- Others

By Production Process

- Extrusion

- Injection Molding

- Blow Molding

- Thermoforming

- Others

By Material

- Polyethylene (PE)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Expanded Polystyrene (EPS)

- Bioplastics

- Others (PC, Polyamide)

By End User

- Food

- Meat, Seafood, and Poultry

- Ready to Eat Meals

- Dairy Products

- Bakery and Confectionery

- Other Food Products

- Beverages

- Alcoholic Beverages

- Non-alcoholic Beverages

- Healthcare

- Cosmetics & Toiletries

- Industrial

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

Get a Sample

Get a Sample

Table Of Content

Table Of Content