What is the Carbon Fiber Market Size?

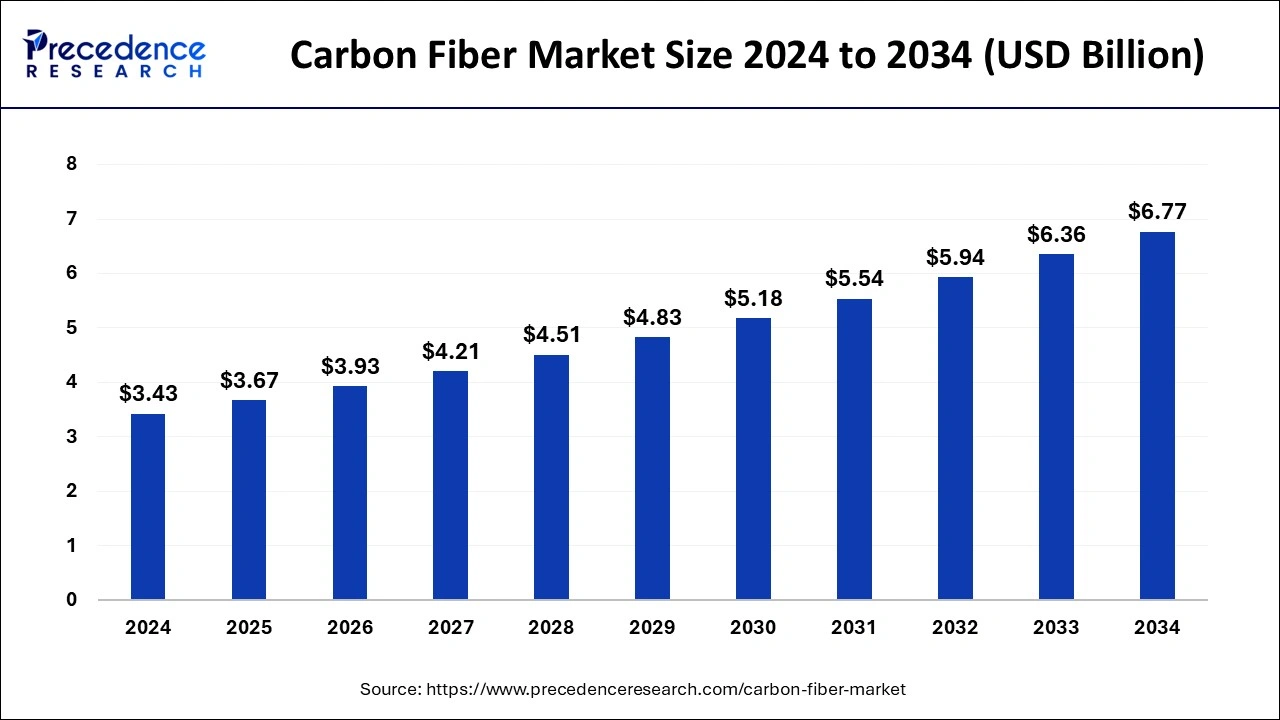

The global carbon fiber market size is calculated at USD 3.67 billion in 2025 and is predicted to increase from USD 3.93 billion in 2026 to approximately USD 7.19 billion by 2035, expanding at a CAGR of 6.96% from 2026 to 2035.

Market Highlights

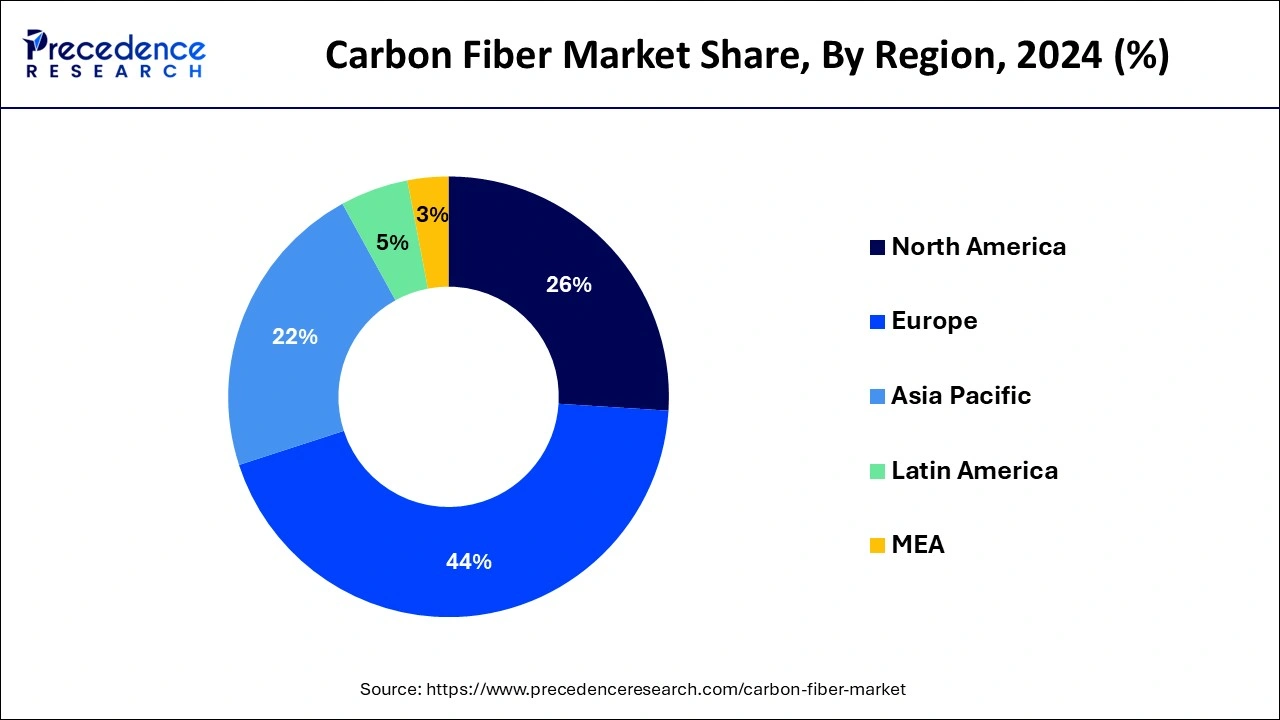

- Europe region dominated the market in 2025.

- By Raw Materials, the PAN segment is projected to grow at a significant CAGR between 2026 and 2035.

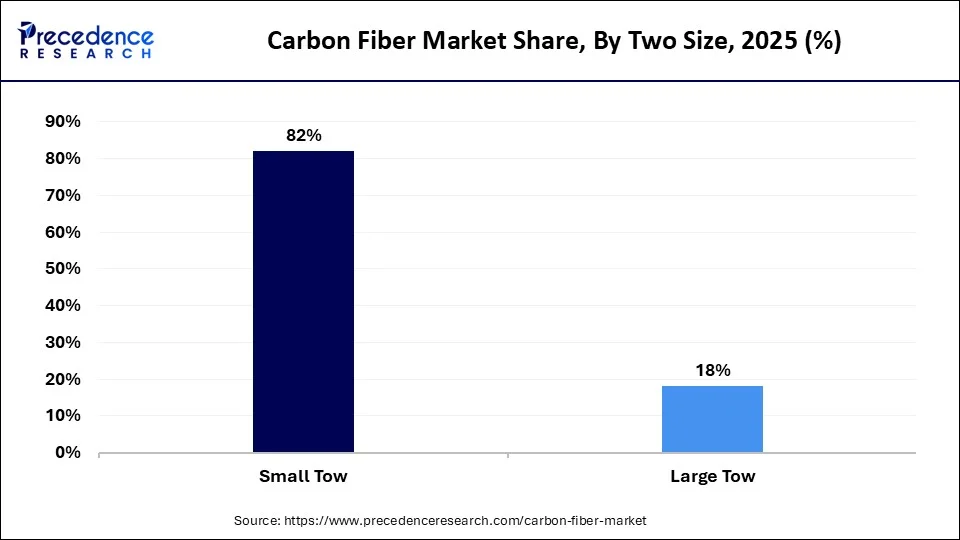

- By Tow Size, the small tow is expected to expand at a significant and fastest-growing segment between 2026 and 2035.

- By Application, the wind turbines and aerospace segment dominated the carbon fusion market in 2025.

Market Size and Forecast

- Market Size in 2025: USD 3.67 Billion

- Market Size in 2026: USD 3.93 Billion

- Forecasted Market Size by 2035: USD 7.19Billion

- CAGR (2026-2035): 6.96%

- Largest Market in 2025: Europe

Market Overview

Carbon fiber has come a long way, influencing nearly every industry, from aerospace to sporting goods, automotive, construction, and wind energy. Carbon fiber has several advantages over other fibers (glass and aramid fiber), including high tensile strength, stiffness, low density, and chemical resistance, leading to increased penetration in various industries.

The global demand for carbon fiber is high, owing to the wide range of sizes (two counts) and the available mechanical capabilities (strength, stiffness). This necessitates a closer examination of the end markets that use carbon fiber. However, according to Roberts (industry veteran and proprietor of AJR Consultancy), total global carbon fiber demand in 2019 was 123,300 metric tons, with the majority of that, 85,000 metric tons, coming from the industrial sector, which includes wind energy, automotive, pressure vessels, and infrastructure. Aerospace, which uses the highest quality carbon fiber, consumed 24,500 metric tons, while sports and leisure consumed 13,800 metric tons.

Furthermore, the increased demand from FCEVs and the increased level of investment in the development of low-cost coal-based carbon fibers will create innovative opportunities for ordinary bearing manufacturers in the future.

MarketScope

| Report Coverage | Details |

| Market Size in 2025 | USD 3.67 Billion |

| Market Size in 2026 | USD 3.93 Billion |

| Market Size by 2035 | USD 7.19 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 7.19% |

| Largest Market | Europe |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Raw Material, Tow Size, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Increase the use of air taxis / Urban air mobility (UAM)

Growing urban populations will cause road congestion and demand for competitive modes of transportation that can alleviate traffic problems and shorten travel times. Air taxis (electric vertical takeoff and landing (eVTOL)) are one of the future modes of transportation that will reduce travel time while maintaining a competitive price. Carbon fiber is used to make structural and interior components in air taxis.

Increased government initiatives and investments by the aviation industry's top players demand air taxis. Moreover, increased development and innovation fuel market growth. Furthermore, the positive impact of products made by numerous startups and top players increases the adoption and growth of air taxis worldwide. For instance, American Airlines invested $25 million in Vertical Aerospace, a U.K.-based company, with an order for 50 aircraft.

Increase pressure vessels for hydrogen storage, driving the market growth

Demand for hydrogen-based fuels is increasing as the emphasis on the decarburization of transportation modes grows. Transport (cars, trucks, rail, aerospace, etc.), distribution (mobile pipeline), and hydrogen refueling stations all use hydrogen storage tanks. Pressure vessels (Type IV) for hydrogen storage are becoming more popular in the automotive and aerospace industries. Carbon fiber composites are excellent for constructing Type IV and Type V pressure vessels.The high cost of carbon fiber poses a challenge in these applications, particularly as demand for hydrogen tanks proliferates.

The US Department of Energy is leading research efforts to make hydrogen-powered vehicles a cost-effective, environmentally friendly, and safe mode of transportation. Under the Energy Policy Act of 1992, hydrogen is classified as an alternative fuel and is eligible for alternative fuel vehicle tax credits.

Restrains

Chemical separation agents, chemical recovery agents, and efficient catalyst carriers are in high demand in the industrial sector

The cost of chemical separation and the catalyst carrier process is rising, increasing demand for cost-effective and dependable solutions. Catalysts such as platinum, palladium, and rhodium are expensive components for many chemical reactions, forcing industries to use them wisely. In addition, costly solvent recovery is a significant challenge for enterprises.

Moreover, disruptions in supply chains and fluctuating prices of ACF raw materials, such as synthetic fiber, which is non-degradable and tends to bind with particles of dangerous chemical pollutants, such as flame retardants and pesticides, would have an impact on the market expansion. Developing an environmentally friendly process is a significant challenge for the activated carbon fiber market.

Opportunities

Increasing demand for fuel sales provides future opportunities

Fuel cell demand is driven by rising demand for portable devices and increasing interest in hydrogen fuel cell vehicles in developing countries. Carbon fiber composites are essential components of the fuel cell stack. Carbon fiber composites make significant components such as bi-polar plates and gas diffusion layers, which reduce system weight and part counts and increase mechanical strength and corrosion resistance. For instance, According to JATO Dynamics data, global sales of hydrogen fuel-cell cars will total 15,500 units in 2021.

Segments Insights

Raw Material Insights

PAN segment dominated the market in 2025

Polyacrylonitrile (PAN) or pitch are the primary raw materials used in producing carbon fiber. PAN's superior properties are expected to increase acceptance in various applications. The global PAN market is expected to grow at a remarkable CAGR, creating a demand for more than 200 kilotons. Due to the growing demand for higher strength-to-weight ratio carbon fiber, PAN precursor is widely used due to its superior material properties. PAN's lower cost than pitch-based carbon fiber is also expected to help the segment grow.

Tow Size Insights

Small tow segment dominated the market in 2025

Carbon fiber is made up of yarns that are 92% carbon. A tow is formed by grouping together some parallel filaments. Tiny tow fibers have filaments with up to 24,000 strands. Tiny tow fibers are commonly used in the aerospace industry due to their high tensile strength and modulus when composites are used in various applications. Small-tow fibers are more expensive than large-tow fibers. The small tow is expected to be the most significant and fastest-growing segment between 2024 and 2033.

Application Insights

The wind and Aerospace industry dominate the carbon fusion market

Regarding tons of carbon fiber demand, wind and aerospace are expected to be the top two applications. Wind energy and aerospace accounted for 17% and 27% of the more than 45,000-tonne market in 2021. CF's automotive and pressure vessel applications are also expected to account for a sizable portion of CF demand, which is expected to be around 20% by the end of this decade. Wind energy, aerospace, automotive, and pressure vessels are expected to have lower demand than the described applications highly relevant to EERE's mission (oil and gas and civil infrastructure).

Although demand from the aerospace industry was comparable to demand from the wind energy sector in 2021 and 2022 (the two were within 5,000-6,000 tons of each other), demand from aerospace manufacturers is expected to grow at a slower rate than demand from the automotive sector, so that their demand will be roughly equal by 2020. Wind energy applications are expected to grow at the fastest speed.

Strategic Considerations for Carbon Fiber Market Players

Carbon fiber has found use in various industries and applications, ranging from aerospace to construction. Due to carbon fiber's high strength and stiffness characteristics, any moving part is a good target for carbon fiber composites to drive fuel efficiency and other performance benefits. Emerging carbon fiber applications in robots, drones (UAV), 3D printing, air taxis, fuel cells, hydrogen tanks, and other areas will drive carbon fiber growth in the future.

The carbon fiber industry is ever-changing and dynamic. Successful industry participants must be masters of innovation, change, and adaptation. To maintain this status, they must be aware of current trends. Carbon fiber will have promising applications in the automotive, aerospace, and sporting goods industries. The carbon fiber market is expected to grow at a 5.5% CAGR between 2024 and 2033. The growing demand for high-performance and lightweight composite materials and increasing performance requirements in end-use industries are driving this market. Carbon fiber market participants can improve their ability to use alternative precursors to reduce manufacturing costs. Players can concentrate on pan-based precursors that are expected to drive future trends.

Regional Insights

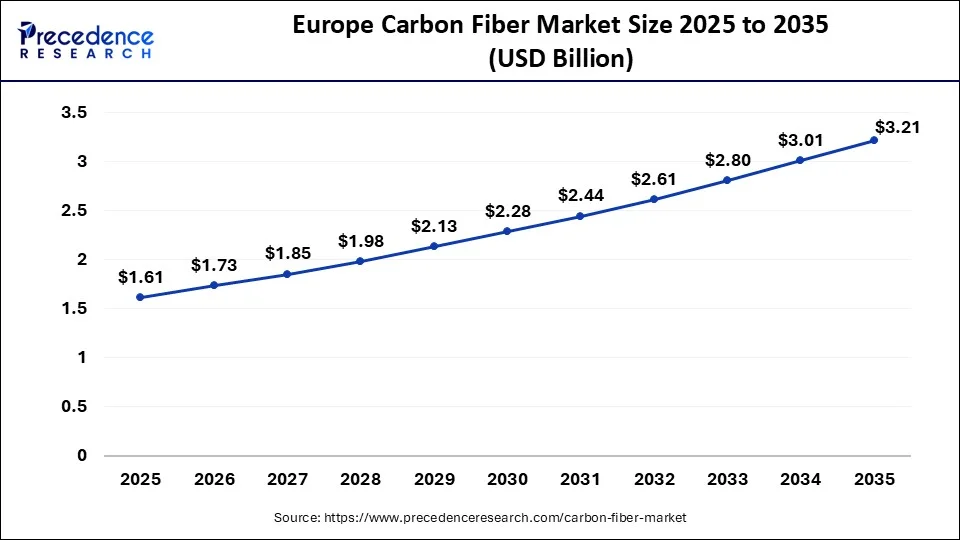

What is the Europe Carbon Fiber Market Size?

The Europe carbon fiber market size was exhibited at USD 1.61 billion in 2025 and is projected to be worth around USD 3.21 billion by 2035, growing at a CAGR of 7.14% from 2026 to 2035.

Why did North America become a Notable Player in the Carbon Fiber Market?

The carbon fiber industry began in North America, Europe, and Japan, and it remains concentrated in terms of supply and demand. According to current distributions and forecasts, Europe will be the leading region in terms of tones CF demanded in 2022, with an estimated demand of 16,650 tons, or approximately 37% of the global total. In 2022, Europe's share of total demand was expected to increase by more than 43%. Asia was the second leading region in 2022, with North America coming third. However, North America is expected to be nearly equal to Asia in terms of CF demand by 2022.

The demand for carbon fiber in North America is propelled by increasing needs in sectors such as aerospace, automotive, and renewable energy. The growing demand for lightweight, durable materials to improve fuel efficiency and lower emissions has played a major role in the expansion of the market. Key participants in the North America Carbon Fiber Market consist of Toray Industries, Hexcel Corporation, SGL Carbon, Mitsubishi Chemical Holdings, and Teijin Limited. These firms have gained considerable market share by consistently investing in research and development.

U.S. Carbon Fiber Market Analysis

The U.S. industry experiences advancements in aerospace and defense, a well-established infrastructure for renewable energy, and the increased demand for high-performance materials. The Biden-Harris Administration of the U.S. provided US$6 billion in funds for 33 projects to boost heavy manufacturing.

What makes the Asia Pacific reach the Fastest Growth in the Carbon Fiber Market?

Asia and Japan are expected to lose their share of global CF demand. Over this time, Europe, North America, and the rest of the world have increased their market share. However, according to the most recent forecast, Asia and Europe will account for 35% and 32% of total global demand, respectively, compared to 27% in North America by 2024.

The carbon fiber market in the Asia Pacific is advancing quickly, fueled by increasing demand from automotive, aerospace, renewable energy, and high-performance sports equipment sectors. As the region develops into a major manufacturing center, carbon fiber is transforming from a specialized luxury material into a strategic component for lightweight, resilient, and high-strength solutions across various industries.

India Carbon Fiber Market Trends

India advances in the carbon fiber industry, led by the expansion of clean energy, the increased use of carbon fiber wraps, the boom of electric vehicles, and stringent emission regulations. The market is also supported by government initiatives such as “Make in India” and strategic investments that aim to build indigenous production capacity and reduce dependency on imported raw materials. In January 2024, Reliance Industries invested over $150 billion to establish a world-class carbon fibre facility in Gujarat.

In September 2024, Giriraj Singh, the Union Textiles Minister, announced that carbon fibre will be produced by India in 2025-26.

How did Europe hold the Largest Share in the Carbon Fiber Market in 2025

The Europe carbon fiber market shows remarkable growth potential, fueled by rapid industrial innovation and bold governmental sustainability efforts. Swift advancements in carbon fiber production and manufacturing are generating unparalleled opportunities for market growth. The growing awareness of environmental issues among producers and significant investments in lightweight material options are fundamentally transforming the manufacturing landscape.

Germany's carbon fiber industry is expanding robustly as demand grows from its automotive and aerospace sectors for lightweight, high-performance materials that improve fuel efficiency, reduce emissions, and support advanced vehicle and aircraft design. The country holds a significant share of the European carbon fiber composites market due to strong industrial demand and its leadership in premium car manufacturing and engineering innovation.

Latin America

Why is Latin America a Pivotal Region in the Expanding Carbon Fiber Market?

Latin America is expected to grow at a significant rate in the market, driven by shifts in local manufacturing and supply chain, government incentives for green technologies, and the growing focus on circular economy models. In February 2025, the Climate Fund Managers (CFM) planned to strengthen the presence of Latin America with inaugural investments in Colombia and the new regional headquarters in Bogota.

MEA

Why do the Middle East and Africa hold a Considerable Position in the Carbon Fiber Industry?

The Middle East and Africa are expected to grow at a lucrative rate in the market, owing to sustainability, the circular economy, and multi-billion-dollar investments in aviation. Significant infrastructure and construction investments in countries like Saudi Arabia and the UAE are also driving carbon fiber use in composites for building and industrial applications. Overall, the MEA carbon fiber trend reflects gradual scaling of domestic supply chains, increased application diversification, and stronger integration.

Value Chain Analysis of the Carbon Fiber Market

- Feedstock Procurement:This stage is driven by primary feedstock, bio-based feedstocks, circular procurement of recycled carbon fiber, and regional procurement shifts.

Key Players: Toray Industries, Inc., Hexcel Corporation, Mitsubishi Chemical Group, Teijin Limited, SGL Carbon, Zhongfu Shenying Carbon Fiber, and Solvay. - Waste Management and Recycling:This stage is expanding due to thermal reclamation, chemical reclamation, mechanical recycling, closed-loop resin systems, and traceability.

Key Players: Procotex, Vartega, Carbon Conversions, Gen 2 Carbon, Alpha Recyclage Composites, Toray Industries, Teijin Limited, Mitsubishi Chemical Group. - Regulatory Compliance and Safety Monitoring:This stage focuses on AI-driven safety and quality, electrical hazard mitigation, chemical safety, emissions, and carbon tracking, etc.

Key Players: SGS, TUV SUD, Intertek, Nemko, MiCOM Labs, Toray Industries, Hexcel Corporation, SGL Carbon.

Carbon Fiber Market Companies

- Toray Industries Inc. (Japan)

- SGL Group (Germany)

- Hexcel Corporation (U.S.)

- Mitsubishi Rayon Co. Ltd. (Japan)

- Teijin Limited (Japan)

- Plastics Corporation (Taiwan)

- Solvay (Belgium)

- Jiangsu Hengshen Co. Ltd. (China)

- Hyosung (South Korea)

- BASF SE

- SGL Group

- Teijin Limited

- Mitsubishi Rayon Co., Ltd.

- Hexcel Corporation

Recent Development

- In March 2025, Teijin Carbon, a manufacturer of carbon fibers and carbon fiber-derived materials, launched a new brand, Tenax Next, to showcase its advanced carbon fiber offerings. These incorporate circular feedstock with a notably lower carbon footprint while preserving the strength, durability, and performance of conventional Tenax carbon fiber products.

- In April 2025, Levante, an Italian company specializing in carbon fiber solar panels, introduced new waterproof products of 110 W and 55 W that are portable, lighter, glass-free, and constructed from recycled carbon fiber. The CarbonCore modules were showcased at JEC World, a trade fair for composite materials recently conducted in Paris.

- In July 2024, China unveiled a pioneering breakthrough in high-speed rail technology, reinforcing its status as a worldwide leader in the field. As reported by Interesting Engineering, the nation has introduced the first passenger train made entirely of carbon fiber. Due to its significantly lighter weight compared to traditional trains, this train is expected to greatly reduce pollution, according to Yahoo Tech reports.

- In 2022, Teijin Limited announced a collaboration with Fuji Design Co. Ltd, a recycled carbon fibers manufacturer based in Japan, to establish a business for producing, supplying, and commercializing carbon fiber-reinforced plastic products derived from recycled carbon fibers using a low environmental impact process.

- In 2022, Hexcel and Archer Aviation Inc. signed a letter of intent outlining a potential partnership to supply high-performance carbon fiber material for Archer's production aircraft.

- In 2022, Dassault signed a long-term contract with Hexcel to supply carbon fiber prepreg for the Falcon 10X program. This is the first Dassault business jet program to use advanced carbon fiber composites in the fabrication of its aircraft wings.

- Company Profiles and Competitive Intelligence

Segments Covered in the Report

By Raw Material

- PAN Based

- Pitch Based

By Tow Size

- Small Tow

- Large Tow

By Application

- Automotive

- Aerospace & Defense

- Wind Turbines

- Sports equipment

- Molding & Compounding

- Construction

- pressure vessels

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- The Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting