Generative AI and ERP systems are reshaping supply chains by enabling real-time insights, smarter decisions, and more agile, resilient operations.

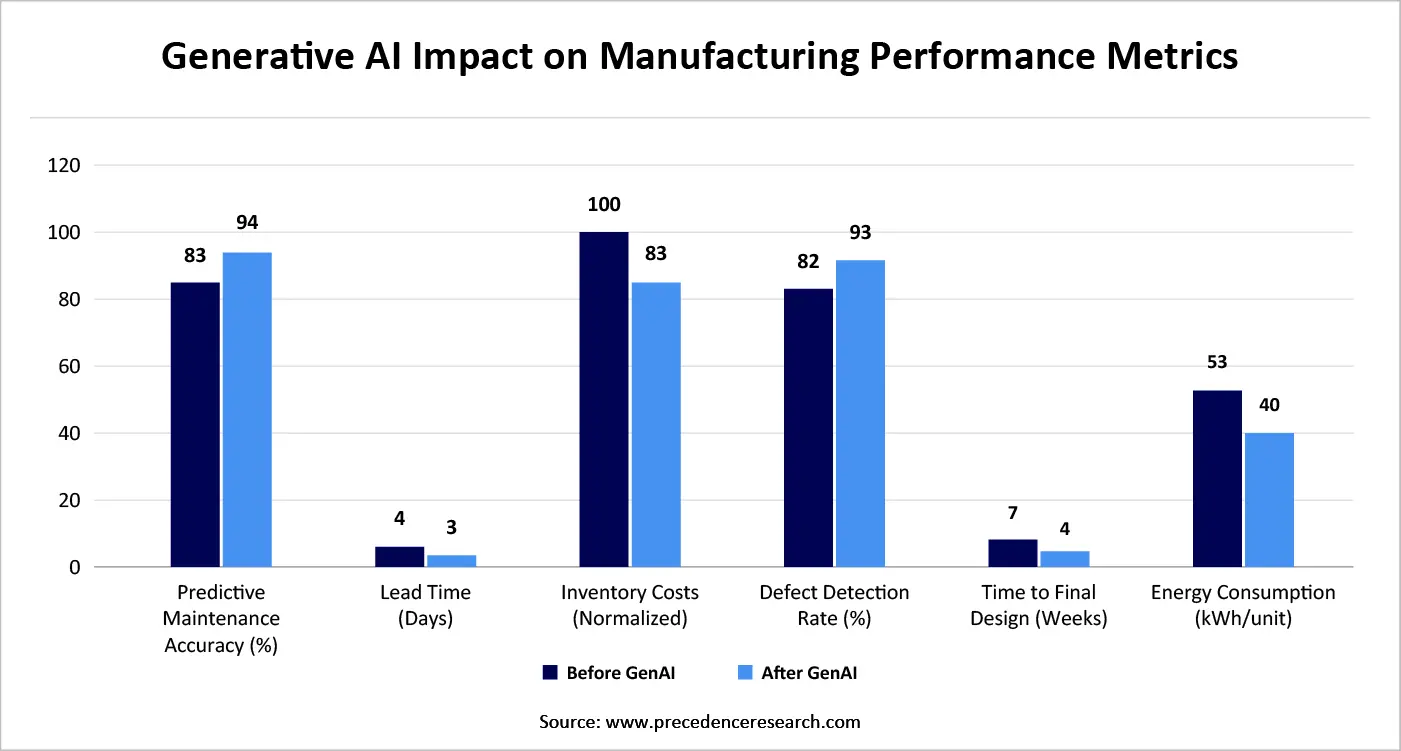

Generative AI is significantly transforming supply chain management by enhancing efficiency, reducing costs, and improving decision-making processes. By leveraging advanced algorithms and data analytics, organizations can optimize inventory management, forecast demand with greater accuracy, and streamline logistics operations. This technology enables real-time data processing and predictive analytics, empowering businesses to respond swiftly to market changes. Moreover, the integration of generative AI supports innovative product design and development, ultimately leading to more agile and resilient supply chains. As industries continue to adopt these advancements, the future of supply chains looks promising, driven by automation and intelligent systems.

Executive Summary

Generative AI is revolutionizing supply chain management by significantly enhancing operational efficiency, reducing costs, and refining decision-making capabilities. With the integration of advanced algorithms and data analytics, organizations can better manage inventory, accurately forecast demand, and optimize logistics processes. This technology allows for real-time data processing and predictive analytics, enabling businesses to swiftly adapt to shifts in the market. Furthermore, the adoption of generative AI fosters innovation in product design and development, making supply chains more agile and resilient. As more industries adopt these technological advancements, the future of supply chains appears promising, driven by automation and intelligent systems that deliver enhanced performance and responsiveness in a rapidly evolving marketplace.

How Does SAP Procurement Chain Optimize Supply Chain Management in Industry?

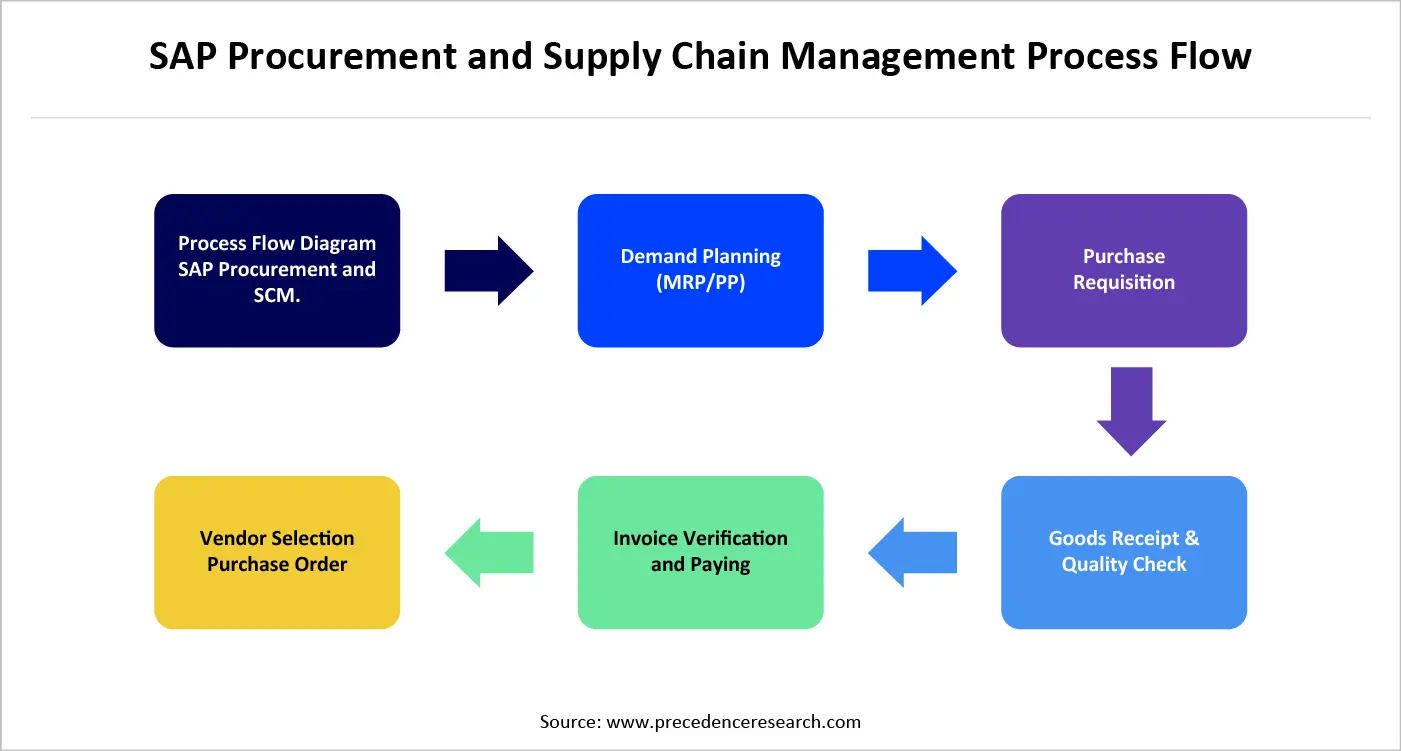

Procurement and Supply Chain Management (SCM) are supporting blocks of industrial efficiency, cost control, and operational resilience. SAP is an important factor in the current industrial context: complex supplier networks, large production, and strict compliance issues mean that a single, coherent system is created based on a digital backbone provided by SAP. Industrial organizations require a sustained and consistent supply of raw material, components, and services. Effective procurement means that the necessary inputs are in place at the right time, at the right cost, and to the right quality. SCM synchronizes the end-to-end flow of suppliers to manufacturing units and ultimately to customers. The absence of integrated systems is usually associated with poor procurement and supply chain operations due to fragmented data, lack of visibility, delayed decision-making processes, and increased operational risks.

SAP will solve these problems by allowing a real-time stream of information, standardization of processes, and centralized control within the industrial processes. SAP is a system that is enterprise-wide but smoothly connected to the procurement and supply chain as well as the main business processes. It works to eradicate silos by consolidating materials management, production planning, inventory management, logistics implementation, and financial accounting.

Real-time data and integrated planning help organizations to predict disturbances and address them before they occur. One of the characteristics of strategic management is its ability to influence performance in industries. Through the integration of procurement and supply chain execution, SAP is changing procurement from a transactional activity to a strategic function. Industrial organizations have an opportunity to coordinate sourcing to production demand, decrease downtime, and strengthen supplier collaboration. Through its digital underpinnings, scalability, resilience, and prolonged competitiveness, SAP-enabled procurement and SCM offer the digital foundation that the globalized manufacturing and unstable supply environment demand and need.

SAP Procurement and Supply Chain Management Process Flow

From Noble Minds to Modern Marvels: The Nobel Legacy in Global Industry Transformation

The fascinating journey from the realms of noble intellect to the bustling corridors of modern industry exemplifies the profound impact of groundbreaking discoveries honoured by the Nobel Prize. This prestigious award highlights exceptional contributions to humanity, with many laureates laying the groundwork for innovations that resonate today. For example, the work of economists like Daniel Kahneman and Alvin Roth has profoundly influenced our understanding of decision-making and market dynamics, creating a rich foundation for the algorithms that drive today's generative AI technologies.

Harnessing these insights, businesses have embraced artificial intelligence to revolutionize supply chain management, optimizing processes and enhancing operational efficiency on a global scale. Modern industries now leverage advanced data analytics and real-time forecasting, significantly improving inventory management and logistics. The ripple effect of these advancements extends beyond local markets, fostering a collaborative global economy where companies can swiftly adapt to changing demands and challenges.

This integration of Nobel-inspired innovation into everyday business practices illustrates not only the value of intellectual pursuits but also their enduring legacy in shaping our world. The seamless fusion of theory and application has not only made supply chains more resilient and agile but has also transformed how industries operate, highlighting that the visionary ideas of the past continue to illuminate the path toward a more interconnected and efficient future.

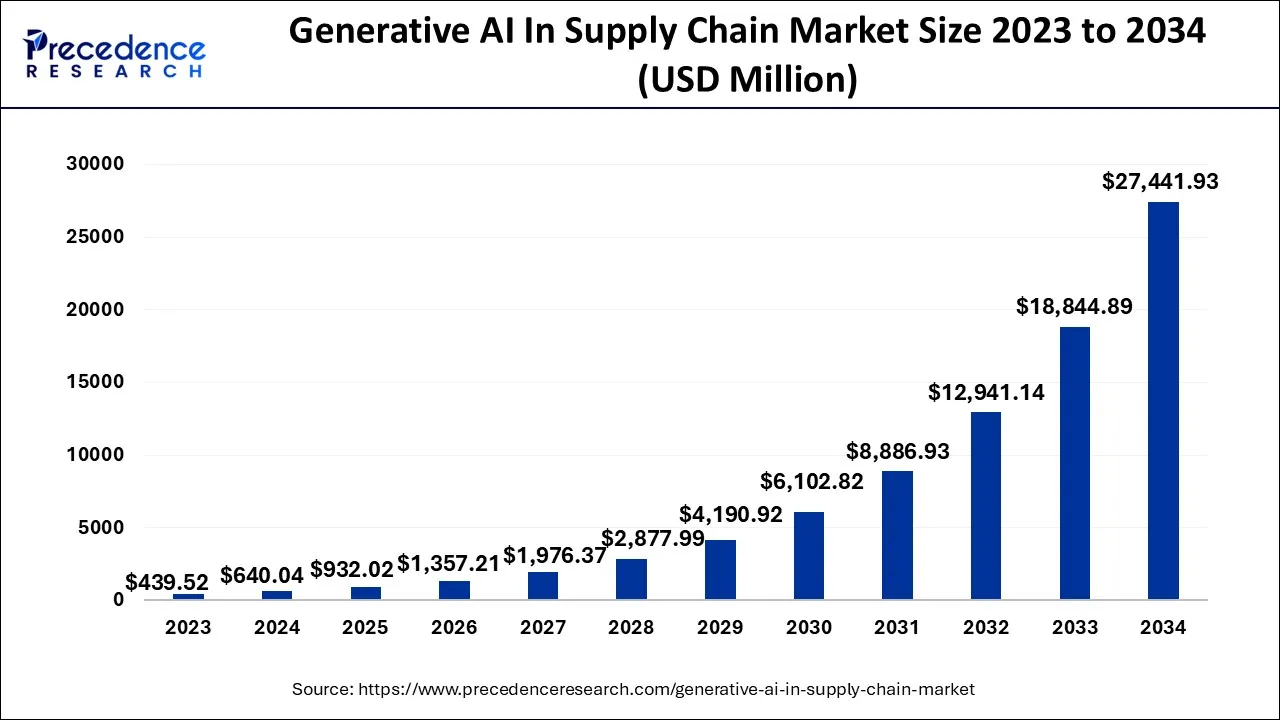

What is Generative AI in Supply Chain Market Size?

The global generative AI in supply chain market size is worth around USD 932.02 million in 2025 and is anticipated to reach around USD 34,243.44 million by 2035, growing at a CAGR of 43.39% over the forecast period from 2026 to 2035.

Market Highlights

- North America led the market with the largest market share in 2025.

- Asia Pacific is expected to expand at the fastest CAGR between 2026 to 2035

- By deployment, the cloud-based segment contributed more than 61% of revenue share in 2025.

- By end-user, the retail segment dominated the market with the largest market share in 2025. Additionally, the hospital segment is expected to be the most lucrative segment of the market.

Generative AI Use in Architecture Supply Chains: Generative AI Enabling Adaptive and Intelligent Networks.

| Processing Differences in Traditional v/s GenAI Methods | ||

| Dimension | Traditional method | GenAI |

| Data processing | Dependency on structured data | Processing unstructured text, images, and temporal data |

| Flexibility | Fixed rules | Adaptive generation of new strategies |

| Real-time | Batch processing optimization | Dynamic response |

| Scene coverage | Limited preset scenarios | Generate unknown risk scenarios |

GenAI is altering the principles of architectural integrity of modern supply chains. GenAI is more of a cross-cutting intelligence layer rather than a standalone analytical tool that is integrated into the digital supply chain architecture. It is meant to integrate the data, create scenarios, and enable adaptive decision-making in the planning, execution, and risk management. This change in architecture transforms the supply chains into networks of learning and anticipation rather than deterministic and rule-based.

- Linear Architectures to Intelligent Supply Chain Stacks.

The classic supply chain designs were developed as linear systems that are sequential in nature. Information was transferred between transactional systems and the planning systems, and decisions were transferred through pre-established workflows. Although successful in a stable environment, the architectures did not provide flexibility in the volatile and uncertain environments. GenAI presents an intelligence-driven, non-linear architecture. It facilitates information flow in both directions, lifelong learning, and dynamism. Supply chains turn into dynamic systems that can create and examine a variety of futures at the same time, rather than using the traditional optimization model.

- Basic Layer: Data Fabric and Integration.

The foundation of GenAI-enabled supply chain is a strong data fabric. It is a layer that combines structured information (ERP, WMS, TMS, MRP) with unstructured and semi-structured information (supplier communications, contracts, market signals, geopolitical indicators, weather data).

- The most important architectural features are:

- Ingestion and harmonization of real-time data.

- Semantic consistency and metadata management.

- Governance controls, data quality, and lineage.

This base will guarantee that GenAI models will be trained on trusted, contextualized data, and no single dataset. The intelligence layer is the main architectural component of GenAI. The models are based on generating a plausible scenario, as opposed to single-point predictions, by synthesizing historical data, real-time signals, and contextual constraints. Generative AI has much greater potential in the architectural functions of supply chains than automation or analytics. GenAI is the thinking machine that links information, decision-making, and action into a complete learning system. Organizations that make GenAI the backbone of the supply chain architecture will be in a better position to survive uncertainty, organize complexity, and maintain competitive advantage in a dynamic global environment that is getting more volatile.

Impact of ERP Systems: Transforming Organizations Through Integrated Intelligence

Enterprise Resource Planning (ERP) systems have fundamentally reshaped how organizations operate, govern resources, and make decisions. By integrating core business functions into a unified digital platform, ERP systems move organizations from fragmented, function-centric operations to coordinated, data-driven enterprises. Their impact extends beyond operational efficiency, influencing strategy, culture, and long-term competitiveness.

1. Operational Integration and Process Standardization

One of the most significant impacts of ERP systems is the elimination of functional silos. ERP platforms integrate finance, procurement, supply chain, manufacturing, human resources, and sales into a single system of record. This integration standardizes processes across departments, ensuring consistency, accuracy, and transparency. Standardized workflows reduce redundancy and manual intervention, enabling smoother handoffs between functions. As a result, organizations experience faster cycle times, fewer errors, and improved operational reliability.

2. Enhanced Visibility and Real-Time Decision-Making

ERP systems provide real-time access to enterprise-wide data. Managers and executives gain a holistic view of operations, allowing them to monitor performance, identify bottlenecks, and respond to issues proactively. This visibility transforms decision-making from retrospective analysis to near-real-time management. With integrated dashboards and reporting, organizations can align daily operations with strategic objectives, improving responsiveness and control.

3. Financial Control and Governance

ERP systems strengthen financial discipline by tightly integrating operational transactions with accounting and reporting. Automated postings, budget controls, and audit trails ensure accuracy and regulatory compliance. This integrated financial governance reduces the risk of errors, fraud, and non-compliance. It also enables organizations to conduct more accurate forecasting, cost analysis, and profitability assessment across products, projects, and business units.

4. Supply Chain and Resource Optimization

In supply chain and resource-intensive industries, ERP systems play a critical role in synchronizing demand, supply, and production. By linking procurement, inventory, and manufacturing, ERP enables organizations to optimize resource utilization and minimize waste. Material requirements planning, inventory visibility, and supplier integration help reduce stockouts, excess inventory, and production downtime. The result is a more resilient and cost-effective supply chain.

5. Scalability and Organizational Agility

ERP systems provide a scalable foundation for growth. As organizations expand into new markets, products, or geographies, ERP platforms support increased complexity without proportionate increases in operational overhead. Standardized processes and centralized data allow organizations to adapt more quickly to change. Whether responding to market shifts, regulatory updates, or business restructuring, ERP systems enable controlled and agile transformation.

6. Workforce Productivity and Role Evolution

By automating routine and transactional tasks, ERP systems free employees to focus on higher-value activities such as analysis, planning, and innovation. Roles evolve from data entry and reconciliation to insight generation and decision support. This shift enhances workforce productivity and supports the development of analytical and strategic capabilities across the organization.

ERP as the Digital Backbone for AI-Driven Strategic Advantage

Beyond operational improvements, ERP systems serve as strategic enablers. They provide the digital backbone required to support advanced technologies such as analytics, artificial intelligence, and intelligent automation. ERP platforms align operational execution with strategic intent, ensuring that enterprise goals are reflected in day-to-day processes. Organizations that leverage ERP strategically gain improved resilience, transparency, and competitive advantage.

The impact of ERP systems extends far beyond automation and efficiency. By integrating processes, data, and governance, ERP platforms transform organizations into cohesive, intelligent enterprises. They enable real-time insight, disciplined execution, and strategic agility capabilities that are essential in today’s complex and competitive business environment. Ultimately, ERP systems are not merely IT implementations; they are organizational transformations that redefine how value is created, managed, and sustained.

Further analysis through comparative studies from industry giants like Reliance, Ernst & Young (EY), and PricewaterhouseCoopers (PwC) reveals a decisive edge in the procurement domain. These organizations have successfully harnessed AI-driven models, notably utilizing SAP FICO (Financial Accounting and Controlling) for backend data processing. This approach has allowed them to analyse historical data over the past four years, facilitating insightful comparisons that inform strategic decision-making and forecasting.

The emphasis on using ERP systems across HR processes underscores their critical role in streamlining operations, improving data accuracy, and enhancing HR’s strategic capabilities. By utilizing these advanced systems, organizations can not only optimize their resource management but also refine their overall operational frameworks. The integration of AI within ERP systems further amplifies this impact, equipping HR and procurement departments with the analytical tools necessary to adapt to changing market dynamics and drive sustainable growth.

As industries continue to evolve, the reliance on ERP systems, particularly in HR and procurement, will likely expand, reinforcing their importance as foundational components of a modern organizational strategy. The data-driven insights gained from these systems will be crucial in navigating the complexities of today's business environment, ultimately leading to more informed decision-making and enhanced competitive advantage.

Distribution Outcomes Across Functional Fields: Marketing, Logistics, Production, and Supply Chain

Distribution is not a standalone activity; it is a cross-functional outcome shaped by coordinated decisions across marketing, logistics, production, and the broader supply chain. The effectiveness of distribution is ultimately reflected in how well products reach the right customers, at the right time, in the right condition, and at the right cost. Each functional field contributes distinct yet interdependent outcomes that collectively determine distribution performance.

1. Distribution Outcomes from a Marketing Perspective

From the marketing viewpoint, distribution is a market-facing capability that directly influences customer experience and brand perception.

Key Outcomes:

- Market Reach and Coverage: Effective distribution expands geographic and channel reach, enabling access to targeted customer segments.

- Service Level Performance: Product availability, shelf presence, and on-time delivery enhance customer satisfaction and loyalty.

- Channel Effectiveness: Alignment with retail, digital, and partner channels ensures consistent brand representation and pricing integrity.

- Demand Fulfillment Accuracy: Distribution responsiveness supports promotions, seasonal demand, and product launches.

Strategic Impact:

Marketing-driven distribution outcomes translate into higher customer retention, stronger brand equity, and improved revenue realization.

2. Distribution Outcomes from a Logistics Perspective

Logistics focuses on the physical movement and handling of goods. Distribution outcomes in this field emphasize efficiency, reliability, and cost control.

Key Outcomes:

- On-Time and In-Full (OTIF) Delivery: Reliable transportation and warehousing ensure delivery commitments are met.

- Cost Efficiency: Optimized routing, consolidation, and storage reduce transportation and handling costs.

- Inventory Accuracy: Precise tracking minimizes losses, damages, and discrepancies.

- Flexibility and Responsiveness: Ability to reroute, expedite, or adjust shipments in response to disruptions.

Strategic Impact:

Logistics-driven distribution outcomes improve operational reliability and protect margins while supporting service-level commitments.

3. Distribution Outcomes from a Production Perspective

Production influences distribution through manufacturing schedules, capacity planning, and product readiness.

Key Outcomes:

- Production–Distribution Synchronization: Alignment between manufacturing output and distribution demand reduces bottlenecks and delays.

- Reduced Lead Times: Efficient production planning enables faster order fulfillment.

- Quality Consistency: Stable production quality ensures products arrive in market-ready condition.

- Capacity Utilization Balance: Production pacing prevents overproduction or shortages that disrupt distribution.

Strategic Impact:

Production-aligned distribution outcomes ensure continuity of supply, reduce backorders, and stabilize downstream operations.

4. Distribution Outcomes from a Supply Chain Perspective

The supply chain view integrates marketing, logistics, and production into an end-to-end value flow.

Key Outcomes:

- End-to-End Visibility: Real-time insight across sourcing, manufacturing, and distribution improves coordination.

- Inventory Optimization: Balanced stock levels across nodes reduce carrying costs while maintaining service levels.

- Resilience and Risk Mitigation: Diversified sourcing and adaptive distribution networks reduce disruption impact.

- Cost-to-Serve Optimization: Distribution strategies are tailored by customer, region, or product profitability.

Distribution outcomes are the cumulative result of coordinated decisions across marketing, logistics, production, and supply chain functions. When these fields operate in isolation, distribution becomes fragmented and inefficient. When aligned through integrated planning and shared objectives, distribution transforms into a strategic capability, enhancing customer satisfaction, operational efficiency, and competitive advantage. In modern industrial and commercial environments, the success of distribution is no longer measured solely by delivery metrics, but by how effectively it supports market strategy, operational resilience, and long-term value creation.

Comparative Summary of Distribution Outcomes

| Function | Primary Focus | Key Distribution outcomes |

| Marketing | Customer and market alignment | Availability service levels and channel performance. |

| Logistics | Physical flow and cost control | OTIF delivery and cost efficiency. |

| Production | Manufacturing readiness | Lead time and reduction |

| Supply chain | End-to-end coordination | Visibility and resilience |

The Future: From Linear Operations to Intelligent Ecosystem

The industry is being redefined with a radical converging digital intelligence, automation, and ecosystem-oriented collaboration. Existing industrial paradigms, with their linear processes and inflexible structures and competition based on assets, are being replaced by adaptive, data-driven systems that perpetually learn and evolve. In this new terrain, industry is not characterized by the capacity to produce anymore, but by intelligence, resistance, and the capability to coordinate networks of complexity.

The inception of industry is shifting to semi-autonomous and autonomous systems. More machines, production lines, and supply networks are being intelligent enough to monitor themselves, predictively maintain themselves, and adaptively optimize themselves. Instead of responding to failures or disturbances, the systems in the industry of the future will foresee them. The process of decision-making is going to be more akin to real-time, with the help of artificial intelligence and sophisticated analytics embedded in operations.

Information will be one of the major sources of industrial capital, just as important as physical goods. Related devices, digital twins, and smart platforms will continuously produce data that drives design, creation, quality, and distribution. The organizations that will have mastered data governance, integration, and analytics will have a disproportionate advantage. The creation of value will not be based on the mere production of goods, but rather the extraction of intelligence in all the industrial lifecycle stages.

The industrial future will not be without human beings; it will be human-enhanced. With the replacement of repetitive and computationally intensive activities by machines, the human functions will become reshaped to supervision, creativity, moral judgment, and strategic decision-making. Engineers, planners, and operators will become more system designers and decision architects, and work with intelligent machines to deal with complexity and innovation.

There will be more integration of industries through interconnections and less autonomy of individual businesses. There will be platform-based models that will facilitate cooperation between the manufacturers, suppliers, technology providers, and customers. The competitive advantage will change basis of asset ownership to the coordination of ecosystems.

The ability to design inclusive and scalable platforms will determine the industry standards that companies will follow and the value flow across networks. The future industries will be concerned with resilience and efficiency. The weakness of highly optimized inflexible systems has been made apparent by global disruptions. Industrial supply chains will be made more dynamic, with real-time visibility, scenario planning, and distributed manufacturing. Next-generation industrial resilience will be characterized by flexibility, redundancy, and intelligence.

Conclusion

In conclusion, the integration of generative AI within supply chain management signals a pivotal shift towards enhanced efficiency, cost reduction, and strategic decision-making. This technology not only optimizes inventory management and logistics but also fosters innovation in product design, resulting in more agile and resilient supply chains. The role of platforms like SAP in this transformation cannot be overstated, as they provide the necessary framework for real-time data processing and integrated planning, ultimately turning procurement into a strategic advantage.

Moreover, the insights gained from influential economic theories and discoveries celebrated by the Nobel Prize continue to shape the landscape of modern industry. By leveraging these principles, businesses are now equipped to navigate complex global markets with greater agility and responsiveness. As industries increasingly adopt these technological advancements, the future of supply chains looks bright, characterized by automation and intelligent systems that drive performance and competitiveness in an ever-evolving environment.

About the Authors

Aditi Shivarkar

Aditi, Vice President at Precedence Research, brings over 15 years of expertise at the intersection of technology, innovation, and strategic market intelligence. A visionary leader, she excels in transforming complex data into actionable insights that empower businesses to thrive in dynamic markets. Her leadership combines analytical precision with forward-thinking strategy, driving measurable growth, competitive advantage, and lasting impact across industries.

Aman Singh

Aman Singh with over 13 years of progressive expertise at the intersection of technology, innovation, and strategic market intelligence, Aman Singh stands as a leading authority in global research and consulting. Renowned for his ability to decode complex technological transformations, he provides forward-looking insights that drive strategic decision-making. At Precedence Research, Aman leads a global team of analysts, fostering a culture of research excellence, analytical precision, and visionary thinking.

Piyush Pawar

Piyush Pawar brings over a decade of experience as Senior Manager, Sales & Business Growth, acting as the essential liaison between clients and our research authors. He translates sophisticated insights into practical strategies, ensuring client objectives are met with precision. Piyush’s expertise in market dynamics, relationship management, and strategic execution enables organizations to leverage intelligence effectively, achieving operational excellence, innovation, and sustained growth.

Request Consultation

Request Consultation