What is the Linear Actuator Market Size?

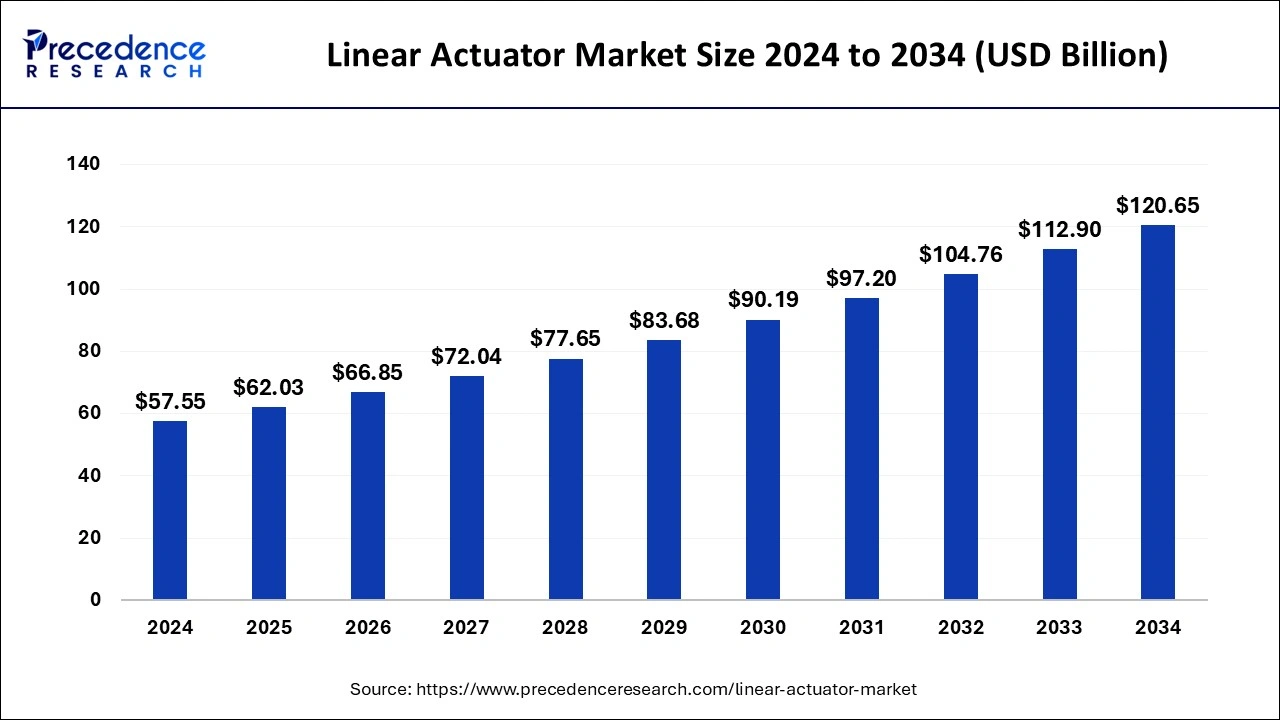

The global linear actuator market size is estimated at USD 62.03 billion in 2025 and is predicted to increase from USD 66.85 billion in 2026 to approximately USD 120.65 billion by 2034, expanding at a CAGR of 7.68% from 2025 to 2034 The need for linear actuators in the manufacturing, automotive, aerospace, healthcare, and other sectors has risen in tandem with the expansion of industries worldwide, propelling the market's growth.

Market Highlights

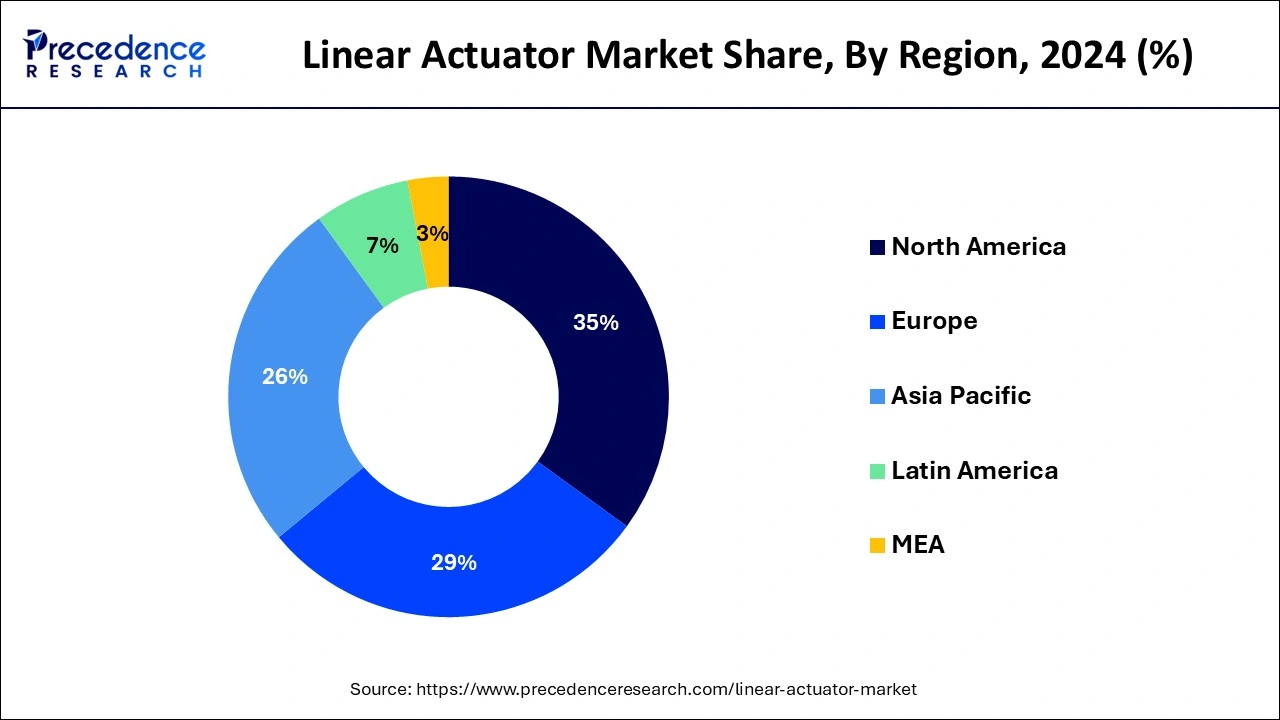

- North America hold the largest share of 35% in 2024.

- Asia Pacific is expected to grow at the fastest rate during the forecast period.

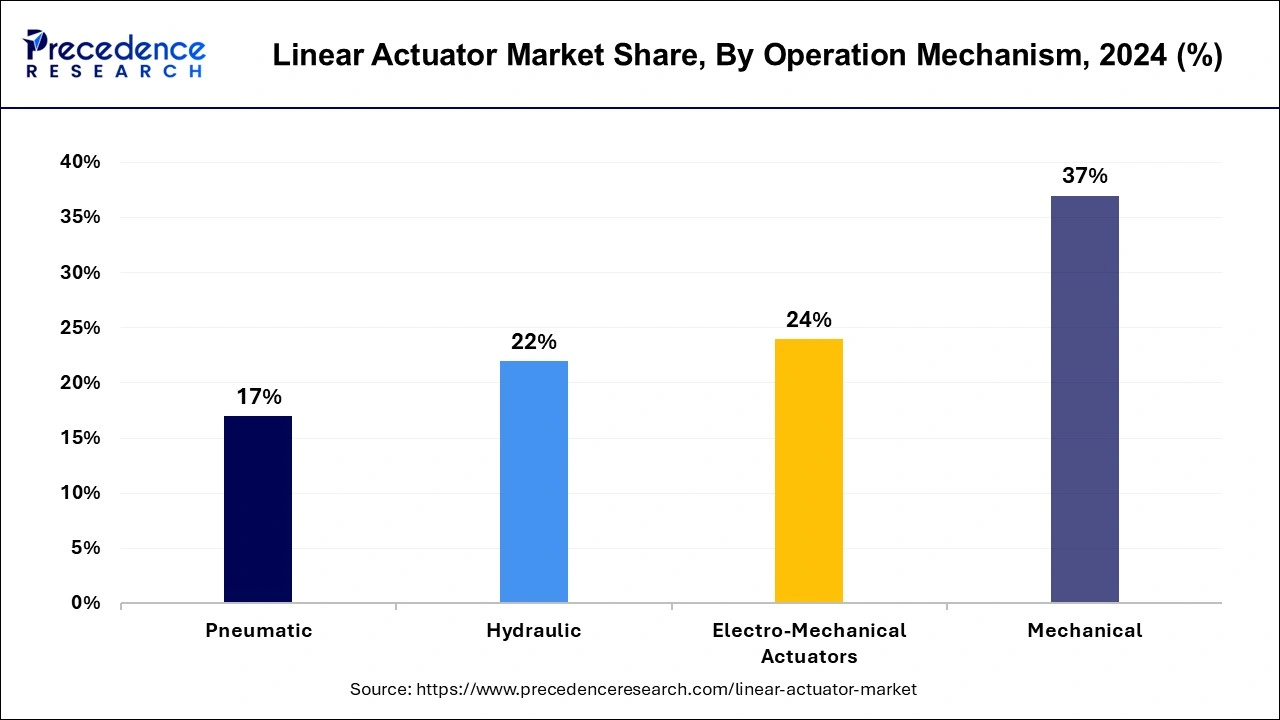

- By operation mechanism, the mechanical segment generated largest revenue share of 37% in 2024.

- By end user industry, the automotive segment held the largest market share in 2024 and is expected to continue this dominance throughout the forecast period.

Market Size and Forecast

- Market Size in 2025: USD 62.03 Billion

- Market Size in 2026: USD 66.85 Billion

- Forecasted Market Size by 2034: USD 120.65 Billion

- CAGR (2025-2034): 7.68%

- Largest Market in 2024: North America

- Fastest Growing Market: Asia Pacific

Market Overview

Due to their ability to precisely control linear motion, linear actuators are essential to industrial automation. The demand for linear actuators in the manufacturing and processing industries is anticipated to continue to be robust due to the ongoing trend toward industrial automation and Industry 4.0 efforts. In order to achieve precise movement in robotic grippers, arms, and other devices, linear actuators are essential parts of robotics.

High-performance linear actuators will probably become more and more in demand as robotics applications spread throughout sectors like healthcare, logistics, and automobiles. The linear actuator market is being driven by the increasing use of smart home technologies and building automation systems in applications such as motorized window blinds, movable furniture, and automated doors and windows.

It is anticipated that the need for linear actuators with accurate control and dependability will increase as long as healthcare facilities keep investing in cutting-edge medical technologies. Electric car components such as seat adjustments, trunk doors, and charging port mechanics all require linear actuators.

The need for linear actuators in the automotive industry is anticipated to rise in response to the increasing acceptance of electric vehicles and the ongoing attempts to enhance their convenience and efficiency. Advanced linear actuators with features like more precision, more load capacity, enhanced energy efficiency, and integration with IoT platforms for remote monitoring and control are the focus of manufacturers.

Linear Actuator Market Outlook

- Industry Growth Overview:From 2025 to 2034, the linear actuator market is expected to grow significantly, driven by advancements in automation, increased demand for precision control in industries like robotics, healthcare, and automotive, and the rising adoption of electric actuators for their energy efficiency and sustainability. Additionally, the integration of IoT, AI, and smart technologies is further fueling market expansion, enabling real-time monitoring and predictive maintenance capabilities.

- Technological Innovation:Technological evolution in the market is increasingly focused on smart electric actuators that integrate real-time sensors, encoders, force feedback, IoT connectivity, and onboard diagnostics for predictive maintenance. The rise of digital twin technology allows engineers to simulate product performance and reliability before deployment, enhancing design precision. Additionally, the growing integration of actuators with AI-controlled motion controllers is expected to significantly raise performance standards, driving innovation and efficiency in the years to come.

- Global Expansion:Leading actuator vendors are rapidly expanding geographically to enhance supply chain resilience and position themselves closer to high-growth OEM clusters, particularly in the automotive and industrial automation sectors. Additionally, by forming strategic alliances with regional distributors and system integrators, these companies are tapping into middle-income markets that demand tailored solutions, further driving the shift toward more flexible, globally integrated production networks.

- Major Investors:Major investors in the market include global industrial giants such as Siemens, Bosch, and Parker Hannifin, who contribute by funding research and development for more advanced, efficient actuator technologies. Additionally, venture capital firms and private equity investors are supporting startups and scale-ups focused on integrating AI, IoT, and robotics into linear actuators, accelerating innovation and driving market expansion across diverse industries.

- Startup Ecosystem:The startup ecosystem in the market is expanding rapidly, driven by the growing demand for ultra-compact actuators, high-force servo actuators, and energy-efficient alternatives to traditional pneumatic systems. New companies from the U.S., Germany, Japan, South Korea, and India are pushing the boundaries of performance by leveraging advanced materials, innovative screw designs, and smart control algorithms, while introducing breakthrough innovations such as self-lubricating mechanisms, friction-reducing coatings, adaptive force control, and fully integrated linear modules.

Linear Actuator MarketGrowth Factors

- The need for linear actuators is being driven by the implementation of Industry 4.0 principles, which place an emphasis on automation, data interchange, and smart manufacturing technologies. These actuators are essential to the automation of many operations in the automotive, aerospace, manufacturing, and healthcare sectors.

- Because of its accurate control, low energy consumption, and simplicity of integration with digital control systems, electric linear actuators are becoming more and more common. The linear actuator market is expanding as a result of the move toward electric actuators, especially in sectors like aircraft, medical devices, and robotics.

- The linear actuator market is experiencing innovation due to trends in lightweight design and miniaturization, which facilitates its integration into a wider range of applications such as automotive components, consumer electronics, and portable gadgets.

- In medical devices, including patient lifts, diagnostic tools, surgical robots, and rehabilitation equipment, linear actuators are essential components. The healthcare industry's linear actuator market is expanding as a result of rising healthcare costs and technical developments in assistive technology and medical robots.

- Linear actuators are essential parts for automated systems that handle materials, assemble, package, and inspect. The need for linear actuators is predicted to rise gradually as industries implement more process automation.

- The growth of emerging markets, particularly in Latin America and Asia-Pacific, has created new prospects for the linear actuator market. Furthermore, new applications like wearable technology, drones, 3D printing, and smart infrastructure are opening up new possibilities for using linear actuators.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 62.03 Billion |

| Market Size in 2026 | USD 66.85 Billion |

| Market Size by 2034 | USD 120.65 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 7.68% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Operation Mechanism, End-user Industry, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

E-commerce growth

Manufacturers of linear actuators can reach a worldwide market through e-commerce platforms, eliminating the need to set up actual distribution networks in each location. Companies in the linear actuator market are able to expand their consumer base and access new markets because of this increased reach. Inventory management systems and online storefronts can be integrated to help businesses optimize stock levels, cut lead times, and guarantee on-time product delivery to customers.

Because e-commerce gives consumers access to product details, reviews, and pricing, it promotes openness in the linear actuator market. Producers and distributors can use this data to discover new market trends, obtain insightful knowledge about consumer preferences, and adjust their product lineups accordingly.

Restraint

Dependency on end-user industries

Applications for the linear actuator market can be found in automobiles' convertible tops, power windows, sunroofs, and seat automation systems. The need for linear actuators is directly impacted by the car industry's need for automation, safety, and comfort features. In consumer electronics items like game consoles, cellphones, cameras, and household appliances, linear actuators are used for features like autofocus and magnification, as well as opening and closing mechanisms.

For accurate movement and control, linear actuators are used in construction equipment, including excavators, cranes, and lifts. They are also used in infrastructure projects for things like solar panels, gates, and barrier placement. Technological developments in energy production and distribution, regulatory requirements, and energy demand all have an impact on the linear actuator market demand.

Opportunity

Renewable energy sector

Solar tracking systems, which maximize the amount of sunlight absorbed throughout the day by optimizing the position of solar panels or mirrors, heavily rely on linear actuators. In order to maximize energy capture and efficiency, these actuators modify the angle or pitch of the blades to optimize their location with respect to the direction of the wind.

Actuators provide accurate control over these components' movements, which makes water management and energy generation more efficient. Linear actuators are used in wave and tidal energy converters to move different parts, like turbines or buoys, in order to capture energy from tidal currents or ocean waves efficiently.

Segments Insights

Operation Mechanism Insights

The mechanical segment held the largest share of the linear actuator market. The physical parts of linear actuators that translate rotary motion into linear motion are usually referred to as the mechanical section of the linear actuator market. Electromechanical devices called linear actuators are used to produce motion in a straight line. Numerous sectors and applications, including robotics, manufacturing, automotive, healthcare, aerospace, and more, heavily rely on them.

The main methods for transforming rotary motion into linear motion are as follows. Whereas ball screws employ ball bearings to lower friction and increase efficiency, lead screws use threads to translate rotational action into linear motion. Shafts and bearings are frequently used in linear actuators to support and precisely guide linear motion.

The hydraulic segment has held a 22% revenue share in 2024 and it is also expected to hold a considerable share of the linear actuator market. The method by which hydraulic energy is transformed into mechanical motion powers hydraulic linear actuators. Usually, they are made up of a hydraulic fluid, piston, and cylinder. A force that moves the piston and produces linear motion is created when hydraulic pressure is supplied to one side of the piston.

Tasks like lifting, pushing, tugging, and adjusting the position of different mechanical parts can all be done using this action. Because they can produce higher force outputs than other linear actuator types, hydraulic actuators are well-suited for heavy-duty applications like industrial automation, agricultural gear, and construction equipment.

End-user Industry Insights

The automotive segment held the largest market share in 2024 and is expected to continue this dominance throughout the forecast period. This is due to the rising demand for automobiles and increasing investment in healthcare. The linear actuator market plays a vital role in the automotive industry, and their adoption has increased globally along with the growing automotive sector. With the continued increase in global demand for automobiles, automation in their manufacturing is also expanding.

Linear actuators are essential components used in automotive applications of various sizes and shapes, ranging from small to large. Many automobile manufacturers use robots to perform tasks such as clamping and fixing, spot welding, and assembly pressing. With the increased adoption of robots in the automotive industry, the use of electric linear actuators has become critical, which will boost sales. Linear actuators are used in a wide range of automotive applications, including hoods, trunks, tailgates, tonneau covers, and rumble seats.

Regional Insights

Manufacturers of linear actuators are seeing opportunities as more vehicles switch to electric ones, especially in areas like automatic doors, seat adjustment mechanisms, and electric power steering systems. The design and development of linear actuators are influenced by regulatory requirements and environmental factors, especially with regard to energy efficiency, sustainability, and compliance with industry standards.

North America held the largest share of the linear actuator market

In order to provide accurate movement and control in a variety of machinery and equipment, there is an increasing demand for linear actuators due to the automation of manufacturing and production processes. In robotics applications, such as industrial robots and service robots utilized inlogistics, healthcare, and other fields, linear actuators are essential components. The growing robotics sector is driving the demand for sophisticated linear actuator systems.

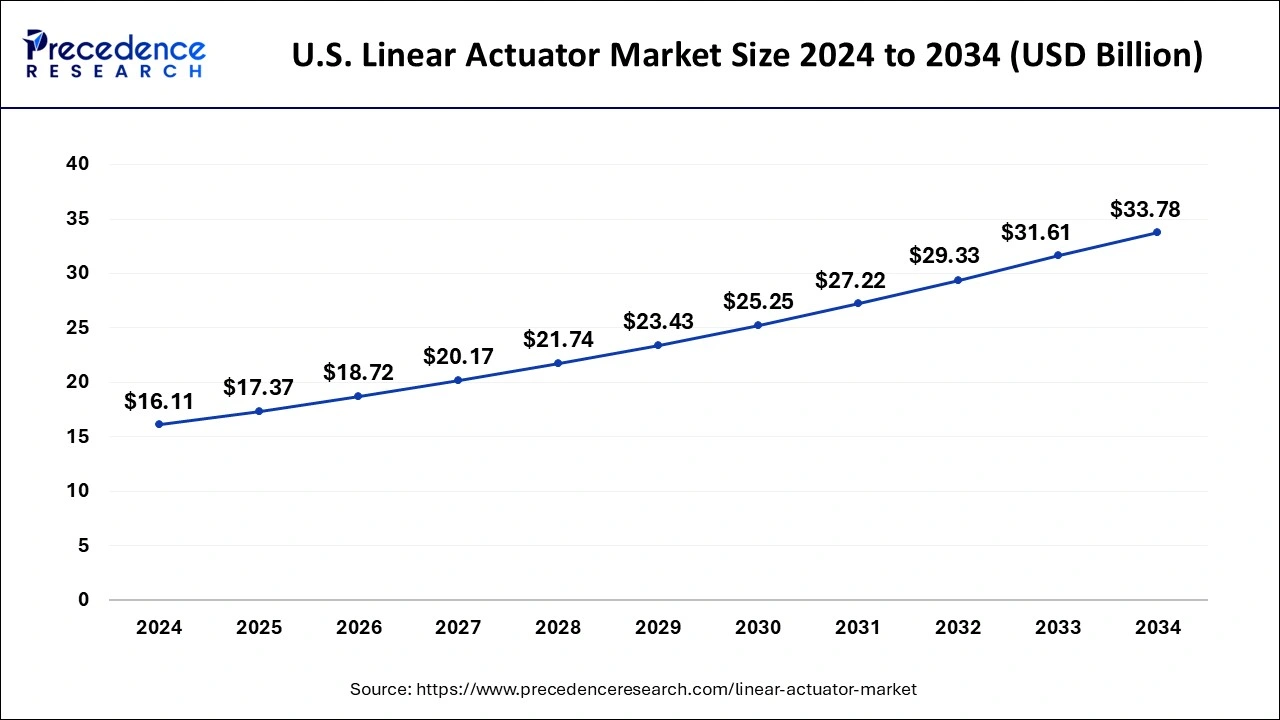

U.S. Linear Actuator Market Size and Growth 2025 to 2034

The U.S. linear actuator market size was estimated at USD 17.37 billion in 2025 and is projected to surpass around USD 33.78 billion by 2034 at a CAGR of 7.70% from 2025 to 2034.

The U.S. is poised to retain its leadership in North America, driven by significant investments in robotics, AGVs, and precision assembly machinery across sectors like automotive, aerospace, and electronics. Major OEMs, including Rockwell Automation and Emerson, are accelerating the adoption of advanced servo-driven actuator systems, while the ongoing shift toward energy-efficient production processes is expected to further boost the replacement of pneumatic systems with electric actuators.

What Makes Asia Pacific the Fastest-Growing Region in the Linear Actuator Market?

China Linear Actuator Market Analysis

China is a major contributor to the Asia Pacific linear actuator market due to its strong manufacturing base and rapid industrialization, which drives demand across sectors like automotive, robotics, and electronics. The country's large-scale adoption of automation and precision machinery, combined with significant investments in advanced technologies such as robotics and AI, further fuels the growth of the linear actuator market. Additionally, China's focus on energy-efficient and cost-effective solutions in production processes is accelerating the shift from pneumatic to electric actuators, strengthening its position as a market leader in the region.

What Makes Europe a Notably Growing Area?

Europe is emerging as a notably growing region in the linear actuator market due to its strong focus on automation, robotics, and precision manufacturing, particularly in automotive, industrial machinery, and aerospace sectors. The region's emphasis on energy-efficient technologies and sustainability is driving the adoption of electric actuators, as industries seek to reduce energy consumption and carbon footprints. Additionally, Europe's well-established industrial automation infrastructure, combined with advanced manufacturing hubs in countries like Germany, France, and Italy, supports the demand for high-performance, reliable actuator systems.

The ongoing digitalization and Industry 4.0 initiatives across European industries are further accelerating the growth of the linear actuator market. Germany leads the market due to its strong automotive, machine tool, and industrial robotics sectors that heavily depend on precision electromechanical actuators.

How is the Opportunistic Rise of Latin America in the Linear Actuator Market?

Latin America is experiencing an opportunistic rise in the linear actuator market, fueled by increased industrialization, especially in automotive manufacturing, robotics, and renewable energy sectors. Countries like Brazil and Mexico are witnessing a surge in demand for automation solutions as industries modernize to stay competitive globally, resulting in a greater reliance on precision motion control technologies such as linear actuators. Furthermore, the region's growing emphasis on energy efficiency, cost savings, and sustainability is promoting a shift from traditional pneumatic systems to electric and hybrid actuators.

What Potentiates the Growth of the Middle East and Africa Linear Actuator Market?

The market in the Middle East and Africa (MEA) is expanding, driven by increasing industrial automation projects across the UAE, Saudi Arabia, and South Africa. The diversification programs in the Gulf region are expected to accelerate the implementation of advanced motion systems in clean energy, water treatment facilities, and high-tech industries. The growing collaboration between Gulf industrial groups and global automation suppliers is anticipated to promote long-term growth.

The UAE leads the market with its rapid growth in smart factories, clean-energy projects, and high-tech industrial clusters. The use of electromechanical actuators is expected to increase in solar tracking systems, desalination plants, material handling, and automated packaging. The ongoing infrastructure upgrades are projected to boost demand for durable, precise linear actuation products.

Linear Actuator Market – Value Chain Analysis

Raw Material Sourcing

The value chain begins with the extraction and supply of essential raw materials, including aluminum, stainless steel, specialty alloys, copper windings, rare-earth magnets (for motors), polymers, and sealing materials, which form the mechanical and electrical foundation of linear actuators.

Key Players: Rio Tinto, ArcelorMittal, Nucor Corporation, China Baowu Steel Group.

Mechanical & Electronic Component Fabrication

Raw materials are processed into actuator components, including lead screws/ball screws, guide rails, housings, gears, bearings, motor windings, electronic drivers, limit switches, sensors, and seals. This stage focuses on precision machining, metallurgy, and electronics manufacturing to produce high-performance, durable actuator assemblies.

Key Players: NSK Ltd., THK Co., Ltd., SKF Group, Nidec Corporation.

Actuator System Manufacturing & Assembly

Manufacturers integrate mechanical, electrical, and control components into complete actuator systems, such as electric linear actuators, hydraulic actuators, pneumatic actuators, and electromechanical systems. Processes include motor integration, gear-train assembly, performance calibration, load testing, IP rating certification, and quality control.

Key Players: Bosch Rexroth, Parker Hannifin, Kollmorgen, LINAK, Oriental Motor, Emerson.

Integration into Automation & Motion Control Solutions

Finished actuators are combined with control systems, sensors, drives, and software to create full motion-control solutions used in robotics, industrial automation, medical equipment, and material-handling systems. This stage involves system engineering, custom configurations, and the deployment of B2B solutions.

Key Players: Rockwell Automation, Siemens, ABB, Mitsubishi Electric.

Distribution, OEM Supply & Aftermarket Services

Final products are shipped through OEM partnerships, industrial distributors, and automation integrators to end-use sectors including manufacturing, automotive, aerospace, healthcare, agriculture, and logistics. Aftermarket services include maintenance, spare parts, retrofitting, upgrades, and lifecycle management.

Key Players: Motion Industries, W.W. Grainger, RS Group, Fastenal.

Linear Actuator Market Companies

- Bosch Rexroth AG (Germany)

A global automation leader offering high-precision electric, hydraulic, and electromechanical linear actuators engineered for heavy-duty industrial motion control and advanced manufacturing systems. - Emerson Electric Co.

Provides rugged linear actuation solutions integrated with smart controls, widely used in process automation, energy infrastructure, and industrial motion applications. - HepcoMotion Ltd. (UK)

Specializes in linear motion components and actuators built for high-accuracy guidance, automation machinery, and demanding production environments. - Kollmorgen Corporation

Delivers high-performance electric linear actuators powered by servo technology, supporting robotics, aerospace, and precision automation. - LINAK (Denmark)

A global leader in electric linear actuators for medical equipment, industrial automation, and ergonomic furniture, known for reliability and intelligent motion systems. - Oriental Motor Co., Ltd. (Japan)

Offers compact electric linear actuators and motor-driven motion systems designed for precision positioning, electronics manufacturing, and small-scale automation. - Parker Hannifin Corporation

Produces a wide range of hydraulic, pneumatic, and electromechanical linear actuators used across transportation, factory automation, and heavy-industrial sectors. - Rockwell Automation

Integrates advanced linear actuator solutions within its industrial control ecosystem, supporting smart manufacturing, motion control, and connected production systems.

Recent Developments

- In October 2023, Emerson Electric Co. took over a Swiss-based company specializing in automation solutions and assembly technology, Afag Holding.

- In December 2022, Bosch Rexroth introduced a new compact, self-contained actuator, CytroMotion, to its product line. This system solution, designed for linear movements with forces up to 110 kN, enables more efficient and sustainable operations in smaller spaces.

Segments Covered in the Report

By Operation Mechanism

- Mechanical

- Hydraulic

- Pneumatic

- Electro-mechanical Actuators

By End-user Industry

- Automotive

- Construction

- Energy & Mining

- Healthcare

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting