What is the Coating Resins Market Size?

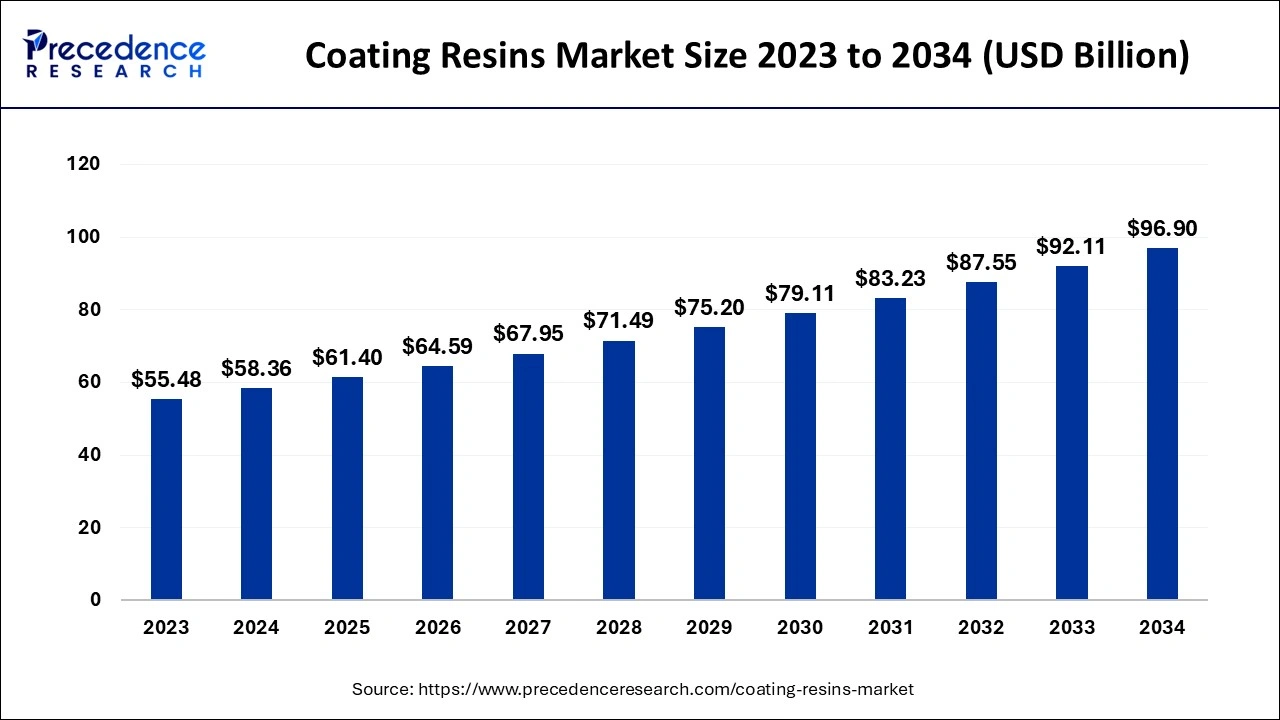

The global coating resins market size was accounted at USD 61.40 billion in 2025 and is predicted to increase from USD 64.59 billion in 2026 to approximately USD 101.54 billion by 2035, growing at a CAGR of 5.16% from 2026 to 2035.

Coating Resins Market Key Takeaways

- Asia Pacific dominated coating resins market in 2025.

- By technology, the waterborne innovation segment led the market in 2025.

- By type, the acrylic segment dominated the market in 2025.

What are the Coating Resins?

Coating resins are polymer intensifies utilized as key fixings in the creation of coatings and paints. These inventive materials act as defensive layers for a great many items and are exclusively utilized to give consumption, hardness, climate, and stain obstruction.

Coating resins are put to the outer layer of an item to give hardness, consumption obstruction, climate opposition, and stain opposition. To coatings, resins give speedy drying periods, gleam maintenance, and astounding enduring. At the point when the resins and hardener are blended, a compound response happens that causes cross-connecting of the components as it fixes. Coating resins are made using various ways. The detailing may be water-based or dissolvable based. The technique used to incorporate the coating sap for a specific not entirely settled by necessities like area, base material, coating reason, etc. so characteristics like resins thickness, variety, adherence, and union can be changed for productive application.

Gum coatings are the most famous strategy for conveying defensive coating layers in many applications, including engineering, auto, development, hardware, marine, wood, paper and mash coatings, wood, and other modern purposes. Water-based polyurethane, water-based alkyd, water-based epoxy, and water-based acrylic sap are most regularly found in automobiles, holders, and other modern and hostile to erosion coatings. In the paint business, coating resins are generally alluded to as sap fasteners. Engineered resins are applied to wooden floors, concrete yards, metal surfaces, carports, and decks to make strong, finished, extreme, and outwardly satisfying surfaces. Coating resins are likewise utilized in rush hour gridlock paints, textures, and food bundling to make durable and great items. Coating saps are likewise used in buyer hardware, modern plastics, and bundling coatings and inks.

How is AI contributing to the Coating Resins Industry?

AI substitutes trial-and-error research with predictive formulation design, speedier development cycles, higher quality reliability, reduction of waste, sustainable replacements, smarter output control, predictive maintenance, digital twins, and performance forecasting of actual operating conditions, which enhance cost efficacy, speed, and regulatory conformity.

Coating Resins Market Growth Factors

Organizations of coating resins market are underscoring on reception of new innovations, for example, water-based, dissolvable based, and high solids. As of now, the accessibility of restricted petrochemical assets and rising natural issues are fueling innovative work exercises around the world. Expansion in expandable pay and spotlight on way of life has expanded the use of paint and coating, which thusly is assessed to help the coating and paint industry. A few makers are anticipating giving harmless to the ecosystem items and cycles for many enterprises. These variables are supposed to push the coating resins market in the following couple of years.

Expanding the Use of Liquid and Bio-based Epoxy Resin is one of the significant development drivers of the market. Different epoxy resins are broadly used in electrodeposition (ED) coatings and modern coatings, especially in the transportation, modern support, and marine ventures. Epoxy resins are additionally as often as possible used in powder coatings. The utilization of fluid epoxy resins in the advancement of high solids and super high solids details is turning out to be progressively normal. Fluid epoxy pitch is utilized to accomplish 100 percent strong epoxy syntheses for use as substantial surfaces, tank linings, and other comparative applications. It is as often as possible enhanced with phenoxy and novolac pitches to expand execution and highlights.

Waterborne epoxy gum innovation's presentation has improved, taking into account more noteworthy application. In light of the broad utilization of metal coatings, just a little part of innovation was achieved. Lately, rising natural and financial worries, as well as the vulnerability that accompanies restricted petrochemical assets, have resisted a critical expansion in innovative work endeavors to make bio-based polymers. Makers are endeavoring to supplant polymers got from normally happening biofuels with petrol-based items to fulfill the modern need for ecological assurance. Besides, making more secure polymer creation processes, for example, the utilization of more secure structure blocks and added substances, is vital. DGEBA, cycloaliphatic epoxies, or diglycidyl ethers of Novolac saps are widely used to make business epoxy pitches. Inexhaustible normal assets have made it conceivable to go about as building blocks for polymers because of their minimal expense, naturally harmless nature, and capacity to be effectively epoxidized.

In Addition, Advances in powder coating innovation, for example, the improvement of slight film powders (one millimeter or more slender), UV-relieved powders, lower-temperature restored endlessly powders impervious to high-warm clear coatings, are pushing the business. Mechanical headways in powder coating materials, their particular purposes, and high-level relieving methods have expanded the use of powder coating in heat-touchy substrates. Perhaps of the main development in powder coatings is medium-thickness fiberboard (MDF), a composite board holding manufactured sap with wood particles. These items incorporate entryways, kitchen and shower cupboards, office furniture, store installations, and shows, and prepared to-collect furniture for work environments and homes.

Factors restricting the use of coating pitches incorporate variable natural substance costs and diminishing petrochemical stocks. These variables block market development. Be that as it may, the overall coating resins industry still can't seem to understand its maximum capacity.

Market Outlook

- Industry Growth Overview: Increasing rates of use of advanced waterborne coating resins demand in construction, automotive, and infrastructure drive the coating resins market.

- Sustainability Trends: The emphasis on sustainability leads to the increased shift to low-VOC, waterborne, bio-based resin, which complies with strict environmental requirements.

- Major Investors: The key players are BASF SE, Arkema S.A., Covestro AG, Dow Inc., DIC Corporation, and Allnex Netherlands B.V.

Trends in the coating resins market for 2025

Surge in Demand for Low-VOC and Eco-Friendly Resins

The industry is moving toward low-VOC waterborne and bio-based resins due in large part to environmental sustainability. Manufacturers' innovation is being compelled by stricter emissions regulations in areas such as North America and Europe. Products with green certifications are becoming more and more popular among consumers and businesses. The global movement toward the concepts of the circular economy is also consistent with this trend.

Growing use in 3D Printing and Additive Manufacturing

To provide accurate surface finishes, high heat resistance, and strength coating resins specifically designed for 3D printing are being developed. These specialty resins find application in consumer electronics, dental, and aerospace industries. This innovation has been driven by the need for complex geometries that are lightweight. Because of their performance and adaptability, UV and epoxy-based formulations are especially preferred.

Shift towards Waterborne and Hybrid Resins

Because of their high performance and low toxicity, waterborne and hybrid resins are becoming more and more popular. These resins are resistant to weathering corrosion and UV rays while also meeting regulatory requirements. Hybrids of acrylic-polyurethane and epoxy are increasingly used in industrial and architectural coatings. Additionally, manufacturers are refining formulations to balance adhesion, drying time, and cost.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 61.40Billion |

| Market Size in 2026 | USD 64.59 Billion |

| Market Size by 2035 | USD 101.54Billion |

| Growth Rate from 2026 to 2035 | CAGR of 5.16% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Technology, Type, End User and Geography |

Market Dynamics

Key Market Drivers

Increase popular from development and car ventures

The development of the development business and different forthcoming activities are the essential variables supporting the paints and coatings market. Development spending overall has expanded throughout the course of recent years; it was assessed at USD 11.4 trillion out of 2018, up from USD 9.5 trillion of every 2014. This number is additionally expected to increment throughout the following couple of years inferable from populace development, urbanization, and mechanical progressions. China, India, and the US are supposed to drive the development business throughout the following couple of years. This can be ascribed to the recuperation from monetary precariousness and quick industrialization in agricultural nations.

Auto OEM coatings are a fundamental piece of car producing

These coatings offer brilliant quality and strength, and have better mechanical properties than safeguard autos from scratches, cruel climate, and substance openness. Inside auto coatings work on a superficial level area of car. The expansion in the discretionary cashflow of customers in creating economies, for example, China has powered the interest for traveler vehicles. Auto makers are laying out assembling offices in arising nations like China, India, Thailand, and Brazil because of low work costs, positive unofficial laws, and simple availability to natural substances. These makers are progressively moving toward minimal expense and elite execution OEM coatings. Car restoring additionally serves the interest for coatings from OEMs, thusly prompting the interest for coating resins.

Key Market Challenges

- Stringent administrative arrangements- With next to no apparent meeting among themselves, the coating resins industry mediators in many nations have campaigned their governing body to try not to determine a solitary consistence course. The business technique is that decreased emanations are alluring, however it wishes to see guidelines outlined around air quality principles or outflow limit values communicated as the mass of complete discharges. This approach leaves the business allowed to choose the control choice. Through this course, the best control choice will be created by aggressive strain.

Key Market Opportunities

- Growth expected in less managed areas - North America and Europe are profoundly directed markets. Significant makers of coating resins situated in these areas need to follow severe government rules and approaches. Be that as it may, the creating districts have less or no standards for this market. The coatings and coating saps markets in APAC and other arising economies are less directed, opening open doors for the producers.

Segment Insights

Technology Insights

The waterborne innovation represented the biggest portion of 57.6%, regarding esteem, of the general market in 2025. The dissolvable borne innovation portion has lost its predominant situation because of the developing pattern of utilizing dissolvable free coatings.

In 2024, the dissolvable borne coatings section represented a 25.7% offer, regarding esteem, of the coating resins market; nonetheless, its descending pattern is supposed to proceed. In the following couple of years, waterborne, powder, and radiation-reparable advances are supposed to acquire a higher piece of the pie, with regards to esteem.

Type Insights

In light of type, the acrylic portion ruled the worldwide coating resins market and held a portion of 27.9% in 2025. Moreover, the fragment is likewise expected to extend at an eminent CAGR of 5.6% during the gauge time frame. Acrylic coating resins have higher gooey consistency when contrasted with that of different resins. They are utilized in cements, coatings, supported plastics, and composite materials, for example, fiberglass and carbon fiber, which stay in salvageable shape under extraordinary circumstances. Acrylic coating resins can be applied to different surfaces. They give the covered region a shiny, solid scratch-safe completion, which shields the surface from dampness and material weakening.

End UserInsights

The paints and coatings industry are one of the noticeable customers of saps worldwide. Coating resins go about as folios, keeping the whole plan intact. The worldwide paints and coatings industry is extending at a huge speed. The business is full grown; in any case, it is going through change and is moving toward new advancements and eco-accommodating items, because of expanded mindfulness in regards to VOC emanations around the world. Interest for paints and coatings from different areas, like car, modern and marine, is ascending at a fast speed. Paints and coatings are utilized to give predominant surface completion and assurance from climatic circumstances. Development of the auto business is additionally energizing the interest for paints and coatings. Car paints are solid; they have better restoring properties, forestall erosion, and make vehicles light in weight to further develop eco-friendliness. Ascend in populace and improvement in moneresinsy circumstances have prompted an ascent in the use on lodging and framework improvement across the globe. This is assessed to expand the interest for brightening coatings during the figure time frame.

Defensive coatings, which is one of the significant application fragments, is seeing fast ascent sought after for paints and coatings. These variables are assessed to drive the interest for paints and coating and subsequently, support the coating resins market during the conjecture time frame.

Regional Insights

What is the Asia Pacific Coating Resins Market Size?

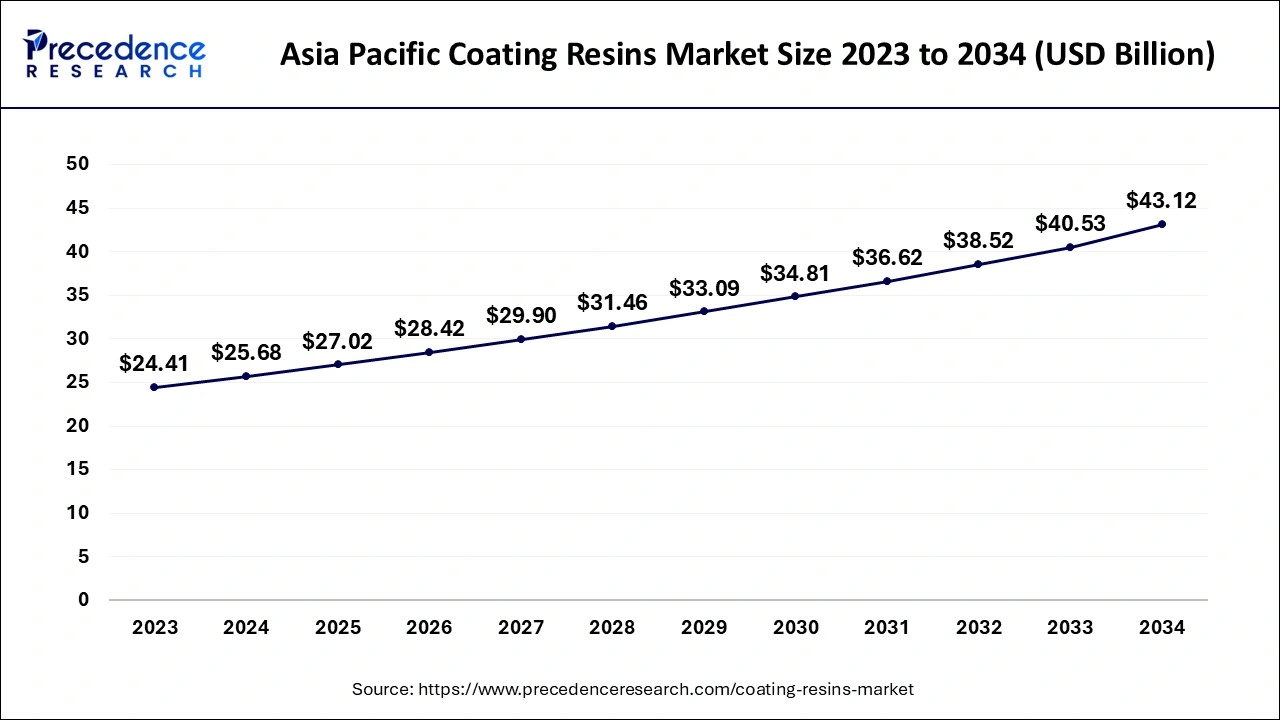

The Asia Pacific coating resins market size was evaluated at USD 27.02 billion in 2025 and is predicted to be worth around USD 45.32 billion by 2035, rising at a CAGR of 5.31% from 2026 to 2035.

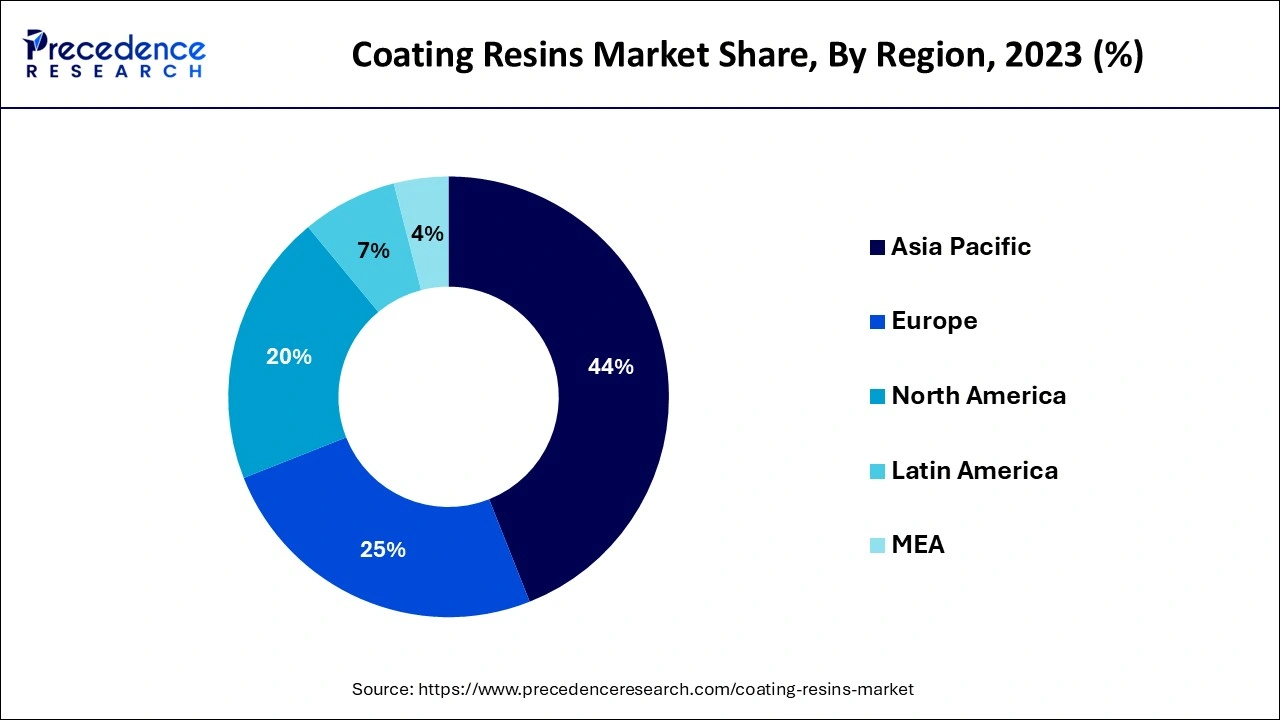

Asia Pacific held 44% portion of the worldwide coating resins market in 2025. Utilization was significantly credited to popularity for acrylic and alkyds, which represented 20.73% and 24.85% offers, separately, in the market in Asia Pacific. China represented close to 33% of the coating resins market in Asia Pacific.

Asia Pacific continues to be the worldwide leader in the coating resin market, driven by the region's strong industrial sectors and a concerted transition to sustainable technologies. As an indication of its dominance, China accounts for nearly 1/3 of the region's resin consumption, fueled by the region's large construction and marine industries. India is now the second largest market by volume, ahead of Japan, because of strong urbanization and infrastructure initiatives.

China Coating Resins Market Trends

China leads the Asia-Pacific region through its approach to transforming economic value. The market now requires specialized coating solutions that provide operational benefits. Waterborne products have become the leading solution because they meet environmental requirements. The market expansion of anti-corrosion, self-cleaning, and heat-reflective resins, which support infrastructure development, energy production, and advanced manufacturing ecosystems.

North America and Europe are likewise conspicuous shoppers of coating resins, and the locales held 20% and 25% offer, separately, of the worldwide market in 2025. Design coatings, modern coatings, and car coatings are growing application fragments of the coating saps market in these districts. Latin America is a moderately minor purchaser of coating resins when contrasted with Middle East and Africa.

North America is poised for rapid growth in the coating resin market, coming off a spike in residential and non-residential construction projects, led in large part by the U.S. There has also been a significant demand for low VOC formulations, on waterborne resins, due to environmental initiatives over the past five years.

U.S. Coating Resins Market Trends

The U.S. focuses on implementing low-VOC solutions, which use regional supply networks, develop electric vehicle coatings, protect its infrastructure, and create functional surfaces. The regulatory environment pushes manufacturers to adopt waterborne and powder coating technologies. Companies invest their resources to create products that deliver lasting performance, automate processes, and enhance manufacturing operations through intelligent technologies.

What Are the Driving Factors of The Coating Resins Market in Europe?

Europe is expected to grow at a significant rate during the forecast period. The European market develops according to sustainability requirements, which enforce limitations and environmental regulations. The market demand now seeks environmentally friendly technologies that deliver exceptional performance. The resin demand from healthcare construction and renewable infrastructure development maintains stability through regulation-based requirements.

Germany Coating Resins Market Trends

Germany leads the development of new technologies. The industry now prioritizes production of valuable high-end coatings instead of its previous focus on coating volume. The renewable energy sector increases its demand for epoxy products. The combination of digital color matching, automated blending, and sustainable chemistries creates sustainable solutions that improve efficiency for architectural and industrial applications.

Value Chain Analysis of the Coating Resins Market

- Feedstock Procurement: Procurement of raw materials in a strategic manner, balancing between reliability of the suppliers, cost, and long-term availability.

Key Players: ExxonMobil, Shell Chemicals, Olin - Chemical Synthesis and Processing: Carrying out managed reactions of feedstocks to functional intermediates or completed resins.

Key players: BASF SE, Dow Inc., Allnex, Covestro AG, Arkema S.A. - Compound Formulation and Blending: This is the exact combination of resins, solvents, and additives to form the desired coating performance properties.

Key Players: AkzoNobel N.V., PPG Industries, DIC Corporation, Kansai Paint Co., Ltd. - Quality Testing and Certification: Assuming adherence to safety, durability, and performance standards before commercial release.

Key players: SGS S.A., Intertek Group, Bureau Veritas, TÜV SÜD - Packaging and Labelling: Readying resins to be distributed using conforming shipping containers, documents, and identifications that are transport-accepted.

Key players: BASF, Dow, and Covestro

Coating Resins Market Companies

- Allnex Holdings S.à r.l.: Provides wide-resin portfolios, additives to industrial, architectural, automotive, and functional-oriented coating systems across the world.

- BASF SE: BASF SE is the manufacturer of polymer emulsions, Joncryl, and Acronal resins (acrylic binders) used in architectural, automotive, and industrial finishes.

- LANXESS: Provides waterborne binders, pigments, additives, and high-performance resin systems based on sustainability and durability.

Other Major Key Players

- Royal DSM N.V.

- DowDuPont Inc

- DIC Corporation

- Bayer AG

- Celanese Corporation

- Arkema S.A.

- Solutia Inc.

- INEOS Group Holdings S.A.

- Huntsman International LLC.

- Evonik Industries AG

Recent Developments

- In March 2025, BASF and Sika have jointly developed a new amine building block for curing epoxy resins, which is now commercially available under BASF's Baxxodur EC 151 brand. Baxxodur EC 151 gives epoxy resin flooring solutions a low viscosity and optimum flow properties. Epoxy resin coatings formulated with Baxxodur EC 151 cure quickly and thoroughly over a wide temperature range.

- In September 2024, Engineered Polymer Solutions (EPS) launched a new all-acrylic resin polymer for cutting-edge flat through semi-gloss interior and exterior architectural coatings. EPS 2746 is a versatile polymer for architectural DIY and professional paint formulations.

- In September 2024, PPG launches PPG STEELGUARD 951 fire protection coating in the Americas. Flexible epoxy coating provides commercial infrastructure with up to four hours of fire protection.

- In April 2024, Sherwin-Williams launches Sher-Bar TEC – The first damage-tolerant textured epoxy coating for Rebar. Designed for an array of construction applications and environments, the textured epoxy coating (TEC) redefines standards for rebar coatings.

- On 30 April 2025, Hubergroup Chemicals introduced groundbreaking bio-based oligomers designed for industrial UV curable coatings at RadTech 2025. These oligomers aim to enhance sustainability in coating applications by reducing reliance on fossil-based materials, aligning with the industry's shift towards eco-friendly solutions.

- In March 2024, EPS announced the launch of EPS 2746, marking its fourth product release in 2024, and EPS 2460, an all-acrylic polymer suitable for flat to semi-gloss coatings. These additions expand EPS's industrial wood portfolio, demonstrating the company's commitment to innovation and meeting evolving market needs.

- On 11 October 2024, Evonik Industries revealed plans to scale back its adhesives and health care units, focusing on core assets. The restructuring includes shedding operations such as its polyester business and a production line for keto acids, affecting approximately 260 employees. The move aims to align resources with the company's strongest business segments.

- In February 2021, Arkema as of late presented ENCOR 2793 functionalized unadulterated acrylic fastener, another definition devoted to various substrate groundworks and remodel paints. It is planned without alkylphenol ethoxylates and is formaldehyde sans releaser. ENCOR 2793 unadulterated acrylic has a great bond profile on wood, concrete, clay, plastics, and others. It is not difficult to plan. This permits a wide scope of uses, for example, multi-substrate groundwork, wall paints, wood finishes, color and tannin impeding preliminary, or two-coat remodel paints.

- In January 2020, Arkema reported that viable March 1, 2020, Brenntag Canada would be the essential wholesaler in Canada for all Arkema waterborne resins sold under the ENCOR, CELOCOR, SNAP, and NEOCAR business trademarks. These resins are utilized to plan items across different enterprises, including design and modern coatings, cements, caulks and sealants, development items, traffic markings, and others.

Segments covered in the report

By Technology

- Waterborne Coatings

- Solvent borne Coatings

- Powder Coatings

- Others

By Type

- Acrylic

- Polyurethane

- Alkyd

- Epoxy

- Vinyl

- Amino

- Polyester

- Others

By End User

- Architectural Coatings

- Paints and Coatings

- Industrial Coatings

- Automotive Coatings

- Wood Coatings

- Protective & Marine Coatings

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting