Manufacturing is evolving into a smart, sustainable, and inclusive engine of growth driven by digital technology, strategic alignment, and human capability, reshaping productivity, supply chains, and development while balancing innovation with responsibility and long-term resilience.

The manufacturing industry remains a cornerstone of global economic development, continuously evolving in response to technological progress, market dynamics, and socio-economic pressures. Over the past few decades, manufacturing has undergone a transition from labor-intensive production systems to highly automated and data-driven operations. This article examines the structural transformation of the manufacturing industry, highlighting key drivers, technological advancements, operational challenges, and future trajectories. By adopting a research-oriented perspective, it aims to provide a holistic understanding of how manufacturing is redefining productivity, resilience, and competitiveness in a rapidly changing global landscape.

Introduction

The manufacturing industry plays a pivotal role in shaping industrial economies by converting raw materials into value-added goods across various sectors, including automotive, electronics, pharmaceuticals, consumer goods, and heavy machinery. It significantly contributes to employment generation, trade balance, and technological innovation. Historically driven by scale and efficiency, modern manufacturing is now influenced by flexibility, speed, and intelligence. Globalization, digitalization, and sustainability imperatives have collectively reshaped traditional production paradigms. As a result, manufacturing is no longer confined to physical production but has expanded into integrated value networks.

Empirical Analysis

This part contains the empirical framework applied in analyzing structural as well as behavioral dynamics in the manufacturing industry. The analysis will be aimed at analyzing the connections between technological adoption and operational performance on the one hand, and industry performance on the other. A systematic econometric methodology is followed to make it robust and clear in inference. The empirical approach advances the descriptive evaluation to a causal estimation and then passes through the analysis of mediation and moderation. This stratified method enables gaining a full comprehension of the direct and indirect impacts.

Descriptive Statistics: Descriptive statistics will present the preliminary picture of the most important variables that will be considered in the empirical model. The measures of central tendency, like the mean and median, are applied to gain insight into the overall behavior of a specific industry, and dispersion measures, like the standard deviation, can be used to measure the variability of firms or regions. The correlation analysis indicates the initial correlations between manufacturing output, technology intensity, labor productivity, and measures of sustainability. The descriptive outcomes indicate apparent heterogeneity among manufacturing segments, which is a manifestation of the variation in scale, capital intensity, and digital maturity. These trends support the fact that multivariate analysis is necessary to separate cause-and-effect relationships.

| Variable | Obs | Mean | Std.Dev | Min | max |

| SCR | 20265 | 0.169 | 0.042 | 0.077 | 0.532 |

| EDTI | 10666 | 65.144 | 376.507 | 0.000 | 13922.000 |

| Size | 21932 | 22.032 | 1.178 | 19.585 | 26.452 |

| Lev | 21932 | 0.380 | 0.190 | 0.035 | 0.908 |

| ROA1 | 20363 | 0.045 | 0.066 | -0.373 | 0.247 |

| Cashflow | 21932 | 0.052 | 0.066 | 0.066 | 0.267 |

| Board | 21903 | 2.103 | 0.189 | 1.609 | 1.609 |

Baseline Estimates: The base estimation forms a direct correlation between basic explanatory variables and the manufacturing performance indicators. Manufacturing productivity or growth in output is determined using a typical regression model as a dependent variable, which evaluates capital investment, workforce capability, and the use of technology. Control variables are included to explain the firm size, scale of operation, and market exposure. The results of the baseline suggest a statistically significant and positive correlation between advanced manufacturing technologies and the performance outcomes. Such estimates can be used as a benchmark in further mediation and moderation analysis.

Mediation Analysis: Analysis of mediation is performed to investigate the operation of the adoption of technology on the manufacturing performance. In particular, the variables tested as possible mediating variables are operational efficiency and supply chain integration. It has been demonstrated that a significant portion of the overall impact of technology adoption is indirect by way of process efficiency. This observation indicates that technology does not result in performance improvements unless it is converted into operational realization. The mediation effects emphasize complementary capabilities as key to realizing the maximum benefits of technological investments.

Generally, empirical evidence shows that technology adoption has a positive impact on manufacturing performance, either directly or indirectly. Operational efficiency is a pivotal channel of transmission, whereas firm-specific and institutional determinants influence the intensity of effect. The interplay of descriptive statistics, baseline estimation, mediation, and moderation analysis offers a highly refined and policy-related knowledge of manufacturing transformation. These observations support the importance of combined approaches that harmonize technology, human resources, and regulatory systems.

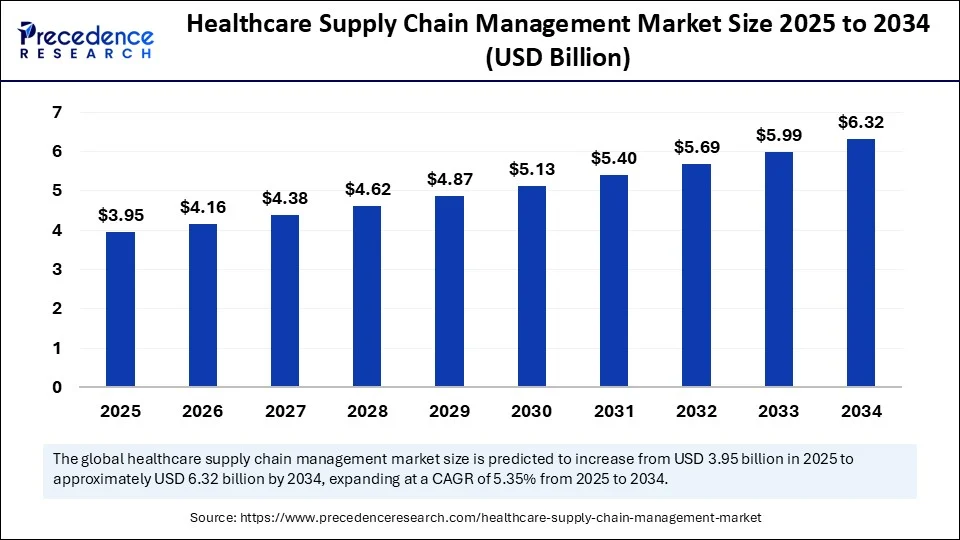

What is the Healthcare Supply Chain Management Market Size?

The global healthcare supply chain management market size is calculated at USD 3.95 billion in 2025 and is predicted to increase from USD 4.16 billion in 2026 to approximately USD 6.32 billion by 2034, expanding at a CAGR of 5.35% from 2025 to 2034. The growth of the market is driven by rising demand for medical products and transparency in supply chains. Additionally, the rising adoption of AI, IoT, cloud, and blockchain technologies to enhance security in supply chains contributes to market growth.

Healthcare Supply Chain Management Market Key Takeaways

- In terms of revenue, the global healthcare supply chain management market was valued at USD 3.75 billion in 2024.

- It is projected to reach USD 6.32 billion by 2034.

- The market is expected to grow at a CAGR of 5.35% from 2025 to 2034.

- North America dominated the healthcare supply chain management market with the largest market share of 39.8% in 2024.

- Asia Pacific is expected to expand at the fastest CAGR between 2025 and 2034.

Unlocking Agility: How Digital Tools Master Global Supply Chain Complexity?

New digital tools in supply chain management can offer transformative solutions by reshaping how organizations plan, execute, and respond to disruptions. Technologies such as artificial intelligence, advanced analytics, and digital twins enable real-time visibility across complex supply networks, allowing firms to anticipate demand fluctuations and optimize inventory levels.

Cloud-based platforms facilitate seamless data sharing among suppliers, manufacturers, and distributors, improving coordination and decision-making. Automation and robotics enhance efficiency in warehousing and logistics while reducing human error and operational costs. Blockchain and traceability tools strengthen transparency, trust, and compliance by creating immutable records of transactions and product movement. Collectively, these digital innovations transform the supply chain from a reactive, cost-focused function into a resilient, intelligent, and strategically driven ecosystem.

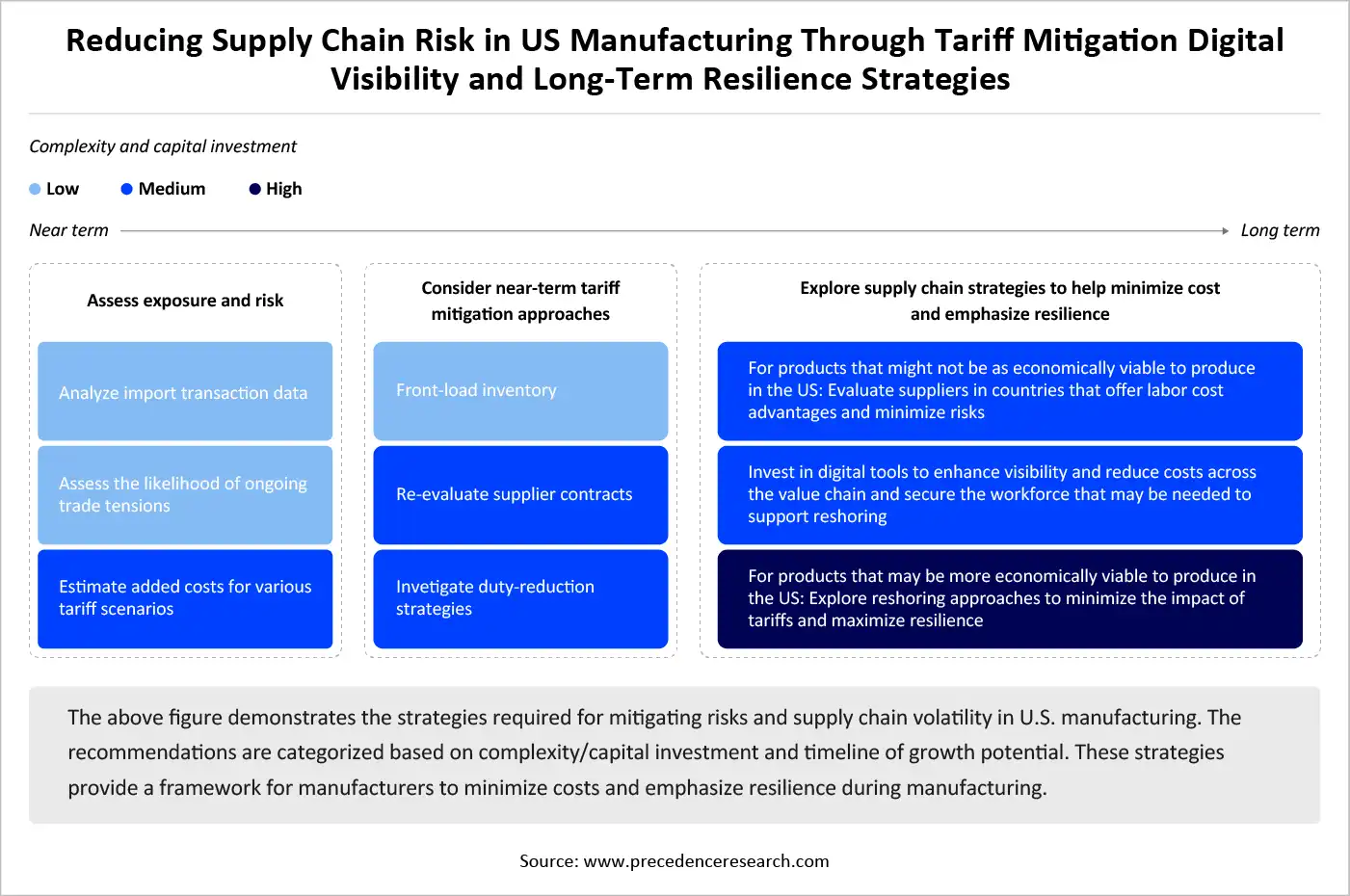

Reducing Supply Chain Risk in US Manufacturing Through Tariff Mitigation Digital Visibility and Long-Term Resilience Strategies

From Transparency to Trust: Blockchain as a Catalyst for Sustainable Supply Chains

Blockchain technology is increasingly recognized as a powerful enabler of sustainability within modern supply chains, addressing long-standing challenges related to transparency, traceability, and accountability. Traditional supply chains are often fragmented and opaque, making it difficult to verify the environmental and social impact of sourcing, production, and distribution activities. Blockchain introduces a decentralized and immutable ledger that records transactions across every stage of the supply chain. This shared, tamper-proof data environment builds trust among stakeholders while enabling more responsible and sustainable decision-making.

One of the most significant contributions of blockchain to supply chain sustainability is enhanced traceability. By recording the origin, movement, and transformation of raw materials and finished goods, blockchain allows companies to verify ethical sourcing and compliance with environmental standards. This is particularly critical in industries such as food, textiles, and minerals, where sustainability claims are often difficult to substantiate. Real-time traceability helps identify inefficiencies, reduce waste, and prevent the circulation of counterfeit or non-compliant products. As a result, companies can align their operations more closely with sustainability goals.

Blockchain also supports environmental sustainability by improving resource efficiency and reducing carbon footprints. Accurate, real-time data enables better demand forecasting, inventory optimization, and logistics planning, which in turn lowers energy consumption and emissions. Smart contracts can automate sustainability-related actions, such as enforcing supplier compliance with emission thresholds or triggering penalties for non-adherence to environmental standards. By embedding sustainability rules directly into supply chain processes, blockchain transforms sustainability from a reporting exercise into an operational practice.

Social sustainability is another area where blockchain delivers substantial value. The technology can be used to verify labor practices, ensure fair wages, and monitor working conditions across extended supply networks. Immutable records discourage unethical behavior and empower organizations to demonstrate compliance with social responsibility commitments. Consumers, regulators, and investors are increasingly demanding evidence of ethical practices, and blockchain offers a credible mechanism for verification. This strengthens corporate reputation and stakeholder confidence.

Furthermore, blockchain enhances circular economy initiatives by enabling efficient tracking of products through their entire lifecycle. From production and use to recycling and reuse, blockchain records support product take-back programs and responsible waste management. Manufacturers can better manage reverse logistics, while recyclers gain access to verified material histories. This level of visibility supports closed-loop supply chains and reduces dependence on virgin resources, contributing to long-term environmental sustainability.

Despite its potential, the adoption of blockchain for supply chain sustainability is not without challenges. High implementation costs, interoperability issues, and data governance concerns can hinder widespread adoption. However, as digital ecosystems mature and standards evolve, these barriers are expected to diminish. In conclusion, blockchain represents a transformative technology that moves supply chains towards greater transparency, accountability, and sustainability. By integrating blockchain into supply chain strategies, organizations can create resilient systems that balance economic performance with environmental and social responsibility.

From Looms to Laboratories: India’s Journey from Ancient Craftsmanship to Modern Manufacturing Powerhouse

India’s manufacturing story is not merely an economic narrative; it is a civilizational continuum that reflects ingenuity, resilience, and adaptation across millennia. Long before the term “industry” entered the global lexicon, the Indian subcontinent was a thriving center of production, innovation, and trade. From handwoven textiles admired across continents to today’s advanced industrial corridors, India’s manufacturing evolution mirrors the transformation of society itself.

In ancient India, manufacturing was deeply rooted in skilled craftsmanship and community-based production systems. The Indus Valley Civilization demonstrated remarkable manufacturing sophistication through standardized brick-making, metallurgy, pottery, and bead production. Textiles such as cotton and silk, metalware, shipbuilding, and jewellery flourished under guild-based systems that ensured quality and knowledge transfer. Indian goods travelled along the Silk Route and maritime trade networks, earning global recognition for their precision and artistry. Manufacturing was not confined to economic activity but was intertwined with culture, identity, and sustainability.

The medieval period witnessed the expansion and refinement of these manufacturing traditions. Indian textiles, particularly muslin, calico, and silk, dominated global markets and were coveted in Europe, West Asia, and Southeast Asia. Metallurgical excellence reached new heights, exemplified by wootz steel, which later influenced weapon-making across the world. Production remained decentralized, powered by skilled artisans and regional specialization. India’s manufacturing strength during this era lay in its ability to combine technical mastery with aesthetic excellence.

The advent of colonial rule marked a profound disruption in India’s manufacturing landscape. British industrial interests systematically dismantled indigenous manufacturing systems, redirecting India’s role from producer to supplier of raw materials. Traditional industries declined, artisan communities suffered, and the economy became increasingly dependent on imports of finished goods. Yet, even amid this decline, seeds of modern manufacturing were sown through the establishment of railways, ports, and basic industrial infrastructure. The colonial period thus represented both erosion and reluctant transformation.

Post-independence, India embarked on the ambitious task of rebuilding its manufacturing base. Guided by state-led industrialization, the country invested heavily in steel plants, heavy engineering, chemicals, and public sector enterprises. Manufacturing became a pillar of nation-building, supporting self-reliance and economic sovereignty. While this era prioritized capacity creation over efficiency, it laid the foundation for industrial capabilities across sectors. The focus was not only on economic growth but also on social development through employment generation.

The liberalization era of the 1990s marked a decisive turning point. Economic reforms opened Indian manufacturing to global competition, private investment, and technological collaboration. Industries modernized, productivity improved, and export-oriented manufacturing gained momentum. Sectors such as automotive, pharmaceuticals, electronics, and textiles underwent rapid transformation. Manufacturing began to integrate with global value chains, redefining India’s industrial identity.

In the present era, Indian manufacturing stands at the intersection of tradition and technology. Advanced automation, digital manufacturing, artificial intelligence, and sustainable practices are reshaping factories into intelligent production ecosystems. Government initiatives promoting domestic manufacturing and innovation are accelerating this transition. At the same time, India’s deep-rooted culture of craftsmanship continues to inspire design-led and small-scale manufacturing. This coexistence of heritage and high technology gives Indian manufacturing a distinctive global character.

Empowerment of the Margins: Gender, Rural Industrialization, and Inclusive Growth of Developing Nations

In rural areas, rural industrialization has become a key way of realizing inclusive and sustainable development in most developing countries, as it has provided a way of narrowing the long-standing economic gap between urban and rural areas. Decentralization of industrial activity and proximity to rural populations are believed to create more jobs, alleviate migration pressure, and boost local economies by governments and development agencies. Nevertheless, the effects of rural industrialization do not stop at economic indicators; they have a tremendous influence on societal organization, especially gender roles and opportunities. This intersection is to be understood so that it can be possible to design equitable and effective development strategies.

Rural industries in most developing nations, such as agro-processing, textiles, handicrafts, food preservation, and small-scale production, have been found to offer an easy access point through which women can venture into the formal and semi-formal economy. Such industries tend to be compatible with the available skills, besides providing a source of income other than subsistence farming. Working in rural industrial enterprises can empower women with financial freedom, households with better livelihoods, as well as invest more in education and health. The bargaining power of women in the household and community can tend to increase as women have access to paid work.

The rural industrialization is also transitional in that it is redefining traditional gender norms. With local jobs available, men do not have to move out of town, and women can work and do household chores. Collective workspaces and cooperatives in a particular context create social networks that generate a perception of leadership, cooperation, and collective bargaining among women. The result of this economic engagement over time is the ability to challenge social norms that are restrictive and enable women to take up more roles in making decisions within the household and community levels.

Rural industrialization, although promising, is not always a sure way to ensure gender equity. Rural industries tend to keep women confined to low-paid, labor-intensive jobs with limited job security and chances of skill development. Structural barriers that cause gender gaps in wages, ownership of enterprises, and access to credit include limited education, mobility barriers, and discriminatory norms. Rural industrialization will only reproduce old inequalities without a policy effort to come down on them.

Finance, technology, and training are also critical factors in improving gender outcomes. Rural women entrepreneurs often face difficulties financing their activities and using new technologies of production. Specialized skills development plans, online literacy campaigns, and gender-sensitive financial services would go a long way in enhancing women's participation and productivity. Safe transportation, childcare, and dependable energy infrastructure are additional factors that show whether rural industrialization will result in the effective empowerment of women.

Policy-wise, there is a need to incorporate a gender lens into the rural industrial policies. This will involve encouraging women-owned businesses, labor standards, promotion of equal pay, and cooperatives and self-help groups. Gender-disaggregated outcomes can help policymakers determine whether industrialization efforts are producing inclusive growth. When carefully planned, rural industrialization can become a potent tool of gender equality, changing the rural economies and empowering women as key forces of development.

To sum up, rural industrialization in developing countries has great potential in enhancing gender-based growth, but this should be done through deliberate design and execution. Rural industries can no longer be perceived as engines of social transformation because they create employment, but investing in the capacities of women will help them transcend beyond that level. The intersection of rural industrialization and gender is, therefore, not only a chance to get an economic opportunity, but also a gateway towards fairer and stronger societies.

Harnessing Technology and Strategy for Sustainable Growth

In an increasingly competitive and interconnected world, sustainable growth is no longer driven alone by scale but by the intelligent alignment of technology and strategy. Organizations and economies that successfully integrate digital innovation with long-term strategic planning are better positioned to enhance productivity, adapt to change, and create enduring value. Technology acts as an enabler, while strategy provides direction, ensuring that innovation translates into measurable growth rather than fragmented experimentation.

Technological advancements, including artificial intelligence, automation, data analytics, and cloud computing, have fundamentally transformed the way businesses operate. These tools enable real-time decision-making, operational efficiency, and deeper insights into customer behavior and market trends. However, technology on its own does not guarantee success. Without a clear strategic framework, digital investments risk becoming cost centers rather than drivers of growth. Strategic clarity ensures that technology adoption is purpose-driven and aligned with organizational goals.

Strategy plays a critical role in prioritizing technological investments and managing transformation. By identifying core competencies and growth opportunities, organizations can deploy technology where it delivers the highest impact. This includes optimizing value chains, enhancing customer experience, and developing new business models. A well-defined strategy also helps manage risks associated with digital disruption, cybersecurity, and workforce displacement. Thus, strategy converts technological potential into competitive advantage.

Human capital is central to harnessing technology for growth. Skilled talent, continuous learning, and a culture of innovation determine how effectively technology is utilized. Organizations must invest in reskilling and upskilling to enable employees to work alongside advanced technologies. Leadership commitment and change management further influence the success of technology-driven strategies. Growth becomes sustainable when people, processes, and technology evolve in harmony.

At a broader level, governments and institutions also play a vital role in enabling technology-led growth. Supportive policies, digital infrastructure, and innovation ecosystems create an environment where strategic technology adoption can thrive. Public–private collaboration accelerates the diffusion of innovation and enhances economic resilience. When aligned with inclusive and sustainable development goals, technology and strategy together become powerful levers of long-term growth.

In conclusion, harnessing technology and strategy for growth requires more than adopting the latest innovations. It demands a coherent vision, disciplined execution, and continuous adaptation. When technology is guided by strategy and supported by human capability, growth becomes not only faster but also more resilient, inclusive, and sustainable.

Future Possibilities

Technology, strategy, and human ability are converging, and the future is incredibly open to possibilities. The swift development of artificial intelligence, automation, and data intelligence is likely to redesign productivity in terms of smarter decision-making and highly adaptive systems across all industries. Predictive and autonomous operations will become increasingly popular in organizations, with insights becoming increasingly accurate over time. This change will open new growth trajectories that are less susceptible to unpredictability and disturbance.

New technologies will also open possibilities for totally new business models and value networks. The ecosystems of platforms, digital marketplaces, and collaborative innovation frameworks will grow and erase the traditional boundaries of the industry. Advanced manufacturing and analytics will allow manufacturing customization on a large scale, making it a characteristic of competitive advantage.

Meanwhile, innovation that is based on sustainability will create opportunities for green technologies, circular economies, and low-carbon development plans. In terms of society, the future is potentially more inclusive in terms of development. Education, finance, healthcare, and job opportunities can be democratized using digital tools, especially in the underserved areas.

Conclusion

The convergence of technology, strategy, and inclusive development marks a defining moment for future growth across industries and economies. As digital tools reshape production systems, supply chains, and organisational models, their true impact depends on strategic alignment and human capability. Growth driven by innovation is most sustainable when it is purposeful, adaptable, and grounded in long-term vision rather than short-term gains.

Equally important is the need to ensure that technological progress translates into broad-based benefits. Integrating sustainability, gender inclusion, and rural development into growth strategies strengthens economic resilience and social equity. Challenges related to skills, governance, and access must be addressed proactively to prevent widening disparities. When technology is harnessed responsibly and guided by a coherent strategy, it becomes a powerful force for transformation.

In conclusion, the path forward lies in balanced progress where innovation is matched with strategy, efficiency with responsibility, and growth with inclusion. Such an approach not only enhances competitiveness but also lays the foundation for a resilient, equitable, and future-ready development paradigm.

About the Authors

Aditi Shivarkar

Aditi, Vice President at Precedence Research, brings over 15 years of expertise at the intersection of technology, innovation, and strategic market intelligence. A visionary leader, she excels in transforming complex data into actionable insights that empower businesses to thrive in dynamic markets. Her leadership combines analytical precision with forward-thinking strategy, driving measurable growth, competitive advantage, and lasting impact across industries.

Aman Singh

Aman Singh with over 13 years of progressive expertise at the intersection of technology, innovation, and strategic market intelligence, Aman Singh stands as a leading authority in global research and consulting. Renowned for his ability to decode complex technological transformations, he provides forward-looking insights that drive strategic decision-making. At Precedence Research, Aman leads a global team of analysts, fostering a culture of research excellence, analytical precision, and visionary thinking.

Piyush Pawar

Piyush Pawar brings over a decade of experience as Senior Manager, Sales & Business Growth, acting as the essential liaison between clients and our research authors. He translates sophisticated insights into practical strategies, ensuring client objectives are met with precision. Piyush’s expertise in market dynamics, relationship management, and strategic execution enables organizations to leverage intelligence effectively, achieving operational excellence, innovation, and sustained growth.

Request Consultation

Request Consultation