What is Internet of Things (IoT) in Chemical Market Size?

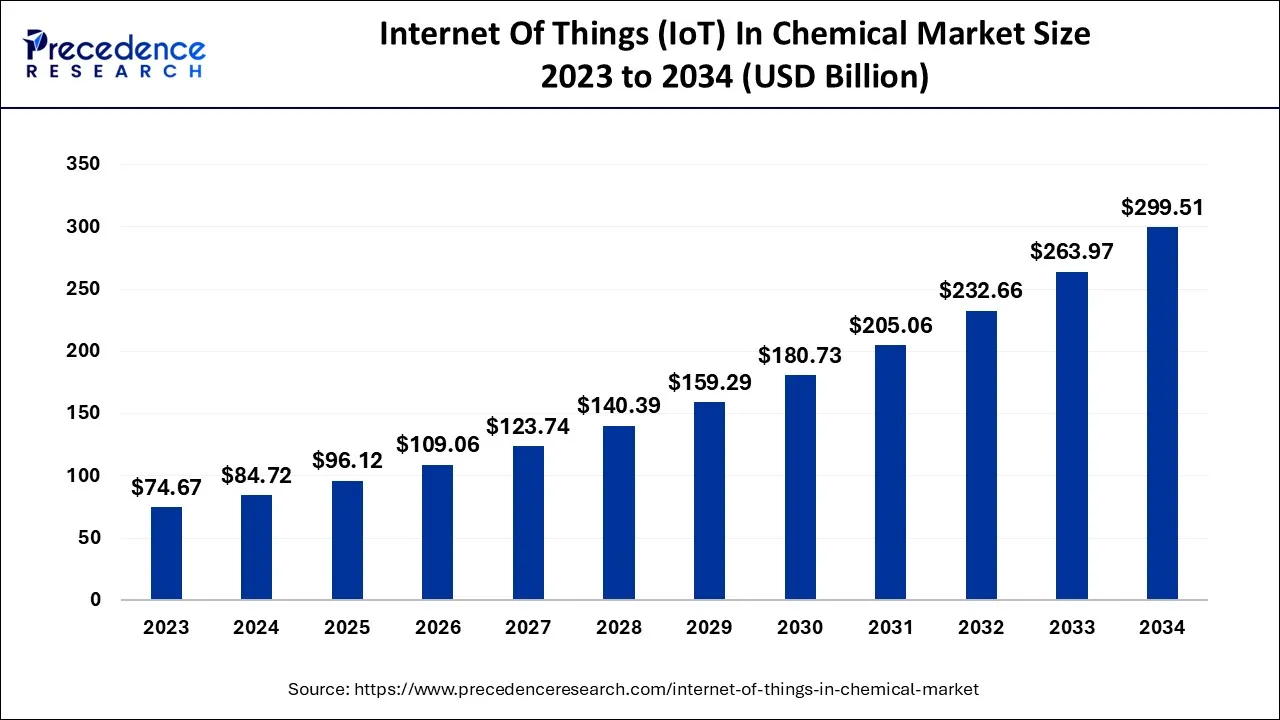

The global internet of things (IoT) in chemical market size is expected to be valued at USD 96.12 billion in 2025 and is anticipated to reach around USD 332.23 billion by 2035, expanding at a CAGR of 13.2% over the forecast period from 2026 to 2035

Market Highlights

- North America led the market and contributed to the maximum market share in 2025.

- By Technology, the artificial intelligence segment contributed to the largest market share in 2025.

- By Chemical Verticals, the chemicals segment dominated the market and generated the highest market share in 2025.

Market Overview

IoT application in the chemical market uses IoT sensors for real-time monitoring of chemical processes. This allows for greater control and optimization of production processes, improving quality, increased efficiency, and reduced costs. For instance, IoT sensors can monitor variables such as temperature, pressure, and pH levels in chemical reactors. By collecting and analyzing this data in real-time, operators adjust the process parameters to ensure optimal conditions and prevent deviations that can lead to production issues.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 96.12 Billion |

| Market Size in 2026 | USD 109.06 Billion |

| Market Size by 2035 | USD 332.23 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 13.2% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | By Technology, By Chemical Verticals, and region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

The rising need for predictive maintenance in the chemical industry

As chemical plants have grown older and become more complex, the cost of equipment failure and downtime has increased significantly. To ensure equipment reliability and minimize downtime, chemical companies have turned to predictive maintenance, which involves using real-time data to predict when equipment is likely to fail and proactively taking steps to prevent that failure from occurring.

IoT solutions are crucial in enabling predictive maintenance in the chemical industry. Using IoT sensors to collect real-time data on equipment health, operators can identify potential issues before they occur and take corrective action to prevent downtime and reduce maintenance costs. For instance, IoT sensors can monitor vibration levels in pumps and motors, detect leaks in pipelines, and track temperature and pressure in chemical reactors.

In addition to reducing downtime and maintenance costs, predictive maintenance can improve safety by detecting potential equipment failures before they become a hazard. This is especially important in the chemical industry, where a reactor or storage tank failure could have severe consequences. Thus, the rising need for predictive maintenance is expected to be a key driver of IoT adoption in the chemical industry as companies look for ways to improve equipment reliability, minimize downtime, and reduce maintenance costs.

Restraint

Cybersecurity concerns

IoT solutions can be vulnerable to cyberattacks because they rely on transferring and storing large amounts of data. In the chemical industry, where the consequences of a breach can be severe, cybersecurity concerns can be a significant barrier to adopting IoT solutions. The chemical industry is particularly vulnerable to cyberattacks, as it is a high-value target for hackers due to the sensitive nature of its operations and the potential impact of a breach.

The cyberattack compromises sensitive information disrupts operations and poses a safety risk to personnel and the surrounding community. To address these concerns, chemical companies must ensure that their IoT solutions are designed with security. This includes implementing secure data transfer protocols, encrypting sensitive data, and implementing robust access controls to prevent unauthorized access to IoT devices and data.

In addition to these technical measures, companies must ensure that their employees are trained in cybersecurity best practices and aware of the risks associated with IoT devices. This includes regular security awareness training, limiting access to sensitive data, and implementing multi-factor authentication for all IoT devices. Thus, cybersecurity concerns are expected to continue significantly restraining IoT adoption in the chemical industry. Companies must take a proactive approach to address these concerns to successfully implement IoT solutions in their operations.

Opportunity

Improved predictive maintenance

Predictive maintenance uses data collected from sensors and other IoT devices to predict when maintenance is needed on chemical plant equipment. By detecting early signs of equipment failure, maintenance can be scheduled before the equipment breaks down, reducing the risk of costly downtime.

Predictive maintenance can be applied to various chemical plant equipment, including pumps, valves, motors, and pipelines. By monitoring these assets in real time, IoT devices can detect changes in performance that may indicate a potential issue. For instance, vibration levels, temperature, or pressure changes can indicate impending equipment failure.

Predictive maintenance can also help reduce maintenance costs by enabling companies to schedule maintenance when needed rather than on a fixed schedule. This can reduce the frequency of unnecessary maintenance and reduce the cost of spare parts and labour. Implementing predictive maintenance requires the installation of sensors and other IoT devices on equipment throughout the chemical plant.

These devices collect data on the performance of the equipment, which is analyzed using machine learning algorithms to detect patterns and anomalies that may indicate potential issues. Using predictive maintenance, chemical companies can improve equipment reliability, reduce downtime, and lower maintenance costs. This increases overall operational efficiency and improves profitability in the chemical market.

Segment Insights

Technology Insights

The IoT in the chemical market is segmented on technology into machine vision, 3D printing, digital Twin, plant asset management, manufacturing execution systems, distributed control systems, Industrial Robotics, big data, artificial intelligence, augmented reality and virtual reality, and Others. In 2025, the artificial intelligence technology segment dominated the market, generated for the highest market share. AI technology uses machine learning algorithms to analyse data, make predictions, and automate decision-making. AI can optimize production processes, improve product quality, and reduce costs in the chemical industry.

For instance, predictive maintenance- By analyzing data from sensors and other IoT devices, AI algorithms can predict equipment failures before they occur. This allows chemical companies to schedule maintenance activities proactively, reducing downtime and increasing equipment lifespan. Quality Control- AI algorithms can analyse data from various sources, including sensors and production logs, to identify patterns and detect anomalies in the production process.

This allows chemical companies to identify quality issues early and take corrective action before products leave the factory. Thus, AI technology has the potential to significantly improve the efficiency, productivity, and sustainability of the chemical industry. As more chemical companies adopt AI technology, there is increased optimization of production processes, reduced downtime, and improved product quality.

Chemical Verticals Insights

Based on the chemical verticals, the IoT in the chemical market is segmented into mining & metals, food & beverages, chemicals, pharmaceuticals, paper & pulp. In 2025, the chemicals vertical dominated the market and captured the maximum market share. Chemical production involves a complex process that requires precise monitoring and control to ensure quality, safety, and efficiency.

IoT technology can help chemical companies optimize production processes by providing real-time temperature, pressure, and chemical composition data. This information can be used to optimize the production process, reducing waste and improving efficiency. In addition, the chemical industry is subject to strict regulatory requirements to ensure the safety and quality of the products produced. IoT technology can monitor environmental conditions and chemical production processes, ensuring compliance with regulatory requirements.

Regional Insights

How did the North America Region dominate the Internet of Things (IoT) in Chemical Market in 2025?

North America dominated the market and accounted for the highest market share in 2025. The region has many chemical manufacturing companies and is known for its early adoption of advanced technologies, making it a key market for IoT solutions in the chemical industry. The United States is the leading country in this region, accounting for the largest share of the market.

The growth is attributed to chemical companies' increasing adoption of IoT solutions to enhance their operations' overall efficiency and productivity. However, it's important to note that the market is dynamic and subject to changes in the future due to various factors such as regulatory policies, technological advancements, and economic conditions.

Why is Asia Pacific the Fastest-Growing Region in the Internet of Things (IoT) in Chemical Market?

Moreover, Asia Pacific is expected to grow during the forecast period. The region has many chemical manufacturing companies and is expected to witness significant growth in adopting IoT solutions in the coming years. Countries like China, India, Japan, and South Korea are driving this growth due to the increasing demand for chemical products and the need to improve their manufacturing processes. The growing adoption of Industry 4.0 technologies, coupled with government initiatives to promote the digitalization of the manufacturing industry, is also expected to boost market growth in this region.

U.S. Internet of Things (IoT) in Chemical Market Analysis

The U.S. market for IoT in chemical industry is driven by compliance with cybersecurity, increased focus on operational efficiency, and sustainability initiatives. According to the National Institute of Standards and Technology (NIST), federal investments in IoT infrastructure offer a better 10-20X return. Chemical companies are increasingly using IoT-enabled sensors, connected equipment, and real-time analytics to optimize process efficiency, enhance plant safety, and reduce operational costs through predictive maintenance.

• In May 2025, Aramco, the leading integrated energy and chemicals company, signed MoUs and agreements of US$ 90 billion with U.S. companies. This collaboration is realting to a range of Aramco's acitives like fuels, LNG, emission-reducing technologies, and chemicals.

India Internet of Things (IoT) in Chemical Market Analysis

The Indian market for IoT in chemical industry is experiencing the fastest growth, owing to the rising trends like green manufacturing, supply chain resilience, and a strategic shift towards Industry 4.0. The growth is further supported by rapid industrial digitalization and growing adoption of smart manufacturing practices. Chemical manufacturers are increasingly deploying IoT sensors and connected systems to improve process control, enhance plant safety, and reduce downtime through predictive maintenance.

How is the Notable Growth of Europe in the Internet of Things (IoT) in Chemical Market?

Europe is expected to grow at a notable rate in the market during the studied period due to regulatory compliance and safety, advanced manufacturing, Industry 4.0, and cost-optimization. Chemical companies are leveraging IoT-enabled sensors, connected equipment, and real-time monitoring systems to enhance operational efficiency, ensure regulatory compliance, and improve safety standards. Strong emphasis on sustainability and energy efficiency across the region is accelerating the use of IoT for emissions tracking, predictive maintenance, and waste reduction.

• In October 2024, the European Union announced a €865 million initiative to boost the digital infrastructure of Europe through the Connecting Europe Facility (CEF) Digital program of the European Commission. The plan is designed to boost European connectivity infrastructure.

Germany Internet of Things (IoT) in Chemical Market Trends

Germany's market is gaining strong momentum, driven by the country's advanced manufacturing base and rapid adoption of Industry 4.0 practices. Chemical producers are increasingly deploying IoT sensors, smart meters, and connected control systems to optimize process efficiency, improve safety, and reduce energy consumption.

Strict regulatory requirements around environmental protection and workplace safety are further encouraging real-time monitoring and predictive maintenance solutions. In addition, integration of IoT with data analytics and AI is enabling better asset management and supply chain visibility.

What are the Major Factors Contributing to the Internet of Things (IoT) in Chemical Market within South America?

South America is expected to experience lucrative growth during the forecast period due to the rising trend of industrial robotics, supply chain transparency, and safety. The South American countries have adopted stricter chemical regulations that have addressed by the global chemical industry.

What Opportunities Exist in the Middle East and Africa in the Internet of Things (IoT) in Chemical Market?

MEA is expected to grow at a significant rate in the market in the coming years, driven by the growing demand for petrochemicals and specialty chemicals, and rapid 5G and connectivity. The IoT adoption and its deployment in the Gulf countries of the Middle East are encouraged by the government initiatives for emerging technologies like AI and IoT.

Internet of Things (IoT) in Chemical Market-Value Chain Analysis

- Feedstock Procurement

This stage is driven by the major applications of IoT, such as inventory tracking, transportation, logistics, quality monitoring, and predictive procurement.

Key Players: Siemens AG, Honeywell International, Emerson Electric Co., ABB Ltd., Schneider Electric, Yokogawa Electric Corporation. - Distribution to Industrial Users

In this stage, IoT adoption is distributed across various industries like petrochemical, pharmaceuticals, specialty chemicals, mining and metals, and paper and pulp.

Key Players: Microsoft, Siemens AG, ABB Ltd., Honeywell International Inc., Schneider Electric, Rockwell Automation. - Waste Management and Recycling

In this stage, some of the major applications of IoT are real-time monitoring and tracking, asset maintenance, and AI-driven sorting.

Key Players: Waste Management, Inc., Veolia, SUEZ, Clean Harbors, LanzaTech.

Internet of Things (IoT) in Chemical Market Companies

- Siemens AG

- General Electric Company (GE)

- Honeywell International Inc.

- Cisco Systems, Inc.

- Intel Corporation

- SAP SE

- IBM Corporation

- Schneider Electric SE

- Rockwell Automation, Inc.

- Yokogawa Electric Corporation

Recent Developments

- In September 2025, ABB Ltd. was recognized and honored as a Leader in the 2025 Gartner Magic Quadrant for Global Industrial IoT Platforms due to the company's commitment to offering innovative industrial IoT and AI solutions.

- In December 2025, SUEZ reported its mission towards IoT and AI-smart management of the whole water cycle through the company's 7 million meters connected globally, aiming to meet the demands of over 1,500 customers that are using its Smart Water systems and platforms.

- In March 2021, BASF, a leading chemical company, partnered with Litmus Automation, an IoT platform provider, to develop a digitalization solution for chemical production. The solution will enable real-time monitoring of production processes and improve operational efficiency.

- In Feb 2021, Honeywell, a multinational conglomerate, launched its Sentience Industrial Internet of Things (IIoT) platform for the chemical industry. The platform enables real-time monitoring and predictive analytics to optimize production processes and reduce downtime.

- In Oct 2022,Siemens, a global technology company, has introduced a range of IoT solutions for the chemical industry, including the Siemens Digital Enterprise Suite for Chemicals. The suite enables the digitalization of the entire value chain, from production planning to maintenance and service.

Segments Covered in the Report

By Technology

- Machine Vision

- 3D printing

- Digital Twin

- Plant Asset Management

- Manufacturing Execution System

- Distributed Control Systems

- Industrial Robotics

- Big Data

- Artificial Intelligence

- AR and VR

- Others

By Chemical Verticals

- Mining & Metals

- Food & Beverages

- Chemicals

- Pharmaceuticals

- Paper & Pulp

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- The Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting