What is the Distillation Systems Market Size?

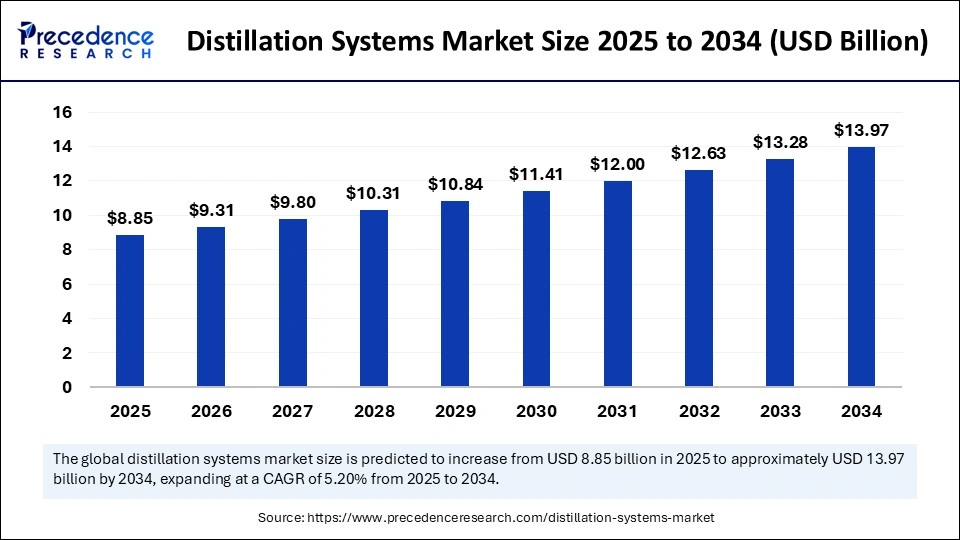

The global distillation systems market size is calculated at USD 8.85 billion in 2025 and is predicted to increase from USD 9.31 billion in 2026 to approximately USD 13.97 billion by 2034, expanding at a CAGR of 5.20% from 2025 to 2034. The growth of the market is attributed to the rising demand for distillation systems from various industries.

Distillation Systems Market Key Takeaways

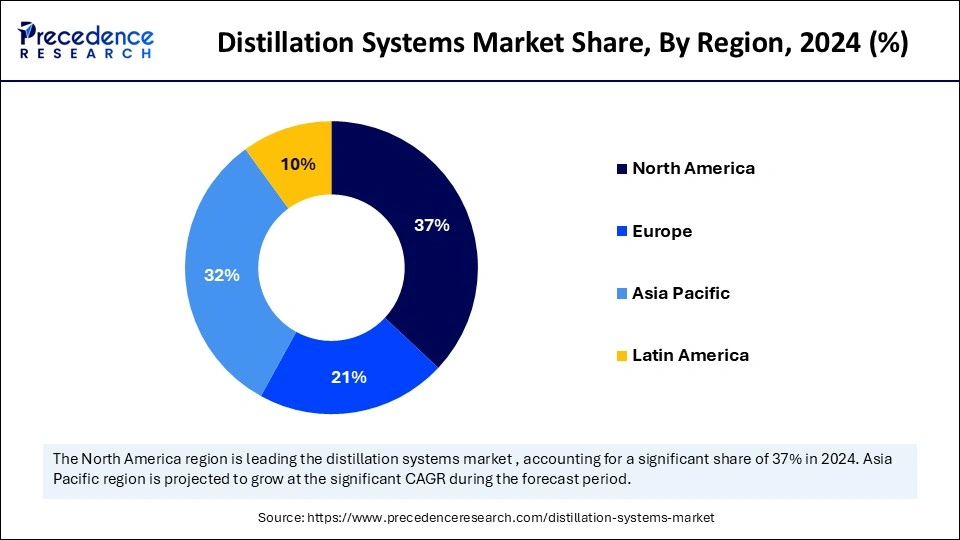

- North America dominated the distillation systems market with the largest revenue share of 37% in 2024.

- Asia Pacific is expected to witness significant growth in the upcoming period.

- By component, the column shells segment held a considerable revenue share in 2024.

- By component, the plates & packings segment is expected to grow at a significant rate in the coming years.

- By end-user, the petroleum & biorefinery segment led the market in 2024.

- By end-user, the water treatment segment is likely to grow at a significant CAGR during the forecast period.

How is AI Impacting the Distillation Systems Market?

Artificial Intelligence has the potential to enhance the performance and sustainability of distillation processes for several applications. AI techniques have been applied in the optimization, modelling, and control of membrane separation processes. AI improves sustainability and performance in distillation processes. Machine Learning models predict permeate flux, rejection rates, and fouling with high precision. AI optimization lessens energy use and fouling in the distillation system. AI algorithms analyze real-time data from distillation processes to optimize operating parameters, such as pressure, temperature, and flow rates. This leads to improved efficiency and reduced energy consumption.

What are the Emerging Technologies of Distillation Systems?

The distillation system is a widely used separation technique in various industries, like pharmaceuticals, petrochemicals, oil & gas, and wastewater treatment. The distillation process involves heating a liquid to its boiling point and then condensing the vapor to obtain a purer form of the substance. Distillation is highly effective in separating liquids with different boiling points. By carefully controlling the temperature and pressure, achieving a high degree of purity in the desired product is possible.

Distillation can be applied to various substances, such as water, essential oils, alcohols, and petroleum fractions. Its versatility makes it suitable for various industries and processes. It is an efficient method for obtaining a pure substance from a mixture of liquids. The distillation process not only enhances separation efficiency but also contributes to significant reductions in energy usage. Modern distillation equipment incorporates energy-saving technologies such as insulated columns, heat exchangers, and energy recovery systems. Therefore, these systems help reduce operational costs and minimize environmental impact. Advanced distillation processes, like multi-stage distillation and heat integration, have enhanced energy efficiency, lowering the cost of operation.

Distillation Systems MarketGrowth Factors

- Increasing industrialization is expected to boost the growth of the distillation systems market. With the rising growth of industrial activities, the demand for chemicals and fuels is increasing. Distillation processes are crucial in manufacturing chemicals and fuels.

- Technological advancements open up new avenues for market growth. The effectiveness of distillation systems can be enhanced by applying different modifications, like adding or removing trays or packing, varying the feed location, regulating the reflux ratio, and increasing or decreasing the heat input or output.

- Stringent environmental regulations encourage the adoption of advanced distillation systems that offer better performance and reduced environmental impact.

- The rising need for wastewater treatment due to shortages of drinking water is expected to boost the growth of the market. Water treatment helps in eliminating hazardous substances and contaminants from the water, making it safe and clean to drink and be used for various purposes.

Distillation Systems Market Outlook

- Global Expansion: A comprehensive progression is impelled by water scarcity, driving desalination, the growth of biofuels, and the adoption of advanced technologies, including AI for efficiency and automation.

- Major Investor: In January 2025, the Government of the Hashemite Kingdom of Jordan and the consortium powered by Meridiam-SUEZ signed a 30-year concession contract for the desalination and conveyance of drinking

- Startup Ecosystem: SEPPURE, a Singapore-based startup that merges nanofiltration membranes and systems created to replace energy-intensive thermal separation solutions, including distillation in industrial chemical separation.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 13.97 Billion |

| Market Size in 2025 | USD 8.85 Billion |

| Market Size in 2026 | USD 9.31 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.20% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Component, End-User, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Developments of Micro Distillation Systems

The rising developments of fully automated micro distillation systems that are capable of processing up to 12 gallons per hour are driving the growth of the market. Engineered to handle diverse aqueous fluids with septic system water, residential laundry water, industrial rinse water, and ocean salt water, these systems demonstrate exceptional energy efficiency with a specific energy requirement of under 37 Watt-hr/gallon and deliver distilled water with conductivity as low as three microsiemens/cm. This innovation not only ensures high output and compact design but also helps seamless integration with microfluidic systems, providing tailored heat loads and lowering energy consumption. Such developments address challenges associated with sustainability and operational efficiency.

Restraint

High Energy Consumption and Complex Operations

Distillation processes, especially for large-scale industrial units, require a lot of energy to boil the water and also to cool the steam down to condense it. A distillation system is complex and needs specialized equipment, like reboilers, condensers, and distillation columns. Some substances are sensitive to high temperatures, making distillation inappropriate for heat-sensitive materials. Distillation processes generate vapors and wastewater that necessitate proper disposal and treatment, posing environmental challenges, which limit the growth of the distillation systems market.

Opportunity

Emerging Hybrid Technologies

Advancements in hybrid separation technologies are creating novel opportunities in the distillation systems market. Hybrid distillation membrane configurations, specifically for ethanol purification, have gained traction due to their significantly lower energy consumption. The integration of distillation with pervaporation marks a breakthrough in chemical manufacturing, delivering higher separation efficiency, improved product purity, and reduced energy consumption. These hybrid approaches provide a cost-effective and technically feasible path for debottlenecking existing systems, rather than fully replacing them.

Component Insights

The column shells segment dominated the distillation systems market with a considerable share in 2024. Column shells play a crucial role in distillation systems. They facilitate the separation of components based on boiling points, ensuring accurate control over distillation processes. They are applicable in pharmaceutical production, specialty chemicals manufacturing, and food & beverage processing. Column shells redefine operational efficiency in the various industries. Column shells house reaction vessels, creating a controlled atmosphere for chemical reactions to occur in the column.

The plates & packings segment is expected to grow at a significant rate in the coming years, as they handle a broad range of liquid and gas flow rates. They are used to enhance separation performance. They also enhance energy efficiency, making distillation systems more energy efficient. The petroleum refining and chemical processing industries heavily rely on these components as they provide high-purity outputs.

End-User Insights

The petroleum & biorefinery segment led the distillation systems market in 2024. Distillation systems play a significant role in separating various components in the mixture, enabling the isolation of particular substances based on their specific characteristics. Petroleum fractional distillation contributes to purifying oil by eliminating impurities and separating desirable components, ensuring a high-quality end product. Petroleum is composed of a mixture of hydrocarbons with fluctuating boiling points. Distillation is a key process in the production of various petrochemical products, such as polymers and solvents.

The water treatment segment is likely to grow at a significant rate during the forecast period. The rising concerns about water scarcity and stringent environmental regulations drive the demand for distillation systems in wastewater treatment applications. The distillation process eliminates a wide range of inorganic compounds in the water, including metals such as iron, lead, sodium, nitrates, hardness minerals, and other dissolved materials. The distillation process is effective in killing bacteria, viruses, and other microbes. It efficiently eradicates numerous contaminants from drinking water, including inorganic and many organic compounds.

Regional Insights

U.S. Distillation Systems Market Size and Growth 2025 to 2034

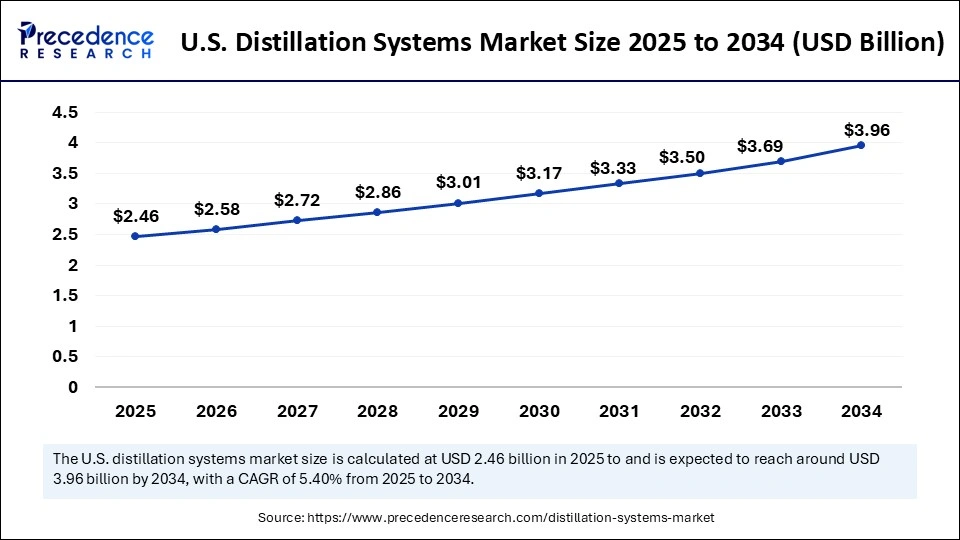

The U.S. distillation systems market size is exhibited at USD 2.46 billion in 2025 and is projected to be worth around USD 3.96 billion by 2034, growing at a CAGR of 5.40% from 2025 to 2034.

Why did North America Dominate the Market in 2024?

North America accounted for the highest revenue share of 37% in 2024. This is mainly due to the increased industrialization in the region. There is a high demand for petroleum products, such as plastics. The region has well-established oil & gas, petrochemicals, and pharmaceutical industries, which bolstered the growth of the market in the region as distillation systems are essential in these industries. The region is known for technological innovation, leading to the development of advanced distillation systems, sustaining the region's position in the market.

Enforcement of Stricter regulations: Supports the US Market

The U.S. is a major player in the North American distillation systems market. The growing need for water treatment because of the high risk of exposure to different contaminants supports market growth. Stringent environmental regulations are encouraging the adoption of advanced distillation systems that meet these regulations. In addition, the increasing production of biofuels is likely to drive the adoption of distillation systems.

Persistent Demand for Generics & Biologics is Fostering the Asia Pacific

Asia Pacific is expected to experience significant growth during the forecast period. The growth of the market in the region can be attributed to the increasing growth of the chemical industry, government initiatives, research and innovation, and a focus on sustainable solutions. Governments around the region are investing in infrastructure and industrial development. This, in turn, creates the need for distillation systems. The pharmaceutical industry continues to expand at a steady rate due to the rising demand for generics andbiologics. Distillation systems are essential in the production of high-quality pharmaceutical ingredients.

Progression of Petrochemical Chemistry: Boosts the Chinese Market

China is expected to have a stronghold on the Asia Pacific distillation systems market. This is mainly due to the rapid expansion of the petrochemical industry. The demand for high-purity products, such as pharmaceuticals and chemicals, is rising in the region, facilitating the growth of the market. Distillation separates impure components based on boiling points, resulting in the development of high-purity products.

India also plays a major role in the market. In India public water supply is highly contaminated with heavy metals, chemicals, viruses, and bacteria. Along with growing populations, the demand for pure water is increasing. As a result, the need for wastewater treatment is rising, in which distillation process is essential. In addition, the country is witnessing rapid industrialization, creating the need for distillation systems.

Substantial Initiatives are Promoting Europe

A lucrative growth of the distillation systems market in Europe has been propelled by the ongoing significant initiatives, such as Sulzer Ltd. unveiled energy-efficient distillation columns with advanced heat integration for the oil refining and chemical sectors. Moreover, GEA Group established a modular distillation system for small and medium-scale food and beverage producers.

A Surge in Novel Projects: Bolsters the UK Market

The UK market is widely influenced by the consistent projects in the era, with a focus on future expansion. Such as Carbon Capture, Usage and Storage (CCUS), for which the UK government invested broadly in CCUS to develop a competitive market by 2035. The HyNet and East Coast Cluster are both government-backed carbon capture projects that have reached final investment decisions and are termed "shovel-ready".

Recent Developments in the Market

- In April 2025, PAC, a global leader in analytical instrumentation with over 5,000 distillation instruments deployed worldwide, announced the launch of OptiDist 2, setting a new benchmark in atmospheric distillation. OptiDist 2 delivers unparalleled precision, efficiency, and reliability with its patented thermosiphon cooling system, enhanced safety features, and seamless PACe integration for optimized lab performance.

- In September 2024, Sulzer announced the launch of VoltaSplit, its new electrified distillation solution that significantly enhances energy efficiency while enabling the reduction of direct CO2 emissions. VoltaSplit relies on electricity instead of traditional energy-intensive steam boilers, reducing CO2 emissions of distillation units by up to 90%. This also enables process industries to meet regulatory requirements, improve operational performance, and reduce their long-term environmental impact.

- In March 2024, Prospero Equipment Corporation joined forces with Barison Industry to launch a revolutionary continuous distillation system.

Key Players Offerings:

- Alfa Laval- It usually offers core components and modular solutions that allow efficient atmospheric and vacuum distillation processes.

- Anton Paar- It provides the Diana series of atmospheric distillation analyzers (Diana 700 and Diana 300 models).

- Büfa Composite Systems- It mainly specializes in diverse composite materials, processing machinery (BÜFA Tec), and sustainability solutions that complement the use of solvent recovery and recycling systems.

- Bosch Packaging Technology- A company immensely offers this system for the pharmaceutical industry to produce high-purity media such as Water for Injection (WFI) and pure steam.

- Core Laboratories- A major players leverages a specific piece of equipment called the Cryogenic Distillation Unit (CDU).

Distillation Systems Market Companies

- Alfa Laval

- Anton Paar

- Büfa Composite Systems

- Bosch Packaging Technology

- Core Laboratories

- EPIC Modular Process Systems

- GEA AG

- Pilodist

- L&T Hydrocarbon Engineering

- Praj Industries

Segments Covered in the Report

By Component

- Column Shells

- Plates & Packings

- Reboilers & Heaters

- Condensers

- Others

By End-User

- Petroleum & Biorefinery

- Water Treatment

- Food

- Beverage

- Pharmaceuticals

- Others

By Region

- North America

- Europe

- Asia Pacific

- Middle East & Africa

- Latin America

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting