Polymer Emulsion Market Size and Forecast 2025 to 2034

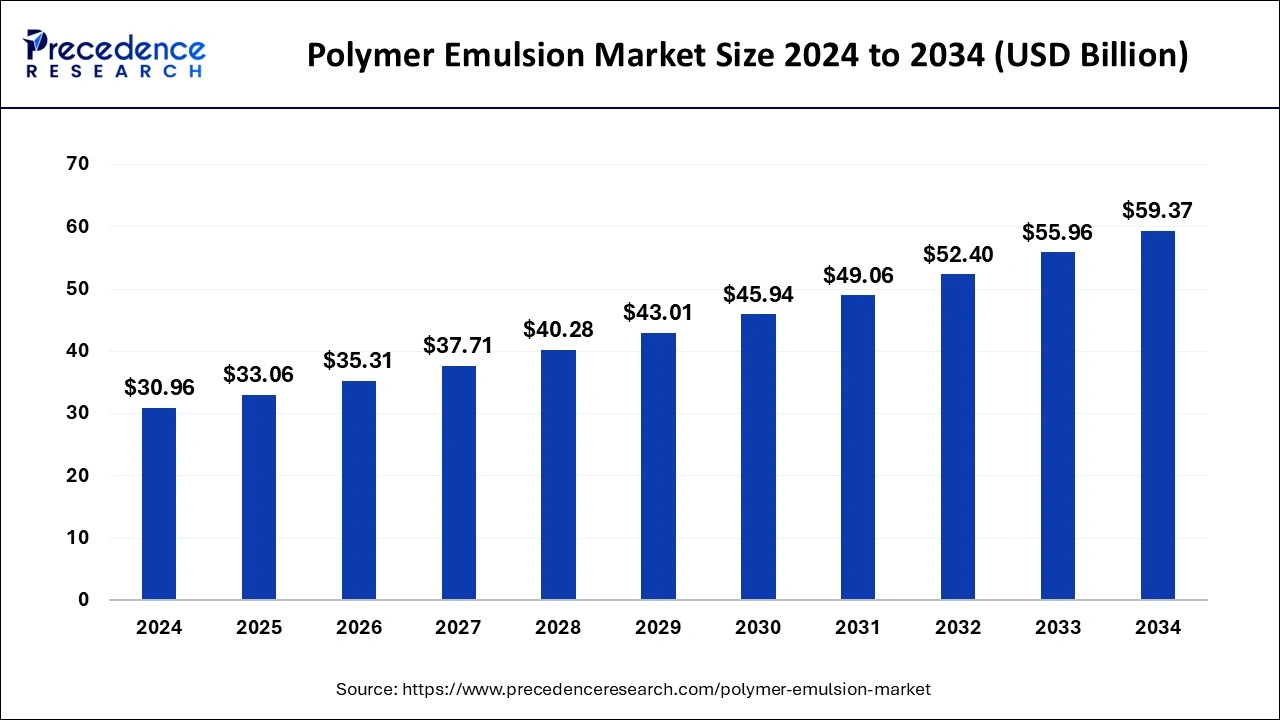

The global polymer emulsion market size accounted for USD 30.96 billion in 2024 and is expected to exceed USD 59.37 billion by 2034, growing at a CAGR of 6.73% from 2025 to 2034.

Polymer Emulsion Market Key Takeaways

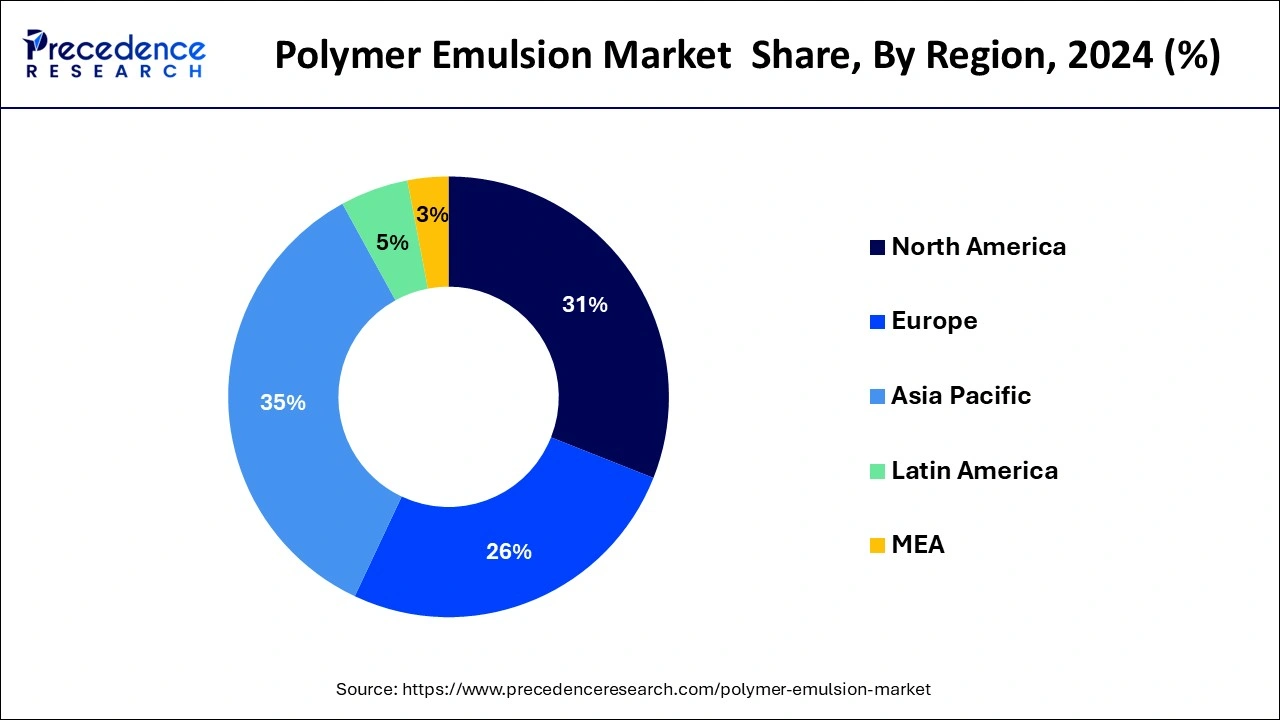

- Asia Pacific dominated the global market and generated more than 35 % of the revenue share in 2024.

- By Type, the acrylic segment captured the maximum market share in 2024.

- By Application, the paint & coatings segment generated the highest market share in 2024.

- By End Use, the building and construction segment recorded more than 38% of revenue share in 2024.

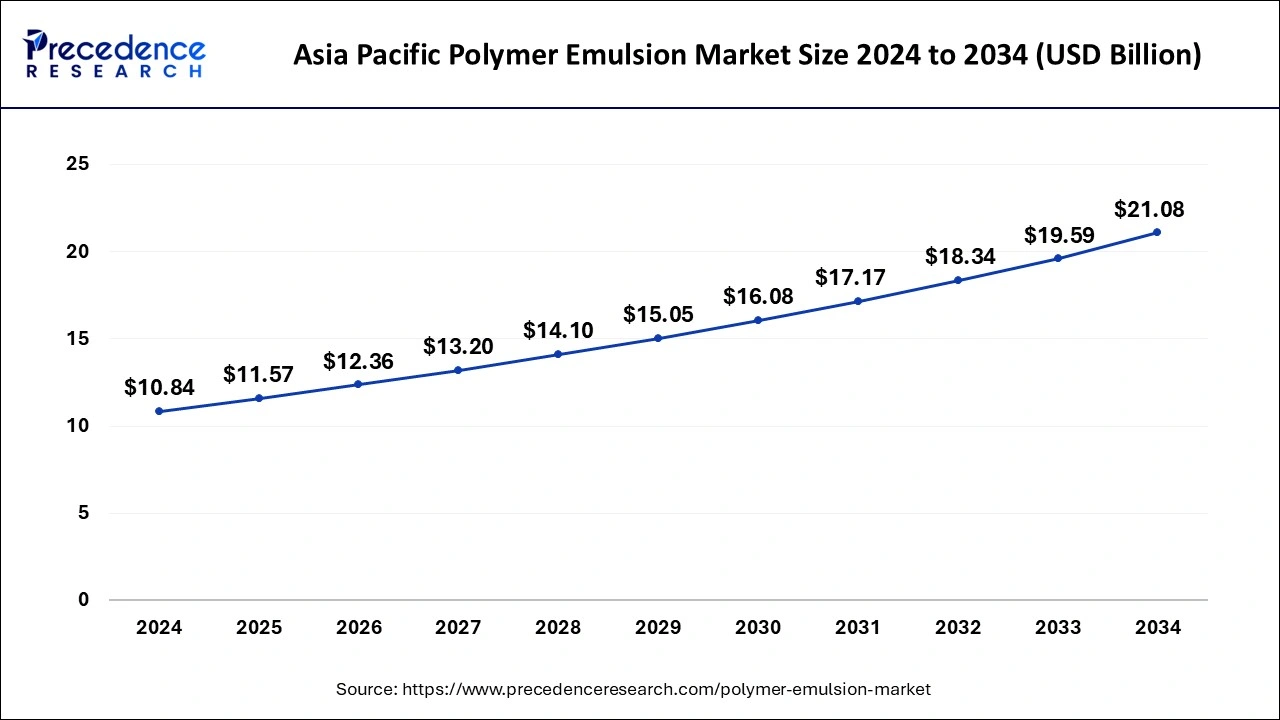

Asia Pacific Polymer Emulsion Market Size and Growth 2025 to 2034

The Asia Pacific polymer emulsion market size was evaluated at USD 10.84 billion in 2024 and is projected to be worth around USD 21.08 billion by 2034, growing at a CAGR of 6.88% from 2025 to 2034.

In 2024, Asia Pacific dominated the global polymer emulsion market with a maximum market share of 35% and is expected to grow at a faster rate during the forecast period. Moreover, the availability of low-cost raw materials, land, equipment and skilled labour are some factors driving the growth of the Asia Pacific emulsion industry. The rapidly expanding Chinese and Indian markets are the primary drivers of this significant growth.

Many construction projects and investments are planned in India, China, the Philippines, Vietnam, and Indonesia, which is expected to increase demand for architectural paints, coatings, and adhesives. India, Thailand, Vietnam, Pakistan, and Malaysia have seen significant increases in automotive production. China, the world's largest automaker, intends to increase EV production to 2 million units per year by 2020 and 7 million units per year by 2025.

Furthermore, with cultural change, the influence of Western culture, increased cosmetic demand from the youth population, and rising women's employment, demand in the cosmetic & personal care industry is growing at a noticeable rate in the region. As a result, market players in this market are increasing investments and production, driving up demand for raw materials such as polymer emulsion. As a result, all of these favourable market trends are expected to drive the growth of the Asia-Pacific polymer emulsion market during the forecast period.

- In September 2023, Kamdhenu Paints, a brand of Kamdhenu Group and leading manufacturer of high-quality paints & emulsions, re-strengthened its Dual Emulsions Paint product portfolio with the launch of ‘Kamodual Platinum Emulsion. This brand-new dual emulsion promises Extra Sheen and also offers a 6-year warranty with certain terms and conditions.

North America is expected to grow at the fastest rate over the forecast period. The growth of the region can be credited to its strong economy, increased state and federal funding for infrastructure projects, along with favourable government policies. Moreover, the construction industry in the United States is rapidly growing due to high population growth in the country, which positively impacts the housing market.

Market Overview

Polymeremulsion is a type of polymerisation reaction that begins with an emulsion that contains water, monomer, and surfactant. An oil-in-water emulsion is the most common type of emulsion polymerisation, in which droplets of monomer (the oil) are emulsified (with surfactants) in a continuous phase of water. Emulsion polymers have a high molecular weight, polymerise quickly, and are non-toxic to the environment.

In the paper industry, emulsion polymers make sheets, paper bags, boxes, cartons, and other items. As a binding agent, it is used in adhesives such as bands, stickers, glue, windings, and hygiene products. These end-user segments contribute significantly to the growth of the polymer emulsion industry.

MarketScope

| Report Coverage | Details |

| Market Size in 2025 | USD 33.06 Billion |

| Market Size in 2024 | USD 30.96 Billion |

| Market Size by 2034 | USD 59.37 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 6.73% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, and End Use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Rising utilisation of polymer emulsion in the automotive industry

As polymer emulsions are used in LASD coatings and can be tailored for flexibility, adhesion, and filler content, the automotive industry is expected to increase demand for them. Another excellent feature for manufacturers is that they easily attach to metal components. Other advantages of using polymer emulsions include lower application costs and improved consistency and repeatability of placement. These coatings are made with styrene-butadiene polymer emulsions.

This is due to its ability to withstand high filler loadings, compatibility with anti-corrosion pigments, and range of strength and flexibility to meet the demands of harsh operating environments. With all of the facts stated above, it is expected that growth in the automotive industry will drive demand for polymer emulsion.

- In March 2024, Asian Paints Polymers, a wholly owned subsidiary of Asian Paints, announced plans to establish a state-of-the-art facility in Dahej, Gujarat, for the production of vinyl acetate-ethylene emulsion (VAE) and vinyl acetate monomer (VAM). The project's estimated cost stands at Rs 2,100 crore.

Restraint

Fluctuations in raw material Cost

Some raw materials used by industry operators are derived from petrochemical-based feedstocks, such as crude oil and natural gas, which are subject to significant price fluctuations. These price fluctuations could be exacerbated by global macroeconomic factors and supply and demand factors, such as OPEC production quotas and increased global demand for petroleum-based products. Significant changes in the cost and availability of raw materials may have a negative impact on industry operations.

Opportunity

The rise in global residential and commercial development has boosted the demand for polymer emulsions used in architectural paints and coatings. With the growth potential and growing housing needs in Asia, large-scale residential and commercial development projects have been underway. Government initiatives in the Middle East to promote non-oil industries are encouraging investment in sectors such as tourism, hospitality, and healthcare, which has increased demand for and spending on commercial infrastructure.

COVID-19 Impact:

As a result of the COVID-19 outbreak, almost every country has tightened travel restrictions. Since March 2020, the increasing number of infected patients and total lockdown in major industrial hubs have halted the manufacturing industry. Workers have either returned to their hometowns or been quarantined to prevent the spread of the coronavirus. Due to potential upstream supply chain issues, construction, automotive, chemical, textile, and coatings companies have been forced to close locations.

The demand for residential building construction is expected to be low as people are discouraged from looking for new homes due to negative consumer sentiment and declining incomes. Due to the uncertainty of the future, demand for automobiles has dropped dramatically. The global impact on textile orders for clothing and accessories has decreased by 30%.

Chemical manufacturers have either ceased production or are operating at a low utilization rate. However, with the lifting of the lockdown, government bodies around the world are gradually encouraging construction, automotive, chemical, and textile & coatings companies to resume work, and companies are working towards market recovery with the expected increase in sales gradually in coming years.

Type Insights

Based on type, the global polymer emulsion market is segmented into acrylics, vinyl acetate polymers, and SB latex. In 2023, the acrylic segment accounted for the largest market share. The growth of this segment is due to its properties such as low VOC emission and excellent durability, acrylic polymer emulsion is widely used in various applications.

In addition to its versatility, it is also preferred in multiple end-use applications. Acrylics can make rigid, flexible, ionic, non-ionic, hydrophobic, or hydrophilic polymers. They are transparent, resistant to breakage, have a high finish gloss, improved adhesion to non-porous surfaces, and have good flow and stability. They are also commonly known as polyacrylates.

Acrylic emulsion polymers can be easily incorporated into overprint varnishes and inks to provide water resistance, rub resistance, alkali resistance, and high gloss. They can also be used to improve oil, grease, and water resistance in barrier coatings for paper and paperboard products.

Application Insights

Based on application, the global polymer emulsion market is segmented into paints & coatings, adhesives & sealants, and paper & paperboard. In 2023, the paint & coatings segment accounted for the largest market share. The growth of this segment is due to the high demand in industries such as construction and automotive. Polymer emulsion is widely used in paints and coatings due to its lower carbon footprint during manufacturing.

The high VOC content of solvent-based products, combined with the implementation of government air pollution control regulations, has fueled the development of low-VOC paints and coatings. This increased demand for water-based paints and coatings drives growth in the paints and coatings segment.

End Use Insights

Based on end use, the global polymer emulsion market is segmented into buildings & construction, automotive, textile & coatings. In 2023, building and construction accounted for the largest market share of around 38%. The high demand for polymer emulsion in architectural paints, deck & trim paints, and elastomeric wall coatings, among others, is driving the segment growth. Its high-water resistance and durability drive its demand in the end-use industries.

Polymer Emulsion Market Companies

- Arkema S.A

- BASF SE

- Celanese Corporation

- DIC Corporation

- Dow Chemical Company

- OMNOVA Solutions Inc.

- Synthomer Plc

- The Lubrizol Corporation

- Trinseo S.A

- Wacker Chemie AG

Recent Developments

- In June 2023, Avient Corporation and BASF partnered to introduce Color grades of Ultrason high-performance polymers. Color grades of Ultrason high-performance polymers were introduced to the global market through a collaboration between Avient Corporation and BASF. The collaboration will offer customers in the consumer and food service, electrical and electronics (E&E), and healthcare industries.

- In November 2023, Engineered Polymer Solutions launched EPS 2585, a high-solids waterborne acrylic emulsion that has the capability to formulate direct-to-metal applications at <100g/L VOC. EPS 2585 is recommended for high-performance general industrial and railcar coatings with excellent hardness, block resistance, and early water resistance.

- In October 2023, Asahi Kasei announced plans to invest in new coating equipment for its HiporeTM lithium-ion battery separators. The coating lines will be installed at the company's current facilities in the U.S., Japan, and South Korea, and operations will commence in the first part of fiscal 2026.

Segments Covered in the Report

By Type

- Acrylics

- Vinyl Acetate Polymers

- SB Latex

By Application

- Paints & Coatings

- Adhesives & Sealants

- Paper & Paperboard

By End Use

- Buildings & Construction

- Automotive

- Textile & Coatings

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- The Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting