What is the 3D Concrete Printing Market Size?

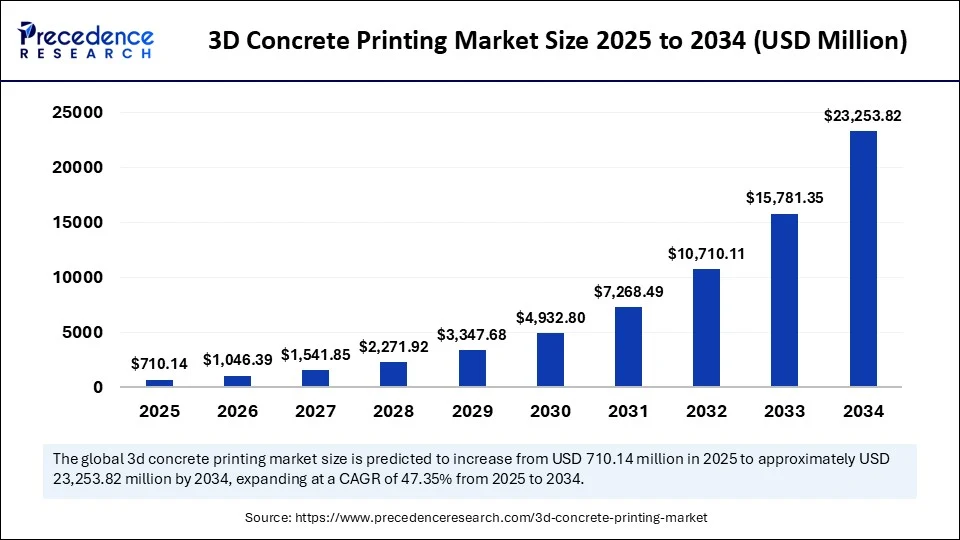

The global 3D concrete printing market size is accounted at USD 710.14 million in 2025 and predicted to increase from USD 1,046.39 million in 2026 to approximately USD 23,253.82 million by 2034, expanding at a CAGR of 47.35% from 2025 to 2034. The market is driven by global demand for sustainable and cheaper alternatives to construction and urbanization, technology improvements, less material product waste, and design efficiencies.

3D Concrete Printing Market Key Takeaways

- In terms of revenue, the global 3D concrete printing market was valued at USD 481.94 million in 2024.

- It is projected to reach USD 23,253.82 million by 2034.

- The market is expected to grow at a CAGR of 47.35% from 2025 to 2034.

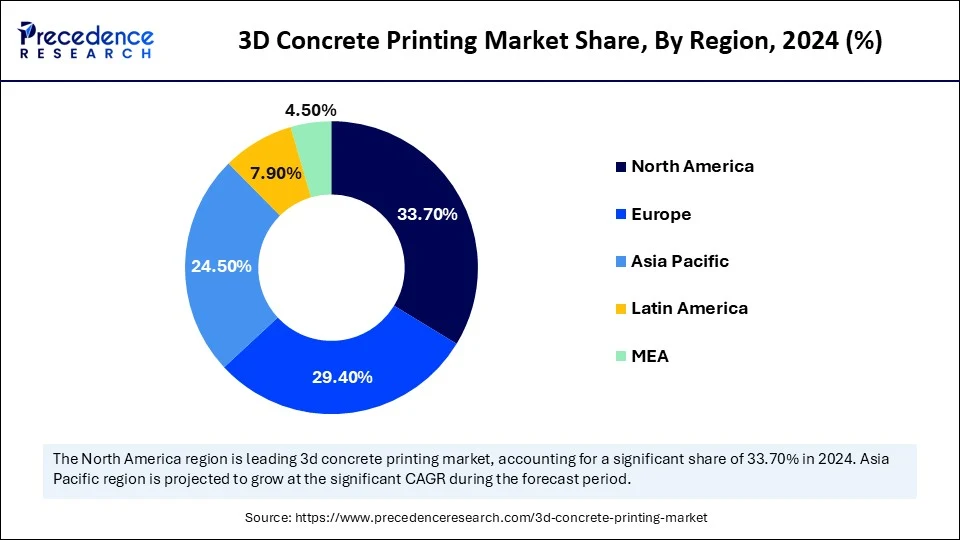

- North America dominated the 3D concrete printing market with the largest market share of 33.7% in 2024.

- Asia Pacific is estimated to expand the fastest CAGR between 2025 and 2034.

- By printing system/equipment, the gantry-based systems segment led the market in 2024.

- By printing system/equipment, the robotic arm-based systems segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By printing method/process, the extrusion-based printing segment captured the largest market share in 2024.

- By printing method/process, the powder/binder-jetting methods segment is expected to expand at a notable CAGR over the projected period.

- By material type, the cement-based concrete mixes segment held the biggest market share in 2024.

- By material type, the geopolymer/low-carbon mixes segment is expected to expand at a notable CAGR over the projected period.

- By application, the residential housing segment captured the highest market share in 2024.

- By application, the public infrastructure (bridges, retaining walls, utilities) segment is expected to expand at a notable CAGR over the projected period.

- By end user, the general contractors/construction firms segment generated the major market share in 2024.

- By end user, the prefabrication/modular manufacturers segment is expected to expand at a notable CAGR over the projected period.

Building the Future with AI-Powered Construction

Artificial intelligence is rapidly becoming core to the development of 3D concrete printing. Primarily through a more predictive, precise, and resource-efficient process, the full integration of machine learning and AI into 3D concrete printing holds great potential. By implementing machine learning models, we could predict how a material will behave in terms of strength, rheology, and curing, greatly reducing the trial-and-error associated with mix design. Computer vision systems integrated with AI provide an opportunity to detect microcracking and verify geometric accuracy in 3D printing, which increases the overall structural integrity of concrete.

Generative design algorithms and digital twins are opening avenues towards architectural applications that minimize material use. In October 2024, COBOD International, the global leader in 3D construction printing technology, launched the advanced BOD3 3D Construction Printer, enabling the 3D printing of real concrete. This launch demonstrates how automation and AI are transforming the construction industry, from experimental buildings to scalable, smart infrastructure. Also, Missouri S&T secured US$1.4 million from the U.S. Army Corps of Engineers to develop an artificial intelligence (AI)-augmented program of research to improve 3D concrete printing that will work to increase material efficiency and structural resiliency.

3D Concrete Printing Market Overview: Exploring the Concrete Innovations

3D concrete printing, also known as 3D construction printing, is the computer-controlled, automated, additive manufacturing of concrete structures that minimizes the amount of formwork and manual work. The technology supports complex designs, reduces construction time, lowers costs, and optimizes material usage while also aligning with sustainability goals by reducing material waste. The overall market is rapidly growing, bolstered by demand for affordable housing, innovative infrastructure, and sustainable construction.

Sustained investment by developers and construction companies, research bodies, and government agencies also helps to push the technology forward. Furthermore, its implementation in the residential, commercial, and industrial markets demonstrates its revolutionary change to conventional construction and potential solutions to global housing issues.

3D Concrete Printing Market Growth Factors

- Increased Need for Affordable Housing:Concrete printing facilitates cheap, fast construction to help fight the global housing crisis. Its ability to decrease labor, material, and time makes it a strong opportunity for affordable housing initiatives worldwide.

- Sustainability and Waste Reduction: 3D concrete printing is also helpful in reducing materials and the carbon footprint associated with construction waste. In an environment of increasingly growing sustainability regulations and environmental building practices, 3D concrete printing is in an environment of adoption for an industry building towards a greener future.

- Design Flexibility and Innovation:3D concrete printing also provides flexibility and innovation in design, enabling complex designs, customized structures, and complex geometries. This heightens the interest of architects and developers looking to create modern-day construction solutions with the potential for innovation and integration from once often stagnant construction processes.

- Investments from Government and Industry: The level of funding or initiatives and pilot projects, as well as construction infrastructure, has been attracted from both government and industry, creating momentum for adopting as it has continued to develop.

3D Concrete Printing Market Outlook: Predicting the Future Trends

- Industry Growth Overview: Increasing demand for sustainable, affordable, and repaid construction solutions for addressing the global housing shortage and infrastructure development is contributing to the market growth.

- Sustainability Trends: Sustainability trends involve the use of eco-friendly printable materials, optimizing their efficiency, and better thermal performance to reduce their environmental impact and material waste.

- Global Expansion: The focus on cost and time savings, growing environmental sustainability initiatives, material science advances, and technological advancements is responsible for global market expansion.

- Major Investors: Large material and construction corporations and venture capital firms are the major investors in the market. Holcim, Sika AG, and Moderne Ventures are some of the major investors in the market.

- Startup Ecosystem: The development of integrated and automated solutions is the focus of the startup ecosystems. Apis Cor and Mighty Building are actively participating in these advancements.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 23,253.82 Million |

| Market Size in 2025 | USD 710.14 Million |

| Market Size in 2026 | USD 1,046.39 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 47.35% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Printing System/Equipment, Printing Method/Process, Material Type, Application, End-User, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Is Urbanization and the Need for Affordable, Fast Construction Driving the 3D Concrete Printing Market?

The increased demand for lower-cost housing and rapid timelines is driving the global uptake of 3D concrete printing. Asia-Pacific alone has 54% of the planet's urban population, which is projected to increase from 2.3 billion to 3.5 billion by the year 2050. The need to innovate scalable and cost-effective civic and commercial building techniques has never been more urgent.(Source: https://www.undp.org)

Recent initiatives such as the European Union's Renovation Wave target to double the rate of renovation by 2030, and a major underlying premise of the Renovation Wave is a strong emphasis on using energy-efficient and recyclable materials. 3D concrete printing supports this initiative. It eliminates waste with excess materials, reduces timelines and delivery of projects, and has spin-off projects that support sustainable urban growth. 3D concrete printing is positioned to provide a solution for rising urbanization and infrastructure demands.

Restraint

Does Material Standardization Represent the Greatest Barrier to 3D Concrete Printing?

The most significant barrier to the 3D concrete printing market is the absence of standardized and high-performance materials. The materials used to 3D print concrete must balance flowability, rapid setting, and strength; however, there is still no reliable standardized formulation. Therefore, there are insufficient ideas of structural uncertainty, in addition to limitations in scaling. A study conducted in June 2025 illustrated that the amount of shrinkage strain associated with 3D printed concrete was considerably higher than that observed using traditional concrete.(Source: https://www.sciencedirect.com)

Whether this will increase the risk of cracking when under restraint is still unclear, industry observers exclaim that the fact that there are no material standards across the world or consistent tests of the materials' character, inhibits construction companies from full buy-in of this technology. A lack of standardization will be a critical blocker of 3D printed counties from experiments to the normal planned developments.

Opportunity

Can Sustainability Goals Fuel the Next Big Rush in 3D Concrete Printing?

The increased focus on sustainable construction on a global scale is providing new possibilities for 3D concrete printing. Governments and developers face increased scrutiny on their carbon emissions and construction waste, and 3D concrete technology has the potential to help achieve these goals; material production can be reduced by 60% and innovative 3d concrete printing methods can allow alternatives to cement, and utilize recycled aggregates.

In May 2024, Holcim completed an architecture-focused, 3D printed concrete "Green Wall" project in Switzerland based on circular construction that included significantly lower carbon footprints. As these targets tighten and green building performance goals increase, so too does the inclination from decision-makers to implement 3D concrete printing as a valid opportunity to bring efficiency and innovative sustainability to the next generation of infrastructure and housing development. (Source: https://cobod.com)

Printing System/Equipment Insight

Why Gantry-Based Systems Have the Largest Share in the 3D Concrete Printing Market?

In the 3D concrete printing market, the gantry-based systems segment led in 2024. These systems enable contractors to deliver large-scale construction projects, such as residential housing and commercial buildings, quickly. Gantry systems also possess considerable stability, accuracy, and can print very large objects in a continuous manner; thus, they are very reliable and cost-effective. As a result, gantry-based systems remain the first option for contractors with high-volume applications.

The robotic arm-based systems segment is expected to be the fastest-growing segment over the next few years. Robotic arm systems can handle complex designs, accommodate tighter or irregularly shaped spaces, and lend themselves easily to prefabrication and modular construction. As interest in smart construction technology and automation grows, robotic arm-based systems are becoming increasingly viewed as the next frontier of innovation in 3D concrete printing.

Printing Method/Process Insights

Which Printing Method/Process Dominates the 3D Concrete Printing Market in 2024?

The extrusion-based printing segment dominated the 3D concrete printing market in 2024, primarily due to its widespread use and ability to produce durable and continuous structures with minimal waste and faster construction cycles compared to other methods. Concrete extrusion is used in residential housing and commercial developments where speed, structural integrity, and cost are critical, making it the most proven method for large-scale applications.

The powder/binder-jetting methods segment is expected to grow rapidly over the coming years, given their expanded opportunity to create detailed and finishes designs that allow for customizable construction. Eventually, the developments of binder-jetting technologies will offer even greater opportunities for sustainable construction and complex customization in a variety of construction-related projects (e.g., heavy public infrastructure).

Material Type Insights

Which Material Type Dominated the 3D Concrete Printing Market in 2024?

In the 3D concrete printing industry, the cement-based concrete mixes segment was dominant in 2024. Though cement-based mixes were the most popular material type, due to their strong structural characteristics, high availability, and compatibility with construction practices, cement-based mixes were popular, particularly for larger-scale projects, in residential and commercial buildings, resulting in the largest share of market share due to large-scale adoption, where reliable performance is critical for appropriate structure completion.

The geopolymer/low-carbon mixes segment is expected to be fastest fastest-growing materials segment. The push in the industry towards sustainability and carbon emissions reductions, coupled with geopolymer and low-carbon mixes, which have greater resistance and durability against extreme environments, and are related to green building initiatives around the world, are becoming increasingly important to future development projects.

Application Insights

Which Application Dominates the 3D Concrete Printing Market?

The residential housing segment was the largest application within the 3D concrete printing market in 2024. The domain encompasses affordable housing initiatives, small dwellings, and fully customizable homes, and is gaining a foothold in real estate due to the speed of development, fewer labor requirements, and less cost for complex design work. Governments and private builders are able to leverage this segment to help with the housing shortage in a timely manner.

The public infrastructure segment is expected to be the fastest-growing application segment. Bridges, retaining walls, and utility structures have been highlighted because 3D concrete printing enables fast-track passes for deployment, savings in money, and material efficiency. As urbanization and sustainability are fuelled for acceleration, public authorities will continue to explore methods to keep infrastructure up-to-date and reduce the time and carbon footprint associated with construction.

End User Insights

Which End-User Dominated the 3D Concrete Printing Market in 2024?

The general contractors/construction firms segment dominated the 3D concrete printing market in 2024 because of their extensive involvement in performing large-scale construction projects such as housing, commercial buildings, and infrastructure projects. General contractors benefit relatively greatly from 3D printing capabilities in completing projects swiftly, minimizing material costs, and executing more complex architectural designs with an improved method for efficient evolution and execution compared to traditional construction methods.

The prefabrication/modular manufacturers segment is expected to be the fastest-growing end-user segment. The prefabricated and modular market segment of the industry has been increasingly utilizing the potential of 3D printing to create customized building modules and components to be built off-site without the use of heavy machinery, therefore minimizing labor hours and time spent on-site. The demand for modular housing and sustainable prefabricated buildings is fueling this growth, creating a vital technology driver for the future.

Regional Insights

U.S. 3D Concrete Printing Market Size and Growth 2025 to 2034

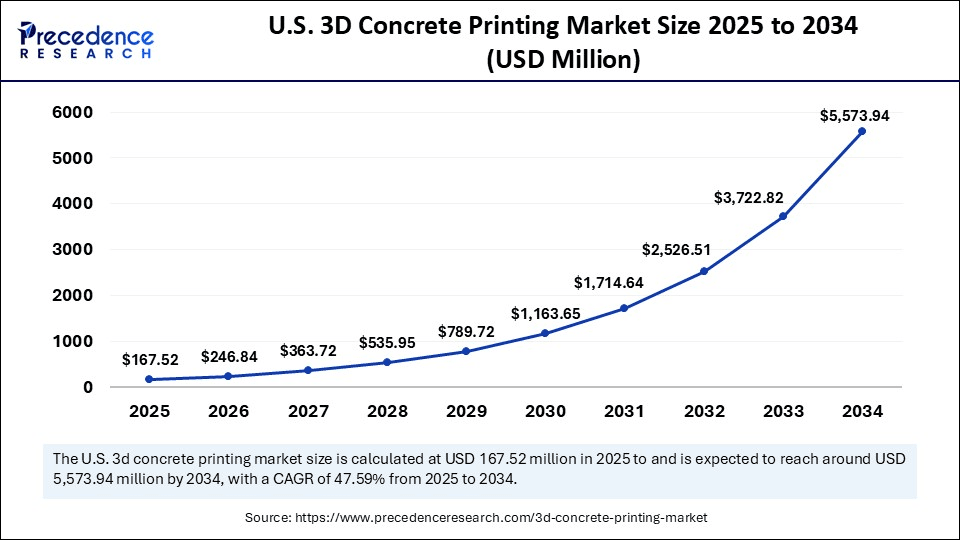

The U.S. 3D concrete printing market size is evaluated at USD 167.52 million in 2025 and is projected to be worth around USD 5,573.93 million by 2034, growing at a CAGR of 47.59% from 2025 to 2034.

How is North America Leading in the 3D Concrete Printing Adoption?

North America is the most advanced region in the adoption of 3D concrete printing, supported by a strong ecosystem of startups, technology providers, and real estate companies. The region is a hotbed for venture-backed innovation, coupled with partnerships between construction companies and robotics providers, and local authorities wish to experiment with printed housing projects. There is a noticeable increase in municipalities approving 3D-printed homes in response to labour shortages and housing affordability, as well as private firms scaling from proof-of-concept into multi-unit developments. The region's focus on standardization, proving costs, and regulatory acceptance will give North America a first-mover advantage for long-term business proof.

Focus On Infrastructure Boost U.S.

The United States is the most active in North America's growth, with Texas positioned as the focal point. Since August 2024, ICON has been working on completing projects with its 100-unit largest 3D printed community at Wolf Ranch, demonstrating the feasibility of scaling this technology to residential.There is a concerted focus on infrastructure at U.S. universities and building-tech firms, whereby applications for 3D concrete include military barracks and disaster-relief housing. The case studies mentioned above show quantifiable evidence of savings on build-time and reliance on the labour workforce, along with formulas that can easily be replicated and shown to developers and policy-makers. (Source: https://parametric-architecture.com)

Why Is Asia Pacific the Fastest-Growing Region in the 3D Concrete Printing Market?

As a growing region for 3D concrete printing, Asia Pacific is becoming dynamic, spurred by urbanization pressures, government-supported housing programs, and advancing research and development. Countries are using 3D concrete printing to address housing demand and labor shortages while also initiating some pilot projects using 3D concrete printing in infrastructure and public projects. Asia Pacific is moving forward using demonstration builds public–private partnerships, and research from universities and other secured funding support.

China Driven by Growing Universities

China is at the forefront of the Asia Pacific's movement, with universities and tech companies demonstrating structural-scale capabilities. For example, a research team built a two-storey, 100 m² building in 22 days using robotic 3D concrete printing, showcasing speed and the ability to scale construction into full-time work. In addition to research, Chinese companies are testing with 3D printing a variety of infrastructure items commensurate with the country's construction demands.

- Additionally, in August 2025, Jinan, China - XISUI Design unveiled a community park of 13,000 m² with boulder-like structures made of 3D-printed concrete that have been sculpted into tunnels, slides, and climbing forms that are safe, smooth, and resemble the natural geology. (Source:https://www.dezeen.com)

Stringent Regulations Shape Europe

Europe is expected to grow significantly in the 3D concrete printing market during the forecast period, due to stringent regulations. This is increasing the shift toward the use of green building technologies, where companies are focusing on low-waste and low-carbon construction solutions, promoting the use of 3D concrete printing. The increasing investment is also increasing their adoption, driving the market growth.

UK Embrace Sustainable Construction Solutions

The UK is experiencing a shift toward the use of sustainable construction solutions, which is encouraging the use of 3D concrete printing. Moreover, the faster and affordable building options are increasing their use. The industries and institutions are also focusing on their innovations, which are supported by funding and investments.

Expanding Infrastructure Propels MEA

Europe is expected to grow significantly in the 3D concrete printing market during the forecast period, due to expanding infrastructure. This is driving the demand for faster construction options, increasing their adoption rates. The rapid urbanization and smart cities development are also increasing their use, which is promoting the market growth.

Growing Investment Drives Saudi Arabia

The growth in the investment for sustainable and low-waste construction is increasing the use of 3D concrete printing in Saudi Arabia. The growing construction projects, government support, and private funding are also increasing their use. Moreover, the companies are also collaborating to enhance their feature and applications.

3D Concrete Printing Market Transformers: Key Players' Offering

- COBOD International A/S: BOD2 printers are provided by the company.

- Apis Cor Inc.: The Company provides highly mobile and crane-like construction 3D printers.

- ICON Technology, Inc.: Vulcan and Lavacrete are the products provided by the company.

- CyBe Construction B.V.: The company provides CyBe RC, software, and materials for construction.

- Winsun/Yingchuang Building Technique (Shanghai) Co., Ltd.: A Special Reinforced concrete mix is provided by the company.

3D Concrete Printing Market Companies

- COBOD International A/S

- Apis Cor Inc.

- ICON Technology, Inc.

- CyBe Construction B.V.

- XtreeE SAS

- Winsun/Yingchuang Building Technique (Shanghai) Co., Ltd.

- D-Shape (and affiliates)

- Contour Crafting Corporation

- MudBots 3D Concrete Printing, LLC

- SQ4D (US)

- WASP S.r.l. (large-scale and alternative materials)

- PERI 3D Construction/PERI Group (printer and systems partner)

- Vertico BV

- Black Buffalo 3D Corporation

- X-Hab 3D (and similar niche contractors)

- Printerra (materials and systems partnerships)

- HeidelbergCement/Italcementi (materials + R&D)

- Holcim (LafargeHolcim) (materials and project partnerships)

- Sika AG (admixtures and printable chemistry)

- Skanska (early adopter/pilot partner in construction projects)

Recent Developments

- In May 2025, Deltasys E-Forming launched a compact tabletop concrete 3D printer specific to R&D. This printer will allow researchers, architects, and universities to design and create materials and smaller construction prototypes in a more effective way.(Source: https://www.voxelmatters.com)

- In March?2024, Vertico introduced the “Solo Robot,” a standalone 3D concrete printing system that provides a unique opportunity for mobility, easy installation, and simplified setup and use to address accessibility to large-scale additive construction worldwide.(Source: https://www.voxelmatters.com)

- In June?2025, the Kyiv National University began a concrete 3D printing project that will utilize recycled materials to help Ukraine with its reconstruction efforts by using sustainable techniques while addressing infrastructure challenges related to post-war reconstruction.(Source: https://3dprintingindustry.com)

Segments Covered in the Report

By Printing System/Equipment

- Gantry-based systems

- Robotic arm-based systems

- Crane-mounted/contour-crafting systems

- Mobile/track-mounted/autonomous platforms

By Printing Method/Process

- Extrusion-based printing

- Powder/binder-jetting methods

- Hybrid/multi-material approaches

By Material Type

- Cement-based concrete mixes

- Fiber-reinforced mixes

- Geopolymer/low-carbon mixes

- Specialty high-performance mixes (e.g., rapid-set, polymer-modified)

By Application

- Residential housing

- Commercial and office buildings

- Public infrastructure (bridges, retaining walls, utilities)

- Architectural/decorative elements and façades

- Industrial/precast components

- Special projects (disaster housing, lunar/martian habitat R&D)

By End-User

- General contractors/construction firms

- Prefabrication/modular manufacturers

- Governments/public agencies (infrastructure and social housing pilots)

- Architects and specialist fabricators

- Research institutions/defence and aerospace (specialised use)

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting