What is the Industrial Gearbox Market Size?

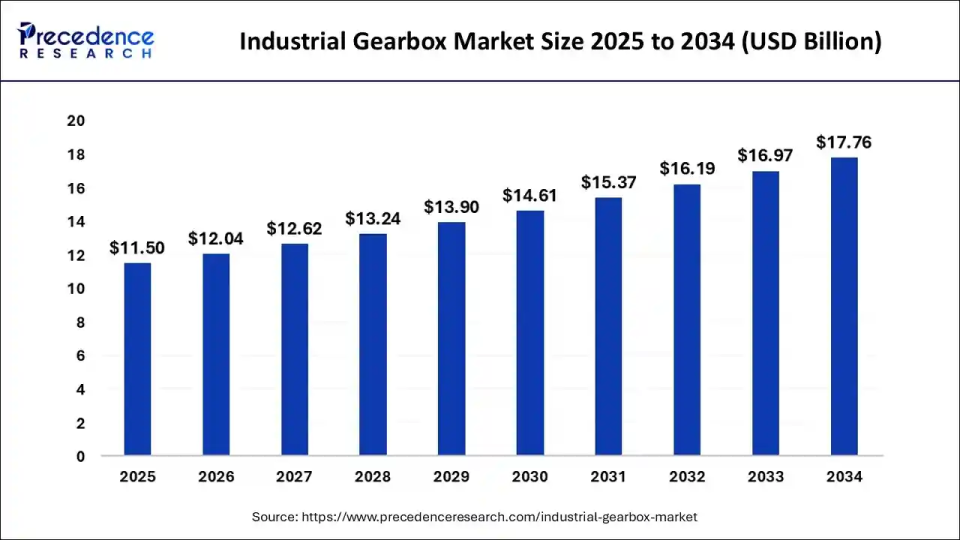

The global industrial gearbox market size is estimated at USD 11.50 billion in 2025 and is predicted to increase from USD 12.04 billion in 2026 to approximately USD 17.76 billion by 2034, expanding at a CAGR of 4.87% from 2025 to 2034. The rising demand for energy efficient solutions, rapid industrialization and urbanization, development of advanced gearbox technology with increasing investments and the increased focus on non-conventional energy sources such as wind power heavily relying on gearboxes for power transmission are driving the growth of the industrial gearboxes market.

Industrial Gearbox Market Key Takeaways

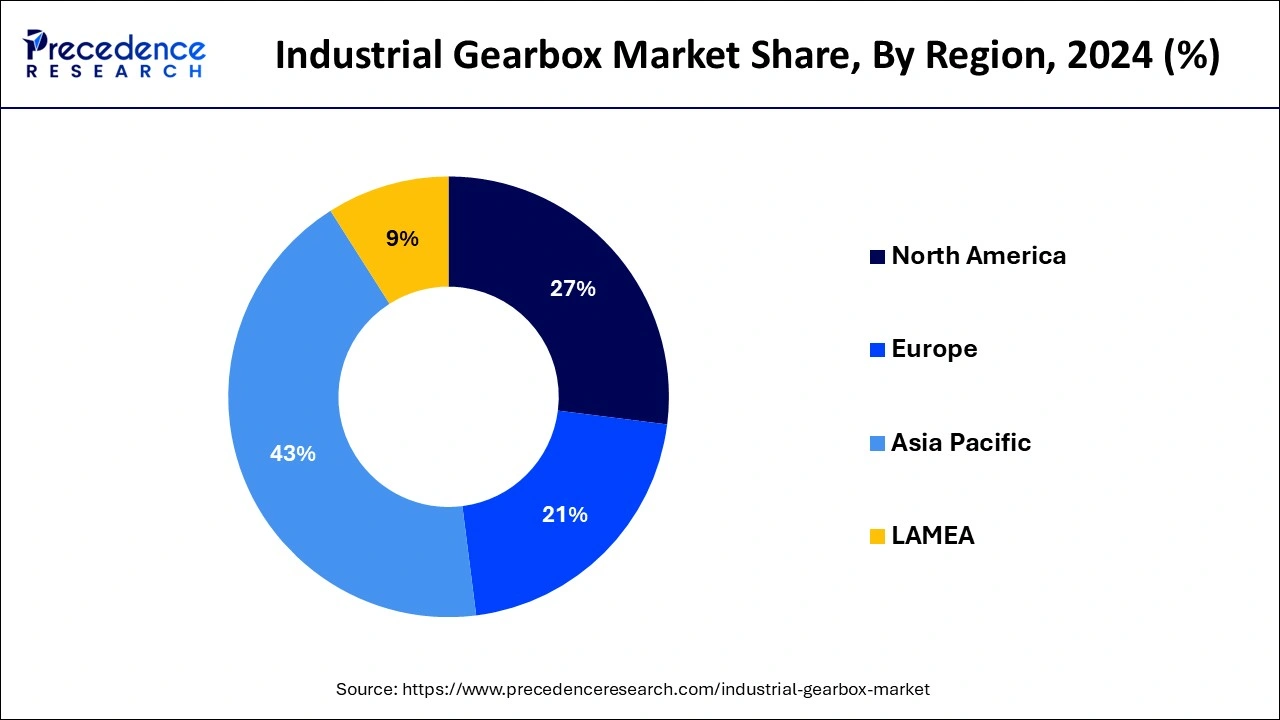

- Asia Pacific dominated the global industrial gearbox market with the largest market share of 43% in 2024.

- North America is expected to expand at the fastest CAGR during the forecast period.

- By type, the helical gearbox segment dominated the market with a 33.80% share in 2024.

- By type, the planetary gearbox segment is expected to grow at the highest CAGR of 7.90% in 2024.

- By design, the standard gearbox segment held a 48.50% market share in 2024.

- By design, the modular gearbox segment is expected to grow at the highest CAGR of 7.60% in 2024.

- By mounting type, the foot-mounted segment led the market by holding 39.70% share in 2024.

- By mounting type, the shaft-mounted segment is expected to grow at the highest CAGR of 7.10% in 2024.

- By end-use industry, the power generation segment held a 21.90% share in 2024.

- By end-use industry, the cement & mining segment is expected to grow at the highest CAGR of 7.80% in 2024.

- By distribution channel, the direct sales (OEMs) segment led the market by holding 44.20% share in 2024.

- By distribution channel, the E-commerce platforms segment is expected to grow at the highest CAGR of 8.20% in 2024.

What are Industrial Gearboxes?

Industrial gearboxes are the core of motion, converting speed, torque, and power in heavy industries such as mining, metals, wind turbines, and material handling. Demand is shifting due to automation, electrification of conveyors, and predictive maintenance expectations, along with a growing need for higher energy efficiency across plant operations. Market segments include standard parallel shaft reducers and worm gearboxes, as well as planetary, helical-bevel, and specially designed gearboxes for tough environments and high-torque applications. As OEMs and end-users pursue uptime, lower lifecycle costs, and modular design, gearboxes are becoming smart, serviceable assets rather than just simple mechanical parts.

Role of Artificial Intelligence in Gearbox

The integration of artificial intelligence (AI) in industrial gearboxes can be applied for predictive maintenance by analysing data from sensors for early fault detection and predicting failures before they occur thereby allowing proactive maintenance interference with minimized downtime. Furthermore, the reduced maintenance costs with improved operation safety, efficiency and dependability by utilizing machine learning algorithms are helping in optimizing industrial gearbox performance for specific applications.

Market Outlook

- Industry Growth Overview: The industrial gearbox market is growing rapidly as demand rises from heavy industries, manufacturing, construction, mining, and renewable energy sectors that require efficient power transmission and torque conversion. Ongoing adoption of automation, industrial modernization, and stringent energy‑efficiency regulations further drives demand for advanced gearbox solutions.

- Sustainability Trend:This trend encourages the use of lower-loss gear designs, recyclable or longer-lasting materials, lubricant optimization (such as bio-based greases), and energy-efficient manufacturing processes. Gearbox reconditioning and remanufacturing decrease embodied carbon and reduce lifecycle costs. Designers are also focusing on minimizing parasitic losses and enhancing overall system efficiency to achieve corporate decarbonization goals. Circular-economy initiatives such as refurbishing, certification, and redeployment are gaining popularity among large industrial users.

- Major Investment Theme:Investors favor companies with digital service platforms, high-precision manufacturing capabilities, and niche specialists in wind and marine segments. Capital is also directed toward advanced heat-treatment and surface-engineering facilities that enhance part lifespan and reliability. Startups offering sensor-integration retrofits, oil-debris analytics, and predictive maintenance SaaS are attracting strategic interest. Investing in localized repair hubs and spare-part inventories helps reduce downtime risks for end-users and is a practical near-term strategy.

Market Trends

- The shift towards industrial automation and demand from various industries for gearboxes as an essential component is a growing trend in the market.

- The increasing emphasis of industries on energy efficiency is increasing the demand for the development and adoption of gearboxes for increased performance and low energy consumption.

- Growing demand for the use of renewable energy sources like wind power and solar to improve efficiency drives the need for high-quality gearboxes, which helps in the market growth.

- Technological advancements like innovation in products and automation, and digitalization of the method and processing, a key growth drivers of the market.

Industrial Gearbox Market Growth Factors

- Rapid industrialization and urbanization in various regions and developing areas.

- Increased development of large-scale infrastructure projects such as power plants, factories requiring robust industrial gearboxes for managing power transmission efficiently.

- Growing government investments in renewable sources of energy requiring industrial gearboxes for effective power transmission.

- Surging demand for automotive parts across the globe.

- Rising need for energy efficient gearboxes optimizing energy usage with reduced operational costs.

- Increased integration of automation and robotics in industrial processes.

- Rising focus of industries on gearbox maintenance and reliability for minimizing downtime and production disruptions.

- Integration of sensors and data analytics in gearboxes allowing predictive maintenance and performance optimization.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 17.76 Billion |

| Market Size in 2026 | USD 12.04 Billion |

| Market Size in 2025 | USD 11.03 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.87% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Design, End User, Geography |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Insights

Type Insights

The helical industrial gearbox segment dominated the market in 2024. The parallel shafts and winding tooth lines are used in helical industrial gearbox. They have stronger teeth seamlessly blended and are quieter as well as the ability to transmit larger loads, making them ideal for elevated applications.

The planetary industrial gearbox segment is fastest growing segment of the industrial gearbox market in 2020. The planetary industrial gearbox is typically utilized as rotation multipliers. The automatic door openers, motorized wheels, and winches are among the most common applications of planetary industrial gearbox.

Design Insights

The standard gearbox segment held a 48.50% market share in 2024. The dominance of the segment can be attributed to the innovations in smart coatings, digital formulation, and improved application techniques. Moreover, the stringent regulations on VOC emissions and increasing consumer demand for sustainable products are boosting segment growth further.

The modular gearbox segment is expected to grow at the highest CAGR of 7.60% in 2024. The growth of the segment can be credited to the growing industrial automation and the surge in renewable energy projects, along with the rapid innovations in production. Also, there is an increasing need for energy-efficient gearbox designs to minimize overall operational costs.

Mounting Type Insight

The foot-mounted segment led the market by holding 39.70% share in 2024. The dominance of the segment can be linked to the growing demand for industrial automation and the rising adoption of energy-efficient designs. Foot-mounted designs are simple to use on a flat base or surface, which boosts setup and alignment.

The shaft-mounted segment is expected to grow at the highest CAGR of 7.10% in 2024. The growth of the segment can be driven by the growing need for more durable and compact gearboxes in the material handling and packaging sectors. Additionally, the demand for efficient and high-torque solutions in different applications has favored the adoption of shaft-mounted gearboxes.

End-Use Industry Insight

The power generation segment held a 21.90% share in 2024. The surge in demand for energy and power, combined with the rising awareness regarding renewable energy, is driving the growth of the global industrial gearbox market. The industrial gearbox has many benefits, such as enhanced radial and axial load and reduced positioning time, which is driving the demand for industrial gearboxes for power generation.

The cement & mining segment is expected to grow at the highest CAGR of 7.80% in 2024. The growth of the segment can be linked to the surge in global infrastructure development, especially new construction projects in cement and mining operations. Furthermore, the operation of mining and cement manufacturing involves heavy-duty machinery, which necessitates high-torque and durable industrial gearboxes.

Distribution Channel Insight

The direct sales (OEMs) segment led the market by holding 44.20% share in 2024. The dominance of the segment is owing to the expanding manufacturing sector, particularly in the Asia-Pacific region, coupled with the growing demand for energy-efficient solutions across different sectors such as automotive and food processing.

The E-commerce platforms segment is expected to grow at the highest CAGR of 8.20% in 2024. The growth of the segment is due to the growing customer inclination towards convenient online purchasing and the expansion of Industry 4.0 technologies, allowing individualized digital experiences for buyers, driving segment growth further.

Regional Insights

Asia Pacific Industrial Gearbox Market Size and Growth 2025 to 2034

The Asia Pacific industrial gearbox market size is evaluated at USD 4.95 billion in 2025 and is predicted to be worth around USD 7.73 billion by 2034, rising at a CAGR of 5.01% from 2025 to 2034.

Asia-Pacific dominated the global industrial gearbox market with the largest market share of 43% in 2024. China dominated the industrial gearbox market in North America region. The industrial gearbox is widely used in different sectors. In 2020, steel output is expected to increase by 6.5% over the previous year in China. This factor is driving the growth of industrial gearbox market. With 38.6 gigawatts installed wind capacity as of 2020, India is the world's fourth largest onshore wind market by deployments. The factors such as growing demand for energy, rapid industrialization and urbanization, and rising initiatives for infrastructural development are boosting the growth of industrial gearbox market in Asia-Pacific region.

India Industrial Gearbox Market Trends

India has seen a steady growth in the industrial gearbox market. The growth of the market is driven by the strong and developing industrial and manufacturing sector in the country, which demands industrial gearboxes, boosting the growth of the market. The rapid industrialization and economic growth fuel the growth globally, and increasing government focus in the country on sustainability drives the demand for the use of renewable energy sources like wind turbines and related equipment, and growing emphasis on industrial automation and energy efficiency in manufacturing processes fuels the growth and boosts the market expansion in India.

What Makes North America the Fastest-Growing Region?

North America is expected to expand at the fastest CAGR during the forecast period. The U.S. and Canada dominate the industrial gearbox market in North America region. The growing manufacturing sector and the existence of major market players operating in industrial gearbox market are propelling the expansion of industrial gearbox market in the region. In addition, the adoption of innovative technologies for reducing human interference in different industries is also driving the growth of industrial gearbox market in North America region.

U.S. Industrial Gearbox Market Analysis

The U.S. has seen a significant growth in the Industrial Gearbox Market, and the growth is driven by various factors like technological advances, entry into the country to enhance the design and performance, and to enhance the efficiency and reliability of the product, which attracts industries for wider adoption. Increase in industrial sector and demand for industrial automation to reduce the elaboration cost and enhance the precision and performance, use of renewable energy sources through government regulations and initiatives to preserve the natural energy sources, drives the growth and fuels the market expansion in the region.

The use of industrial gearboxes is increasing in the UK due to their enhanced reliability. At the same time, new developments are also being established to improve their application as well as performance. This results in increased collaborations within the industries. Moreover, the government is also providing its support to these developments.

What Makes Europe a Significant Market?

Europe is expected to grow significantly in the industrial gearbox market during the forecast period. The industries in Europe are adopting various advanced technologies, which are increasing the use of industrial gearboxes. At the same time, the use of AI is helping in real-time monitoring, which in turn, is enhancing its use. Moreover, IoT sensors are also being used to enhance their performance as well as reliability. This, in turn, is increasing their use in automotive as well as aerospace. These are further supported by the government investments as well. Thus, this enhances the market growth.

Various sectors such as healthcare, automotive as well as aerospace is increasing the demand for the use of industrial gearboxes. At the same time, use of IoT, AI or robotics is further enhancing their features, which is attracting the clients. Thus, all these developments are driving the market growth.

Europe's gearbox market focuses on high-quality engineering, long-term reliability, and compliance with strict efficiency and emissions standards across energy and industrial sectors. Demand remains strong for wind-energy gearboxes, advanced manufacturing equipment, conveyors, and process-plant drives where precision and durability are essential. European manufacturers lead in advanced metallurgy, precise machining, and integrated condition-monitoring systems for predictive maintenance. Regulatory and sustainability demands encourage suppliers to develop low-loss gearing solutions and use recyclable materials.

Germany Industrial Gearbox Market Analysis

There is strong demand for precision gearboxes for robotics, automotive manufacturing, and wind turbines. German suppliers emphasize high-efficiency gear trains, tight precision tolerances, and comprehensive lifecycle services, including dynamic balancing and gearbox reconditioning. Machinery builders frequently collaborate with local gearbox specialists to co-develop solutions that meet exact performance and integration standards, while Germany's robust vocational training system ensures a skilled workforce for service and assembly.

What Potentiates the Growth of the Industrial Gearbox Market?

In the Middle East & Africa, the industrial gearbox market is fueled by rising demand from energy, oil & gas, petrochemical plants, large-scale infrastructure, mining, and desalination projects, all of which require heavy-duty, corrosion-resistant gear systems. Mega-projects and regional industrialization initiatives drive procurement of high-capacity, purpose-built gearboxes designed to withstand sand, salt, and extreme temperatures. Due to remote operating conditions, reliability and long maintenance intervals are prioritized, while the aftermarket is increasingly critical as operators seek localized repair services, spare-part availability, and condition-monitoring retrofits.

UAE Industrial Gearbox Market Analysis

The UAE's industrial diversification and logistics strengths make it a regional hub for gearbox distribution and maintenance services, supporting projects from ports to renewable energy parks. Local service providers offer remanufacturing, dynamic balancing, and corrosion protection upgrades tailored to harsh operating conditions. Free zones encourage global gearbox manufacturers to establish regional repair facilities and spare-part inventories. The UAE also facilitates rapid export logistics for supporting projects across the region.

Value Chain Analysis

Raw Material Sourcing

High-quality steel, alloys, and lubricants are sourced to ensure durability, corrosion resistance, and performance under heavy loads.

- Key Players: ArcelorMittal, Tata Steel, POSCO, Lubrizol.

Component Manufacturing

Manufacturing gears, shafts, bearings, housings, and couplings to precise tolerances is the core of gearbox production.

- Key Players: Bosch Rexroth, SEW-Eurodrive, Bonfiglioli, Moventas.

Gearbox Design & Engineering

Gearboxes are engineered for specific applications, including load requirements, efficiency targets, and environmental conditions.

- Key Players: Siemens, NORD Drivesystems, Flender (Siemens), Sumitomo Drive Technologies.

Industrial Gearbox Market Companies

- Watt Drive Antriebstechnik GmbH

- Nidec Motor Corporation

- Dana Brevini Power Transmission

- China High Speed Transmission Equipment Group Co. Ltd

- Johnson Electric Holdings Limited

- Sumitomo Heavy Industries Ltd.

- Bondioli and Pavesi S.p.A.

- Emerson Electric Co.

- Comer Industries

- SEW Eurodrive

Key Developments

- In April 2025, for attracting investments, enhancing sustainable growth, and generating employment, 3 new industrial polices were launched by the State government, under the leadership of Chief Minister Nara Chandrababu Naidu. These polices will transform Andhra Pradesh into an industrial powerhouse by setting a key milestone as per the officials.

- In November 2024, in October, stable production growth in the major industrial enterprises was observed in China, due to the backing of the government's existing and incremental pro-growth policies.

- In December 2024, WEG which is a Brazilian energy and automation firm announced investment of $29 million for developing a factory producing industrial gearboxes in Turkey.

- In September 2024, Dodge Industrial Inc., launched the Optify breather as an intelligent desiccant breather using their acclaimed Industrial Internet of Things (IIoT) solution allowing customers to remotely monitor breather status thereby extending gearbox life with streamlined maintenance.

Segments Covered in the Report

By Type

- Helical Gearbox

- Bevel Gearbox

- Worm Gearbox

- Planetary Gearbox

- Spur Gearbox

- Cycloidal Gearbox

- Others

- Harmonic Gearbox

- Parallel Shaft Gearbox

By Design

- Standard Gearbox

- Custom/Engineered Gearbox

- Modular Gearbox

By Axis Orientation

- Horizontal Axis Gearbox

- Vertical Axis Gearbox

By Torque Range

- Low Torque (< 50 kNm)

- Medium Torque (50–200 kNm)

- High Torque (> 200 kNm)

By Mounting Type

- Foot Mounted

- Shaft Mounted

- Flange Mounted

- Others (e.g., Torque Arm Mounting)

By Application / End-Use Industry

- Power Generation

- Wind Energy

- Hydropower

- Thermal

- Cement & Mining

- Food & Beverage Processing

- Material Handling

- Conveyors

- Cranes

- Construction Equipment

- Pulp & Paper

- Chemicals & Petrochemicals

- Marine

- Automotive Manufacturing

- Agriculture

- Oil & Gas

- Textiles

- Pharmaceuticals

- Aerospace & Defense

- Other Industrial Machinery

By Distribution Channel

- Direct Sales (OEMs)

- Distributor/Dealer Network

- E-commerce Platforms

- System Integrators

By Power Rating

- Up to 50 kW

- 51-200 kW

- 201-500 kW

- Above 500 kW

By Geography

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting