North America Aluminum Extrusion Market Size and Forecast 2025 to 2034

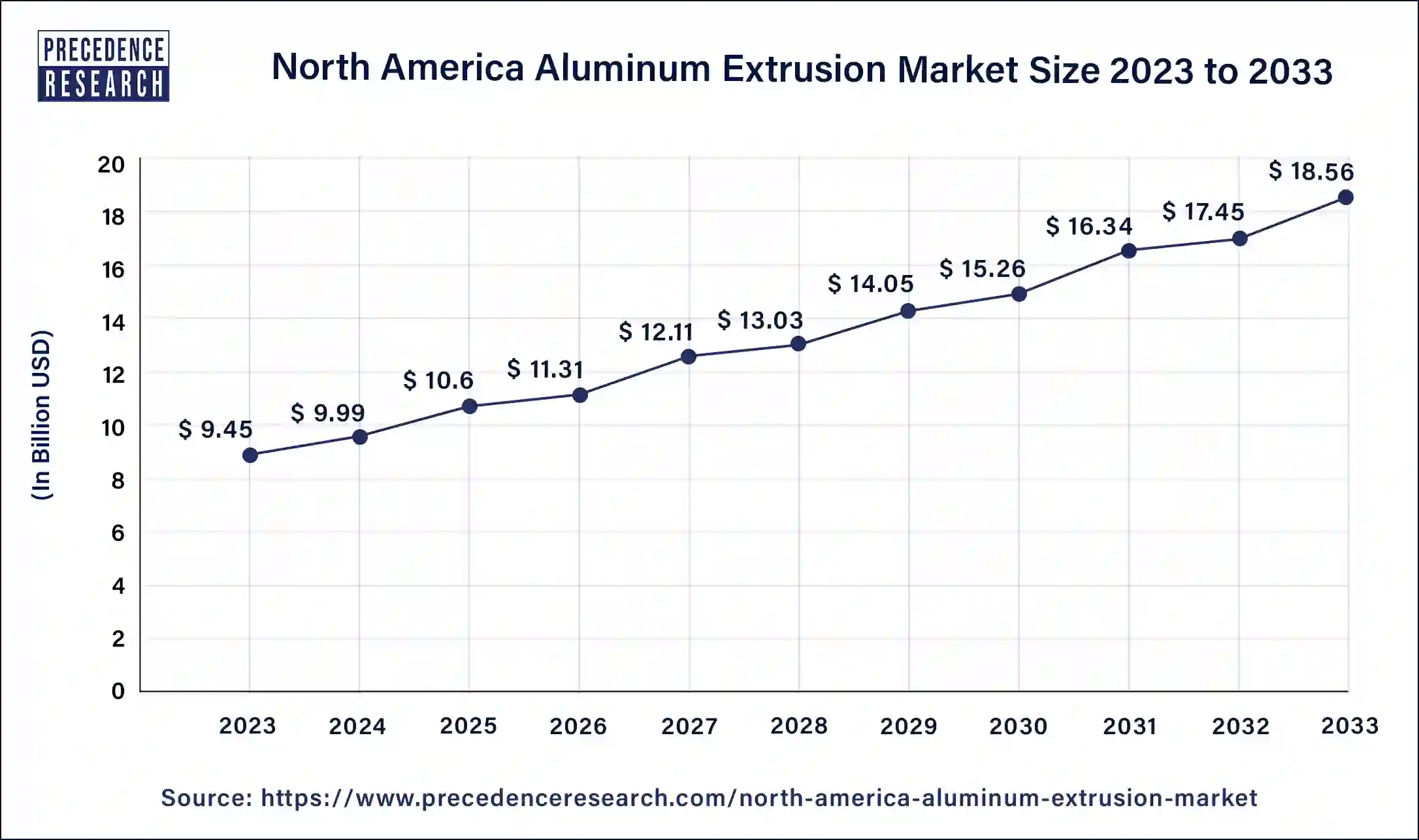

The North America aluminum extrusion market size is calculated at USD 9.99 billion in 2024 and is expected to reach around USD 19.67 billion by 2034, expanding at a CAGR of 7.01% from 2025 to 2034. The rising environmental concern in industrial applications are driving the growth of the market.

North America Aluminum Extrusion Market Key Takeaways

- By product, the shapes segment has held a major revenue share of 76.6% in 2024.

- By product, the rods and bars segment is anticipated to be the fastest growing segment in the market during the forecast period.

- By application, the building and construction segment has contributed more than 63% of revenue share in 2024.

- By application, the automotive and transportation segment is expected to grow at the fastest rate during the forecast period.

What is the Role of AI in North America Aluminum Extrusion Market?

Artificial intelligence (AI) offers unprecedented opportunities to improve efficiency, reduce costs, and meet sustainability goals. The use of AI technology practically removes the room for human error and substantially amplifies the production rates of companies with a lot to offer in a plate. The benefits of AI in aluminum industry include data analytics and AI, precise engineering, maintenance and quality control, supply chain optimization, streamlined activities, and industry 4.0.

AI-based quality control during the aluminum extrusion process, guaranteeing early scrap identification. AI aluminum extrusion analysis is a powerful technology that allows business to improve their aluminum extrusion process, reduce costs, innovation, new product development, yield improvement, predictive maintenance, process optimization, and improve product quality.

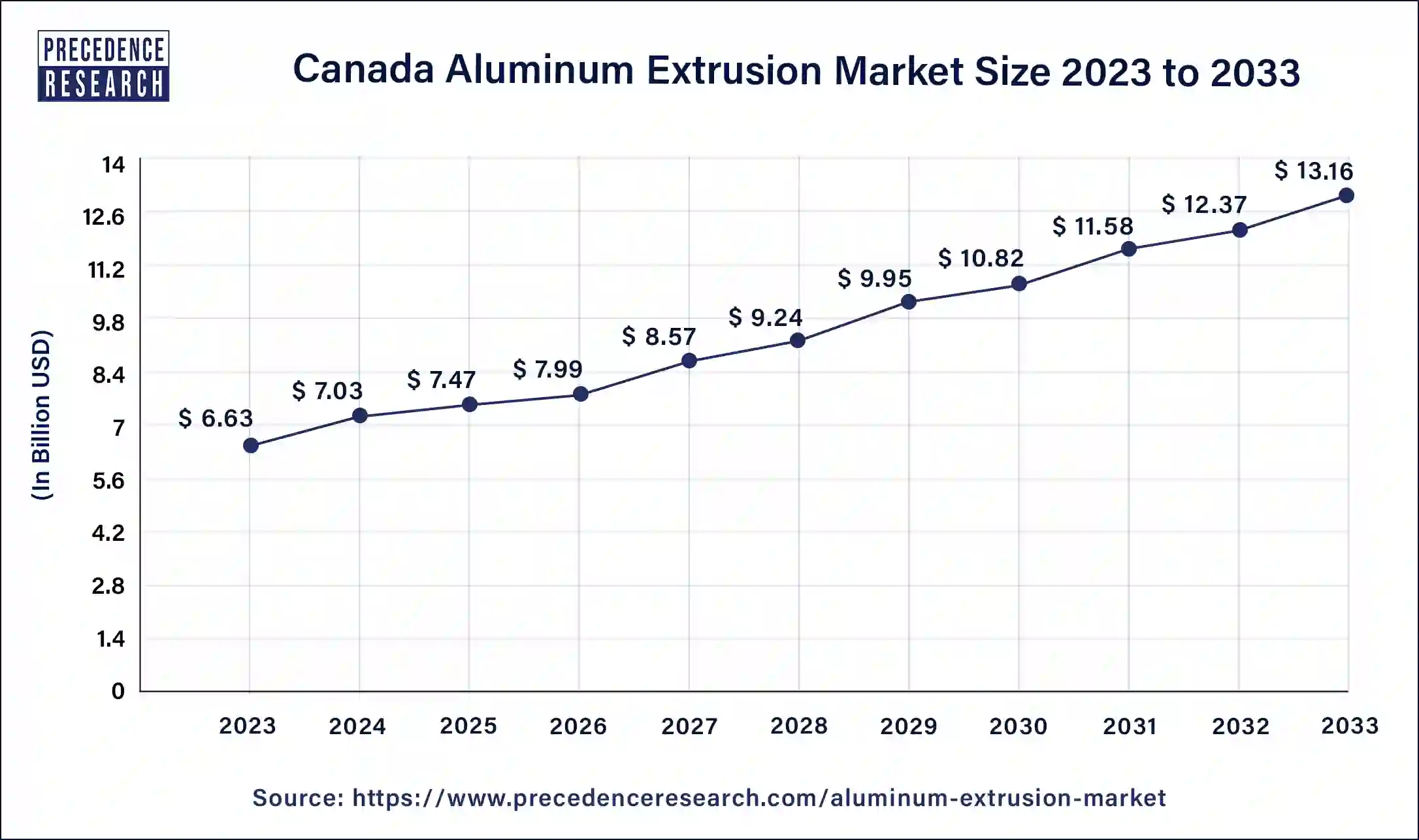

Canada Aluminum Extrusion Market Size and Growth 2025 to 2034

The Canada aluminum extrusion market size reached USD 6.63 billion in 2023 and is projected to attain around USD 13.16 billion by 2033, poised to grow at a CAGR of 7.22% from 2024 to 2033.

Canada dominated the North American aluminum extrusion market with the largest revenue share of 70.2% in 2023. The increasing infrastructural development and the rising industrialization, such as automotive, manufacturing, energy, consumer goods, and other industries, are driving the demand for aluminum extrusion activities. The rising investment in the manufacturing units and industrial development is boosting the growth of the market. Increasing economic development and the government support in the infrastructural development is contributing to the growth of the market.

Market Overview

The North America aluminum extrusion market revolves around the offering of processes of pressing aluminum raw material by the die with the specific cross-sectional profile that helps in transforming aluminum into the objects that can be used in the wide range of applications. Aluminum extrusion is majorly divided into the two categories direct and indirect, in the direct extrusion, the die or mold remains constant, and the ram applied forces into the metal to move through it. And in the indirect extrusion the metal remains constant while the die moves against it and creates pressure to push the metal through it. The rising demand for aluminum due to its beneficial properties and the lightweight material that are driving the growth of the North America aluminum extrusion market.

North America Aluminum Extrusion Market Growth Factors

- The rising demand for aluminum extrusion in the several end-use industries such as construction, automotive and transportation, aerospace, and defense is driving the demand for the aluminum extraction market.

- North America has been seeing significant economic growth in the last several years, which positively impacted the industrialization in the regional countries that contributed to the expansion of the aluminum extrusion market.

- The rising population and the increasing demand for commercial, residential, and industrial buildings are driving the growth of the construction industry. The rising demand for aluminum in the construction industry is increasingly fostering the growth of the market.

- The rising concern about the environmental pollution is one of the major factors for the adoption of aluminum in the various end use industries and driving the growth of the North American aluminum extrusion market.

- The beneficial properties of aluminum, such as durability, strength, ductility, non-magnetic properties, conductivity, and repeated recyclability without losing its strength, is driving the growth of the market.

- Growing demand for consumer electronics

- Growth in aerospace and defense sector

- Government initiatives for sustainable infrastructure

- Increasing demand for lightweight materials in automotive industry

North America Aluminum Extrusion Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 10.60 Billion |

| Market Size in 2024 | USD 9.99 Billion |

| Market Size by 2034 | USD 19.67 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.01% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product and Application |

Market Dynamics

Driver

Rising industrialization in the region

The rising population and economic development is driving the growth of industrialization across the region. Furthermore, the rising demand for aluminum in the several industries like in construction, automotive, packaging, transportation, aerospace and defense, consumer goods, healthcare, energy, manufacturing industries, and infrastructural development are fueling the growth of the market. Aluminum is used in the wide range of industrial applications such as aluminum extrusion is used in the manufacturing of vehicles, in the making of conventional gas-or-diesel powered vehicles, steel is replaced by the aluminum to make it lightweight and helps in lowering carbon emission from the vehicle.

The automobile and transportation industry is wholly responsible for 25% of the total carbon emission in the United States. Aluminum extrusion in the consumer goods industry is responsible for producing high strength, lightweight, high thermal conductivity, ease in fabrication, and non-corrosive consumer products. Thus, the higher adaptability of aluminum extrusion in the various end-use industries are driving the growth of the aluminum extrusion market.

Restraint

High cost

The increasing initial cost of the aluminum extrusion in the manufacturing industries is restricting the growth of the North America aluminum extrusion market. The cost factor usually limits the entry of new market players in the industry by acting as a hindering factor for the entire market. However, support initiatives by governments are observed to support the market in terms of overcoming the restraint.

Opportunity

Rising implementation in healthcare industry

The increasing healthcare sector due to the rising prevalence of diseases in the population and the increasing demand for technologically advanced diagnostic machines and equipment are highly contributing to the growth of the market. The rising adoption of the aluminum extrusion for the production of surgical equipment to the diagnostics machines due to its beneficial properties like corrosion resistance, light weight, design flexibility, fabrication, ease of machining, cost effectiveness, and durability that makes the materials an ideal for the production of machines. Aluminum extrusion is time saving, lower in cost, and delivers the near-net shape process than the other manufacturing methods.

Aluminum extrusion is used in healthcare applications like patient care, the manufacturing of beds, equipment stands, patient positioning systems, cubicle curtain tracks, corridor crash/handrails, service panels and electrical/utility raceways, and surgical lights. Thus, the rising demand for the healthcare industry in North America is driving the growth opportunity in the market.

Product Insights

The shapes segment held a dominant presence in the market in 2024.

- In November 2023, six new aluminum alloy materials were launched by Shandong Weiqiao Group.

The rods and bars segment is expected to grow at the fastest rate in the market during the forecast period of 2025 to 2034.

- In September 2023, new panic and emergency exit hardware for aluminum doors was launched by ASSA ABLOY. These are designed for aluminum doors with Concealed Vertical Rods (CVR), their newly launched range of push bar, push pad, and touch bar panic and emergency exit devices and external hardware forms an integral part of building safety.

ASSA ABLOY launches new panic and emergency exit hardware for aluminium doors | ASSA ABLOY

Application Insights

The building and construction segment accounted for a considerable share of the market in 2024.

- In February 2025, the launch of the new AX450 Aluminum Moving Glass Wall was announced by MILGARD Windows and Doors, part of the MITER Brands portfolio and manufacturer of vinyl, fiberglass, and aluminum windows and patios doors for builders, dealers, and homeowners.

MILGARD Windows and Doors launches AX450 Aluminum Moving Glass Wall

The automotive and transportation segment is projected to experience the highest growth rate in the market between 2025 and 2034.

- In October 2020, new interactive tool for automotive design engineers was launched by Aluminum Extruders Council (AEC), a trade association dedicated to advancing the effective use of aluminum extrusion in North America.

https://www.greencarcongress.com/2020/10/20201020-aec.html

The automotive and transportation segment is expected to grow at the fastest rate in the North America aluminum extrusion market during the forecast period. The rising demand for the aluminum extrusion in the automotive industry due to its capabilities to enhance the fuel efficiency in diesel to the battery vehicle, it reduces the cost of production, and make the vehicle lightweight that results in the decrease amount of fuel consumption by the vehicle.

It has higher crash energy than steel, and also provides protection for occupants, and batteries. The higher availability of the leading automobile companies in the United States and the increasing demand for the automobile in the population owing to the rising disposable income in the population is further driving the demand for the aluminum extrusion market in the automotive and transportation segment. Thus, the rising automotive industry in North America is driving the growth of the North America aluminum extrusion market.

North America Aluminum Extrusion Market Companies

- Aluminum Products Company

- Arconic Corporation Bahrain

- Aluminum Extrusion Co. (Balexco)

- Century Extrusions limited

- China Zhongwang Hindalco

Recent Developments

- In August 2025, in the U.S. and Canada, raises the bar for aluminum extrusion quality, reliability, and worth was launched by Metra North America. Extruded aluminum company, Profile Custom Extrusions and Metra Canada unite as Metra North America to redefine aluminum extrusion quality reliability and worth.

Metra North America launches in the US and Canada, raises the bar for aluminium extrusion quality, reliability and worth - In May 2025, with the industry leading a TULC Technology, forging a New Era of Aluminum Beverage Can Manufacturing was launched by ValCan Packaging.

VulCan Packaging Launches with Industry-Leading aTULC™ Technology, Next-Generation Aluminum Beverage Can Manufacturing

Segments Covered in the Report

By Product

- Shapes

- Rods and Bars

- Pipes and Tubes

By Application

- Automotive & Transportation

- Building & Construction

- Consumer Goods

- Electrical & Energy

- Others

By Country

- U.S.

- Canada

- Mexico

Get a Sample

Get a Sample

Table Of Content

Table Of Content