What is the Single-use Bioprocessing Market Size?

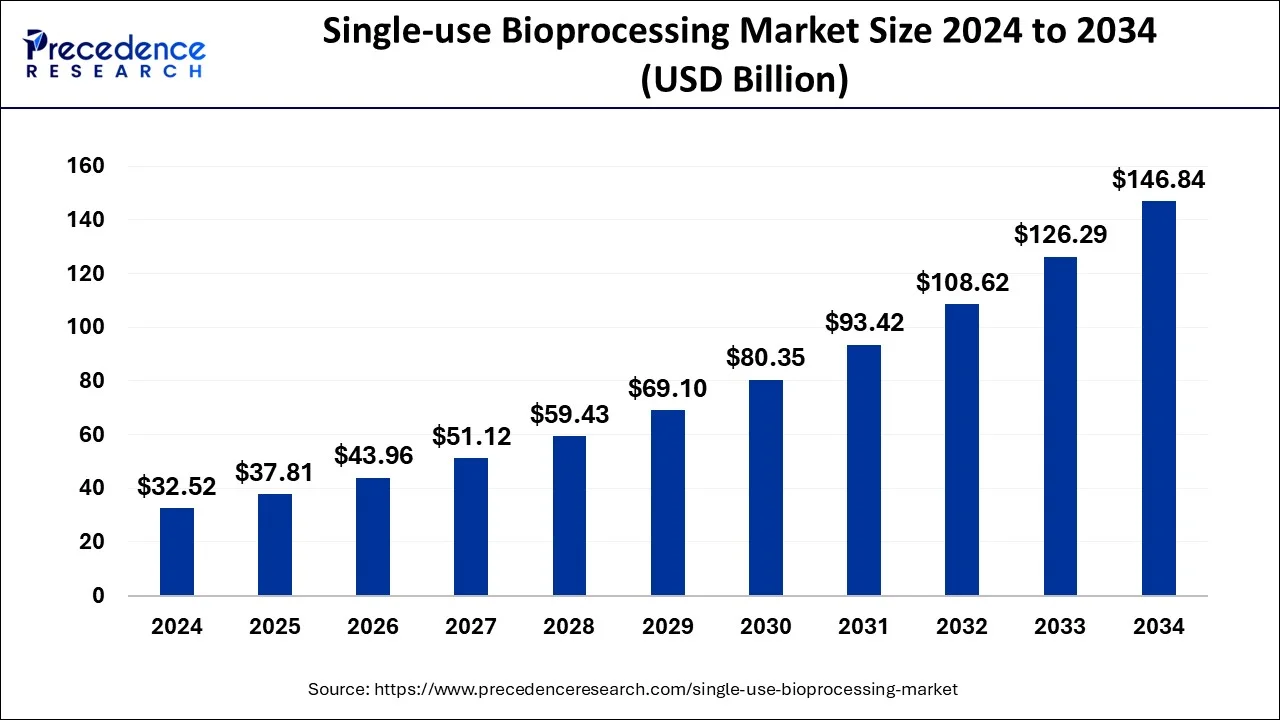

The global single-use bioprocessing market size is estimated at USD 37.81 billion in 2025 and is anticipated to reach around USD 167.39 billion by 2035, expanding at a CAGR of 16.04% from 2026 to 2035.

Single-use Bioprocessing Market Key Takeaway

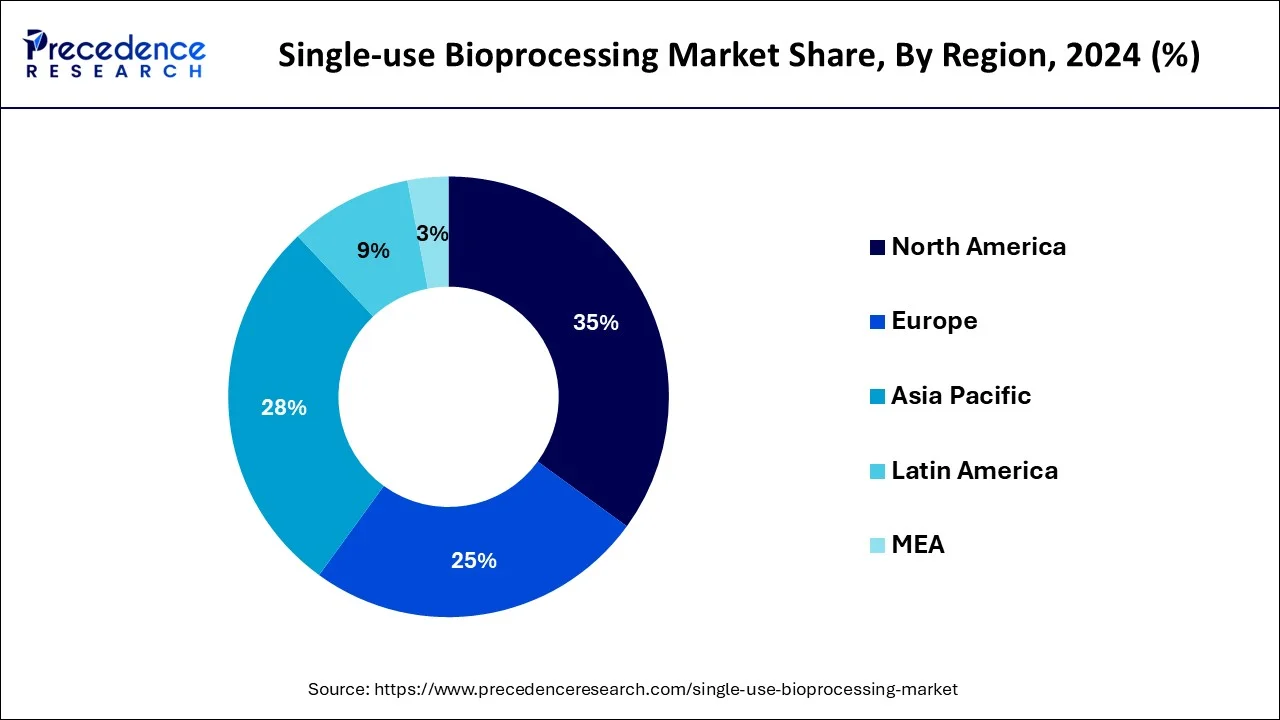

- North America has captured revenue share of 35% in 2025.

- Asia Pacific region is anticipated to grow at fastest CAGR over the forecast period 2026 to 2035.

- By Product, the simple & peripheral elements segment has accounted largest revenue share in 2025.

- By Workflow, the upstream bioprocessing segment recorded significant revenue share in 2025.

- By End-use, the biopharmaceutical manufacturers segment has held largest revenue share in 2025.

How Can AI Improve the Bioprocessing?

Artificial intelligence (AI) introduces automation in bioprocessing methods, enhancing process efficiency, optimizing production workflows, and improving overall output. Several key players have incorporated AI and machine learning (ML) in bioprocessing to improve process analytics, process control, product characterization, supply chain management, and factory operations. AI-enabled robots perform numerous tasks during bioprocessing leading to increased productivity and reducing manual errors due to human intervention. AI can also aid in real-time monitoring resulting in timely decision-making and multivariate analysis. AI enables predictive maintenance to detect errors during manufacturing, improving overall process reliability and product quality. Thus, these advanced technologies significantly influence the market dynamics by introducing new efficiencies and capabilities in bioprocessing applications.

Market Overview

Bioprocessing is the process of manufacturing products using living organisms, cells, or their components. It is useful in the production of biopharmaceuticals, food, and biofuels. It has numerous applications in the manufacturing of biologics, vaccines, monoclonal antibodies, and biotherapeutics. Single-use bioprocessing refers to vessels, conduits, and consumables that come into contact with process fluids and are then discarded. The traditional bioprocessing method involves using stainless steel equipment, whereas single-use bioprocessing involves using high-performance polymer materials. Some common examples of polymers include polyethylene, polypropylene, polyethersulfone, polytetrafluoroethylene, cellulose acetate, and polyamide. Single-use bioprocessing offers numerous advantages, such as cost reduction, increased productivity, simplified disposal, reduced energy and media consumption, efficient use of time and resources, and minimized risk of cross-contamination.

Single-use Bioprocessing Market Growth Factors

- Rapidly Expanding Biopharmaceutical Sector: The market is significantly driven by the growing demand from the biopharmaceutical industry.

- Rising Incidences of Chronic Disorders: The rising incidences and prevalence of chronic disorders due to the increasing geriatric population necessitate the development of biologicals, augmenting market growth.

- Technological Advancements: Technological advancements automate the bioprocessing method, increasing its demand.

- Increasing Investments: The increasing funding by several government and private organizations for manufacturing also propels market growth.

Major Trends of the Single-Use Bioprocessing Market

- Biologics manufacturing is experiencing an accelerated swing towards single-use components instead of stainless-steel systems, to reduce cross-contamination and increase production turnaround time.

- Manufacturers are also meeting the increasing demand for modular, flexible, pre-sterilized bioprocessing components that support multiple products and provide greater facility flexibility.

- The movement towards disposable bioprocessing workflows led to the integration of automation, smart sensors, and digital monitoring as well.

- In addition to the increased use of disposable bioprocessing elements, it has become increasingly important for manufacturers to ensure their suppliers are meeting regulatory expectations, as well as verifying material traceability.

Market Outlook:

- Industry Growth Outlook: The market has experienced a continuous increase in growth as a result of the rising demand for biologics, quicker clinical timeframes, and greater interest in utilizing more flexible manufacturing systems, leading to lower capital expenditures and reduced complexity in operations.

- Sustainability Trends: Manufacturers are emphasizing making eco-efficient buildings through the reduction of material applications, enhancement of waste management programs, and exploration of alternative polymers for the eco-responsible performance of their products.

- Global Expansion: As the establishment of biomanufacturing facilities continues to expand in Asia, Latin America, and the Middle East, favourable government policies and local production incentives have helped to promote this expansion. As a result, businesses have experienced increased investment in biologics infrastructure.

- Startup Ecosystem: Biotech start-ups have increasingly begun to utilise single-use technologies to decrease their initial costs, accelerate their facility development timelines, and enable a quicker transition from clinical to commercial production.

Market Scope

| Report Coverage | Details |

| Market Size in 2026 | USD 43.96 Billion |

| Market Size in 2025 | USD 37.81 Billion |

| Market Sizeby 2035 | USD 167.39 Billion |

| Growth RateFrom 2026 to 2035 | CAGR of 16.04% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Product, End User, Application, Workflow, Region |

Market Dynamics

Driver

Growing Demand for Biologics

The growing demand for biological therapeutics due to rising incidences of chronic disorders such as cancer and autoimmune disorders boosts the single-use bioprocessing market. Biologics including vaccines, monoclonal antibodies, and antibodies are a crucial part of the pharmaceutical sector. They can provide targeted treatments for the patients, enhancing the efficacy of drug products. The favorable regulatory policies and rising investments from various organizations increase the demand for biologics. The latest innovations in single-use bioprocessing enable manufacturers to accelerate biological manufacturing processes. The growing research and development activities lead to the development of novel biologics. The post-pandemic era has significantly increased the demand for biologics, resulting in more product approvals. In 2023, the U.S. FDA approved 17 biologics out of a total of 55 new drugs.

Restraint

Environmental Impact and Leakage

The major challenge of the single-use bioprocessing market is the environmental impact caused due to the use of single-use plastics. The excessive use of plastics increases the carbon footprint which is difficult to recycle. This imposes a negative impact on the environment, hindering market growth. Another major challenge of the market is the leakage of the extractables and leachables from the plastic surface. This is significantly harmful to the patients.

Opportunity

Precision Medicine

The future of the single-use bioprocessing market is promising, owing to the growing preference for personalized medicines. Precision medicine is at the forefront of the drug development and manufacturing sector, which has experienced remarkable growth over the last two decades due to the rise in cell and gene therapy and highly tailored biologics. Since precision medicines are designed for a limited population, they do not require tedious large-scale manufacturing operations. Thus, single-use bioprocessing plays a major role in producing precision medicines. Single-use reactors, membranes, and chromatography systems can reduce time spent on lengthy cleaning processes. After manufacturing a particular therapeutic, the bioprocessing equipment can be discarded, ultimately saving time and costs of manufacturers.

Product Insights

The media bags and containers segment led the global single-use bioprocessing market with remarkable revenue share in 2024 and is anticipated to retain its dominance throughout the forecast period. The use of media bags and containers offers low investment, lower wastes emission, and lower operational costs in the biopharmaceutical industry. Moreover, the single-use media bags and containers offers temperature resistance along with durability. Therefore, the extensive use of media bags and containers in the biopharmaceuticals have augmented the segment growth in the recent years.

End User Insights

The biopharmaceutical manufacturers segment led the market in 2025 and the rapid growth of biopharmaceuticals industry is significantly boosting the growth of this segment. Moreover, more than 80% of the biopharmaceutical plants have adopted the single-use bioprocessing systems as this is cheaper, efficient, and reliable.

The extensive and increasing use of single-use or disposables by the contract manufacturers have augmented the segment growth. Furthermore, the increased demand for the single-use bioprocessing systems in various bioprocessing services is expected to foster the market growth in the foreseeable future.

Application Insights

The filtration segment led the global single-use bioprocessing market with a remarkable revenue share in 2025 and is anticipated to retain its dominance throughout the forecast period. This is attributed to the increasing adoption of single-use bioprocessing system in filtration owing to its efficient filtration even at large scale. It is used for bioburden reduction, polishing of biomolecules, and for ultrafiltration.

Workflow Insights

The upstream segment held a major share of the single-use bioprocessing market in 2024. Upstream single-use bioprocessing is the use of single-use technologies in the initial stages of bioprocessing, where cells or microorganisms are cultivated and prepared for further biomanufacturing. Upstream processing involves disposable bioreactors, mixers, containers, tubing, connectors, probes/sensors, and sampling systems. The segment's growth is attributed to its superior advantages, such as shortened timelines, lowered operational costs, and reduced cleaning needs.

The fermentation segment is predicted to witness significant growth in the market over the forecast period. Single-use fermentation bioprocessing optimizes microbial fermentation, offering flexibility, ease of use, and efficiency. It requires less amount of samples, decreasing validation requirements. It enables rapid scaling of fermentation processes.

Regional Insights

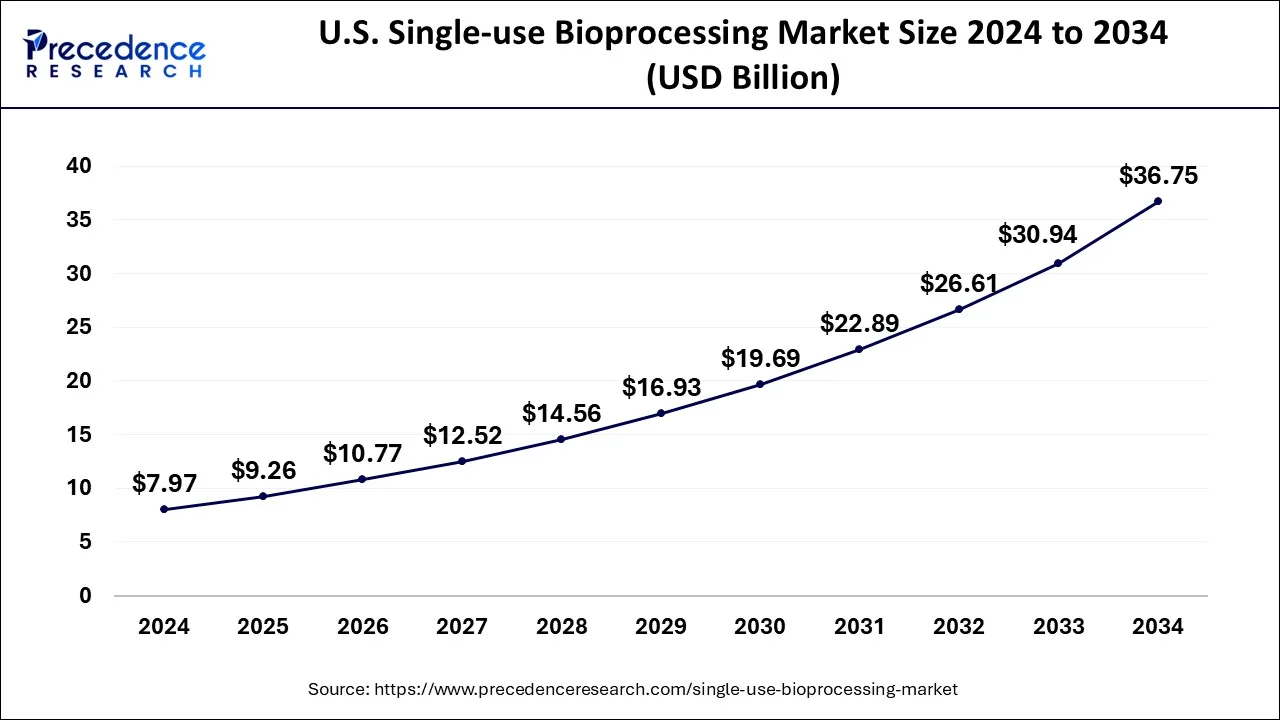

U.S. Single-use Bioprocessing Market Size and Growth 2026 to 2035

The U.S. single-use bioprocessing market size was evaluated at USD 9.26 billion in 2025 and is predicted to be worth around USD 42.56 billion by 2035, rising at a CAGR of 16.48% from 2026 to 2035.

The North America dominated the market with revenue share of 35% in 2025 and is estimated to be the most opportunistic market. This is attributed to the rapid growth and development of biopharmaceutical industry in the region. Moreover, the outbreak of the COVID-19 pandemic stimulated the government to invest heavily in the research and development of the COVID-19 vaccines, diagnostics tests, and drugs. The US government sanctioned over US$ 480 million to Moderna, Inc., for the development of COVID-19 vaccines. The Canada government spent around US$ 160 million in 2020, towards the development of vaccines and drugs for COVID-19 treatment.

The presence of giant players, largescale production units, growing adoption of disposables, increased expenditure in health care, and highly developed healthcare infrastructure are the top factors augmenting the North America single-use bioprocessing market. Moreover, the numerous contract manufacturers and the growing usage of disposables amongst them is exponentially driving the single-use bioprocessing market in the region.

The Asia Pacific has potential growth opportunities owing to the growing biopharmaceutical market in the nations such as China, Japan, and India. Moreover, rising investments by the biotechnology and pharmaceutical companies and the rapid growth of the contract manufacturers may lead to the emergence of Asia Pacific to be the manufacturing hub for the pharmaceuticals. Hence, the region may contribute significantly towards the growth of the single-use bioprocessing market in the forthcoming years.

Innovation in Single-Use Bioprocesses in Europe

Single-use bioprocessing has seen rapid growth in usage and adoption across Europe due to the presence of established biologics manufacturers and strong regulatory frameworks. A wealth of contract development and manufacturing organisations are established in Europe, and these organisations tend to utilise flexible and disposable equipment, which is ideal for single-use processes.

In addition, the increase in funding to create cell and gene therapy therapies has further driven the increasing usage of single-use systems.

Latin America's Growth of Biopharmaceutical Production and Usage of Single-Use Bioprocessing Technology

The landscape for biopharmaceutical manufacturing and development has significantly changed in the last five years in Latin America. The adoption of single-use bioprocessing technology is growing steadily as the region's biologics and biosimilars are produced at greater volumes by many local companies, and these countries are focused on increasing local manufacturing to reduce their reliance on imports.

Slow Strategic Growth in the Middle East and Africa

The development of the MEA bioprocessing market is primarily being driven by local governments creating partnerships with global bioprocessing firms to construct and operate state-of-the-art production facilities to support the need for vaccines throughout the market.

As the usage of single-use systems grows in popularity due to lower capital expenditure requirements, automation, and reduced complexity to operate, the growing demand for biologic product offerings will also continue to penetrate the MEA market.

Key Companies & Market Share Insights

The market is moderately fragmented with the presence of several local companies. These market players are striving to gain higher market share by adopting strategies, such as investments, partnerships, and acquisitions & mergers. Companies are also spending on the development of improvedand efficient solutions. Moreover, they are also focusing on maintaining competitive pricing.

In February 2020, MabPlex, a contract manufacturing company, launched two new cell culture production lines with 2000-liter disposable bioreactors. The various developmental strategies undertaken by key market players increases competition and contributes significantly towards the development of single-use bioprocessing market.

Value Chain Analysis of the Single-Use Bioprocessing Market

- Medical Grade Polymer and Elastomer Processing: The company utilizes medical processors as well as uses the highest quality materials to ensure chemical compatibility, sterility, and leachable control, which represent the basic materials that are vital to manufacturers meeting regulatory compliance and ensuring consistent material performance.

Key Suppliers in this area: Saint-Gobain, Celanese, and Dow. - Manufacturing: of components and assembly includes precision molding, cleanroom assembly, and gamma sterilization as defining characteristics for the manufacture of components and assembly to produce scalable, ready-to-use bioprocessing solutions for both clinical and commercial producing biopharma firms.

Key Suppliers: Sartorius, Thermo Fisher Scientific, and Merck Millipore. - The Distribution and Integration: The end product to the end user involves close collaboration between distribution/sourcing, application providers, and clinical and commercial product manufacturers to customize the assemblies and thus ensure they arrive promptly for clinical and commercial product production.

Key Suppliers: Cytiva, Pall (Danaher), and Entegris.

Single-Use Bioprocessing Market Companies

- Thermo Fisher Scientific, Inc.

- Sartorius AG

- Merck KGaA

- Pall Corporation

- Corning Incorporated

- Eppendorf AG

- General Electric Company (GE Healthcare)

- Lonza

- Rentschler Biopharma SE

- JM BioConnect

- Meissner Filtration Products, Inc.

- Infors AG

- BoehringerIngelheim GmbH

- Entegris, Inc.

- PBS Biotech, Inc.

Latest Announcement by Industry Leaders

- Lina Tao, Vice President, Eppendorf SE Bioprocess Unit, commented that single-use bioreactors eliminate the need for time-consuming and costly cleaning and sterilization processes associated with traditional stirred-tank bioreactors. She also said that the adoption of single-use bioreactors in the CGT (cell and gene therapy) industry represents a transformative shift, supporting the commercialization of life-changing therapies. She envisioned that 3D-stirred bioreactors with single-use technology will become the new gold standard for CGT upstream bioprocesses.

Recent Developments

- In June 2024, Thermo Fisher Scientific, Inc. announced the launch of lower-carbon, biobased films for its single-use technology bioprocessing containers (BPCs). The new solutions include a first-of-its-kind film that can eliminate carbon emissions from plastic resin.

- In June 2024, WuXi Biologics announced the installation of three new sets of 5,000 L single-use bioreactors at its drug substance manufacturing facility in Hangzhou, China. This increases the manufacturing facility from 8,000L to 23,000L.

- In April 2023, Merck announced the launch of Ultimus Single-Use Process Container Film to provide extreme durability and leak resistance for single-use assemblies used for bioprocessing liquid applications.

Segments Covered in the Report

By Product

- Filtration Assemblies

- Disposable Bioreactors

- Disposable Mixers

- Media Bags & Containers

- Others

By Application

- Filtration

- Purification

- Cell Culture

- Others

By End User

- Biopharmaceutical Manufacturers

- Clinical & Academic Research Institutes

- Others

By Workflow

- Upstream

- Fermentation

- Downstream

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting