What is the Machine Condition Monitoring Market Size?

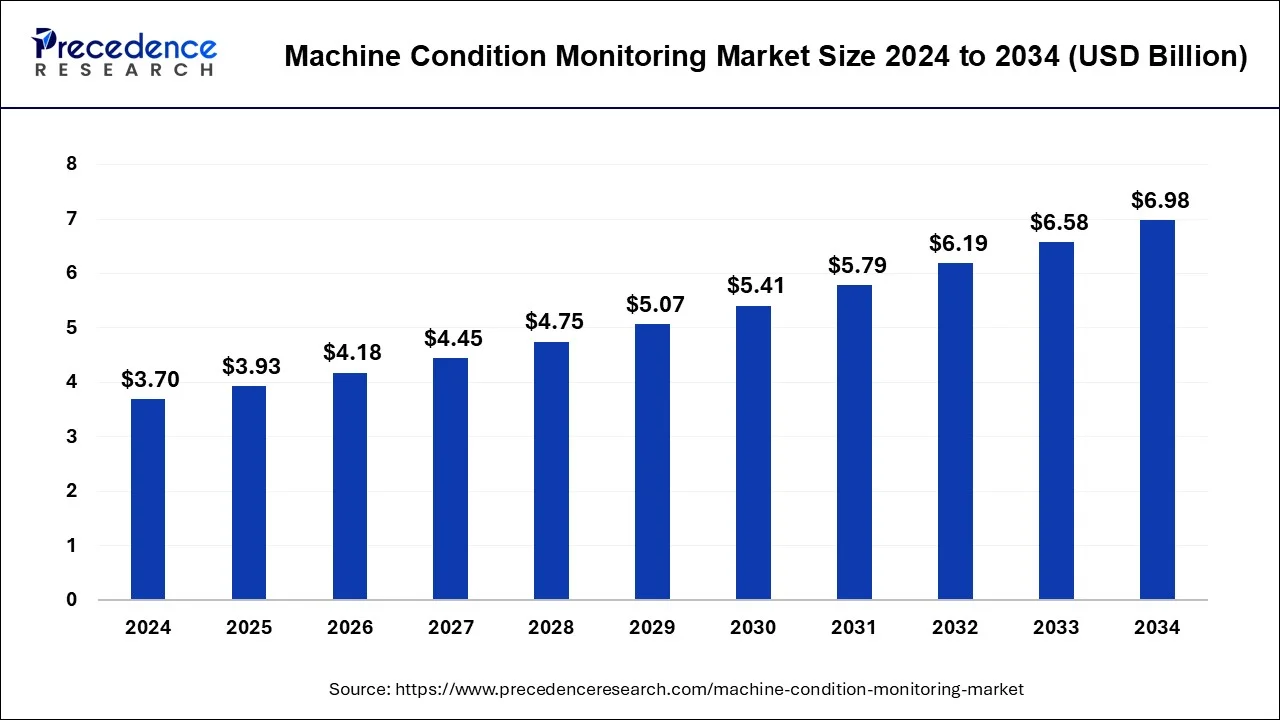

The global machine condition monitoring market size is calculated at USD 3.93 billion in 2025 and is predicted to increase from USD 4.18 billion in 2026 to approximately USD 7.37 billion by 2035, expanding at a CAGR of 6.49% from 2026 to 2035

Market Highlights

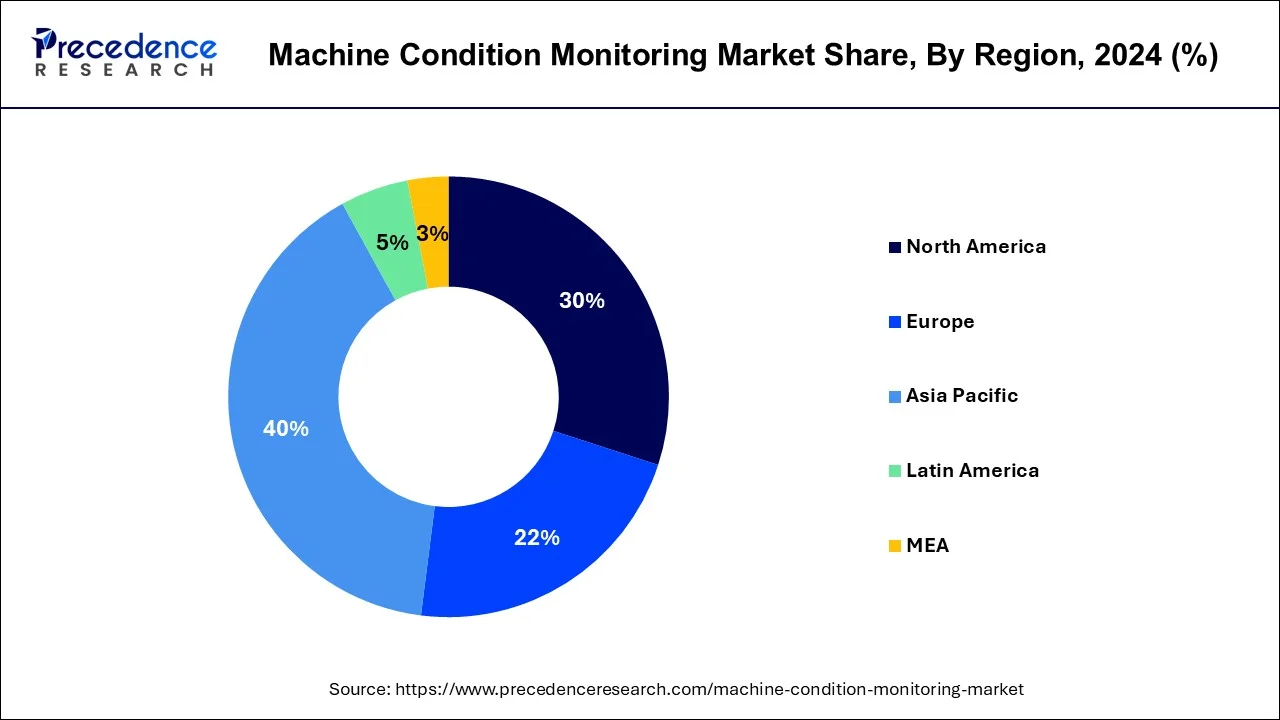

- Asia Pacific region accounted for a market share of 40% in 2025.

- The vibration monitoring technique segment has garnered a 27% revenue share in 2025.

Market Overview

Machine monitoring is generally explained as to monitor the condition of the machine after a certain period of time according to the schedule to maintain the productivity of the machine. Monitoring is basically to detect the temperature, humidity of the machine and the pressure in the equipments. Additionally it involves thermography, vibration of machine, oil analysis, and corrosion, to check the condition of the motor, and ultra sound. Machine monitoring is performed on a large scale to avoid the future problems and to maintain the consistency of the machine in performing the various task. It mainly monitors the unwanted aids produced by the machine for example unwanted ultra sound, excessive temperature, and vibration of the machine components may led to the damage of the inner components of the machine. Which gives good productivity and improves the safety of the machine.

Expansion of the digitalization worldwide with symbolic rising of the market due to increased population and rising demands affected the growth of the market. There is convincing growth seen in the development of oil and gas, manufacturing industries, food and beverages, automotive industries, medical sections, aerospace, defense and marine industries which has created an important growth rate in the market. Machine monitoring is done in both hardware and software components to end up the upcoming future problems in the machine. There are various developed technologies in this digitalization world wireless technologies developed. Such as usage of cloud computing, internet of things affected the market.

Awareness has been created related to the effects of the machine monitoring. Which supports the machine productivity to contribute towards the consistent growth of the market. Which gives the quality to the product and meet the needs as required by the machine for good productivity. The development of new technologies has geared the growth of the machine monitoring market. It gives the idea about if the machine is in good condition for the output and to determine the problems in the machine.

Market Outlook

- Industry Growth Overview: The machine condition monitoring industry is expected to grow at a significant rate from 2026 to 2035, as companies shift toward predictive maintenance strategies, adopt IoT and sensor-based diagnostics, and aim to boost operational efficiency. The growing focus on minimizing downtime and complying with evolving regulatory mandates further contributes to market growth.

- Global Expansion: The market is expanding worldwide due to increasing adoption of predictive maintenance, Industry 4.0 technologies, and the need to reduce equipment downtime and operational costs. Emerging regions offer significant opportunities driven by rapid industrialization, growing manufacturing sectors, and rising investments in smart factories and automation solutions.

- Major Investors: Major investors in the market include large industrial and technology corporations like General Electric, Emerson Electric, SKF, Honeywell, and Siemens, which invest in R&D for advanced sensors, analytics platforms, and predictive maintenance systems. These companies drive the market by developing and commercializing condition-monitoring solutions, leveraging their scale and domain expertise to accelerate adoption and advance innovations in IIoT and AI-based diagnostics.

- Startup Ecosystem: The market's startup ecosystem is thriving, with several specialized firms deploying IoT sensors, AI analytics, and cloud platforms to enable predictive maintenance across manufacturing and infrastructure. These innovative companies are backed by venture funding and strategic partnerships, anchoring themselves in Industry 4.0 trends and collaborating with established industrial players for rapid scaling and deeper market entry.

Machine Condition Monitoring Market Growth Factors

The major growth factors increasing due to various technologies developed and the machines used by the companies and engineers provided for the maintenance of the machine and the interaction made with the companies for the monitoring of the machine conditions. In manufacturing industries wide growth of the machine monitoring conditions due to large scale development of the products which require different plants for the operations. In health sector it is the rising development of the machine monitoring condition which require scheduled maintenance of the machine for the good productivity and to avoid future problems of the machine and improve the good output. Improved digitalization worldwide wireless machines developed with symbolic growth of the machine monitoring condition in the market.

Increasing awareness about the preventive measures to be taken for the maintenance of the machine which induce the market growth. The growth based on deployment type which include cloud and premises. Cloud is wireless which is 24*7 available with increased speed which contributed for the growth of the market because choices are rising towards the software technologies and the increased revenue of the market.

Machine monitoring condition enables to understand the defects in the machine and to keep the maintenance of the machine to run smoothly. Power generation is the expanding sector in the industries which has improved the growth of machine monitoring in power generation. Machine monitoring condition plays an important role in power generation. Oils and gases are also looking for the new developments which are effective and efficient and improved safety. Rising of the demands in metals and mining many companies take the automation for the maintenance of the machine which improves the productivity, decrease the cost and safety. The techniques used for the machine condition monitoring techniques which improved the market rate. The techniques are vibration monitoring technique which is widely used in machine monitoring vibration can be backward or forward motion by using components like motors, gears, bearings, and belts.

Thermography is the monitoring technique which is used to determine the temperature of the machine. Machine condition monitoring has several benefits involves misalignment of the component, lubrication problem, stress and many more. The oil analysis techniques used in fluids, lubricants. To determine the overheating, contaminated soils developments are taking place in the industries to meet the demand of the market. Moreover companies are in process of researching new technology to improve the growth and output. Metals and mining fields also increasing due to demand from the market for metal. Companies have adopted automation technologies to increase productivity and effectiveness in the market.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 3.93 Billion |

| Market Size in 2026 | USD 4.18 Billion |

| Market Size by 2035 | USD 7.37 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.49% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | By Monitoring Technique, By Offering, By Monitoring Process, By Deployment, By Industries, and By Application, and region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segment Insights

Monitoring Techniques Insights

Based on monitoring techniques which involves vibration monitoring, oil analysis, motor current analysis, thermography, corrosion monitoring, and ultrasound emission monitoring determining the defects in machines which enhanced the growth. Types based on offering like Hardware and software. Hardware has gained the largest market growth in the machine monitoring condition in the year 2021. Usage of the sensors, spectrometers, vibration analyzers, ultrasonic detectors, probes and anymore. Software's developed and adopted the components which gives scheduled maintenance and low cost. Divided based on the industry for example marine, health sectors, chemical companies, metals and mining, automotive, food and beverages and others. On the basis of deployment type outlook that is divided in to on premises and cloud. Cloud has contributed for the growth of revenue in machine monitoring condition in the year 2021. It has 24 hour services with increased speed and the services. Another type is Monitor process outlook which is segmented in to portable condition monitoring and online condition monitoring.

Application Insights

Application based on the machine monitoring condition has been segmented in to various industries for example food and beverages, pharmaceutical industries, metals and mining industries, heath sectors, automotive companies, aerospace companies, in power generation, oils and gases, chemical companies and other. As far as market has shown increased economy in the industry sectors with improving various technologies and development with high efficiency and productivity with long terms effects of the servicing has gained the attention of the market and gained a height. Cloud based solutions has increased the growth rate of the market.

Distribution Channel Insights

The machine condition monitoring has flawlessly improved the techniques which ensures good quality with affectivity and efficiency and good productivity. The certified technicians and engineers are called for the scheduled servicing of the machines to operate the machines smoothly with no disturbances in operating system. Increased automatic technologies wireless, internet of things. For some devices improved market trends and increased awareness of the machine servicing cost effective avoid future problems and run smoothly. Automobiles are majorly increasing sector. Technologies developed with improving vehicles facility with electrical vehicles.

Regional Insights

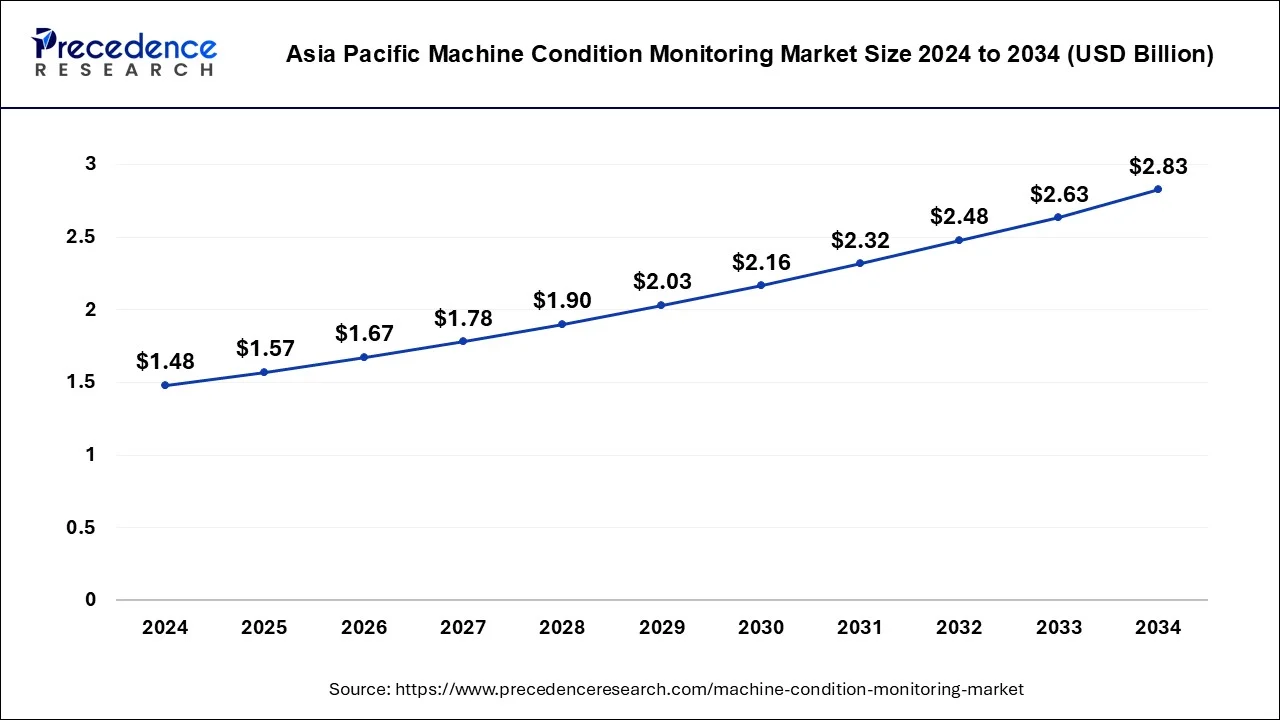

Asia Pacific Machine Condition Monitoring Market Size and Growth 2026 to 2035

The Asia Pacific machine condition monitoring market size reached USD 1.57 billion in 2025 and is anticipated to be worth around USD 2.99 billion by 2035, poised to grow at a CAGR of 6.65% from 2026 to 2035

What Made Asia Pacific the Dominant Region in the Machine Condition Monitoring Market?

Asia Pacific dominated the market with the largest share in 2025 because of rapid industrialization, widespread adoption of smart factory initiatives, and strong government support for automation. China led the market, driven by large-scale manufacturing infrastructure and policies such as "Made in China 2025", which prioritize predictive maintenance and IoT integration. Moreover, increased investment in industrial sectors across India and Japan bolstered demand for monitoring technologies to improve operational efficiency and reduce downtime. These factors together make Asia Pacific a center for advanced condition‑monitoring solutions.

India Machine Condition Monitoring Market Analysis

The market in India is driven by rapid industrialization, the integration of automation, and the adoption of smart technologies such as IoT, Industry 4.0, AI, and ML, which are transforming various industrial sectors. Ongoing innovations in machine control systems, such as GNSS and total station integration, 3D machine control, and cloud-based data sharing, are enhancing efficiency, accuracy, and sustainability at job sites. In May 2024, Schaeffler was recognized by Frost & Sullivan for its OPTIME ecosystem, which delivers smart lubrication and integrated condition monitoring solutions.

In October 2025, the Indian Register of Shipping (IRS) signed an MoU with the Neptunus Power Plant Services Pvt Ltd to introduce India's first home-grown condition monitoring system for marine diesel propulsion systems.

What Makes North America the Fastest-Growing Region?

North America is expected to grow at the fastest rate in the coming years, driven by its mature industrial base rapidly adopting predictive maintenance and Industry 4.0 technologies, supported by strong investments in IoT, cloud analytics, and real-time diagnostics. Stringent regulatory standards for safety and equipment reliability also drive the adoption of advanced monitoring systems across key sectors such as aerospace, manufacturing, and energy. The U.S. leads this regional growth, leveraging its technological leadership, high R&D spending, and widespread deployment of smart sensors and AI-enabled condition monitoring platforms.

U.S. Machine Condition Monitoring Market Analysis

The market in the U.S. is growing due to increasing adoption of predictive maintenance and smart manufacturing technologies aimed at reducing downtime and operational costs. Rising investments in Industry 4.0, IoT-enabled sensors, and data analytics are enabling real-time monitoring and improved equipment performance across industries such as manufacturing, energy, and transportation. Additionally, the focus on sustainability, safety, and regulatory compliance is driving demand for advanced condition monitoring solutions that enhance asset reliability and operational efficiency.

How Big is the Success of Europe in the Market?

Europe is experiencing rapid growth in the machine condition monitoring market due to the swift adoption of Industry 4.0, the growing emphasis on predictive maintenance to minimize downtime, and strict regulatory standards for equipment safety. Government backing for digital transformation, increased factory automation, and expanded 5G connectivity that enable real-time analytics further boost large-scale adoption across various industrial sectors. Germany is a major contributor to the European market, thanks to its highly developed industrial automation sector and strong presence of manufacturing facilities.

What Potentiates the Growth of the Latin American Machine Condition Monitoring Market?

In Latin America, market growth is driven by increasing demand for automation, especially in manufacturing and mining sectors, expanding investments in digital infrastructure and IoT deployments, rising labor-cost pressures that encourage adoption of predictive maintenance, and regional government incentives promoting Industry 4.0 transformation across the region. Brazil is a major contributor to the market due to its large industrial base, especially in sectors like mining, energy, and manufacturing, and growing investments in automation.

How Big is the Opportunity for the Market in the Middle East and Africa?

The Middle East and Africa (MEA) present significant opportunities for the machine condition monitoring market as energy, mining, and infrastructure projects adopt IoT-enabled predictive maintenance. Governments support smart-city and Industry-4.0 initiatives, and companies invest in remote monitoring to maintain uptime in harsh environments. Expanding digital infrastructure, along with cloud providers and 5G rollouts, further drive adoption across industrial and utility sectors, complemented by local workforce upskilling programs.

The UAE leads the Middle East and Africa in the machine condition monitoring market due to proactive Industry 4.0 and 4IR strategies, extensive digitization in the oil, gas, and utilities sectors, and strong public funding and incentives for smart manufacturing. Advanced 5G and cloud infrastructure, the presence of global technology hubs attracting vendors, and widespread adoption of digital twins, remote monitoring, and predictive maintenance solutions by large enterprises further reinforce the UAE's leadership in the region.

Value Chain Analysis

- Raw Material Procurement (Silicon Wafers, Gases)

Suppliers procure electronic components, sensors, semiconductors, vibration transducers, and signal-processing materials for the production of machine condition-monitoring hardware modules.

Key Players:Texas Instruments, Analog Devices, Bosch Sensortec, STMicroelectronics, TE Connectivity, and Honeywell. - Wafer Fabrication / Hardware & Firmware Manufacturing

Manufacturers produce semiconductor wafers, assemble sensor boards, embed firmware for data collection, and integrate wireless or wired communication modules into condition monitoring devices.

Key Players: Siemens, SKF, Emerson Electric, Rockwell Automation, Br�el & Kj�r Vibro, National Instruments, and Fluke Corporation. - Distribution to OEM and System Integrators

Finished equipment is delivered to industrial OEMs and system integrators, who embed sensors into manufacturing assets and deploy software platforms in client plants.

Key Players: ABB, Schneider Electric, GE Digital, Honeywell Process Solutions, Yokogawa Electric, and Mitsubishi Electric. - Life Cycle Support and Recycling

Vendors offer calibration, remote diagnostics, firmware updates, analytics services, refurbishment, and recycling of sensors and electronic modules at end-of-life.

Key Players: ATS Global, TUV S�D, SGS, Veolia Environmental Services, Umicore Recycling, and IT Renew.

Machine Condition Monitoring Market Companies

- SKF (Sweden)

- Emerson Electric (US)

- General Electric (US)

- Honeywell International (US)

- National Instruments (US)

- Parker Hannifin Corporation

- Rockwell Automation, Inc.

- Schaeffler AG

- Fortive Corporation (Fluke Corporation)

- ALS Limited

Recent Developments

- In June 2025, Alfa Laval launched Clariot�, an AI-based condition monitoring solution for hygienic process equipment, providing actionable insights to enhance uptime and optimize resource efficiency. (Source:https://www.alfalaval.com)

- In January 2020, Emerson launched the software of corrosion called Plantweb Insightline corrosion which support oil and gas industry to determine and analysis of the data.

- In January 2021, SKF interacted to Solvang, to launch fleet of tankers maintenance to invest in to new system for monitoring vibration, and enlight.

- In April 2021, Rockwel Automation, Comau Collaborated to deliver instruments or devices required for manufacturing and to improve the efficiency and productivity.

Segments Covered in the Report

By Monitoring Technique

- Thermography

- Vibration Monitoring

- Motor Current Analysis

- Corrosion Monitoring

- Oil Analysis

- Ultrasound Emission

By Offering

- Hardware

- Vibration & Infrared Sensors

- Ultrasound Detectors

- Spectrum Analyzers

- Corrosion Probes

- Others

- Software

- Data Integration

- Order Tracking Analysis

- Others

By Monitoring Process

- Portable Condition Monitoring

- Online Condition Monitoring

By Deployment

- Cloud

- Premises

By Industries

- Marine

- Health

- Oil and Gas

- Power generation

- Metals and mining

- Automotive

- Chemicals

- others

By Application

- Pharmaceuticals

- Food & beverages

- Automobiles

By Region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content