What is the Industrial Belt Scale Market Size?

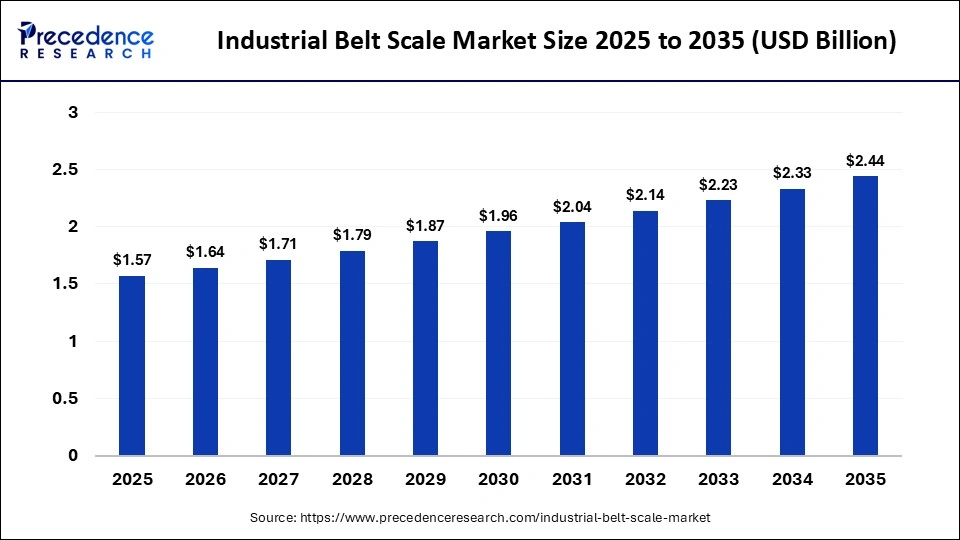

The global industrial belt scale market size is calculated at USD 1.57 billion in 2025 and is predicted to increase from USD 1.64 billion in 2026 to approximately USD 2.44 billion by 2035, expanding at a CAGR of 4.52% from 2026 to 2035. The market is growing significantly due to the rapid expansion of automation in industries such as mining, construction, and food & beverages, with the need for precise data and real-time monitoring in bulk materials handling.

Market Highlights

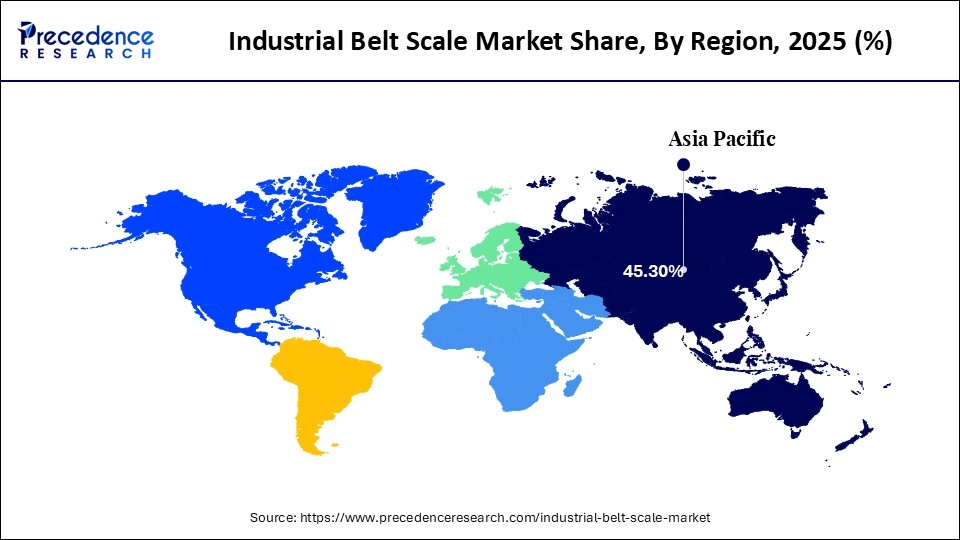

- Asia Pacific held the largest market share of 45.3% in 2025, and it is projected to grow at a CAGR of 6.5% between 2026 and 2035.

- By idler/scale type, the single idler segment held the major market share of 36.8% in 2025.

- By idler/scale type, the multi-idler segment is expected to grow at a strong CAGR of 5.5% between 2026 and 2035.

- By technology, the electronic load-cell belt scale segment contributed the highest market share of 52.3% in 2025.

- By technology, the smart/IoT enabled belt scales segment is growing at a notable CAGR of 5.6% between 2026 and 2035.

- By conveyor belt width, the 500-1200 mm segment captured the biggest market share of 45.8% in 2025.

- By conveyor belt width, the below 500 mm segment is growing at a CAGR of 5.8% between 2026 and 2035.

- By end user, the mining segment held the largest market share of 35.8% in 2025.

- By end user, the logistics & warehousing segment is projected to grow at the fastest CAGR of 5.7% between 2026 and 2035.

- By application, the process control segment generate the largest market share of 42.3% in 2025.

- By application, the blending/batching segment is projected to grow at the fastest CAGR of 5.8% between 2026 and 2035.

Industrial Belt Scale: A Backbone of Modern Material Handling

The Industrial Belt Scale Market includes conveyor-mounted weighing systems used to continuously measure bulk material flow across industries such as mining, aggregates, cement, steel, power, chemicals, food, and logistics. These systems integrate load cells, speed sensors, idler frames, and controllers to provide real-time throughput and production data for process control, inventory management, and commercial accuracy. Demand is driven by automation, compliance, operational optimization, and digital plant transformation, with growing adoption of multi-idler and IoT-enabled smart belt scales.

AI Shifts in Industrial Belt Scale Market

AI's unmatched capabilities in manufacturing and industrial platforms are no longer a futuristic vision but an active force reshaping daily operational workflows. In modern facilities, AI is increasingly integrated with industrial belt scales, robotics systems, and automated inspection lines to maximize cost-effective production and maintain high precision across every stage of material handling. Industrial belt scales equipped with AI-assisted calibration tools can adjust for load variability, vibration, and environmental interference in real time, allowing plants to maintain consistent accuracy without manual intervention. This is especially valuable in mining, cement, food processing, and chemical manufacturing, where even small deviations in material measurement can disrupt batch quality and raise operational costs.

- For example, Tru Trac has leveraged its AI-enabled platform, AccuTrac, designed to make mass flow measurement dynamic and intelligent enough to adapt to sudden changes, rather than being static, as with traditional industrial belts.

Industrial Belt Scale Market Outlook

- Industry Growth Overview: Belt scales are highly crucial for various industries such as mining, agriculture, and cement production. It's a specific short belt used for weighing goods based on rollers, speed sensors, and electronic rollers, which measures total weight and material flow rate in real time. The belt scale market is driven by the increasing demand for efficient material handling solutions and real-time data analytics, which provide businesses with insights to fuel their production. The integration of IoT and automation technologies with the belt scale is further driving market growth.

- Sustainability Trends: The increasing emphasis on environmental sustainability is heavily affecting the belt scale market, as many enterprises are increasingly embracing solutions to reduce overall energy consumption and material waste, encouraging manufacturers to follow eco-friendly belt scales. Many organizations are committed to reducing carbon footprints and to the demand for sustainable belt-scale solutions.

- Major Investors: The market is propelling due to the convergence of leading marketers' huge investment in the production of industrial belts and innovative product launch driven by cutting-edge technologies and their integration with the industrial belt scale. A well-established weighing player includes Siemens, Rice Lake Weighing Systems, Schenck Process, and Merrick Industries, offering technically sound weighing belts for several industries.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 1.57 Billion |

| Market Size in 2026 | USD 1.64 Billion |

| Market Size by 2035 | USD 2.44 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 4.52% |

| Dominating Region | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Idler/Scale Type, Technology, Conveyor Belt Width, End-Use Industry, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Insights

Idler/Scale Type Insights

Why Does Single Idler/Scale Type Lead the Industrial Belt Scale Market?

Single-Idler: The segment held the largest market share in 2025, at 36.8%, due to benefits including cost-effectiveness, a simple mechanical structure, and the ability to track lower-volume materials. It further offers real-time data for process optimization and inventory status across sectors such as mining, agriculture, and cement, where efficient data tracking is more paramount than accuracy.

Multi-Idler: The segment is projected to grow at a 5.5% CAGR over the foreseeable period. The segment is increasing due to its extreme precision, stable operation, and uninterrupted monitoring of large volumes of materials. They can easily integrate with technologies such as IoT, smart manufacturing, SCADA, and predictive maintenance, leading to better data and data-driven solutions and reducing high-cost breakdowns.

Technology Insights

What is Offered by Electronic Load-Cell Belt Scale Technology in the Industrial Belt Scale Market?

Electronic Load-Cell Belt Scales: The segment held the largest market share in 2025, at 52.3%. The segment is dominating due to its unparalleled offerings, including real-time monitoring, operational efficiency, and high-precision inventory management. It is highly applicable to critical productivity and compliance mandates across industries such as logistics, manufacturing, agriculture, and mining. Active players such as ABB, Metso, and Yamato Scale are supporting electronic load-cell belt scales with innovative solutions based on this technology.

Smart/IoT-Enabled Belt Scales: The segment is projected to grow at a 5.6% CAGR over the foreseeable period. The segment is expanding due to benefits such as enhanced data accuracy, operational efficiency, and energy management enabled by real-time monitoring. IoT capabilities allow direct connections to existing plant and ERP systems. Automation further reduces errors and processing time, helping optimize belt speed and material flow while increasing output.

Conveyor Belt Width Insights

Why are 500-1200 mm Conveyor belt widths preferred in the Industrial Belt Scale Market?

500-1200 mm: The segment held the largest market share in 2025, at 45.8%. The segment is dominating due to the convergence of factors and characteristics, such as versatility, optimized flow and accuracy, and standardized size, making it suitable for various applications. This range provides both capacity and space efficiency for applications like manufacturing to mining. Also, the material flow becomes highly stable with this size of conveyor belt, reducing the risk of spillage or material wastage.

Below 500 mm: The segment is projected to grow at a CAGR of 5.8% during the foreseeable period. Growth is driven by its expanding use in precision-focused industries, including electronics manufacturing, robotics assembly, pharmaceutical production, and automated packaging and labeling lines. These sectors depend on conveyor systems that maintain stable load measurement, controlled material flow, and high positional accuracy to protect sensitive components and ensure compliance with quality standards. In electronics manufacturing, for example, narrow-width conveyors and precision belt scales support the transport of circuit boards and micro-components without vibration-induced errors.

End User Insights

What are the Benefits of the Industrial Belt Scale Market to the Mining Industry?

Mining: The segment held the largest market share in 2025, at 35.8%. The segment is dominating due to its benefits, including continuous material movement even in extreme environments such as mining areas, energy-efficient operation, enhanced worker safety, and reduced risk of sudden failure, thereby reducing downtime in the mining industry and unnecessary repair costs. Industrial belt scales can be specifically used for surface or underground mining, crushing, and screening.

Logistics & Warehousing: The segment is projected to grow at the fastest CAGR of 5.7% during the foreseeable period. The segment is primarily increasing due to factors like enhanced productivity in logistics, automation in warehousing that ensures precise shipping costs, and real-time visibility for improved process management without stopping material flow or manual handling.

Application Insights

Why has Process Control Been a Major Application in the Industrial Belt Scale Market?

Process Control: The segment held the largest market share in 2025, at 42.3%. The segment is dominating due to the central role of process control across all industries, delivering maximum benefits and reducing downtime. Maintaining a constant flow of materials is essential for product uniformity, which is easily achieved with an industrial belt scale, ensuring the final output meets the required product specification.

Blending/Batching: The segment is projected to grow at the fastest CAGR of 5.8% over the foreseeable period. The segment is increasing due to the benefits of industrial belt-scale blending/batching, such as monitoring the continuous flow rate of various materials and their total bulk weight as they move on a conveyor belt, providing accurate data for material handling and ensuring product quality.

Regional Insights

What is the Asia Pacific Industrial Belt Scale Market Size?

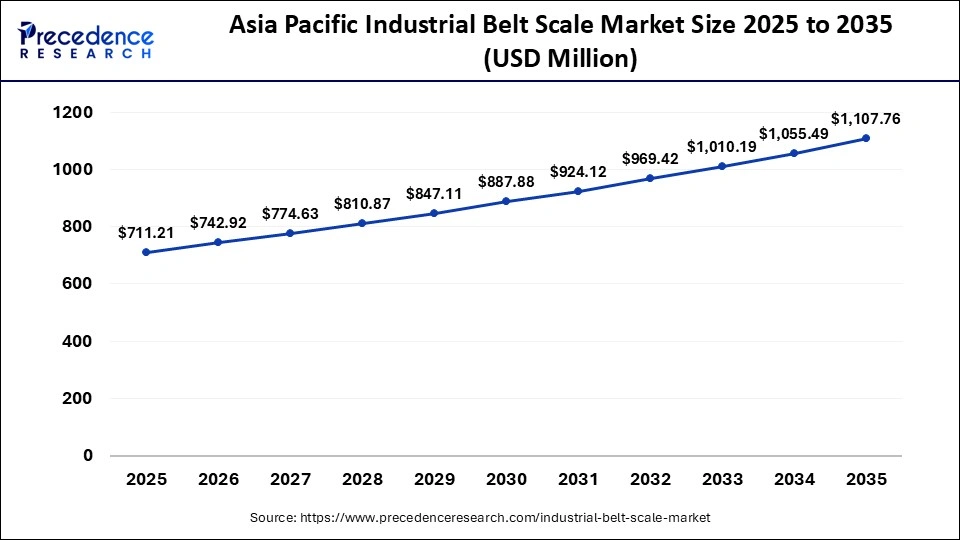

The Asia Pacific industrial belt scale market size is expected to be worth USD 1,107.76 million by 2035, increasing from USD 711.21 million by 2025, growing at a CAGR of 4.53% from 2026 to 2035.

What Made Asia Pacific the Strongest Region in the Industrial Belt Scale Market?

Asia Pacific held the largest market share of 45.3% in 2025, and the same region is projected to grow at a CAGR of 6.5% during the foreseeable period. The area is witnessing rapid growth driven by technological shifts in industrial belt-scale production, reflecting the pace of industrialization and its associated demand. Advanced weighing solutions are in demand to support the rapid evolution of manufacturing, logistics, and supply chain management, which are planning to integrate automation to improve efficiency.

Additionally, investment opportunities in the Asia Pacific region to expand the industrial belt-scale market are substantial, driven by infrastructure development and industrial automation. Partnerships with local distributors and manufacturers can support greater market penetration and the emergence of Industry 4.0 and smart factory initiatives across the Asia Pacific.

Japan Industrial Belt Scale Market Analysis

The country is a major contributor to the Asia-Pacific industrial belt market, owing to growing demand for accurate weighing systems in bulk material handling sectors, including mining, steel, cement, and food processing. Key manufacturers in Japan, such as Merrick, Yamato, and Siemens, are actively launching advanced products that integrate sensor technologies and IoT with digital load cell systems. Also, the Japanese industrial sector faces intense pressure to comply with stringent safety regulations, which is another vital driver of the market.

Why is the North America Industrial Belt Scale Market witnessing Significant Growth?

North America is witnessing significant growth driven by the increasing need for precise material handling equipment to minimize material wastage and the use of proper measurement solutions. Key reasons include strict regulations on material accountability and inventory management; the expansion of construction, mining, and heavy material-handling areas is further contributing to market growth.

Also, the growth in e-commerce and logistics operations is another leading driver of the market's development, as this sector requires efficient material handling and automation to streamline warehouse operations. The increasing adoption of smart technologies such as IoT sensors and AI-powered analytics presents a significant opportunity for the market.

U.S. Industrial Belt Scale Market

The U.S. is a frontier in the North America Industrial Belt Scale Market. It is driven by the increasing priority of process automation, regulatory compliance, and real-time monitoring in several sectors of North America, such as mining, mineral processing, and food and beverage production, by emphasizing batch continuity, traceability, and reducing product loss, highlighting broader changes towards data-based quality control. Also, emerging trends include IoT-based smart belts, predictive maintenance algorithms, and AI-based analytics, allowing operators to predict failures before they occur and continue supply chain flow.

What are the Growth Drivers for Europe's Industrial Belt-Scale Market?

The European Industrial Belt scale market is expected to grow steadily due to industrial automation in the region and strict regulatory compliance requirements for industrial safety. Several leading marketers are seeking benefits such as accurate, efficient weighing solutions while aiming to comply with stringent regulations and enhance product quality. The market is further propelling in the region due to the convergence of emerging technology providers and well-established manufacturers, contributing to a dynamic foundation for industrial growth.

UK Industrial Belt Scale Market Trends

The country is a major supporter of the European Industrial Belt market, and this growth is driven by the increasing adoption of automation in manufacturing and across various processing plants that must comply with stringent material quality and safety regulations while operating on the industrial floor. Another major factor is the rise in renewable energy projects and infrastructure development, such as biomass power plants (currently 266 in the UK) and waste-to-energy plants, which mandate reliable weighing systems in the region.

Why is the Middle East & Africa Industrial Belt Scale Market Notably Expanding?

The market is gradually expanding in the region due to the increasing industrial activity and major exports of specialized spare parts and monitoring devices. The growing adoption of smart weighing equipment integrated with IoT and AI, along with the expansion of Industry 4.0, is influencing the demand for industrial belt scales. Regulatory shifts are further supporting safety and quality standards, thereby increasing market growth in the region. Some of the region's top exporting countries are heavily influencing manufacturing expertise and directly shaping the markets' overall trajectory. For example,

- Turkey is benefiting from proximity to European markets and a wide industrial base.

- The UAE is mainly exporting customized systems and high-tech equipment.

- Egypt is leveraging regional trades.

South Africa Industrial Belt Scale Market Analysis

The region is a leading contributor to the market's growth, driven by its expansion in technological innovation and the robust capabilities of the local manufacturing base across leading industries. Also, sustainability targets are pushing South Africa to adopt an energy-efficient belt with minimal energy usage while maintaining high operational performance and industrial safety compliance, supporting the growth of the industrial belt-scale market.

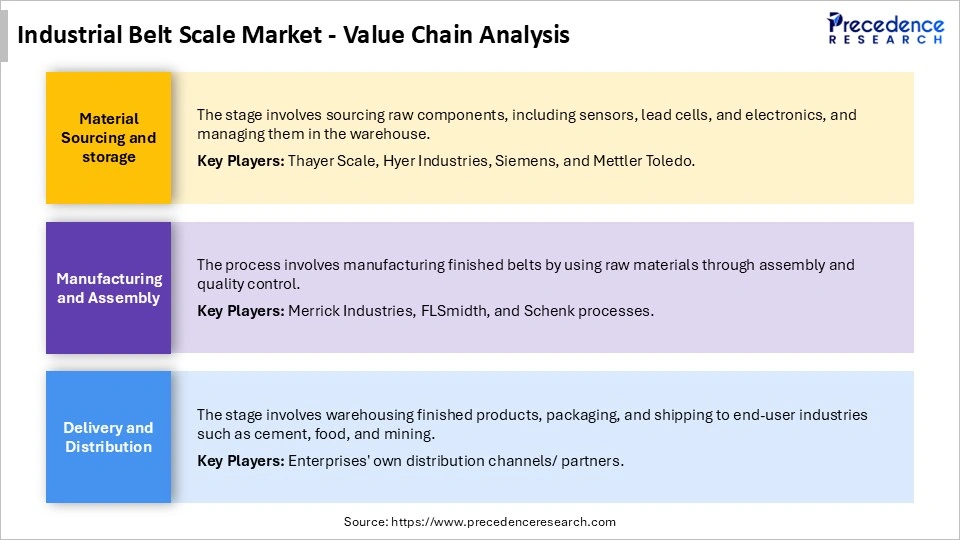

Industrial Belt Scale Market Value chain

Top Companies in Industrial Belt Scale Market & their Offerings

- Schenck Process

- Siemens

- Thermo Fisher Scientific

- Mettler-Toledo

- Rice Lake Weighing Systems

- Merrick Industries

- Thayer Scale

- Tecweigh/Tecnetics Industries

- Yamato Scale

- Minebea Intec

- Bizerba

- Kanawha Scales & Systems

- Sensortechnik

- JENIKE & JOHANSON

- Belt-Way Scales

Recent Developments

- In December 2025, A global leader in engineered bearings and power transmission solutions, Solve Industrial Motion Group, acquired a well-established provider of power drive belts D&D Global, popular for vertically integrated manufacturers of power drive belts.(Source: https://www.morningstar.com)

- In May 2025, TecWeigh introduced its portfolio of highly precise belt scales series name, HDS Heavy Duty S-type Loadcell, aiming to fulfill the increasing demand from the mining industry.(Source: https://www.powderbulksolids.com)

Segments Covered in the Report

By Idler/Scale Type

- Single-Idler

- Multi-Idler

- Dual-Idler

- Triple-Idler

- Fixed-Frame Belt Scale

- Modular Belt Scale

By Technology

- Electronic Load-Cell Belt Scales

- Smart/IoT-Enabled Belt Scales

- Mechanical Belt Scales

- Hybrid Digital-Mechanical

By Conveyor Belt Width

- Below 500 mm

- 500-1200 mm

- 1200-2000 mm

- Above 2000 mm

By End-Use Industry

- Mining

- Cement

- Steel & Metallurgy

- Aggregates & Quarrying

- Power Generation

- Food & Beverage

- Fertilizers & Chemicals

- Logistics & Warehousing

- Ports & Bulk Terminals

By Application

- Process Control

- Loadout/Load Verification

- Inventory & Stockpile Management

- Production Monitoring

- Blending/Batching

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting