What is the Impact Modifier Market Size?

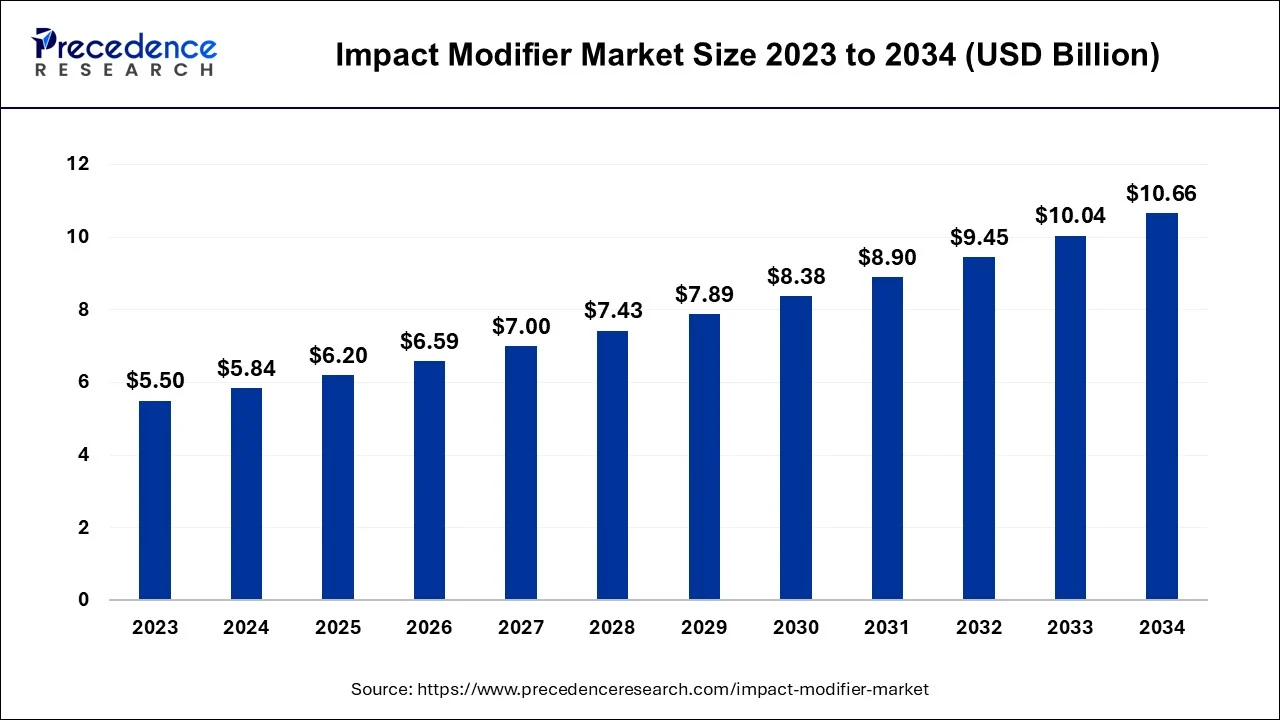

The global impact modifier market size accounted for USD 6.20 billion in 2025and is predicted to increase from USD 6.59 billion in 2026 to approximately USD 11.26 billion by 2035, growing at a CAGR of 6.15% between 2026 and 2035.

Market Highlights

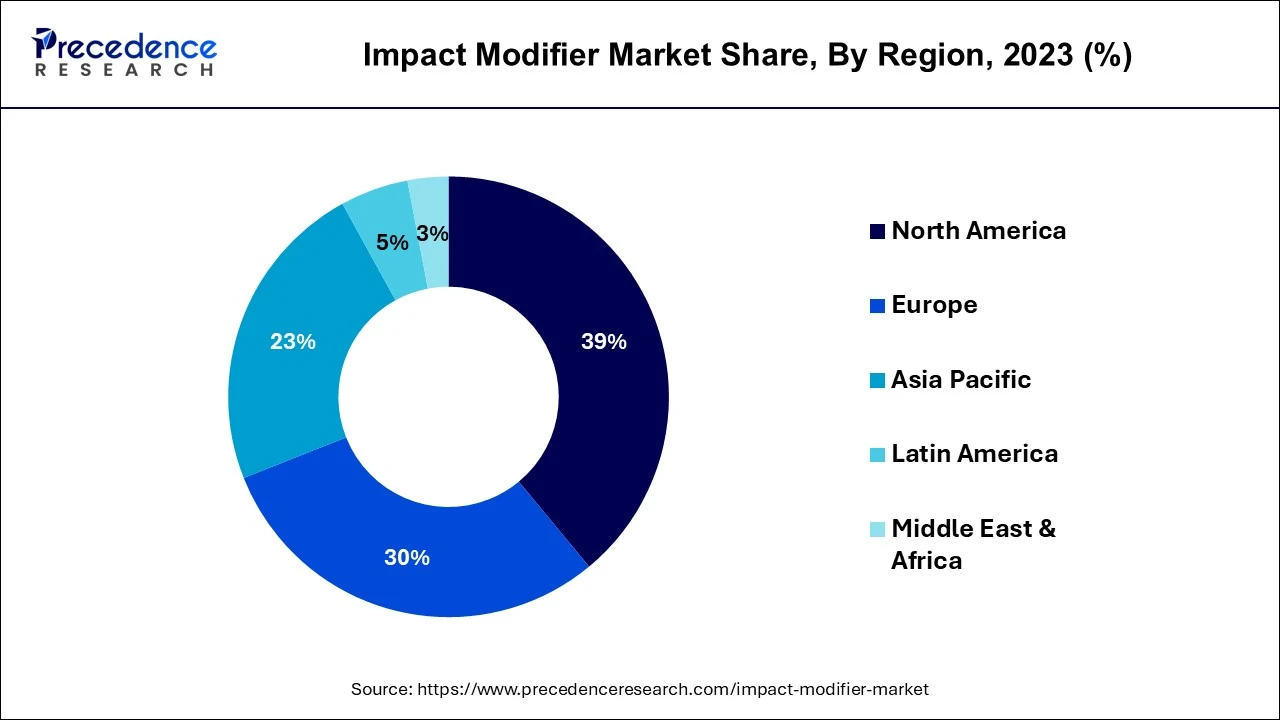

- North America contributed more than 39% of revenue share in 2025.

- Asia Pacific is estimated to expand the fastest CAGR between 2026 and 2035.

- By type, the acrylonitrile butadiene styrene segment has held the largest market share of 36% in 2025.

- By type, the acrylic impact modifiers segment is anticipated to grow at a remarkable CAGR of 7.8% between 2026 and 2035.

- By application, the polyvinyl chloride segment generated over 34% of revenue share in 2025.

- By application, the nylon segment is expected to expand at the fastest CAGR over the projected period.

- By end-user, the packaging segment had the largest market share of 43% in 2025.

- By end-user, the consumer goods segment is expected to expand at the fastest CAGR over the projected period.

Market Overview

The impact modifier market is a segment of the chemical industry focused on additives used to enhance the impact resistance and toughness of plastics. These modifiers are incorporated into polymer formulations to improve the material's ability to withstand impact and stress without breaking or cracking. The impact modifier market is integral to various industries, including automotive, construction, packaging, and consumer goods, where the ability to withstand impact is essential. It is propelled by the demand for robust and secure materials, accentuating the use of lightweight, high-performance plastics. These plastics play a pivotal role in the production of items like automotive parts, construction materials, pipes, and packaging, where enhanced impact resistance and durability are vital characteristics.

How is AI Influencing the Impact Modifier Industry?

Artificial Intelligence is transforming the impact modifier industry, a sector targeted on improving the toughness and even durability of plastics, by accelerating material innovation, improving manufacturing efficiency, and allowing the development of more sustainable products. The usage of AI and robotics in production lines is enhancing the consistency of polymer-modifier mixing. AI-enabled sensors, along with computer vision systems, detect defects in real-time, decreasing waste and ensuring higher quality.

Impact Modifier Market Growth Factors

- The market's growth is powered by the essential requirement for durable and secure materials. This necessity is particularly evident in industries where the use of strong and resilient plastics is paramount for product integrity and safety.

- The market is witnessing a noticeable shift towards lightweight, high-performance plastics, with a particular focus on the automotive sector. In this industry, the reduction of weight, coupled with the preservation of exceptional impact resistance, holds paramount importance. These lightweight materials are instrumental in achieving improved fuel efficiency and overall performance in automotive applications.

- As safety regulations become more stringent, the use of impact modifiers to improve the safety and durability of products gain significance.

- The industry is witnessing a shift toward sustainable impact modifiers to meet environmental concerns and consumer demands for eco-friendly materials.

- The development of tailored impact modifier formulations for specific applications is gaining traction, allowing for improved performance and product compatibility.

- Developing novel and more sustainable impact modifier solutions presents significant business opportunities, catering to the demand for eco-friendly materials.

- Expanding into emerging markets offers growth prospects, as industries in these regions seek enhanced materials for diverse applications.

- Providing tailor-made impact modifiers for specific industries and applications allows for niche market penetration and tailored product development.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 6.20 Billion |

| Market Size in 2026 | USD 6.59 Billion |

| Market Size by 2035 | USD 11.26 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.15% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Type, Application, End-user, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Demand for durable materials and lightweight plastics

The surging demand for durable materials is a primary driver of the impact modifier market. In sectors where the integrity and safety of products are of utmost importance, such as construction and consumer goods, the demand for strong and resilient plastics is indisputable. In such applications, impact modifiers are instrumental in fortifying these materials, ensuring they can endure wear and tear, thereby guaranteeing the durability and safety of the final products. As consumers continue to expect products that stand the test of time, the market experiences a steady influx of demand for impact modifiers to fortify various materials, from packaging to construction materials.

The growing emphasis on lightweight, high-performance plastics, particularly in the automotive sector, is a significant driver. Automakers strive to reduce vehicle weight to enhance fuel efficiency and performance. However, achieving this goal without compromising impact resistance is challenging. Impact modifiers enable the development of lightweight materials that meet both safety and environmental standards, making them invaluable in the pursuit of lighter, more efficient automotive solutions. As the automotive industry and other sectors increasingly prioritize weight reduction, the demand for impact modifiers surges, thus propelling market growth.

Restraint

Product compatibility, cost, and pricing pressure

A significant restraint in the impact modifier market is the challenge of achieving the right balance of impact modifiers with other components in complex product formulations. Compatibility issues can arise, affecting the overall performance of the final product. For instance, in automotive manufacturing, impact modifiers must integrate seamlessly with various plastic components to maintain structural integrity and safety. Any compatibility issues can result in product defects, performance degradation, or higher production costs. Overcoming these challenges often requires extensive testing and custom formulations, increasing development time and costs.

The cost of incorporating impact modifiers into plastic formulations can be a restraint for manufacturers, particularly for smaller businesses. These additives add expenses to the production process, affecting the overall cost of manufacturing. As a result, companies may face pricing pressure, especially in competitive markets. Striking a balance between product quality and pricing becomes crucial, as consumers seek cost-effective solutions without compromising performance. Manufacturers must find ways to remain competitive while managing the increased expenses associated with impact modifiers, which can be challenging and may affect profitability.

Opportunity

Customized formulations, innovation and sustainability

The surge in market demand for impact modifiers is significantly driven by the development of customized formulations. Industries are increasingly seeking tailored impact modifier solutions designed to enhance performance in specific applications. This customization allows for precise adjustments to meet the unique requirements of diverse industries, such as automotive, construction, and packaging. The ability to fine-tune impact modifiers for particular applications not only ensures optimal product compatibility but also fosters their adoption in a wide range of manufacturing processes.

Innovation is a key catalyst in propelling the market demand for impact modifiers. The industry continually seeks groundbreaking solutions that offer enhanced performance and versatility. Novel technologies, such as sustainable impact modifiers, address both consumer demand for eco-friendly materials and regulatory requirements. These innovative products not only enhance impact resistance but also cater to environmental concerns, making them attractive to a broader spectrum of industries.

Moreover, the focus on sustainability is a major driver for impact modifiers. As environmental consciousness grows, industries seek impact modifiers that align with eco-friendly practices. Sustainable impact modifiers are derived from renewable sources and are biodegradable, minimizing environmental impact. This eco-conscious approach resonates with consumers and industries alike, surging the demand for impact modifiers that not only bolster performance but also support environmental responsibility.

Segment Insights

Type Insights

According to the type, the acrylonitrile butadiene styrene segment has held a 36% revenue share in 2025. ABS impact modifiers are polymer additives that enhance the impact strength and toughness of ABS plastics. These modifiers improve the overall performance of ABS resins, making them suitable for a wide range of applications, including automotive parts, pipes, and consumer goods. A notable trend in ABS impact modifiers is the development of sustainable and eco-friendly formulations to align with the industry's shift towards greener practices, offering improved impact resistance without compromising environmental responsibility.

The acrylic impact modifiers segment is anticipated to expand at a significant CAGR of 7.8% during the projected period. Acrylic impact modifiers are additives used to enhance the impact resistance of various plastics, including PVC and engineering plastics. These modifiers are essential in applications where durability and toughness are crucial, such as construction materials and rigid packaging. A trend in acrylic impact modifiers is their increasing use in sustainable and recyclable plastics to meet eco-conscious consumer demands while maintaining the desired impact resistance in end products.

Application Insights

Based on the application, the polyvinyl chloride segment held the largest market share of 34% in 2025. In the impact modifier market, PVC applications are a prominent driver. PVC is a widely used thermoplastic with applications in construction, automotive, and packaging. The demand for impact modifiers in PVC products is increasing due to the need for enhanced impact resistance, especially in construction materials like pipes and fittings. A notable trend in this segment is the shift towards eco-friendly impact modifiers, aligning with sustainability goals in the construction industry.

On the other hand, the nylon segment is projected to grow at the fastest rate over the projected period. Impact modifiers find applications in nylon, another versatile thermoplastic used in automotive components, sports equipment, and consumer goods. The market trend in nylon applications involves custom formulations to cater to specific end-uses, improving impact strength without compromising other properties. Additionally, the demand for sustainable impact modifiers is growing in the nylon segment, meeting the increasing preference for environmentally friendly materials in the production of sports and outdoor equipment.

End-user Insights

In 2025, the packaging segment had the highest market share of 43% on the basis of the end user. In the impact modifier market, the packaging industry seeks impact modifiers to enhance the durability of packaging materials. With a trend toward eco-friendly packaging, the use of impact modifiers aligns with the demand for sustainable and resilient packaging solutions. The industry is increasingly exploring impact modifiers that improve the impact resistance and toughness of packaging materials while also adhering to eco-conscious practices.

The consumer goods segment is anticipated to expand at the fastest rate over the projected period. In the consumer goods sector, the impact modifier market plays a vital role in enhancing the impact resistance of various products, including appliances and household items. A notable trend is the integration of impact modifiers into consumer goods to extend their lifespan, thereby meeting the demand for more durable and long-lasting products. This trend caters to consumers seeking value and reliability in their purchases.

Regional Insights

What is the U.S. Impact Modifier Market Size?

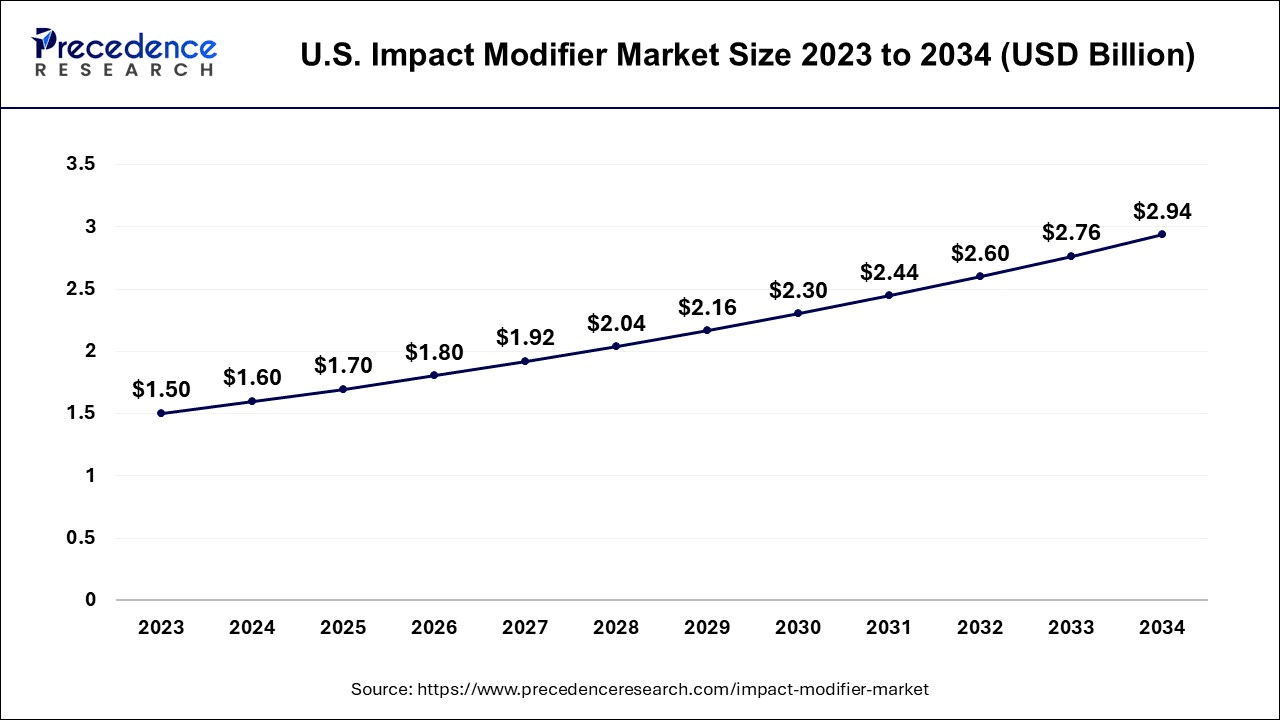

The U.S. impact modifier market size is estimated at USD 1.70 billion in 2025 and is expected to be worth around USD 3.11 billion by 2035, at a CAGR of 6.23% from 2026 to 2035.

North America held the largest revenue share of 39% in 2025. The impact modifier market in North America is marked by a trend towards sustainable and eco-friendly solutions. Regulatory pressures and consumer preferences for environmentally responsible materials are driving the adoption of sustainable impact modifiers in industries like automotive and construction. Additionally, there is a growing emphasis on customized formulations to meet the specific requirements of various applications, such as packaging and consumer goods, ensuring optimal impact resistance.

U.S. Impact Modifier Market Analysis

The market in the U.S. is expanding due to rising demand for lightweight, high-performance plastics in automotive, construction, and packaging industries. Stringent safety and durability standards, increasing use of sustainable polymer solutions, advancements in polymer compounding technologies, and strong domestic manufacturing capabilities are further driving market growth across the country

Why is the Market in Asia Pacific Growing at the Fastest Rate?

Asia Pacific is estimated to observe the fastest expansion. In Asia Pacific, the impact modifier market is witnessing robust growth driven by the expanding construction and automotive sectors. There's an increasing need for durable and impact-resistant materials in these industries, along with a focus on lightweight solutions. As a result, the demand for impact modifiers to enhance the performance of plastics in various applications is on the rise, positioning Asia Pacific as a key growth region for the market.

China Impact Modifier Market Analysis

China's market is growing due to rapid industrialization, large-scale infrastructure development, and expanding automotive and consumer goods manufacturing. Rising demand for durable, lightweight plastics, increasing plastic processing capacity, and government support for advanced materials and domestic chemical production are further boosting the adoption of impact modifiers across construction, packaging, and automotive applications.

What Influences the Market in Europe?

In Europe, the impact modifier market is characterized by a strong emphasis on sustainability and innovation. Industries are progressively adopting eco-friendly and custom-tailored impact modifiers to meet stringent environmental regulations and consumer demand for cleaner, high-performance materials. As safety and regulatory standards evolve, European industries are turning to advanced impact modifiers to ensure compliance and durability in various applications, contributing to market growth and the development of cutting-edge solutions.

UK Impact Modifier Market Analysis

The UK market is expanding due to rising demand for high-performance and sustainable plastics in construction, automotive, and packaging sectors. Strict environmental regulations, growing adoption of recyclable materials, and innovation in polymer formulation are encouraging manufacturers to use advanced impact modifiers that enhance durability, safety, and compliance with evolving material standards.

Rising Demand for Toughest Plastics Drives Impact Modifier Industry Growth in Latin America

Latin America's market shows notable growth during the forecast period, as it is driven by rising cities' demand for durable materials for pipes, window profiles, and even building components. There is an increase in online shopping, which requires resilient, high-performance packaging that withstands transit, increasing the usage of impact modifiers in packaging films and containers. Brazil leads regional expansion with steady growth in the construction and automotive sectors, while other markets such as Argentina, Colombia, and Chile are also contributing to overall market volume.

Argentina Impact Modifier Market Trends

Argentina's market is driven by the increasing need for durable, impact-resistant plastics across construction, automotive, and packaging sectors. Growing urbanization and infrastructure development boost the demand for resilient materials, fueling market expansion.

From Rigid to Resilient: Impact Modifier Market Accelerates in MEA

MEA's market shows a rapid growth rate during the forecast period. With the growth of e-commerce and consumer goods, the need for robust, flexible packaging that can withstand rough handling is increasing, driving the acceptance of impact-modified, high-performance plastics. There is a noticeable shift towards sustainable and higher-performing impact modifiers, including bio-based grades, as manufacturers respond to environmental awareness and regulatory pressures.

Kuwait Impact Modifier Market Trends

Kuwait's market is driven by the increasing need for high-performance plastics in numerous industries, including automotive, construction, and packaging, in line with wider global trends. The rising demand for durable, lightweight, and impact-resistant materials has contributed to an increase in the adoption of impact modifiers.

Value Chain Analysis for the Impact Modifier Market

- Feedstock Procurement

It is highly sensitive to raw material expense volatility, supply chain disruptions, and, increasingly, regulatory pressures aiming for sustainability.

Key Players: Dow Inc., BASF SE, LG Chem Ltd., Kaneka Corporation - Chemical Synthesis and Processing

It works by transforming monomers via controlled chemical reactions, mainly emulsion or suspension polymerization, into tailored rubbery particles programmed to disperse within a plastic matrix and absorb energy.

Key Players: Evonik Industries AG, Shandong Ruifeng Chemical Co., Ltd., LANXESS A.G. - Compound Formulation and Blending

It includes the technical process of incorporating rubbery or even elastomeric additives into a rigid polymer matrix to raise its toughness, durability, and shock resistance, mainly at low temperatures.

Key Players: BASF SE, Mitsubishi Chemical Corporation, Shandong Ruifeng Chemical Co., Ltd

Impact Modifier Market Companies

- Lanxess AG- Produces advanced impact modifiers and specialty polymers that enhance toughness and durability in automotive, construction, and plastics applications.

- Kaneka Corporation- Supplies high-performance impact modifiers and elastomeric additives to improve plastic resilience in packaging, automotive, and industrial products.

- Mitsubishi Chemical Corporation- Offers impact modifiers and engineered polymer blends that boost impact resistance and performance in various plastic materials.

- Dow Inc.- Provides a broad range of impact modifiers and polymer additives designed for enhanced toughness in consumer, automotive, and industrial plastics.

- Evonik Industries AG- Develops specialty impact modifiers and polymer additives that improve durability, flexibility, and performance in high-end plastics applications.

- 3M Company- Offers engineered impact modifier solutions and advanced polymer technologies for strengthened, resilient plastic applications across multiple industries.

- LG Chem Ltd.- Produces impact modifiers and polymer solutions that enhance toughness and performance in automotive, electronics, and consumer plastics.

- Chemtura Corporation- Supplies impact modifiers and chemical additives to boost impact strength and processing performance in plastics manufacturing.

Other Major Key Players

- E. I. du Pont de Nemours and Company

- Arkema S.A.

- Shandong Ruifeng Chemical Co., Ltd.

- Akdeniz Kimya Sanayi A.S.

- Addivant USA, LLC

- Akzo Nobel N.V.

- Baerlocher GmbH

Recent Developments

- In December 2024, Arkema completed the acquisition of Dow's flexible packaging laminating adhesives business, valued at around US $150 million. The deal enhances Arkema's high-value adhesives portfolio and expands its packaging capabilities, supporting performance materials applications, including additives and modifiers.(Source: https://www.arkema.com/ )

- In 2023, BASF Forward AM collaborates with Arkema to boost sustainability in Additive Manufacturing. This partnership offers innovative recycling solutions for both polymer producers and consumers, promoting the adoption of partially recycled grades.

- In 2023, Covestro and Selena Group have joined forces to create sustainable polyurethane foams for improved building thermal insulation. This collaboration combines Selena Group's construction chemicals expertise with Covestro's plastics manufacturing capabilities.

Segments Covered in the Report

By Type

- Acrylonitrile Butadiene Styrene

- Acrylic Impact Modifiers

- Acrylonitrile Styrene Acrylate

- Methacrylate-Butadiene-Styrene

- Ethylene Propylene Diene Monomer

- Chlorinated Polyethylene

- Others

By Application

- Polyvinyl Chloride

- Nylon

- Polybutylene Terephthalate

- Engineering Plastics

- Other

By End-user

- Automotive

- Construction

- Consumer Goods

- Packaging

- Other

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting