What is the Industrial Air Compressor Market Size?

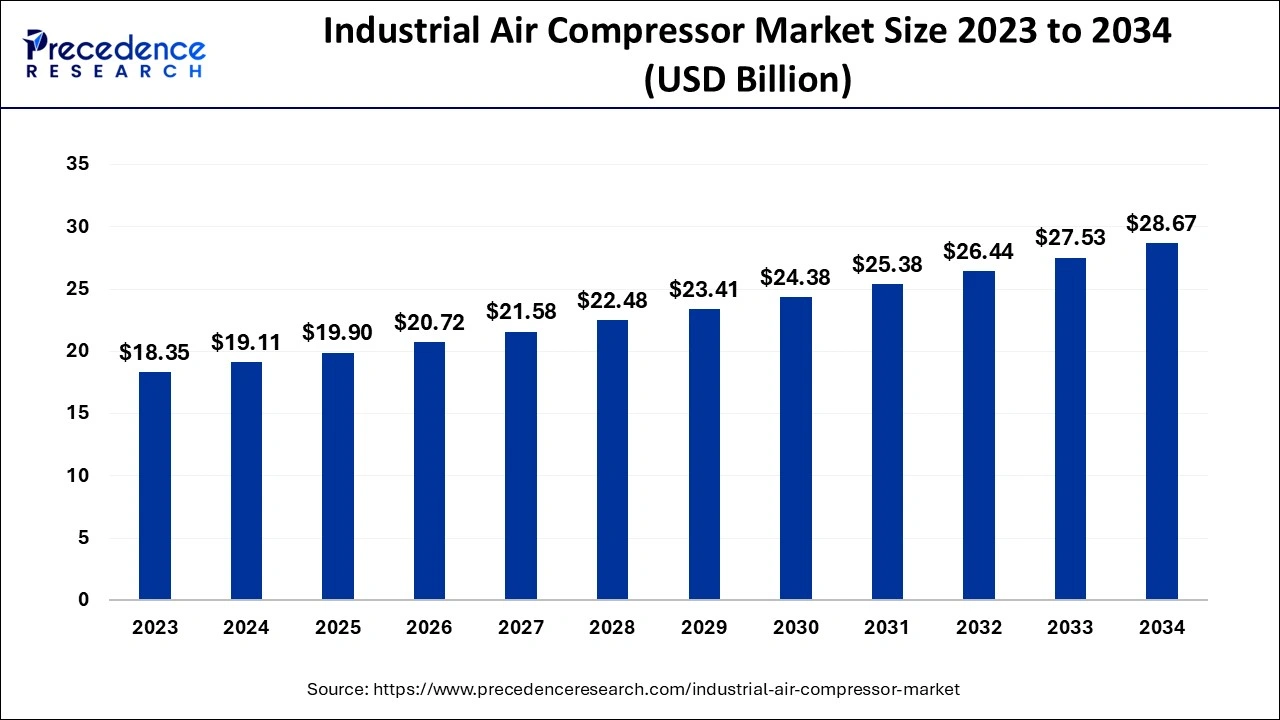

The global industrial air compressor market size is calculated at USD 19.90 billion in 2025 and is predicted to increase from USD 20.72 billion in 2026 to approximately USD 29.81 billion by 2035, expanding at a CAGR of 4.12% from 2026 to 2035

Market Highlights

- Sales in China is projected to increase at a CAGR of 6% from 2026 and 2035.

- The rotary type industrial air compressors record for 31% sales in the market.

- The increasing demand for oil and gas industry is anticipated to rise at a CAGR of 5.2% from 2026 to 2035.

- In 2023, the double compression stage segment accounted market share of around 48%.

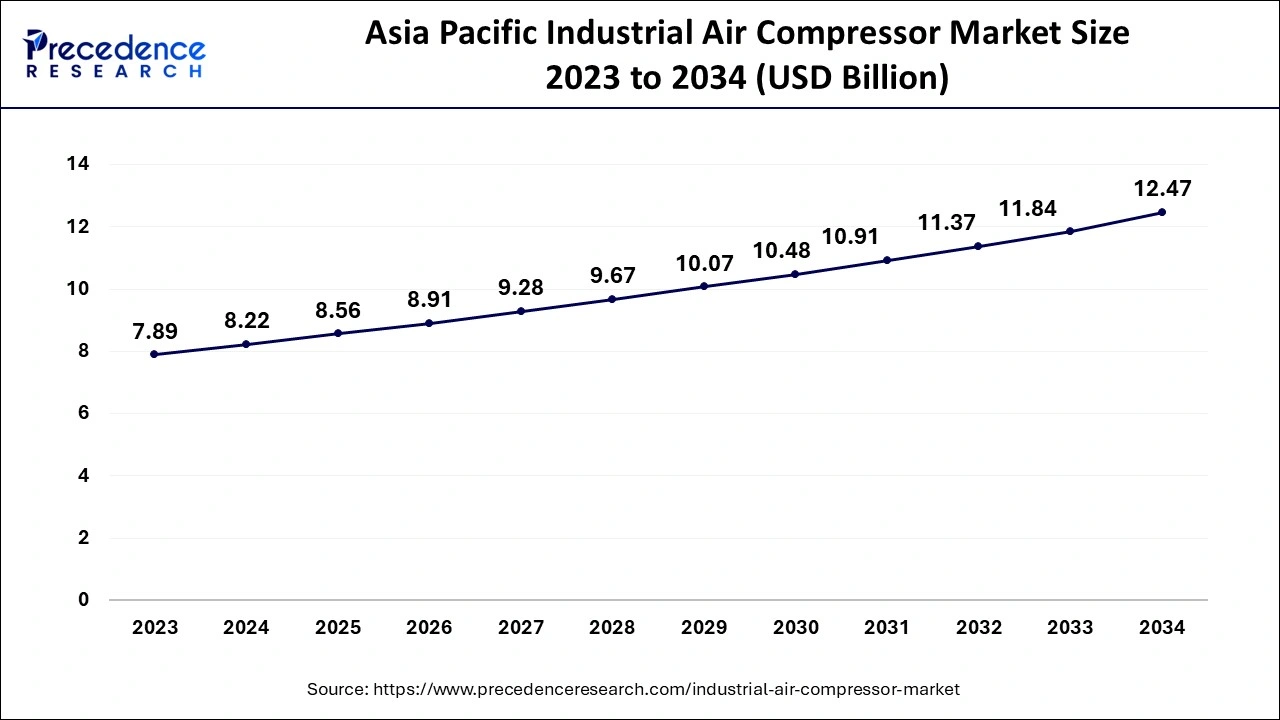

- Asia Pacific region was valued at USD 7.89 billion in 2025.

Market Overview

Industrial air compressors are mechanical devices used to pressurize liquids or gases. The most common is air. A variety of compressors are used in the industry to provide the following features: instrument or shop air; powering air tools, abrasive blast equipment, and paint sprayers, and more. Industrial air compressors are universal devices that provide compressed air for a variety of production processes. When selecting an air compressor for an application, it is important to make sure that the selected unit can produce the desired output while maintaining low maintenance and operating costs. The best air compressor for a particular application depends on many factors, including the purpose, tools or processes it supports, and the project budget.

One of the most important advantages of using air compressors is that they are safe. They can withstand high temperatures and offer the simplicity and security of using only air instead of additional energy sources. When compared to equipment that uses electricity, there is no risk of electric shock to personnel who handle the equipment, and in the workplace, the safety of your team is always vital.

How is Artificial Intelligence Impacting the Industrial Air Compressor Market?

Artificial intelligence (AI) is revolutionizing how industrial air compressors operate. AI enables predictive maintenance, fault detection, and energy optimization in industrial compressor systems using IIoT technology. Companies like Atlas Copco and Siemens are employing AI to enhance the performance of their systems through real-time monitoring, which reduces unexpected downtime and prolongs the lifespan of compressor components. Numerous peer-reviewed articles demonstrate that machine learning algorithms trained on compressor sensor data can accurately identify faults.

The combination of cloud analytics and edge computing allows users to adjust compressor control variables in real-time, including the stage, pressure control, and energy consumption. AI and remote diagnostic features enable vendors to shift from reactive maintenance to condition-based strategies, leading to more reliable compressor operation, reduced lifecycle costs for compressor manufacturers and heavy industry operators, and faster identification of the root causes of compressor issues. Currently, with AI platform integration, compressor operators can quickly pinpoint root causes and obtain fleet-level insights from the platform.

Industrial Air Compressor Market Growth Factors

As the world becomes more urbanized, industries are springing up at a quicker rate in many places. Demand for a variety of industries, such as food and beverages, manufacturing, semiconductors, electronics, and so on, has expanded, particularly in emerging countries. Centrifugal air compressors are widely utilized in these industries because they provide large amounts of air at a low cost. It also has a longer working life, reducing the amount of capital investments even further. Several rising economies, including Asia-Pacific and Africa, have accelerated their industrial and economic growth. Furthermore, government measures to promote industrial automation, as well as a focus on industrial automation for optimal resource usage, are boosting demand for industrial air compressors.

The growing need for automobiles around the world, particularly in the Asia-Pacific region, is expected to boost demand for industrial air compressors, since the product is widely utilized in the automotive industry for manufacturing. The expansion of the vehicle industry in Europe and North America will also help the market thrive. Despite the fact that their populations are growing at a slower rate than those in emerging countries, U.S. and Europe remain the most important markets for the automobile industry, owning to technical advancements. Moreover, the air compressor market outperformed the rest of the industry and is expected to grow.

The rapid industrial improvements in the Asia-Pacific area, spurred by the widespread use of compressed air in practically all manufacturing activities, will push up their use. Stationary air compressors are utilized in a variety of applications, including refrigeration and air conditioning, cars, and industrial uses. Smaller ones are used in autos, freezers, and air conditioners, whereas medium and bigger ones are used by industrial end-users. Hence, the escalating demand throughout the globe due to the improved lifestyle, growing spending power, and increasing population of the region will drive the demand for air compressors.

What are the Major Trends Influencing the Industrial Air Compressor Market?

- Technological Innovation: Innovative technologies like IoT platforms and analytics built on IoT that use sensor technologies enable monitoring, predicting failures, maximizing energy savings, providing remote diagnostics, creating more reliable equipment, and reducing overall costs for industrial users.

- Focus on Energy Efficiency: The rising cost of energy and environmental goals are pushing industrial players to adopt high-efficiency, variable speed drives, and optimized air management in their operations. These technologies reduce total energy consumption, CO2 emissions, and life-cycle costs associated with operating air compressors across the industrial sector.

- Demand for Oil-Free Air Systems: Oil-free air systems have become the preferred choice for many industries to meet strict environmental regulations regarding air quality for food, pharmaceutical, electronics, and healthcare products. The use of oil-free technology minimizes the risk of contamination, reduces regulatory compliance burdens, and eliminates many of the filtration and maintenance costs associated with traditional oil-lubricated compressors.

- Modular Designs are Gaining Popularity: As manufacturing facilities seek more versatile and space-efficient options, compact modular compressor designs are becoming more accepted due to their ease of phased capacity expansion, quick installation, maintenance benefits, and ability to be customized to meet different manufacturer needs.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 19.90 Billion |

| Market Size in 2026 | USD 20.72 Billion |

| Market Size by 2035 | USD 29.81 Billion |

| Growth Rate from 2026 to 2035 |

CAGR of 4.12% |

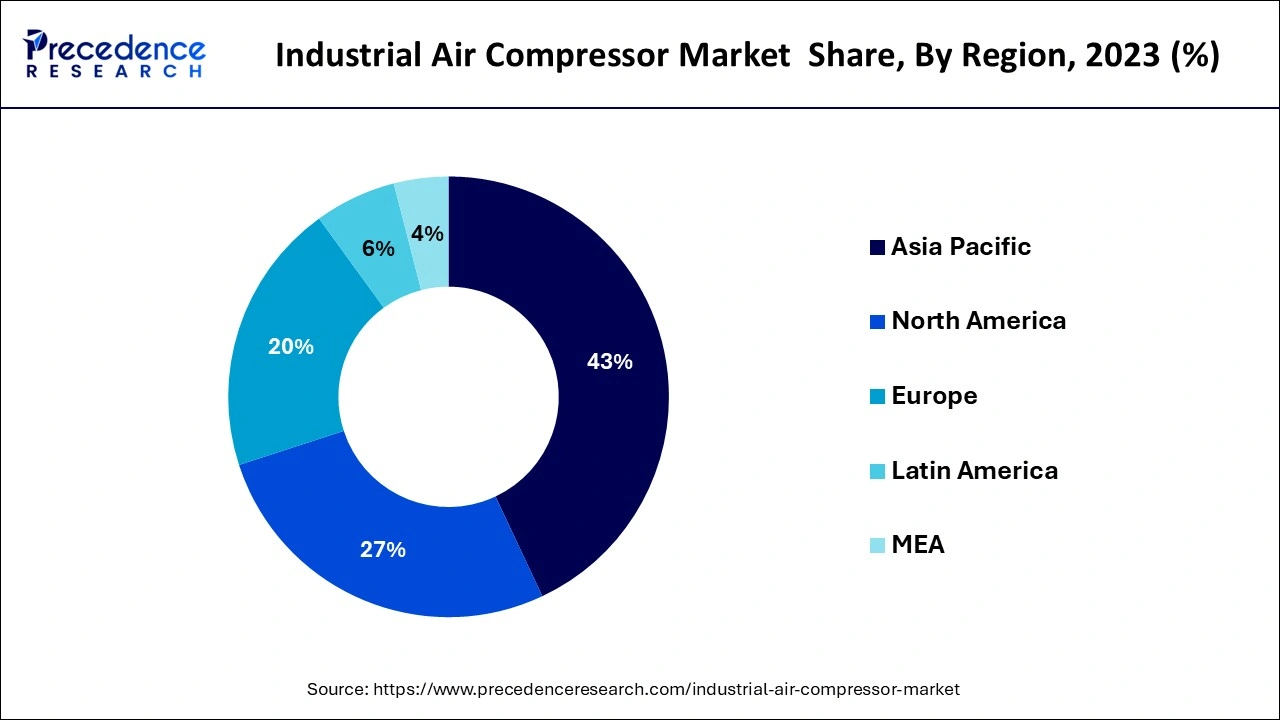

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Product, Design, Technology, Output Power, Seal, Coolant Type, Compression Stage, Driver Type, End User, and Region |

Segment Insights

Product Type Insights

Depending upon the product type, the positive displacement category is predicted to grow. Positive displacement air compressors are used in construction, automotive and transportation, packaging, food and beverage, metals and mining, and other end-user sectors. Increased investment is expected in these areas, which will enhance demand for positive displacement air compressors. The dynamic compressors operate at a constant pressure and are classified according to their axial or radial design. External circumstances, like as variations in inlet temperatures, have an impact on the operation of dynamic compressors.

Design Type Insights

On the basis of by design type, the stationary segment is expected to be the largest segment during forecast period. The industrial air compressors can be fixed at a specified position attributable to their stationary design. These air compressors have a greater cfm rating than portable air compressors because they can create a large amount of compressed air at once. These are used in facilities and industries where the compressor does not need to be mobile. When compared to portable compressors, stationary compressors may deliver higher air pressures.

The portable air compressor market has been steadily growing in recent years, thanks to increased use in building sites, road construction, and packaging machinery across a wide range of industries. Over the forecast period, burgeoning infrastructure initiatives in Asia-Pacific, Middle East, and Africa will provide manufacturers with attractive business prospects.

Pressure Type Insights

On the basis of pressure type, the 0-20 bar segment is expected to be the largest market to show a tremendous growth during the forecast period. Due to increased investments, the up to 20 bar segment is predicted to grow at the fastest rate. Food and beverage companies, as well as pharmaceutical companies, are substantially investing in industrial air compressors. Growth in these industries is expected to raise demand for compressors that can handle pressures in this range over the forecast period. The 20-100 bar segment is steadily moving in the market as it is high pressure air compressor.

Output power Insights

On the basis of output power, the 51–250 kW segment is expected to dominate the industrial air compressor market. The rated pressure for compressors in this range is expected to be 0.3–20 bar. Power plants, water and wastewater treatment plants, the chemical and petrochemical industries, the food and beverage industry, mining, the automotive and transportation sectors, packaging, construction, the metals sector, and manufacturing are all places where they're used. Several large-scale chemical projects, particularly in emerging economies, have boosted demand for industrial air compressors with output powers ranging from 51 to 250 kW, and demand is expected to continue to climb during the projected period.251-500 kW is one of the leading segments in this category after 51-250 kW segment. The demand for high pressure air compressor is used in heavy loaded industries.

Seal Type Insights

On the basis of seal type, the oil-flooded segment accounted largest market share in 2022. They are becoming increasingly popular since they are less expensive than oil-free compressors and can usually complete the compression process in a single stage. The compressor is widely used in areas where cleaner compressed air is not required, such as oil and gas, textiles, rubber and plastics, and metals and mining.

To keep the mechanism functioning smoothly, most oil-free compressors use alternative materials such as water or a Teflon coating. Because bearings and gears are lubricated outside the compression chamber, effective sealing prevents oil from polluting the compressed air. As outcome, there is no oil in the air supply. Some oil-free designs even eliminate metal-to-metal contact within the compression chamber, obviating the requirement for oil-based or synthetic lubrication entirely.

Coolant Type Insights

On the basis of coolant type, the air-cooled segment of the industrial air compressor market is likely to be the largest contributor. Modern compressors are usually air-cooled, with forced ventilation utilizing blowers, heat exchangers, and other components to keep the fluid cool. These compressors made up a larger portion of the industrial air compressor market, and their demand is expected to rise throughout the projected period.

Although water-cooled compressors require less power than air-cooled compressors, the electrical expenses of the cooling system, as well as water and water treatment costs, must be considered when choosing water-cooled. When those costs are taken into account, air-cooled compressors are usually more cost-effective. Hence, the air-cooled type is mostly used.

End User Insights

On the basis of end user, the chemicals & petrochemicals segment accounted largest revenue share in 2025 as developing economies' increased demand for chemical and petrochemical products.

Food and beverages industry is also one of the dominating segments that drive the need of industrial air compressor as they demand for high powered and high efficiency air compressors. Increased investment and demand for oil-free compressors in the food and beverage industry, as well as increased demand from the HVAC business drives the market.

Metals and mining segment is also influencing the air compressor market as rapid urbanization demands the need of such product in the market.

Regional Insights

Asia Pacific Industrial Air Compressor Market Size and Growth 2026 to 2035

The Asia Pacific industrial air compressor market size is evaluated at USD 8.56 billion in 2025 and is predicted to be worth around USD 13.10 billion by 2035, rising at a CAGR of 4.35% from 2026 to 2035.

Asia-Pacific is proving to be a booming market for the growth of the industrial air compressor market, due to increased industrialization and rising investments in LNG, chemicals, and mining, as well as the expansion of the domestic manufacturing sector, which includes automotive, and food and beverage manufacturing. Furthermore, Asia-Pacific is seeing substantial economic growth, and to satisfy its energy demand while adhering to decarburization rules, it is seeing a boom in investments in the hydrogen and green energy sectors.

India Industrial Air Compressor Market Analysis

India plays a key role in the Asia Pacific market, driven by the rapid adoption of energy-efficient compressed air systems. The country's market growth is supported by a range of government initiatives and policies that promote industrial efficiency and sustainability. Domestic players are focusing on designing and launching novel products to meet the rising demand from various industries. There is a rapid shift towards more energy-efficient solutions, contributing to market growth.

What Potentiates the Growth of the North America Industrial Air Compressor Market?

North America region is also proving to be a driving market for this sector pertaining to the rapid urbanization of this region. Demand for air compressors will be influenced by rising demand for residential appliances such as refrigerators and air conditioners, as well as rising living standards. Furthermore, rising vehicle demand, increased mining and oil exploration operations, and advancements in the energy and power generating sectors are all expected to contribute to regional market growth. Product demand will be boosted even more by the extremely promising energy and healthcare industries in the U.S.

U.S. Industrial Air Compressor Market Analysis

In the U.S., the market is growing due to regulatory pressure and emission standards. Federal efficiency standards and testing procedures form a key part of government regulations targeting industrial compressors. New product launches are emphasizing energy efficiency and the integration of smart technologies, such as IoT-enabled monitoring and predictive maintenance. Major industry players are also making significant investments in strategic acquisitions and manufacturing expansions to strengthen their market presence and meet growing industrial demand.

Value Chain Analysis

- Raw Material Supply:

This stage involves sourcing steel, aluminum, cast iron, electronic components, and other essential materials required for compressor manufacturing.

Key Players: ArcelorMittal, POSCO, Alcoa, and Bosch Materials. - Design & Engineering:

Compressors are designed for specific industrial applications, focusing on efficiency, pressure capacity, and durability.

Key Players: Atlas Copco, Ingersoll Rand, Kaeser Kompressoren, and Gardner Denver. - Manufacturing & Assembly:

This stage includes machining, assembly, and quality control of compressors, including rotary, reciprocating, and centrifugal types.

Key Players: Atlas Copco, Ingersoll Rand, Sullair, and Hitachi Industrial Equipment. - End-Use Applications:

Industrial air compressors are deployed across sectors such as manufacturing, construction, oil & gas, automotive, and food processing.

Key Players: Siemens, General Electric, Bosch, and large-scale industrial plants.

Industrial Air Compressor Market Companies

- Atlas Copco

- Ingersoll Rand

- Doosan Infracore

- Hitachi

- BOGE Kompressoren

- Volkswagen (MAN Energy Solutions)

- ELGiEquipments

- Kirloskar Pneumatic

- KaeserKompressoren

- Danfoss (Denmark)

- Coaire

- Siemens Energy

- Sulzer

- Baker Hughes

- Nidec

- EBARA Corporation (Elliott Group)

- Howden Group

- Mitsubishi Heavy Industries

Segments covered in the Report

By Product

- Positive Displacement

- Dynamic Displacement

By Design

- Stationary

- Portable

By Technology

- Rotary

- Reciprocating

- Centrifugal

- Axial

By Output Power

- Up To 20 Bar

- 21–100 Bar

- Above 100 Bar

By Pressure

- Up To 50 kW

- 51–250 kW

- 251–500 kW

- Above 500 kW

By Seal Type

- Oil-flooded

- Oil-free

By Coolant Type

- Air-Cooled

- Water-Cooled

By Compression Stage

- Single Stage

- Double Stage

- Multistage

By Driver Type

- Electric

- Natural Gas

- Fuel Driven

By End User

- Chemicals & Petrochemicals

- Food & Beverages

- Oil & Gas

- Pharmaceuticals

- Construction

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting