Natural Fiber Composites Market Size and Forecast 2025 to 2034

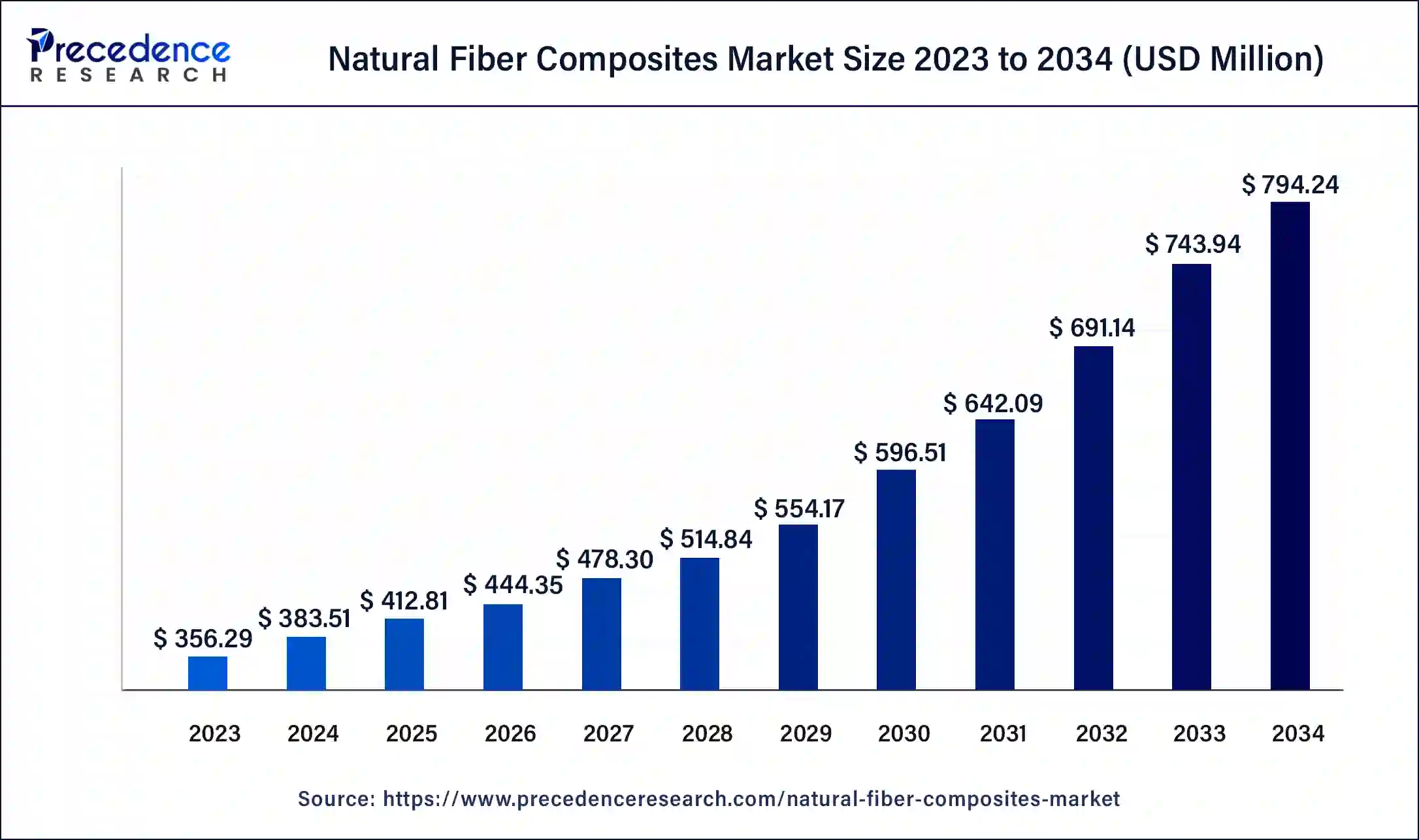

The global natural fiber composites market size was estimated at USD 383.51 million in 2024 and is anticipated to reach around USD 794.24 million by 2034, growing at a CAGR of 7.55% from 2025 to 2034. The natural fiber composites market is driven by the increasing need for sustainable and eco-friendly materials.

Natural Fiber Composites Market Key Takeaways

- The global natural fiber composites market was valued at USD 383.51 million in 2024.

- It is projected to reach USD 794.24 million by 2034.

- The natural fiber composites market is expected to grow at a CAGR of 7.55% from 2025 to 2034.

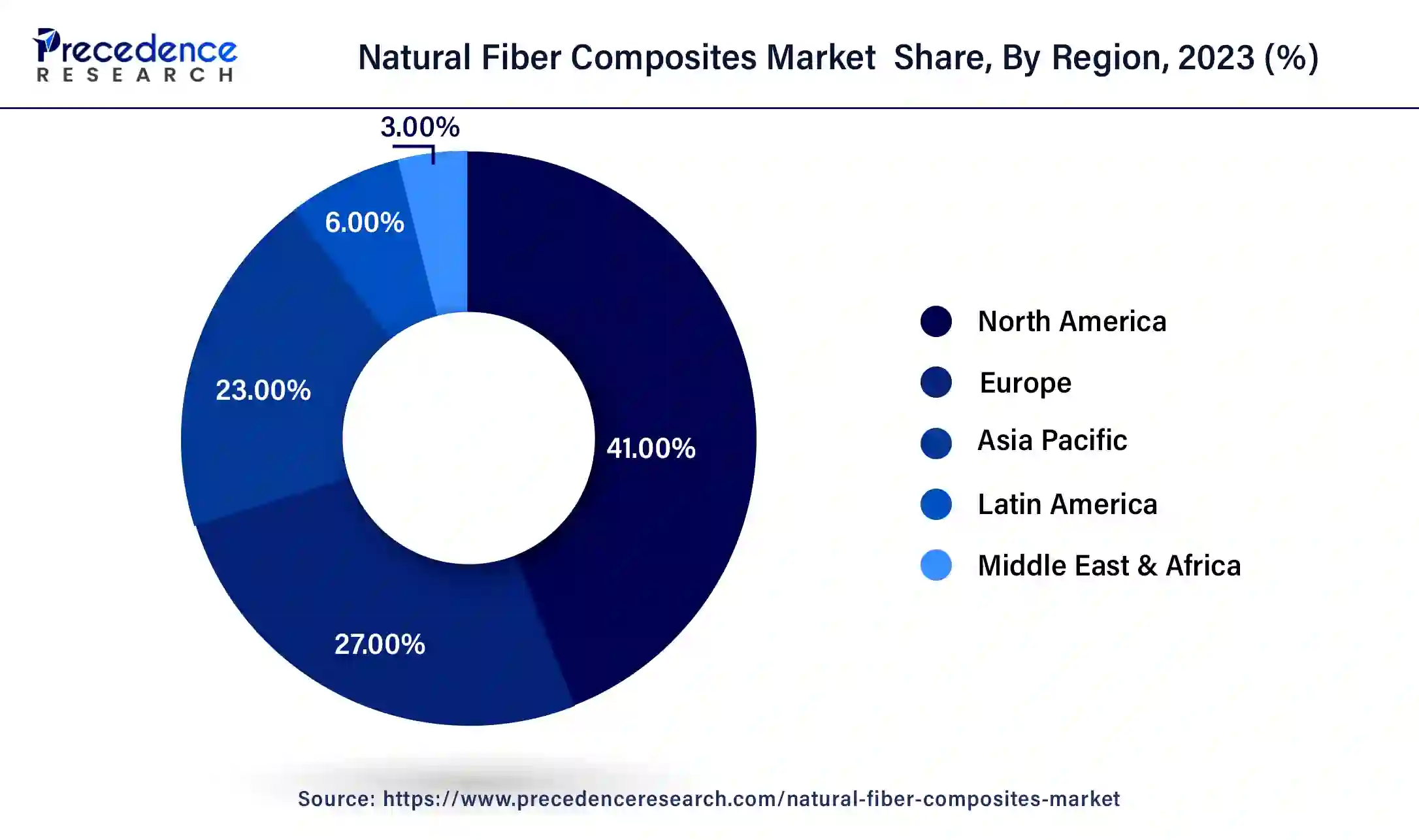

- North America led the market with the largest market share of 41% in 2024.

- By type, the wood fiber composites segment has accounted more than 27% of market share in 2024.

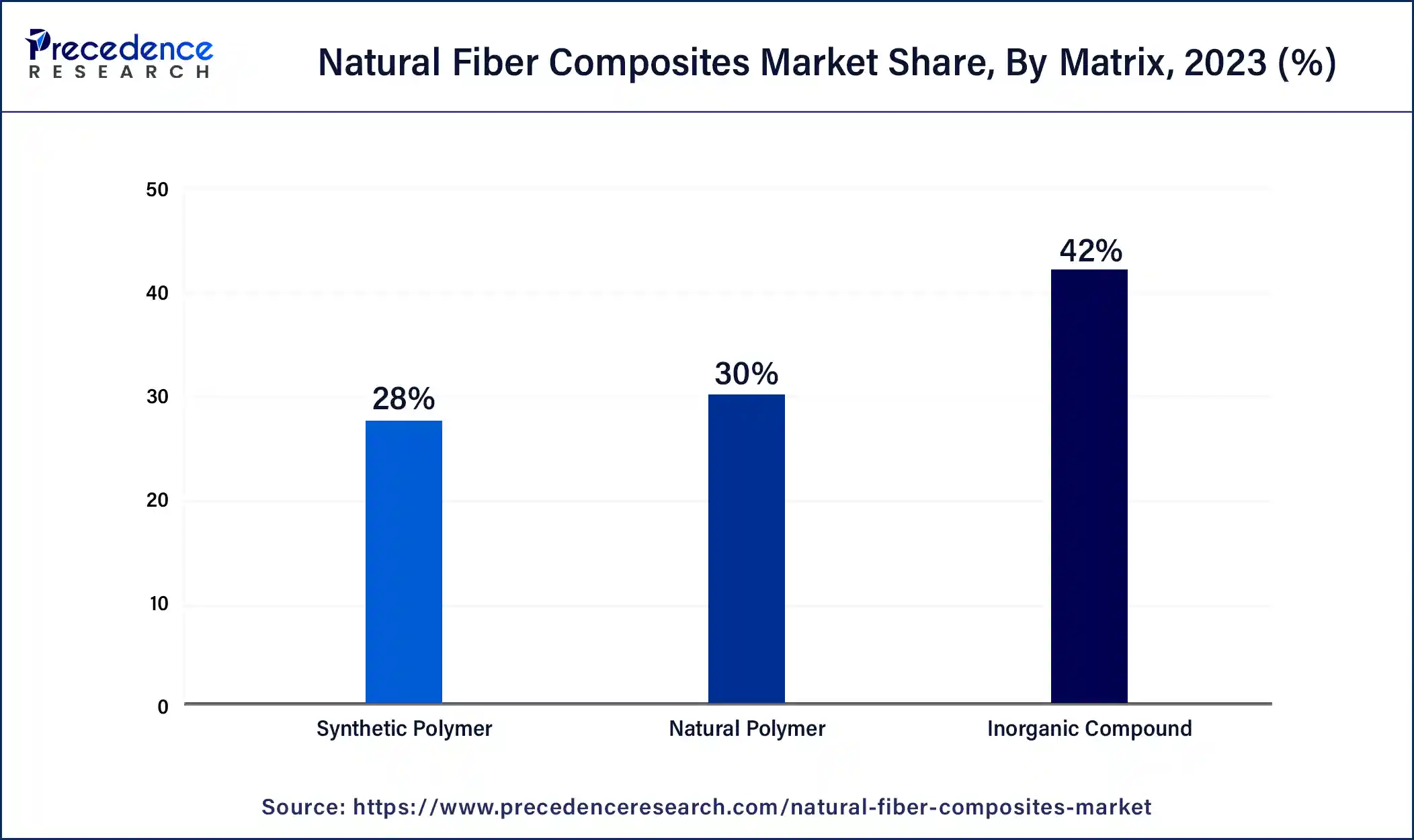

- By matrix, the inorganic compound segment has held the major market share of 42% in 2024.

- By end-use, the automotive segment dominated the natural fiber composites market.

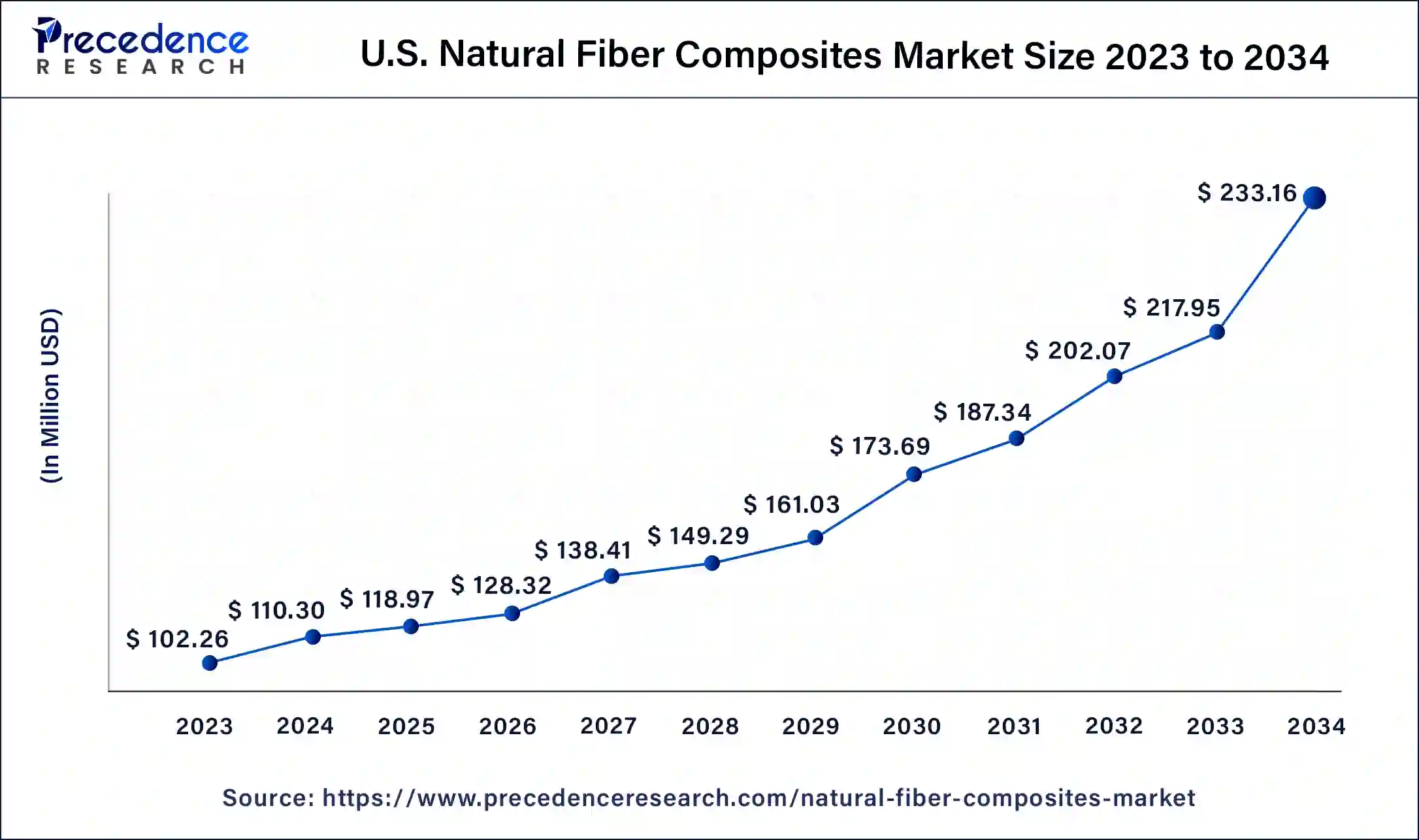

U.S. Natural Fiber Composites Market Size and Growth 2025 to 2034

The U.S. natural fiber composites market size was valued at USD 110.30 million in 2024 and is predicted to be worth around USD 233.16 million by 2034, at a CAGR of 7.77% from 2025 to 2034.

North America had a significant share of the natural fiber composites market in 2024. Natural fiber composites are used mainly by the building and automobile industries. These industries are thriving in North America and are always looking for environmentally friendly substitutes for conventional materials like metal and man-made polymers. Natural fiber composites are becoming more and more appealing to producers in the sector since they provide robust, long-lasting, and eco-friendly solutions.

- For instance, Global lifestyle brand Allbirds uses natural materials to create inventive clothing and footwear products. Their product line includes goods produced from sugarcane-derived EVA foam, a knit fabric created from eucalyptus tree fiber, and superfine New Zealand merino wool. By using these materials, Allbirds hopes to give customers things that feel well, look good, and are environmentally friendly. Through their worldwide retail locations and e-commerce network, they provide services to clients in 35 countries.

Asia-Pacific is observed to be the fastest-growing natural fiber composites market during the forecast period. Natural fiber composites are widely used by the region's rapidly growing construction, automotive, and packaging industries. Many people choose natural fiber composites over their conventional synthetic counterparts due to the increased focus on eco-friendly and sustainable materials. These industries are driving the need for natural fiber composites, promoting regional market expansion. Asia-Pacific nations are making significant R&D investments to improve the qualities and uses of composites made of natural fibers.

Improvements in manufacturing techniques, like composite formulation and fiber treatment, enhance these materials' functionality and robustness. Furthermore, natural fiber composites are becoming more widespread in various industries due to continuous innovation in product design and engineering.

- For instance, companies in India such as Crimsoune Club offers premium clothing for men and women made entirely of natural fiber. Our clothes provide comfort and flair in a wide selection of designs, patterns, and hues. We specialize in Egyptian Giza cotton clothing and American Pima cotton clothing.

Europe is expected to grow significantly in the natural fiber composites market during the forecast period. The demand for natural fiber composites in the automotive sector of Europe is increasing. These are used in the development of reduced carbon emission vehicles. At the same time, the construction sector is using it, due to its lightweight and improved performance. Moreover, they are eco-friendly and also promote sustainability. Furthermore, various policies and initiatives laid by the government are promoting their use. Thus, this enhances the market growth.

Market Overview

The natural fiber composites market is the industry that revolves around the production, innovation and distribution of composite materials and solutions that are generally observed to be a part of fiber obtained from natural sources. The industry is being supported by the rising emphasis on sustainable solutions across the globe.Bio-based polymer composites, also known as natural fiber-reinforced composites, have drawn increased attention because of their renewability, biodegradability, affordability, and lightweight.

Market Trends

- In June 2025, the collaboration between BMW Group and Bcomp has been developing flax-based lightweight components for several years now. The aim to reduce the CO₂e emissions in future vehicle models of the BMW Group is supported by Bcomp. Thus, the natural fibres with a reduced CO₂e footprint in composite materials are becoming crucial for the BMW Group. Moreover, it was demonstrated that the fibres show great suitability, particularly for visible interior and exterior components during the material test. For example, around 40% CO₂e-reduction was observed when the carbon fibre composites were replaced with natural fibre composites in the roof of the next-generation BMW Group portfolio.

(Source: https://www.autocarpro.in)

- In June 2025, to support the recycling capacity for carbon fiber composite materials, a collaboration between Westlake Epoxy and Alpha Recyclage Composites was announced. The customers of Westlake's composite will be supported in their development for production and end-of-life waste by this collaboration. Moreover, to develop a more sustainable substitute to the traditional disposal methods will be the aim of this collaboration, by using the recovered carbon fibers from composite materials for reuse in new or emerging applications.

(Source: https://finance.yahoo.com)

Natural Fiber Composites Market Data and Statistics

- The European Confederation of Flax and Hemp I CELC, the prominent industry authority on flax and hemp, is delighted to declare that it has associated with JEC Group to establish the latest Natural Fiber Village at JEC World 2022.

- Bast Fiber Technologies wipes up $3.33m to trade 100% natural fabrics processing tech.

- Natural Fiber Composites Market Growth Factors

- The increasing need for eco-friendly materials plays a vital role in market growth.

- Growth in the construction, automotive, and electronics fields that can use these composites fuels the growth of the natural fiber composites market.

- Natural fibers offer a good strength-to-weight ratio, attracting lightweight but strong materials applications.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 7.55% |

| Global Market Size in 2024 | USD 383.51 Million |

| Global Market Size in 2025 | USD 412.81 Million |

| Global Market Size by 2034 | USD 794.24 Million |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Matrix, End-use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Advances in processing technologies

Due to advanced processing techniques, natural fiber composites are manufactured more cost-effectively and efficiently. Production process optimization, waste reduction, and throughput have been achieved through automation, robotics, and computer-aided design and manufacturing (CAD/CAM) technology. Because of the decreased production costs overall, natural fiber composites are now more economically feasible for large-scale manufacturing in various industries. The production of natural fiber composites has been able to scale rapidly due to advancements in processing technology, which have allowed producers to fulfill rising demand without sacrificing effectiveness or quality.

Scalable procedures facilitate an easy transition towards broad adoption in the consumer products, construction, automotive, and aerospace industries by enabling seamless integration into current supply chains and infrastructure.

Restraint

Tendency to absorb moisture

In natural fiber composites, dimensional instability may result from moisture absorption. The composite material's overall dimensions are altered due to the fibers' swelling due to moisture absorption. The composite parts may warp, buckle, or otherwise deform due to this dimensional instability, rendering them inappropriate for precision applications demanding close tolerances. This problem may make natural fiber composites less appealing to businesses that require consistent dimensional stability, such as aerospace and the automotive industry.

It may also affect the appearance and surface quality of natural fiber composites. The unequal swelling of fibers in response to moisture exposure can result in surface imperfections and defects on the composite surface. This may lessen the completed items' aesthetic appeal, especially when appearance is crucial.

Opportunity

Rising consumer awareness of sustainability influences purchasing decisions

The global shift toward green and using more natural and sustainable resources includes environmental concerns and the petroleum consumption rate. As synthetic fibers became more prevalent around the end of the 20th century, the significance of natural fibers, used for hundreds of years to meet necessities like clothing and shelter, was significantly diminished. Natural fiber's many benefits are its increased softness, durability, and comfort. This indicates that because of their longer usable life, natural fibers are eco-friendly and excellent for sensitive skin in all seasons. They are also biodegradable, processed using fewer and less hazardous chemicals, and require less water to create. Because of these factors combined, clothing made of natural fibers lowers the dangers to human and environmental health.

Type Insights

The wood fiber composites segment dominated the natural fiber composites market in 2024. Wood fiber composites have many advantages, including dimensional stability, a high strength-to-weight ratio, and resistance to biological and moisture deterioration. For various purposes, these qualities make them a desirable substitute for conventional materials like concrete, metal, and plastics. For example, wood fiber composites offer the natural feel and appearance of wood in outdoor decking, but they require less upkeep and are more weather-resistant than natural wood.

The jute fiber composites segment is the fastest growing in the natural fiber composites market during the forecast period. The jute plant, which produces a high yield and proliferates, is the natural source of jute, a natural fiber. Sustainable and renewable materials are becoming increasingly popular as industry and consumers grow more ecologically conscious. Jute is a desirable option for many applications since it satisfies this requirement. In comparison to synthetic and natural fibers like hemp and flax, it is comparatively cheap. Because of its low cost, it is a financially feasible choice for producers who want to create high-quality composites at a reasonable price.

Jute fiber composites are becoming increasingly in demand in many industries, including consumer goods, automotive, construction, and textiles. Jute composites are utilized in the car industry to make door panels, trunk liners, and interior components since they are eco-friendly and lightweight. Jute composites are also being investigated for panels, insulation, and roofing materials in the building industry.

Matrix Insights

The inorganic compound segment dominated the natural fiber composites market in 2024. When compared to organic fibers, inorganic compounds frequently show better resistance to extreme heat and severe chemicals. This qualifies them for use in settings where exposure to harsh environments is frequent, like in chemical processing and industrial machines. Strict regulatory requirements in some areas, like aerospace and defense, make using materials with well-established and dependable qualities necessary. Since inorganic compounds frequently contain well-established performance data, they are chosen for applications where adherence to safety regulations is crucial.

The natural polymer segment is the fastest growing in the natural fiber composites market during the forecast period. Natural polymer-based composites are becoming increasingly in demand in various sectors, including consumer goods, construction, automotive, and packaging. Natural polymer composites are used in automotive applications to replace conventional materials such as carbon fiber and fiberglass in interior components, which lowers vehicle weight and increases fuel efficiency. These composites are utilized to create long-lasting, environmentally beneficial building materials.

End-use Insights

The automotive segment dominated the natural fiber composites market in 2024. Natural fiber composites are appropriate for various automotive applications because they provide an excellent blend of strength, stiffness, and impact resistance. They can be utilized in structural elements like load flooring, spare wheel covers, body panels, and interior elements like door panels, dashboard trims, and seat backs. Furthermore, natural fibers' adaptability and usefulness in vehicle design are increased by simply molding into intricate shapes utilizing traditional manufacturing processes like compression or injection molding.

Natural Fiber Composites Market Companies

- FlexForm Technologies

- Green Dot Bioplastics

- UPM- Kymmene Corporation

- Trex Company

- Fiberon LLC

- Fiberon Composites

- Tecnaro GmbH

- Procotex Corporation SA

Recent Developments

- In February 2024, Governor Kathy Hochul of New York State disclosed that a $5 million allocation for hemp and bio-based product processing is included in the state's executive budget 2025. In a recent announcement, the governor's office emphasized the possible advantages of this investment. It might result in a notable rise in natural fiber production, aligning with the objectives and sustainability pledges of the garment and fashion industries.

Segments Covered in the Report

By Type

- Wood Fiber Composites

- Hemp Fiber Composites

- Flax Fiber Composites

- Jute Fiber Composites

- Other Natural Fibers

By Matrix

- Inorganic Compound

- Natural Polymer

- Synthetic Polymer

By End-use

- Automotive

- Building and Construction

- Consumer Goods

- Packaging

- Aerospace

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content