What is the Rubber Processing Chemicals Market Size?

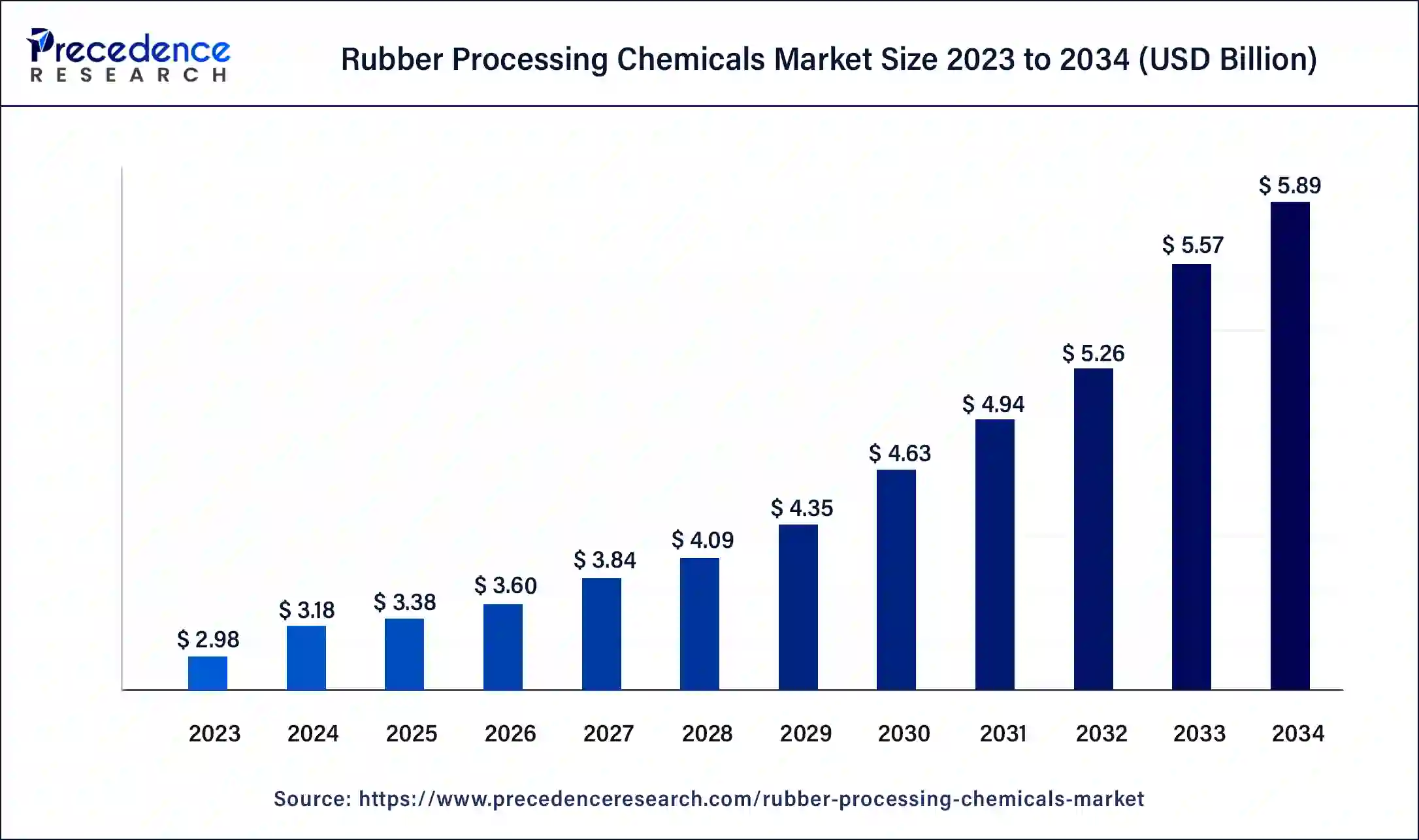

The global rubber processing chemicals market size was USD 3.38 billion in 2025, accounted for USD 3.60 billion in 2026, and is expected to reach around USD 6.20 billion by 2035, expanding at a CAGR of 6.25% from 2026 to 2035.

Rubber Processing Chemicals Market Key Takeaways

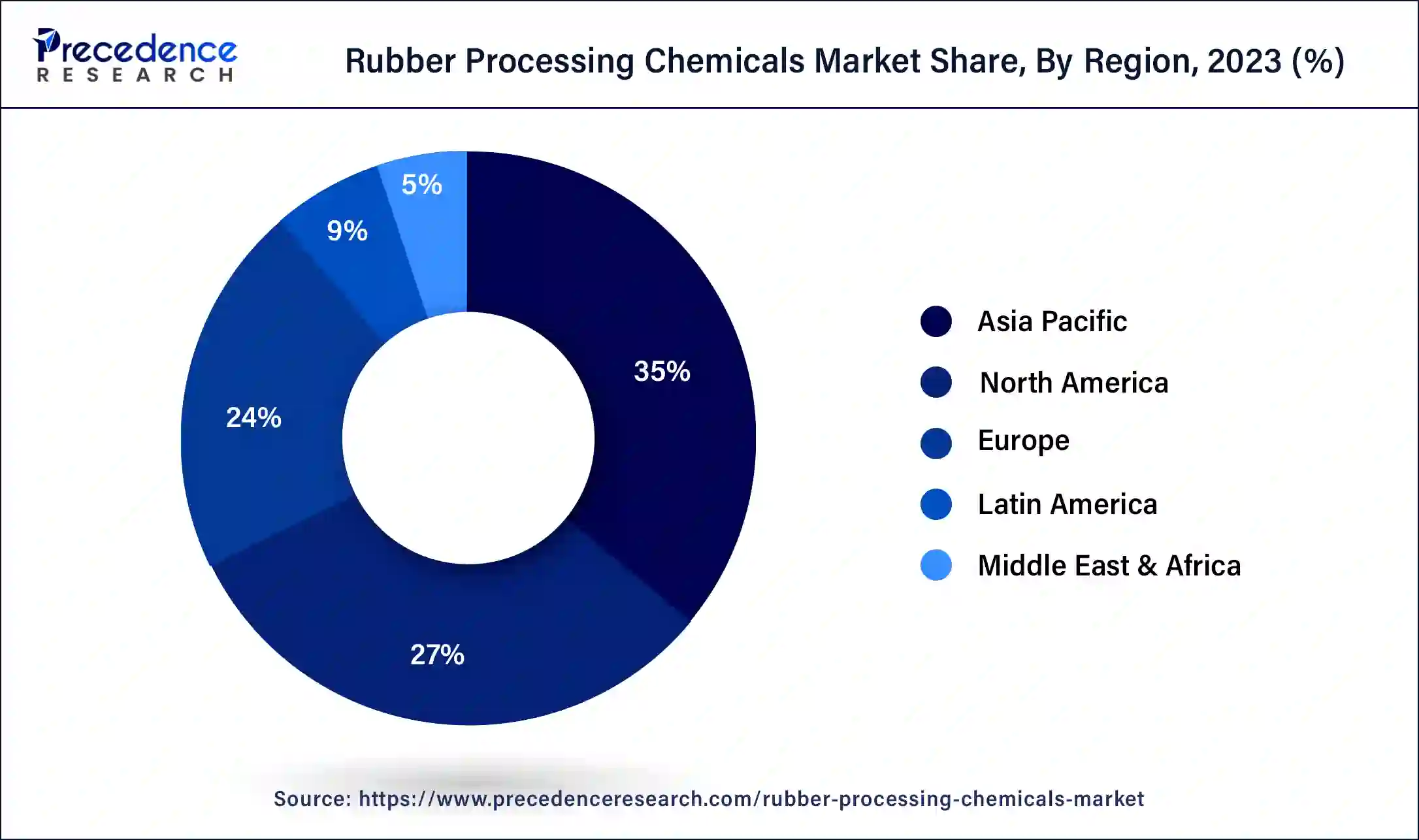

- Asia-Pacific contributed more than 35% of revenue share in 2025.

- Europe region is expected to expand at the fastest CAGR over the forecast period.

- By Product, the anti-degradants contributed around 35.4% of revenue share in 2025.

- By Product, the accelerators segment is expected to expand at a fastest CAGR of 7.8% during the projected period.

- By Application, the automotive components segment is anticipated to hold the highest market share of 28.3% in 2025.

- By Application, the industrial rubber products segment is projected to grow at the fastest CAGR over the projected period.

- By End-use, the tier segment contributed the highest market share of 57% in 2025.

- By End-use, the non-tier is anticipated to expand at the fastest CAGR over the projected period.

What are Rubber Processing Chemicals?

- The rubber processing chemicals market involves chemicals and additives that enhance rubber properties, including durability, elasticity, and heat resistance. These improvements enable rubber's use in diverse applications, such as automotive tires, industrial goods, and footwear.

- The rubber processing chemicals industry is characterized by its dynamic nature, influenced by technological advancements, strict quality criteria, and environmental considerations. Meeting regulatory standards and developing eco-friendly solutions remain central drivers, fostering innovation and competitiveness within the industry.

- The rubber processing chemicals market dynamism is propelled by continuous technological advancements, exacting quality standards, and mounting environmental concerns. Strive to comply with rigorous regulatory requirements and foster the development of eco-friendly solutions.

How is AI contributing to the Rubber Processing Chemicals Industry?

Artificial intelligence provides the means to design formulations based on data analysis, to control processes automatically, to carry out maintenance predictively, to inspect quality intelligently, to manage supply chains optimally, to improve sustainability, etc., thus ascertaining rubber processing chemical producers to achieve global operations that are more efficient, safer, more innovative, and with consistent product performance throughout the value chain.

Rubber Processing Chemicals Market Growth Factors

- Rubber processing chemicals play a vital role in improving rubber's durability, elasticity, heat resistance, and other essential characteristics, making it suitable for a wide range of applications, including automotive tires, industrial products, and footwear.

- The market's dynamic nature is driven by technological advancements, stringent quality standards, and growing environmental concerns, shaping the industry's landscape.

- Furthermore, there is increasing demand for eco-friendly and sustainable solutions. Environmental concerns and regulatory requirements are pushing manufacturers to develop greener alternatives, spurring innovation, and offering growth opportunities.

- Additionally, the surge in the automotive and industrial sectors is a significant growth driver. As these industries expand, the demand for high-performance rubber materials escalates, bolstering the need for advanced rubber processing chemicals.

Market Outlook

- Industry Growth Overview: The market enjoys a slow but steady growth as the automotive industry keeps expanding and the demand for rubber processing applications gets broader.

- Sustainability Trends: The industry is moving towards eco-friendly formulations, bio-based alternatives, and recycling practices as a result of environmental regulations.

- Global Expansion: Asia Pacific is the major contributor to the growth, while North America is still an important player, as it has adopted and is spreading the use of advanced rubber technologies globally.

- Major Investors: The list of major investors includes NOCIL, Apollo Tyres, Grasim Industries, and Eastman Chemical Company, which are globally involved.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2026 to 2035 | CAGR of 6.25% |

| Market Size in 2025 | USD 3.38 Billion |

| Market Size in 2026 | USD 3.60 Billion |

| Market Size by 2035 | USD 6.20 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | By Product, By Application, and By End Use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Industrial, construction and automotive sector demand

The demand from the industrial and construction sectors significantly boosts the rubber processing chemicals market. These sectors rely on rubber materials for applications like conveyor belts, hoses, and seals. As industrialization and infrastructure development continue to expand globally, the need for high-quality rubber products escalates, driving the requirement for processing chemicals.

The reliability and durability of rubber components in these sectors are critical, making the role of rubber processing chemicals indispensable in meeting stringent performance and safety standards. Moreover, the rising demand for fuel-efficient, high-performance vehicles in the automotive industry drives the need for advanced rubber components like tires and seals. To meet these demands, the rubber processing chemicals market experiences increased growth as manufacturers seek additives to enhance rubber properties, ensuring safety, performance, and efficiency in vehicles.

Restraint

Regulatory compliance complexity and environmental impact

Regulatory Compliance complexity hampers market demand in the rubber processing chemicals market by imposing burdensome requirements on manufacturers. Meeting evolving environmental and safety standards, such as REACH and EPA regulations, demands significant investments in research, testing, and documentation. These complexities can increase production costs and hinder product innovation. Environmental impact concerns pose a restraint on the rubber processing chemicals market. Emissions of volatile organic compounds (VOCs) during manufacturing processes contribute to air pollution and environmental degradation. Increasing regulations to curb emissions and reduce the industry's carbon footprint require costly process modifications.

Additionally, heightened consumer awareness of sustainability and eco-friendliness prompts the demand for greener alternatives. Manufacturers must adapt to these environmental pressures to align with regulatory standards and changing consumer preferences, impacting market dynamics. Heightened environmental impact concerns, including emissions like volatile organic compounds (VOCs) during manufacturing, have resulted in heightened scrutiny and regulatory actions. Compliance with these stringent environmental standards often necessitates costly modifications to production processes and the development of environmentally friendly alternatives, impacting the industry's dynamics.

Opportunity

Specialized formulations and supply chain optimization

Specialized formulations in the rubber processing chemicals market significantly boost market demand by offering tailored solutions to diverse industries. Customized rubber compounds are designed to meet specific performance, durability, and environmental criteria address unique challenges, creating a strong value proposition. This fosters partnerships with end-users and builds customer loyalty. The ability to provide bespoke solutions not only enhances market competitiveness but also drives increased demand as industries seek high-performance rubber materials precisely suited to their needs. Moreover, supply chain optimization in the rubber processing chemicals market enhances market demand by ensuring a reliable supply of raw materials and timely deliveries. Efficient logistics and reduced production disruptions result in stable product availability, which instills confidence in customers and fosters increased demand for these essential chemicals in the market.

Segment Insights

Product Insights

According to the product, the anti-degradants held 35.4% revenue share in 2023. Anti-degradants are a class of rubber processing chemicals designed to protect rubber materials from degradation caused by environmental factors such as heat, oxygen, and UV radiation. In the rubber processing chemicals market, a notable trend is the growing demand for eco-friendly anti-degradants, aligning with sustainability goals. Manufacturers are developing formulations that provide effective protection while minimizing the environmental impact. Additionally, advancements in nanotechnology are enhancing the efficiency of anti-degradants, offering improved performance characteristics in rubber products.

The accelerators segment is anticipated to expand at a significant CAGR of 7.8% during the projected period. Accelerators in the rubber processing chemicals market are substances that hasten the vulcanization process, enhancing rubber's physical properties like elasticity and durability. A notable trend in this segment involves the development of eco-friendly accelerators to align with sustainability goals and regulatory compliance. Manufacturers are increasingly focusing on non-nitrosamine accelerators and those with lower environmental impact. This trend reflects the industry's commitment to greener alternatives and addressing environmental concerns in rubber processing.

Application Insights

By application, automotive components is anticipated to hold the largest market share of 28.3% in2023. Automotive components in the rubber processing chemicals market refer to rubber-based parts used in vehicles, including tires, seals, gaskets, and hoses. A significant trend in this segment is the growing demand for performance-enhancing additives to optimize tire efficiency, fuel economy, and safety. Additionally, the development of eco-friendly rubber compounds aligns with the automotive industry's sustainability goals, fostering innovation in processing chemicals for automotive applications. This trend reflects the industry's commitment to improving both performance and environmental impact.

On the other hand, the industrial rubber products segment is projected to grow at the fastest rate over the projected period. Industrial rubber products, including conveyor belts, hoses, gaskets, and seals, rely on rubber processing chemicals for enhanced durability and performance. A key trend in the rubber processing chemicals market is the increasing demand for these chemicals in the industrial sector. As industries expand, the requirement for high-quality rubber products escalates, prompting the use of advanced processing chemicals. Additionally, there is a growing focus on sustainability, pushing manufacturers to develop eco-friendly additives tailored for industrial applications.

End-use Insights

In2023, the tier segment had the highest market share of 57% on the basis of the installation. Tire is a prominent end-use segment in the rubber processing chemicals market. Rubber processing chemicals play a vital role in enhancing tire performance, durability, and safety. Key trends in this segment include the growing demand for high-performance tires with reduced rolling resistance to improve fuel efficiency. Additionally, eco-friendly tire manufacturing is gaining momentum, driving the development of sustainable rubber processing chemicals to meet both regulatory requirements and consumer preferences for greener products.

The Non-Tier is anticipated to expand at the fastest rate over the projected period. In the rubber processing chemicals market, the "Non-Tire" segment refers to the utilization of rubber processing chemicals in applications other than tire manufacturing. This segment encompasses various industries such as automotive components, industrial goods, footwear, and construction materials. Current trends in the non-tire sector include the rising demand for eco-friendly rubber additives, customization of rubber compounds for specific industrial needs, and the integration of advanced manufacturing technologies to enhance product quality and efficiency in various non-tire applications.

Regional Insights

What is the Asia Pacific Rubber Processing Chemicals Market Size?

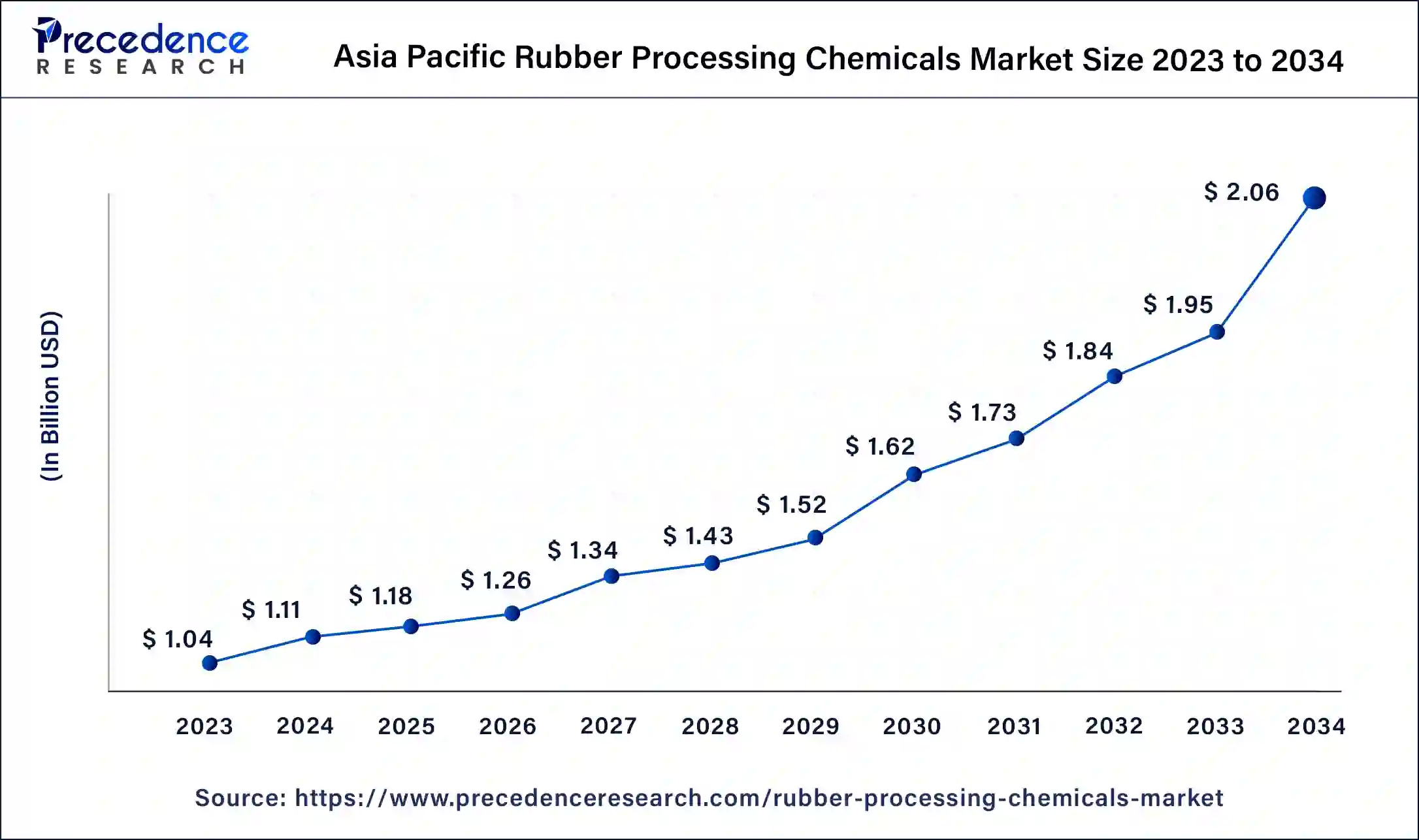

The Asia Pacific rubber processing chemicals market size was estimated at USD 1.18 billion in 2025 and is predicted to be worth around USD 2.17 billion by 2035, at a CAGR of 6.28% from 2026 to 2035.

Asia-Pacific has held the largest revenue share 35% in 2023. In the Asia-Pacific region, the rubber processing chemicals market is witnessing substantial growth driven by the thriving automotive and manufacturing sectors. The demand for high-performance rubber components, particularly in countries like China and India, is surging. Additionally, increased environmental regulations are pushing manufacturers to adopt eco-friendly additives and compounds. The region's economic expansion and focus on sustainable solutions are shaping the evolving landscape of the rubber processing chemicals industry in Asia-Pacific.

Europe is estimated to observe the fastest expansion. In Europe, the rubber processing chemicals market is witnessing trends driven by environmental concerns and stringent regulations. The region is increasingly focused on eco-friendly and sustainable rubber processing chemicals, aligning with its commitment to reducing environmental impact. Additionally, the automotive sector's transition towards electric vehicles and greener technologies is shaping the demand for advanced rubber additives that improve tire efficiency and reduce emissions. Customized solutions and partnerships with end-users are also on the rise to meet diverse industry needs.

Moreover, in North America, the rubber processing chemicals market is witnessing several notable trends. There is a growing focus on sustainable and eco-friendly solutions, driven by stringent environmental regulations. The region also sees increasing demand from the automotive industry for high-performance rubber components. Customization and specialized formulations are gaining prominence as manufacturers collaborate closely with end-users. Additionally, advancements in digitalization and automation are enhancing production processes, increasing efficiency, and driving innovation within the market.

Rubber Processing Chemicals Market-Value Chain Analysis

- Feedstock Procurement: The activity of acquiring and managing oil, gas, and minerals that are necessary for the chemical production process.

Key Players: ExxonMobil, SABIC, Reliance Industries - Chemical Synthesis and Processing: Carrying out the reactions and performing the processing to turn the raw materials into the final products.

Key players: BASF SE, Dow Inc., Mitsubishi Chemical Corporation - Quality Testing and Certification: The process of inspecting and confirming that the products meet the quality and safety standards as well as the regulatory requirements.

Key players: SGS, Intertek, Bureau Veritas

Rubber Processing Chemicals Market Companies

- BASF SE: BASF SE's chemical products for rubber processing consist of amines and tackifiers, which are the building blocks of the efficient vulcanization process and are applied in many different industrial areas.

- Lanxess AG: Lanxess AG's rubber additives portfolio comprises a wide range of products such as accelerators, antidegradants, and processing promoters, which improve the durability of the rubber performance across various manufacturing applications.

- Akzo Nobel N.V.: Akzo Nobel N.V. has stopped selling rubber processing chemicals as it has sold off that segment during the separation of chemicals, focusing on its core business.

Other Major Key Players

- Solvay S.A.

- Eastman Chemical Company

- Arkema Group

- Sumitomo Chemical Co., Ltd.

- LG Chem Ltd.

- Nouryon

- Emerald Performance Materials LLC

- Vanderbilt Chemicals, LLC

- Behn Meyer Holding AG

- Struktol Company of America, LLC

- Lanxess Corporation

- Kraton Corporation

Recent Developments

- In November 2025, LANXESS expanded its Rhein Chemie site in Qingdao, increasing capacity by 50% and upgrading production lines for processing promoters and polymer-bound rubber chemicals to meet growing demand for local rubber additives. (Source: https://www.chinadaily.com.cn )

- In 2020, Arkema announced its acquisition of Fixatti, a producer of high-performance thermobonding adhesive powders. This strategic move enhances Arkema's capabilities in rubber and thermoplastic elastomer applications, strengthening its position in the specialty chemicals industry.

- In 2018, LANXESS has successfully completed the sale of ARLANXEO, a synthetic rubber joint venture, to Saudi Aramco. This strategic move aligns with LANXESS' portfolio optimization strategy and enhances Saudi Aramco's position in the rubber and petrochemical industry.

- In 2018, AkzoNobel Specialty Chemicals successfully concluded the acquisition of Polinox, a leading provider of products for the thermoset industry, in a strategic move to expand its presence and product offerings in the rubber and thermoset markets.

- In 2017, Cabot Corporation and Dow celebrated the groundbreaking of a new manufacturing plant. This strategic collaboration aims to produce polymer-bound rubber chemicals, fostering innovation and expanding their presence in the rubber processing chemicals industry.

- Eastman Chemical Company has completed the acquisition of Taminco Corporation. This strategic move bolsters Eastman's position in specialty chemicals, including rubber processing additives, and strengthens its portfolio to better serve its global customer base.

- Arkema acquisition of Bostik, a global adhesive and sealants manufacturer. This strategic move expands Arkema's product portfolio and market presence, including in the rubber processing chemicals sector.

- Sumitomo Chemical Company has acquired Nihon Oxirane Co. Ltd., bolstering its presence in the rubber processing chemicals industry. This acquisition adds epoxy resin products to Sumitomo's portfolio, enhancing its offerings in the market.

- Solvay is acquiring ERCA Emery Surfactant, a strategic move to bolster its position in the specialty chemicals industry. This acquisition enables Solvay to expand its portfolio with specialty surfactants, further enhancing its offerings in various markets.

Segments Covered in the Report

By Product

- Anti-degradants

- Accelerators

- Flame Retardants

- Processing aids/Promoters

- Others

By Application

- Tire and Related Products

- Automotive Components

- Footwear Products

- Industrial Rubber Products

- Others

By End Use

- Tire

- Non-Tire

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting