What is the Polyurethane Market Size?

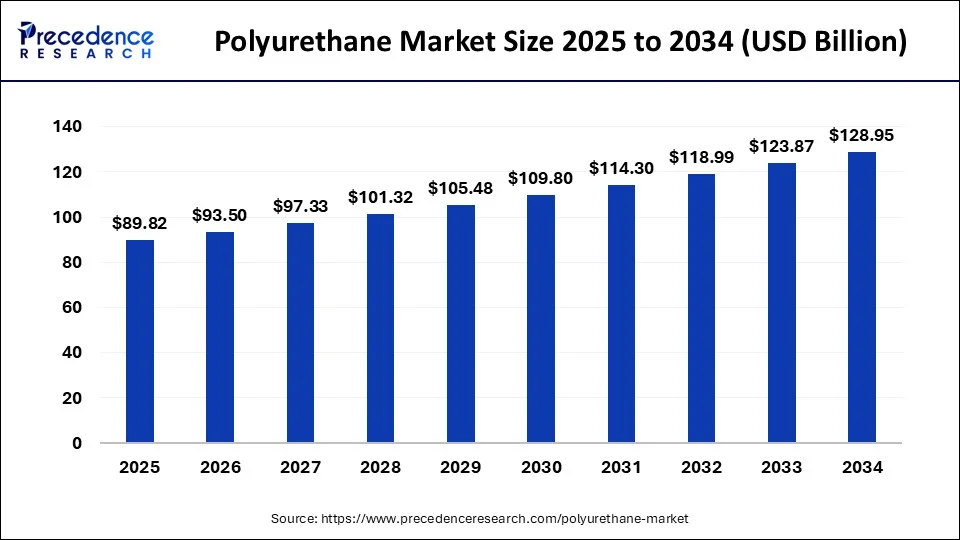

The global polyurethane market size is calculated at USD 89.82 billion in 2025 and is predicted to increase from USD 93.50 billion in 2026 to approximately USD 128.95 billion by 2034, expanding at a CAGR of 4.10% from 2025 to 2034.

Polyurethane Market Key Takeaways

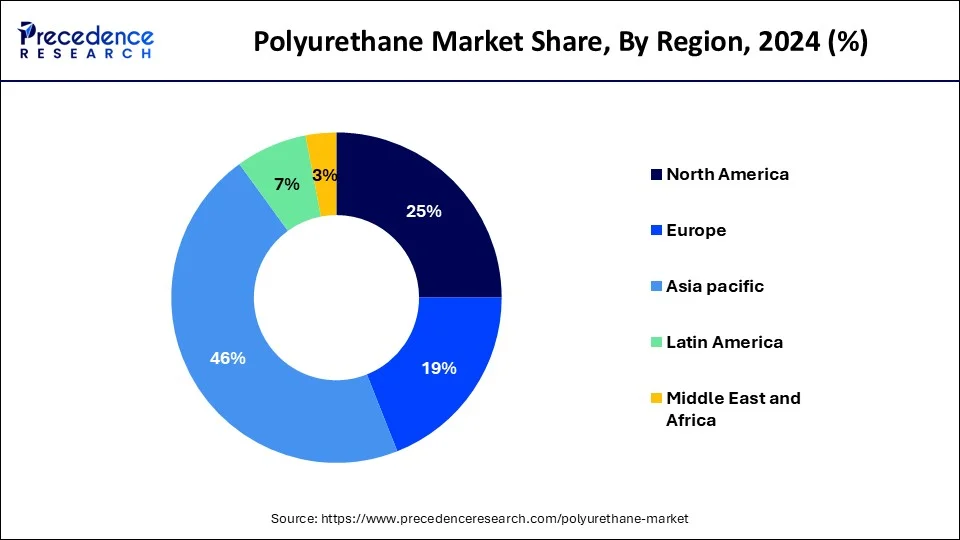

- Asia Pacific dominated the global market with the largest market share of 46% in 2024.

- Rigid foam product segment contributed the biggest market share of 33% in 2024.

- Flexible foam product segment is expected to grow at a steady pace with a CAGR of 6.2% from 2025 to 2034.

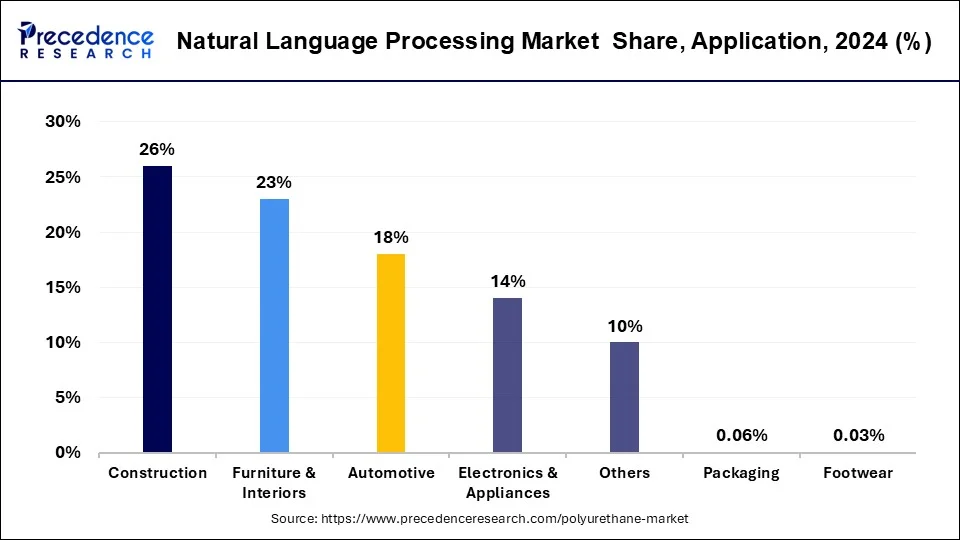

- By application, the construction segment accounted for a market share of 26% in 2024.

Market Overview

- Several governments have tightened environmental regulations, encouraging industries to phase out ozone-depleting substances and adopt greener polyurethane alternatives.

- Incentives and tax benefits are being offered for the use of low-VOC (volatile organic compounds) polyurethane in paints and coatings.

- Building energy codes in countries like Japan, Germany, and India are promoting the use of polyurethane insulation materials for enhanced thermal performance.

- National R&D grants are being provided to companies working on polyurethane recycling technologies and carbon-neutral polyurethane production.

- Smart city and housing missions, especially across Asia-Pacific and Latin America, are boosting the consumption of polyurethane in sealants, flooring, and waterproofing materials.

Market Outlook

- Industry Growth Overview: The polyurethane market is expanding steadily, driven by demand in the furniture, packaging, automotive, and construction sectors. PU is a favored material because of its adaptability, strength, and light weight. Increased use of adhesives, coatings, and insulation across regions also supports growth.

- Sustainability Trends:Manufacturers are concentrating on recycling, lowering hazardous emissions during production, and bio-based polyurethanes. Attempts are underway to reduce PU products' negative environmental effects without sacrificing their functionality. Global eco-friendly foam and coating innovations are becoming more popular.

- Startup Ecosystem: Bio-based polymers are recycled materials and are among the sustainable PU solutions being developed by startups. Businesses are working with material innovators and OEMs to develop high-performing, environmentally friendly products. Additionally, up-and-coming companies are investigating specialized PU applications in electronics, medical devices, and footwear.

Polyurethane Market Growth Factors

The polyurethane chemistry is such that, it allows to be fashioned into unusual shapes without compromising the quality with the same time it enhances industrial and consumer commodities by adding value of comfort and convenience. Polyurethanes are created by perfectly balanced chemical reaction. Polyols with the diisocyanate or polymeric isocyanate are the ingredients that are used in these reactions with proper amounts of additives and catalysts. To meet the specific requirements in various industries, variety of industry solutions are manufactured based on vast range of polyols. Polyurethane products are being used in vast range of consumer goods for day-to-day life use. For instance, polyurethane is used in, rigid foam for casing in walls and roofs, flexible foam in upholstered furniture, TPU in medical devices and footwear. It is also used on floors and automotive interiors, in coatings, sealants, adhesives. Polyurethane has high requirements in construction industry at large scale.

This growing need is for majorly in building insulation. Considering the all global pandemic situation now construction industry is at sustainable growth and it is prudently established that Polyurethane market is further expected to rise in projection period. Sustainability considering the building construction is vast field and it embodies many steps that must be incorporated in primary construction processes since it their potential environmental brunt is very considerable. Due to these reasons green buildings are certainly making their way stronger in the construction industry. Awareness about climate changes and government initiatives are encouraging to increase investments in smart energy-efficient commercial as well as residential buildings. These buildings provide financial opportunities as well as they are also in accordance with federal and environmental regulatory requirements, providing a significant solution to ever growing consumer sustainability demands. Increased building material effectiveness has resulted in a greater requirement for proficient insulating material to control Ventilation, Heating and Air Conditioning and offset the amount of energy wasted owing to inadequate insulation. Polyurethane foam is then used as exceptionally efficient insulation materials, resulting in significant energy savings.

Additionally, Polyurethane products and solutions requirements in the United States is major factor that pushing the market forward. These growing product demands are from the several industries such as automotive, packaging sectors and construction as well. This will drive market for polyurethane further. The construction sector was worst hit by the pandemic in last two years in the U.S. But the conditions at normalcy again and the construction sector is at boom. It is rapidly developing as a result of advanced commercial real estate market fundamentals and enlarged state and federal financing for institutional infrastructure and public infrastructure. Moreover, currently undertaken working construction projects, like the construction of the LaGuardia Airport, San Francisco Civic Centers campus, Second Avenue Subway Construction Project and O'Hare Airport Construction Project are likely to drive the product demand in construction applications in foreseeable future. Furthermore, in addition to these major projects, government of United States announced investments of USD 2 trillion in March 2020. These investments are allocated for roads, government offices, hospital buildings and other infrastructure. This is further expected to propel market growth for Polyurethane in the country.

Polyurethane Market Trends

- Increasing demand for bio-based and recycled polyurethanes due to sustainability initiatives

- Growth in rigid polyurethane foam for energy-efficient building insulation.

- Rising use in automotive lightweighting and EV components for durability and weight reduction.

- Expansion of polyurethane coatings and specialty applications in electronics and packaging.

- Volatility in raw materials (polyols, isocyanates) is impacting production costs.

- Regulatory focus on chemical safety and emissions, pushing greener formulations.

- Sustainability initiatives and consumer demand are driving a market shift towards environmentally friendly PU materials.

- Stricter energy codes in the construction industry are boosting demand for rigid PU foam's superior thermal insulation properties.

- Eco-friendly formulations are increasingly shaping the polyurethane market as manufacturers shift towards bio-based and recyclable alternatives to meet global sustainability standards.

- The demand for high-performance insulation in construction and refrigeration is surging, pushing forward the use of rigid polyurethane foams.

- Lightweight vehicle components made from polyurethane are driving growth in the automotive sector, supporting both electric vehicle manufacturing and fuel efficiency standards.

- Smart furniture and bedding applications using viscoelastic polyurethane foams are gaining popularity due to enhanced comfort, durability, and temperature sensitivity.

- An upsurge in construction and infrastructure projects, especially in emerging economies, is accelerating polyurethane adoption in adhesives, sealants, and coatings.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 89.82 Billion |

| Market Size in 2026 | USD 93.50 Billion |

| Market Size by 2034 | USD 128.95 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.10% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Raw Material, Application, Geography |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Product Insights

Rigid foam product segment accounted largest market share in 2024. Rigid Polyurethane foams are basically closed-cell plastics with high-performance. They are utilized in end-use industries at large, such as industrial insulations & appliances, packaging and transportation. These foams have characteristic, as they are structurally stable, which makes it easier for manufacturers to devise thermally insulating products. Also, rigid foams hold sound insulation qualities, thermal resistance and they possess mechanically higher strength. These structure based qualities of material makes them highly suitable in extreme weather and harsh environments.

Flexible foam segment is expected to grow at steady pace over the forecast period. In 2022, North American market was dominated by this segment with huge market share of 32%. Flexible polyurethane foam is primarily used as cushioning for a many of consumer and commercial products, such as automotive interiors, bedding, furniture and carpet underlay.

Application Insights

In 2024, the construction segment accounted largest market share of total global market. The heavy need for polyurethane in the construction sector is anticipated to cast significant growth over the projection period. Polyurethane possesses various chemical characteristics including bacterial & pest resistance, greater thermal insulation, chemical inertness and lightness. Rapid urbanization with government initiatives and industrialization throughout the globe are probable to fuel the further growth of the global construction industry. While in emerging economies, such as India and China are more focused on grater investments in these sectors. These governments are providing major budget allocations to improve their infrastructure. These development activities on large scale are expected to increase the product demand.

Automotive industry is anticipated to grow at remarkable CAGR trough the projection time frame. Polyurethane has a vast range of sustainable applications in the automotive industry. Using the Polyurethane has its own benefits such as, safety, comfort, lightness together with the design freedom. Polyurethane foam products help automobile designers and manufacturers to design the vehicle seating at their choice. By using polyurethane seating can be easily assembled, disassembled, and recycled. Polyurethane has the enhanced performance specifications with a vast range of firmness without quality compromise and added weight.

Regional Analysis

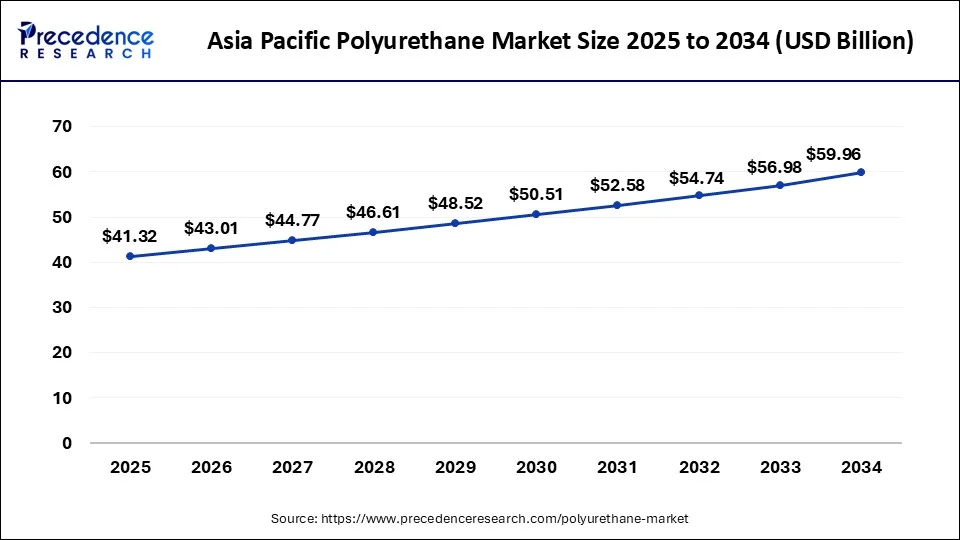

Asia Pacific Polyurethane Market Size and Growth 2025 to 2034

The Asia Pacific polyurethane market size is valued at USD 41.32 billion in 2025 and is expected to expand around USD 59.96 billion by 2034, at a CAGR of 4.20% from 2025 to 2034.

Asia Pacific was the major leading regional market for polyurethane in year 2024. Largely the Asia pacific market is propelled by the significant growth of the large end-use industries, Such as construction, automotive, furniture & interior, electronics & appliances and packaging.

What Makes Asia Pacific Leader In Polyurethane Market?

Asia Pacific remains the number one region for the polyurethane industry, reporting increased growth from its vast manufacturing ecosystem, potential infrastructure developments and increasing consumer goods and automotive demand. Regionally, Asia Pac is seeing diverse developments in regions with capacity demand growth, sustainability, and products and strategies of global players. All are in footwear, electronics, and construction- solidifying its strength in the changing landscape.

- In May 2025, Rymbal, the polyurethane division of Horizon Performance Products Pvt. Ltd. part of the Space World Group, introduced FluidX a ground-breaking polyurethane material that is 100% recyclable through both physical and chemical methods. Completely free from harmful chemicals, the product stands out with its ultra-lightweight profile (density of 260–280 kg/m³), making it ideal for eco-conscious manufacturing.

China has continued to provide the anchor for all other Asia Pacific demand growth, playing new and expanded capacity, Covestro expanded the capacity for dispersions and BASF unveiled upgraded capacity for its MDI plant in Shanghai. The additional governmental support for electric vehicles, and smart infrastructure solidifies China's lead in both demand and technological innovation across PU-based applications.

The Polyurethane Powerhouse

- China: Massive scale in construction, automotive, and furniture industries; leading producer and consumer of polyurethane products.

- India: Fast-growing middle class, government housing schemes, and increasing usage in cold storage infrastructure.

- Japan: Advanced technologies in automotive and electronics are driving demand for high-grade polyurethane components.

- South Korea: Innovations in footwear, electronics, and packaging industries.

Another reason for market's expansion is low cost skilled labour is at disposal of the industry. As mentioned before India and China are pouring their resources into building and develop infrastructure to put world's top auto manufacturers in their country. For example, Tesla is in negotiations with Government of India to put manufacturing plant in the country. These activities in the market are certainly to provide productive growth opportunities to polyurethane manufacturers.

North America - The Fastest Acceleration for Polyurethane

North America, meanwhile, is beginning to establish itself as a region of high growth due to the increasing investment in sustainable materials, energy efficient building systems, and next generation automotive interiors. The versatility of Polurethan's resonance in insulation, packaging and lighter weight components aligns well with the push towards green building and circular economy based solutions.

The United States is an industry leader with advancements in bio-based polyols such as Ford's seat foams that use soybean-based foams. Huntsman's strategic packaging, operations and further innovations in MDI plant operations continues to solidify the industry strength, with a strong tie between industrial strength and greener polyurethane manufacturing.

North America- major factors leading towards the growth of this region

- Stringent environmental regulations by the EPA (Environmental Protection Agency) promote the use of green polyurethane systems.

- Robust automotive sector, particularly in the U.S. and Mexico, leveraging polyurethane for weight reduction and energy efficiency.

- Technological research hubs in the U.S. are leading innovation in bio-based and high-performance polyurethane.

Value Chain Analysis

- Feedstock Procurement: Polyols, isocyanates, and additives are necessary for the production of polyurethane. To guarantee consistent performance and lessen their impact on the environment, manufacturers are concentrating on sourcing sustainable raw materials such as bio-based substitutes.

- Waste Management and Recycling: PU manufacturers implement recycling and reuse of scrap materials, foam offcuts, and production waste. Efficient waste management reduces environmental footprint and supports circular economy initiatives, particularly in construction and automotive applications.

- Regulatory Compliance and Safety Monitoring: In the production of PU, adherence to environmental and occupational safety regulations is essential. Businesses keep an eye on workplace safety emissions and chemical handling to comply with international regulations and guarantee safe, sustainable operations.

Polyurethane Market Companies

- Dow Inc.

- BASF SE

- Covestro AG

- Huntsman International LLC

- Eastman Chemical Company

- Mitsui & Co. Plastics Ltd

- Mitsubishi Chemical Corporation

- Recticel NV/SA

- Woodbridge

- DIC Corporation

- RTP Company

- The Lubrizol Corporation

- RAMPF Holding GmbH & Co. KG

- Tosoh Corporation

Recent Development

- In April 2025, Foam product manufacturer WTEC Group Bhd signed a memorandum of understanding with Jiangsu ChengFeng New Materials Co Ltd (Winfun Foam) to jointly develop and customize polyurethane foam products. China-based Winfun Foam manufactures and develops advanced polyurethane-based products that are widely used across industries such as automotive, aerospace, rail transportation, healthcare, electronics, water treatment, and air filtration.

- In Apr 2024, Evonik Industries AG unveils new sustainable polyurethane solutions at UTECH Europe 2024, including additives based on renewable feedstocks and a global amine platform run on green electricity.

(Source: evonik.com) - In Apr 2024, Huntsman Corporation launches its SHOKLESS polyurethane foam systems designed for EV battery protection, offering wide processing windows and structural/thermal performance enhancements.

(Source: huntsman.com)

Segments Covered in the Report

By Product

- Rigid Foam

- Flexible Foam

- Coatings

- Adhesives & Sealants

- Elastomers

- Others

By Raw Material

- Polyol

- MDI

- TDI

- Others

By Application

- Furniture & Interiors

- Construction

- Electronics & Appliances

- Automotive

- Footwear

- Packaging

- Others

By Geography

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting