What is the Petrochemical Market Size?

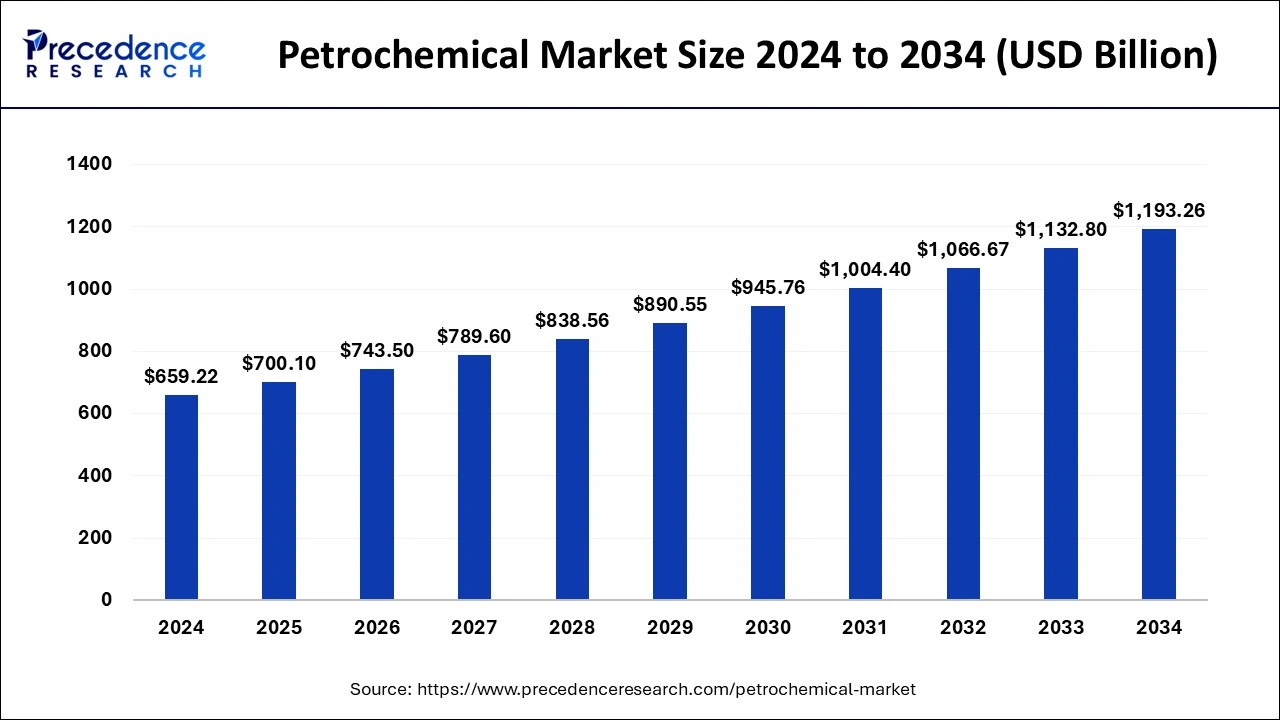

The global petrochemical market size was calculated at USD 700.10 billion in 2025 and is predicted to increase from USD 743.50 billion in 2026 to approximately USD 1,257.50 billion by 2035, expanding at a CAGR of 6.03% from 2026 to 2035. A key driver of the petrochemical market's expansion is the rise in demand for downstream goods from a variety of end-use sectors, including construction, pharmaceuticals, and the automotive sector. This is the reason for the product's increased demand.

Petrochemical Market Key Takeaways

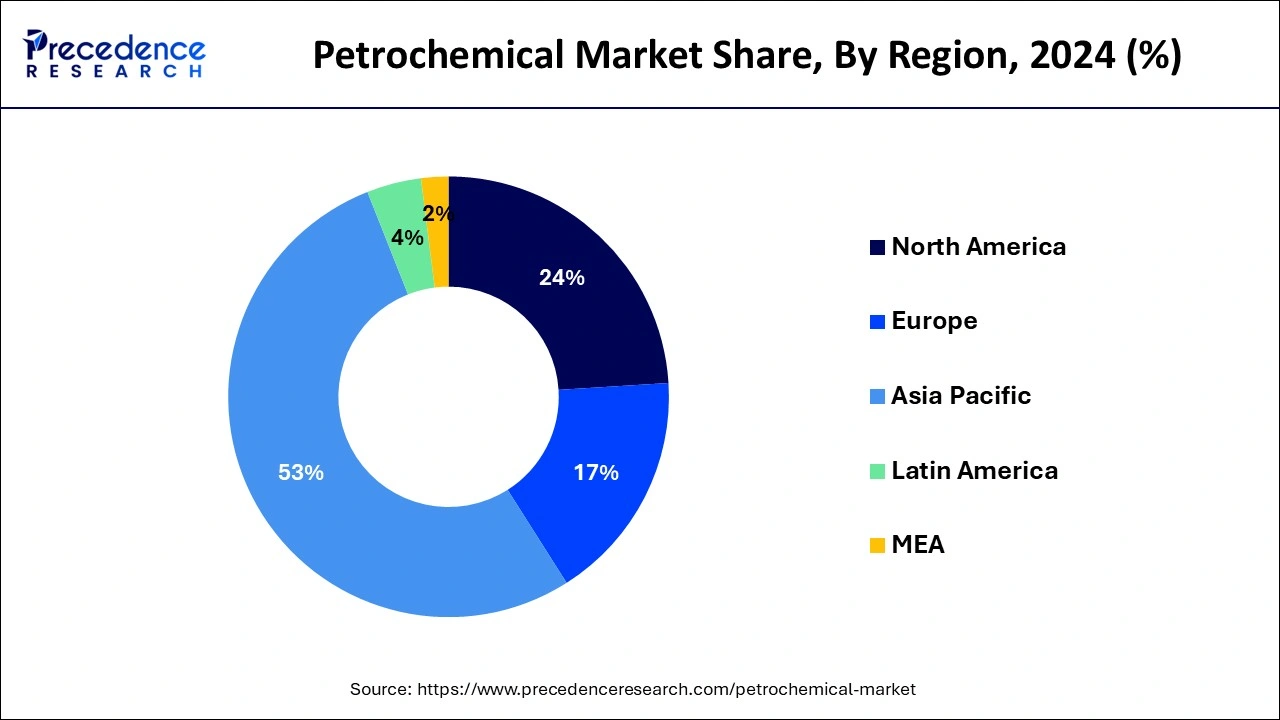

- Asia Pacific has dominated the market with a revenue share of 52.14% in 2025.

- Europe is anticipated to grow at a CAGR of 5.7% during the forecast period from 2026 to 2035.

- By product, the ethylene segment has captured a revenue share of 40.6% in 2025.

- The methanol segment is expected to grow at a CAGR of 7.9% between 2026 and 2035.

How is AI enhancing advancements in the petrochemical Market?

The petrochemical sector is undergoing a change thanks to the synergistic influence of Artificial Intelligence and Internet of things convergence. Large volumes of data produced by sensors integrated into petrochemical equipment may be analyzed by AI and machine learning algorithms, allowing for the early detection of equipment faults. IoT sensors make real-time visibility into different phases of the petrochemical manufacturing process possible. This data may then be used by AI algorithms to locate bottlenecks, adjust process variables, and improve overall productivity. Wearable technology with internet of things (IoT) capabilities and AI-powered video analytics can track employee behavior and environmental factors, spotting possible safety risks and averting mishaps. AI algorithms can further improve transportation timetables and logistical routes, lowering carbon emissions and expenses.

Petrochemical firms may increase customer satisfaction, save costs, and better respond to market needs by streamlining their supply networks. Rapid prototyping and simulation made possible by AI can hasten the development of novel petrochemical products and processes. Large volumes of chemical data may be analyzed by machine learning algorithms to find possible novel substances and forecast their characteristics.

Petrochemical Market Growth Factors

- Global population growth and urbanization drive demand for a wide range of petrochemical goods, such as chemicals, polymers, and plastics. In emerging nations, petrochemical products are increasingly used in manufacturing, construction, and other industrial processes due to economic growth and industrialization.

- Technological developments, especially in petrochemical production processes, can result in lower prices, more efficiency, and the creation of novel and inventive goods.

- The price and accessibility of raw materials like natural gas and crude oil affect the cost of producing petrochemicals. Areas having easy access to feedstock are frequently at a competitive advantage.

- Research and development (R&D) investments stimulate growth and innovation in the petrochemical sector by facilitating the creation of new technologies, procedures, and products.

- The petrochemical sector is encouraged to develop more environmentally friendly and sustainable methods by strict emissions and waste disposal laws and by growing public awareness of environmental issues.

- The types of petrochemical products in demand can be influenced by shifting consumer trends and preferences, such as the increasing desire for ecologically friendly or biobased products.

- The petrochemical industry's cost structure can be impacted by fluctuations in global energy prices, particularly those of natural gas and crude oil, which can affect investment decisions and profitability.

Market Outlook

- Sustainability Trends: Sustainability trends in the petrochemical market focus on reducing carbon emissions, promoting chemical recycling, and adopting bio-based feedstocks. Companies are investing in circular economy models, energy-efficient technologies, and low-impact production methods to minimize environmental impact.

- Global Expansion: Global expansion in the petrochemical market is driven by rising demand from emerging economies, increasing industrialization, and strategic capacity expansions. Companies are investing in new production facilities and partnerships across Asia-Pacific, the Middle East, and Africa to strengthen their global presence.

- Major investors: Major investors in the petrochemical market include ExxonMobil, BASF, Dow, SABIC, Shell, and Reliance Industries. These companies are expanding production capacities, investing in green technologies, digital transformation, and forming global partnerships to enhance efficiency and sustainability in petrochemical manufacturing.

Market Scope

| Report Highlights | Details |

| Market Size in 2025 | USD 700.10 Billion |

| Market Size in 2026 | USD 743.50 Billion |

| Market Size by 2035 | USD 1,257.50 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.03% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Product, Application, and Manufacturing Processes |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, Middle East & Africa (MEA) |

Market Dynamics

Drivers

A decrease in demand for fuel drives interest in Petrochemicals

The fuel industry across various regions is declining, which leads to an increase in demand for petrochemicals. As per a survey, the need for gasoline is anticipated to be lower by 15% from 2018 to 2035. Similarly, the demand for diesel will decrease by 6%. The factors which are contributing to the decline are continuous improvement in technology, autonomous vehicles, renewable substitution, connected and shared vehicles, as well as changing demographics.

The demand for petrochemicals is anticipated to expand 3 to 6 times. The need is expected to grow due to the rising middle class in developing countries. To boost the profitability of those investments, expansion into petrochemicals will be incorporated. A refiner is able to opt to cut crude capacity or diversify into higher-value petrochemicals to offset the predicted decline in US fuel consumption and dwindling export markets. The former would result in stranded capacity and reduced refining margins. Modification into petrochemical manufacturing allows the preservation of crude capacity and results in a considerably better margin than simply generating fuels.

The novel supply-demand relationship for the chemical sector is contributing to enhancing the global competition in the market. Owing to the shale gas resolution, the United States have again gained its position as a low-cost area for production of chemicals after many decades of decline. Presently, the United States manufactures approximately 40% of the global ethane-based petrochemical. Followed by U.S., Middle East led by Iran and Saudi Arabia remains the low-cost region for various petrochemicals, with various projects planned across globe. Europe and China accounts for approximately 1/4th of the global capacity for high value chemicals which are naphtha-based and have minor share of capacity.

Restraints

Environmental Concerns and Regulations

The petrochemical sector witnesses rising scrutiny due to environmental factors such as greenhouse gas emissions, air pollution, and plastic waste. Strict regulations as well as carbon reduction targets are able to require significant investments in emission control technologies, sustainability practices, and waste management, along with potentially increasing production costs.

Various challenges faced by petrochemicals are climate, water pollution, and air quality. Along with this, petrochemical products provide advantages, such as the rising number of applications in various advanced technologies. However, the use, production, and disposal of petrochemical products act as a challenge that needs to be addressed. Though the chemical industry consumes a larger amount of energy than the cement and steel sector, it emits less amount of CO2. The rising demand for bio-based alternatives and renewable alternatives to petrochemical products, like bio-based polymers or biodegradable materials, are expected to impact the market growth potential.

Opportunities

Use of Machine Learning and Artificial Intelligence in chemical manufacturing and data mining

Machine learning techniques are processes that are able to mimic human thinking ability and are able to detect patterns and mine data. They are also capable of evaluating context and conflicting evidence at a faster pace than humans. These technologies are used to assist in the prediction of the outcome of a process or reaction, help in developing hypotheses, and determine gaps in existing scientific literature. A continued trend in the chemical production sector embraces AI, Internet of Things, and machine learning. These advanced technologies are used to enhance efficiency and productivity, as well as decrease energy loss and risk.

Segment Insights

Product Insights

The ethylene segment holds the largest share in the petrochemical market. The primary process used to manufacture ethylene is the steam cracking of hydrocarbons derived from natural gas or crude oil, such as ethane, propane, and naphtha. The competitiveness of ethylene production is impacted by the cost and availability of feedstocks, particularly ethane from shale gas, in areas like the United States. There are several uses for the adaptable chemical ethylene. It is an essential raw ingredient used in manufacturing textiles, resins, polymers, and other industrial chemicals. The expansion of end-use sectors such as consumer products, packaging, buildings, and automobiles affects the demand for ethylene. Global economic conditions, feedstock pricing, and supply-demand balance are some factors affecting ethylene prices.

Numerous businesses use ethylene-based products to keep up with the increasing demand for ethylene worldwide, the petrochemical industry frequently invests in ethylene production facilities and expands its capacity. Technological developments, market trends, and regulatory frameworks are observed to impact investment decisions.

ManufacturingInsights

The fluid catalytic cracking segment holds the largest share in the petrochemical market. The primary goal of FCC is to convert heavy, high-boiling-point hydrocarbons from crude oil into lighter, more valuable products. By using a catalyst and a fluidized bed of catalyst particles, FCC makes it easier for giant hydrocarbon molecules to break down into smaller, more usable ones. Gasoline, diesel, and light olefins (such as propylene and butylene), crucial ingredients in synthesizing numerous petrochemicals, are the principal products acquired through the FCC. The FCC industry has grown in size and significance due in part to the rising demand for refined goods, including gasoline. Global energy demand, regulatory restrictions, and crude oil prices are some elements that impact the FCC industry.

In the FCC process, catalysts are essential because they encourage the right chemical reactions. The goal of ongoing research and development in catalyst technology is to improve selectivity and conversion efficiency. Zeolite-based catalysts are active and selective, making them a popular choice for FCC units. FCC units are made to comply with emission requirements and lessen their adverse effects on the environment as environmental rules get stricter. FCC unit operators are concentrating on integrating modern emission control technology and catalyst regeneration processes—demand for particular refined products and regional expansions of refining capacity impact the FCC segment. The rise of FCC units is primarily due to emerging nations with rising energy needs, especially in Asia and the Middle East.

Application Insights

The building and construction segment heavily influences the petrochemical market since petrochemical products are widely used in various construction-related applications. Petrochemicals are essential raw materials for manufacturing building materials, chemicals, and goods. They are obtained from petroleum or natural gas. Plastics are widely used in building materials like pipes, cables, insulation, roofing, and flooring, and their manufacture requires petrochemicals. These polymers are frequently utilized in construction applications such as fittings and pipes. In the construction sector, petrochemical-based adhesives and sealants are used to join and seal various materials, extending the life and durability of structures.

Government Initiatives

Global governments promote petrochemical innovation with initiatives.

Around the globe, we see governments making deliberate moves to stimulate the petrochemical sector. In May 2025, Kazakhstan's government publicized a $15 billion investment roadmap for six major projects (which includes polyethylene and butadiene) aiming to almost quintuple production by 2030.

Additionally, in May 2025 Nigeria's Dangote Refinery began exporting polypropylene through an agreement with Vinmar Group, reducing its reliance on imports, and is officially the largest refinery in Africa. In November 2024 Indian government officials launched the nationwide industrial safety training for petrochemical units, as part of the governments Viksit Bharat@2047 vision, by holding sessions in major metropolitan areas from November to January 2025 to implement provisions to improve industrial safety compliance.

In March 2024, the UK government provided a €700?million guarantee to Ineos for its “Project?One” ethane-to-ethylene plant in Antwerp, Europe's largest petrochemical venture backed despite environmental concerns and planned legal challenges.

This public support across multiple countries indicates there is a strong global policy push (through funding, safety standards reform, and export development) that is aimed at growing petrochemical capacity while improving the supply chain resilience.

Regional Insights

Asia Pacific Petrochemical Market Size and Growth 2026 to 2035

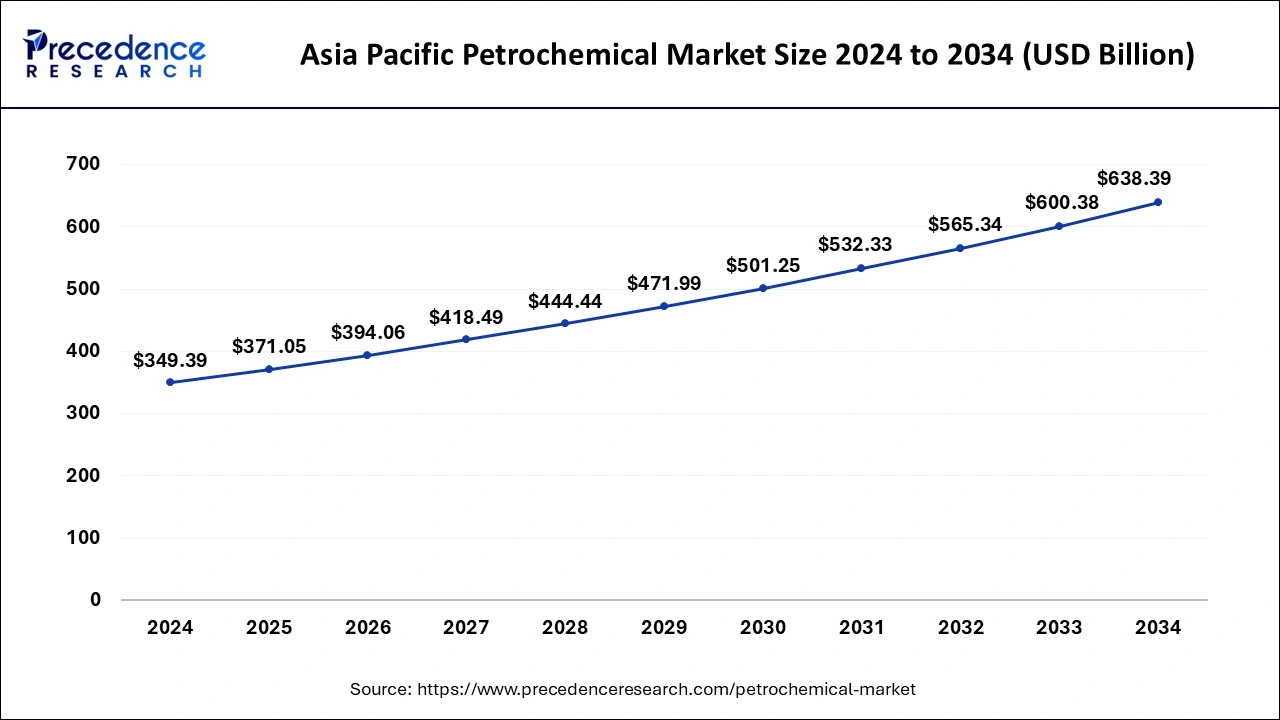

The Asia Pacific petrochemical market size was evaluated at USD 371.05 billion in 2025 and is projected to be worth around USD 674.42 billion by 2035, growing at a CAGR of 6.16% from 2026 to 2035.

The Asia Pacific region has been undergoing rapid industrialization and urbanization, particularly in countries like China and India. This growth drives the demand for petrochemical products, which are essential for various industries, including construction, automotive, and manufacturing. The demand for plastics, a major product of the petrochemical industry, has been consistently rising in the Asia Pacific region. Plastics are widely used in packaging, construction, consumer goods, and automotive applications, contributing to the overall growth of the petrochemical market.

India is expected to lead the global market in the upcoming years. India's petrochemical industry is experiencing robust growth, driven by rising demand for products like electric vehicles, solar panels, and household appliances. The availability of disposable income is fostering this growth.

- The Indian petrochemical sector is expected to continue its growth trajectory in 2025, driven by strong local demand and a growing middle-class population. The Indian petroleum sector is expected to reach $300 billion, up from its current value of $220 billion, with potential for further growth to $1 trillion by 2040.

- From May 8-9, 2025, the Gujarat Chem & PetChem Conference 2025 will be held as a step towards exploring the current opportunities in the Chemicals and Petrochemicals sectors in the state and how these can be translated into reality. The conference will bring together around 500 industry professionals, including 100 Manufacturing Heads/Plant Heads from Gujarat and pan India. The theme of the event is Viksit Gujarat: Viksit Bharat@2047.

North America hosted the dominant petrochemical market in 2025. In the past ten years, North America's petroleum industry has been propelled by technological advancements, especially in the area of hydraulic fracturing, which produces shale oil. The region's domestic fuel consumption has been outpaced by oil and gas production, and investors are anticipated to step up their efforts to build additional production facilities. It is anticipated that the presence of crude oil and the intention of several multinational chemical companies to build new facilities or enlarge existing ones in the area would greatly accelerate regional growth.

In North America, the United States dominated the market in 2024 and is expected to continue to do so for the duration of the projection. Among the top 10 manufacturers of petrochemicals, the nation generates substantial demand from end-use sectors including paints and coatings, construction, and automobiles. Furthermore, the region's need for green petrochemical goods is anticipated to be fueled by growing government activities related to sustainability and recycling.

Europe's Petrochemical Industry Rises Via Green Transition and Refinery New Builds

Europe's petrochemical industry is rapidly developing due to increased demand for sustainable products and strategic investment into circular economy projects. Europe is focusing on bio-based feedstocks and recycling technologies in order to achieve decarbonization. Among European nations, Germany has risen as the leader owing to its existing chemical manufacturing capabilities, its R&D facilities, and the presence of major players, notably, BASF and Covestro. Germany's focus on producing products using energy efficient processes while having an integrated petrochemical sector that connects the automotive and plastic packaging industries makes it the focal point in implementing new ideas and still be resilient in these supply chains.

Value Chain Analysis

- R&D: R&D in the petrochemical market emphasizes sustainable innovations such as recycling and renewable feedstocks.

Focus is placed on improving process efficiency using AI and machine learning.

Development of advanced, high-performance, and specialty chemicals is a key priority.

- Regulatory Approvals: Regulatory approvals in the petrochemical market require obtaining key industry licenses, like factory and explosives licenses.

Environmental clearances such as Consent to Establish (CTE) and Consent to Operate (CTO) from the State Pollution Control Board are mandatory.

Companies must also comply with national regulations, including Quality Control Orders (QCOs) for certain chemicals.

- Packaging: The petrochemical market uses specialized packaging to ensure safe storage and transport of products.

Common options include drums, intermediate bulk containers (IBCs), and bags.

Packaging materials typically consist of durable plastics, metals, or composite materials.

Top Vendors and their Offerings

- BP Plc- BP focuses on petrochemical production involving acetyls, aromatics, and polymers, emphasizing sustainable and energy-efficient manufacturing processes.

- Total S.A. (TotalEnergies)- TotalEnergies offers a wide range of petrochemical products, including polymers, resins, and olefins, with a strong focus on circular economy and low-carbon solutions.

- ExxonMobil Corporation- ExxonMobil produces high-performance polymers, elastomers, and chemical intermediates, leveraging advanced technologies for cleaner and more efficient petrochemical operations.

- BASF SE- BASF manufactures diverse petrochemical products such as solvents, plasticizers, and monomers, integrating innovation and sustainability across its global chemical value chain.

- Dow- Dow specializes in advanced materials, performance plastics, and chemical intermediates, focusing on sustainable production and high-performance applications across multiple industries.

Other Major Petrochemical Market Companies

- Sumitomo Chemical Co., Ltd.

- Chevron Phillips Chemical Company

- Saudi Arabian Oil Co.

- DuPont de Nemours, Inc.

- China Petroleum & Chemical Corporation

Recent Developments

- On May 5, 2025, the American University in Cairo (AUC) announced the launch of a new professional diploma in Process Safety Management (PSM) tailored for Egypt's oil, gas, and petrochemical sectors, following the signing of a Memorandum of Understanding (MoU).

- In April 2025, China Petrochemical Corporation announced the official launch of the country's first cross-region hydrogen heavy-duty truck route, marking a milestone in terms of advancing hydrogen energy development in China's western regions.

- In February 2025, Minister of Petroleum and Mineral Resources Karim Badawi launched the activities of the eighth edition of the Egypt International Energy Conference and Exhibition (EGYPES 2025).

- In January 2025, Union Minister for Petroleum and Natural Gas Hardeep Singh Puri launched the Mangalore Refinery and Petrochemicals Ltd. toluene product during his visit to the refinery. The company has an annual production capacity of 40 thousand metric tonnes, Toluene exemplifies India's progress towards self-reliance and global competitiveness in the petrochemical sector, a release stated.

- In June 2023, the chairman of Thai conglomerate Siam Cement Group told Reuters on Monday that Long Son Petrochemicals, owned by SCG Chemicals, will begin commercial production at its petrochemical facility in southern Vietnam in September. On the fringes of an industry gathering, Roongrote Rangsiyopash of Siam Cement Group stated that the company is testing every functioning unit at the site.

- In March 2023, as part of the multitrillion-dollar Belt and Road initiative, China and Saudi Arabia established a joint venture for an integrated refinery and petrochemical complex for raw materials and fine chemicals. According to the Chinese Daily Global Times, the $12.2 billion project between China and Saudi Arabia, known as a green and low-carbon initiative, was unveiled in Panjin city in the northeastern Liaoning province.

Segments Covered in the Report

By Product Type

- Ethylene

- Polyethylene

- Ethylene oxide

- EDC

- Ethyl benzene

- Other (including alpha olefins, vinyl acetate, etc.)

- Propylene

- Polypropylene

- Propylene oxide

- Acrylonitrile

- Cumene

- Acrylic acid

- Isopropanol

- Other

- Butadiene

- SB Rubber

- Butadiene rubber

- ABS

- SB latex

- Other (nitrile rubber, mechanical belts, etc.)

- Benzene

- Ethyl benzene

- Phenol/cumene

- Cyclohexane

- Nitrobenzene

- Alkyl benzene

- Other (including alkyl benzene, maleic anhydride)

- Xylene

- Toluene

- Benzene

- Xylenes

- Solvents

- TDI

- Others (including pesticides, drugs, nitro toluene, etc.)

- Methanol

- Formaldehyde

- Gasoline

- Acetic acid

- MTBE

- Dimethyl ether

- MTO/MTP

- Other

By Manufacturing Processes

- Fluid Catalytic Cracking (FCC)

- Steam cracking

- Catalytic reforming

By Application

- Aerospace

- Agriculture

- Automotive

- Building & Construction

- Consumer & Industrial Goods

- Others

By Geography

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting