Metal and Ceramic Injection Molding Market Size and Forecast 2025 to 2034

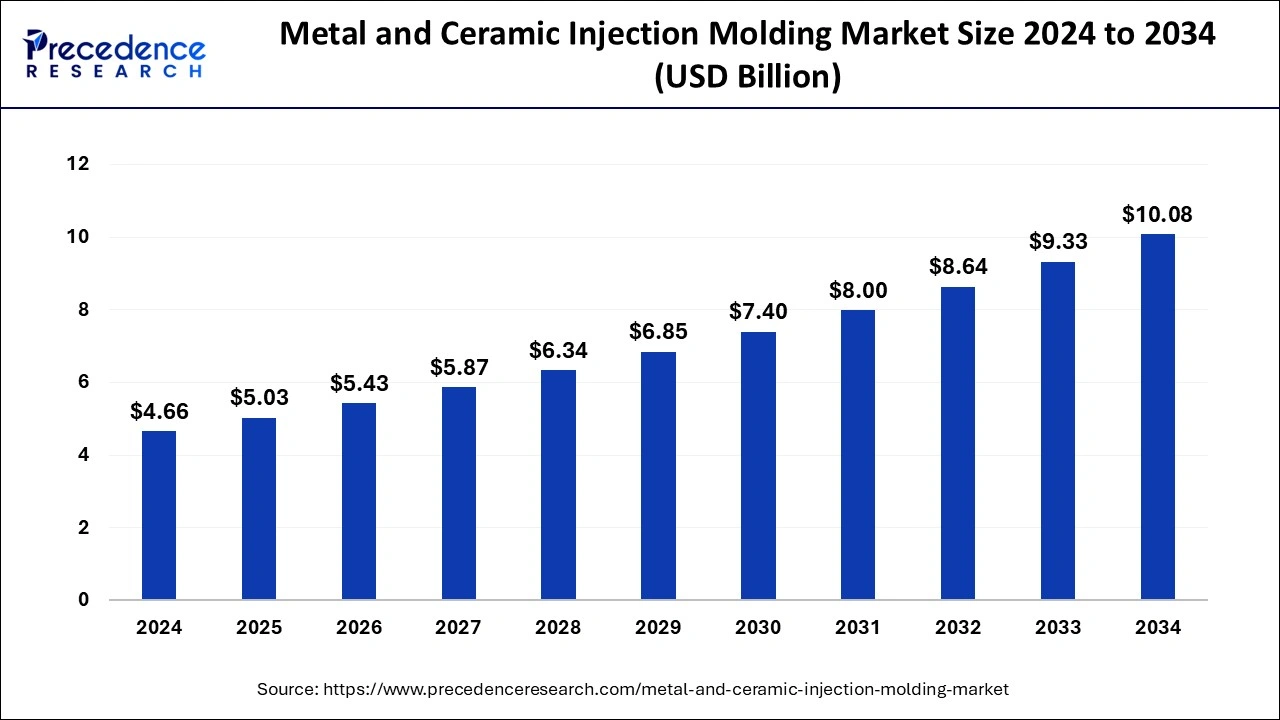

The global metal and ceramic injection molding market size was worth around USD 4.66 billion in 2024 and is anticipated to reach around USD 10.08 billion by 2034, growing at a CAGR of 8.03% from 2025 to 2034. Significant investment in infrastructure, construction as well as the automotive and aviation sector has led to the expansion of the metal and ceramic injection molding market.

Metal and Ceramic Injection Molding Market Key Takeaways

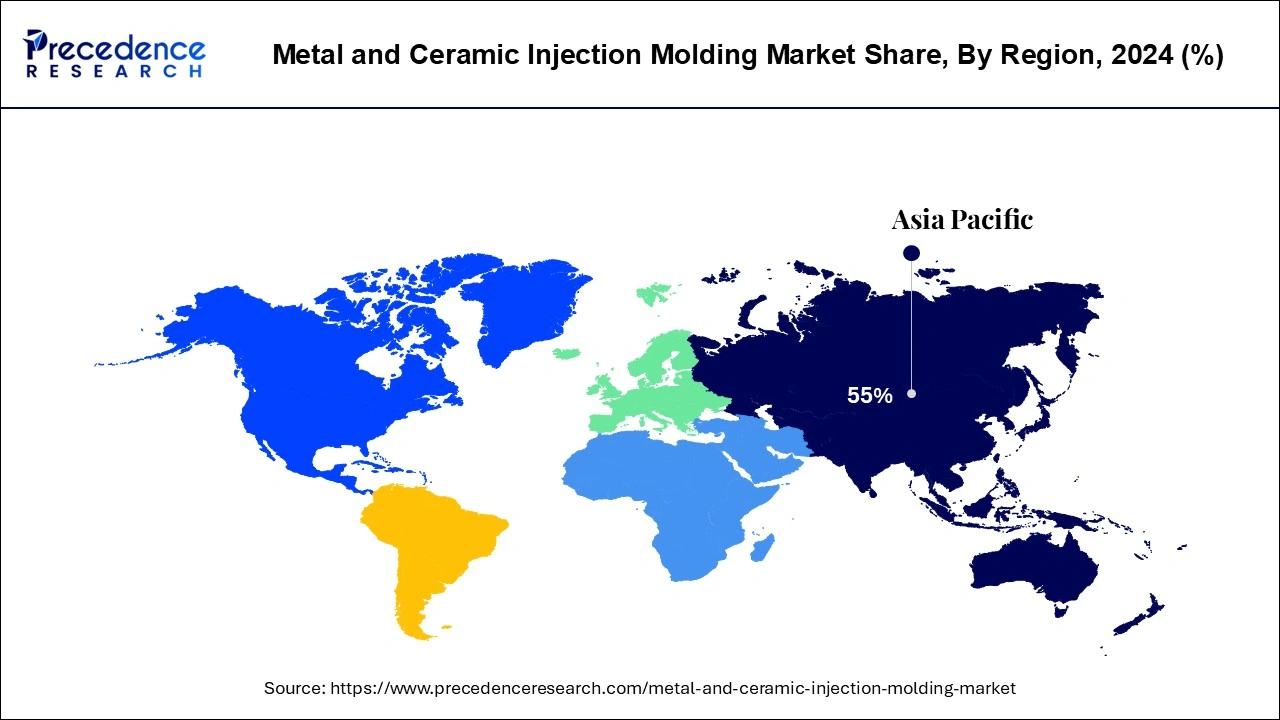

- Asia Pacific dominated the global market with the largest market share of 55% in 2024.

- North America is projected to expand at the notable CAGR during the forecast period.

- By type, the stainless steel segment contributed the highest market share in 2024.

- By type, the alumina segments is estimated to be the fastest-growing segment during the forecast period.

- By end user, the automotive segment captured the biggest market share in 2024.

- By end user, the medial segment is expected to grow at a significant CAGR from 2025 to 2034.

How is AI Changing Metal and Ceramic Injection Molding?

Artificial intelligence (AI) significantly transforms this molding by optimizing process parameters, reducing production waste, and predicting defects. This technology allows real-time monitoring and adaptive control ensuring fewer errors and more accurate outcomes during molding. AI contributes to shortened time-to-market for new products. AI plays an important role in this molding in optimizing energy usage. AI also helps to reduce scrap, machine downtime, and unnecessary energy consumption. These factors help the growth of the metal and ceramic injection molding market.

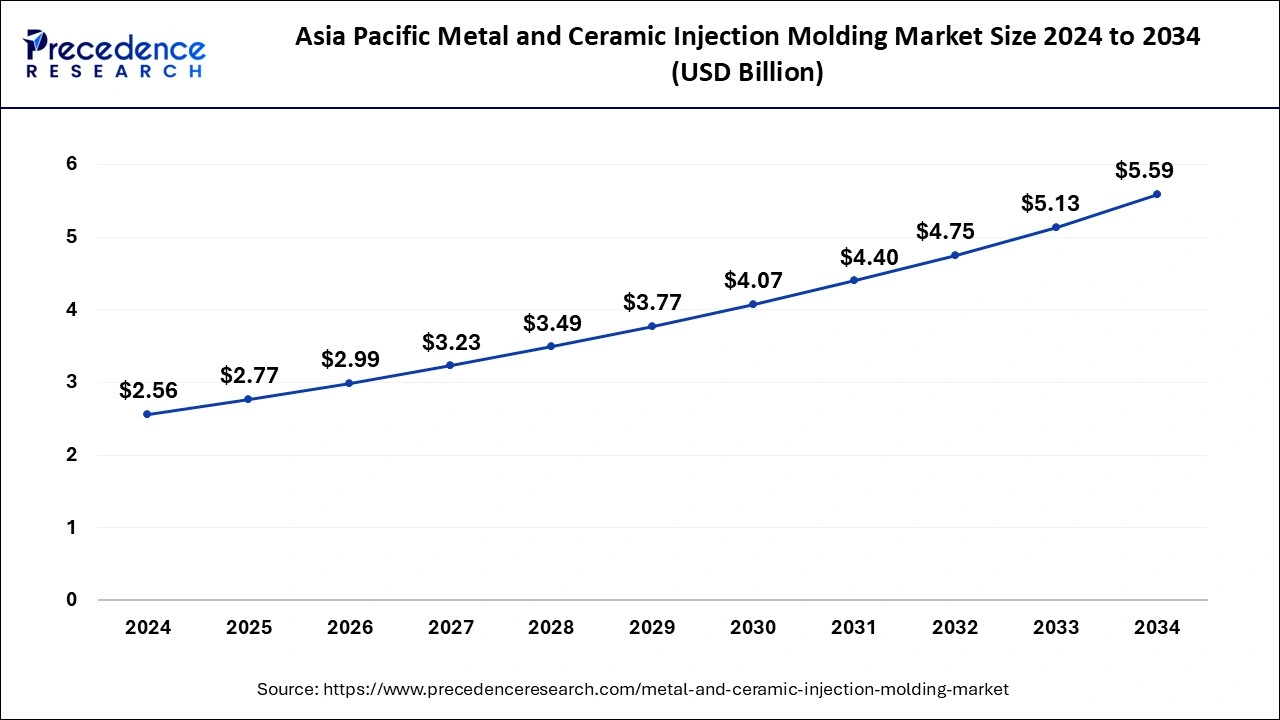

Asia Pacific Metal and Ceramic Injection Molding Market Size and Growth 2025 to 2034

The U.S. metal and ceramic injection molding market size was exhibited at USD 2.56 billion in 2024 and is projected to be worth around USD 5.59 billion by 2034, growing at a CAGR of 8.12% from 2025 to 2034.

Asia Pacific dominated the growth of the metal and ceramic injection molding market. Countries like South Korea, Taiwan, Japan, China, and India are well-known for the production of various consumer goods like consumer electronics. Moreover, Asia Pacific is the manufacturing hub of the globe. The easy and cheap availability of the factors of production and favorable government policies that promotes the region as manufacturing center has resulted in the increased demand for the metal and ceramic injection molding across various industries. Moreover, the surging demand for the electric vehiclesand healthcare devices is expected to further propel the growth of the market in the forthcoming years. Furthermore, the rapidly growing demand for the miniature industrial equipment in the Asia Pacific is significantly boosting the growth of the metal and ceramic injection molding market.

North America is expected to grow at a considerable rate. The rapid industrialization in the past and huge demand for the various healths and industrial equipment in the region has fostered the market growth. The growing demand for the automotive products andmedical devicesis expected to drive the growth of the metal and ceramic injection molding market in North America. Moreover, the surging investments in the adoption of various automated technologies and high-end electronic products are expected to drive the market growth in the forthcoming future.

Metal and Ceramic Injection Molding Market Growth Factors

- The metal and ceramic injection molding is extensively used in the manufacturing of products that involve huge strength, enhanced surface finishing, and complex structures. The surging demand for minimally invasive cosmetic surgeries among the global population is expected to drive market growth significantly during the forecast period.

- Moreover, the surging investments by the manufacturers are contributing towards the growth of the market. Ceramic and metal molding is a complex process that is managed with high accuracy to provide a particular product to the end user industry.

- The materials such as stainless steel, low-alloy steel, titanium alloys, and soft magnetic alloys are extensively used to manufacture certain end products across different industries. Therefore, the rising demand for electronic devices and medical equipment across the globe is driving the demand for metal and ceramic injection molding.

- The most prominent applications include electronic gadgets, medical equipment, and components of automotive. The rapid urbanization in developing regions is a major factor that is expected to drive the growth of the global metal and ceramic injection molding market.

- The burgeoning demand for production in the automotive industry coupled with the increased demand for metal and ceramic injection molding technology is spurring the growth of the global metal and ceramic injection molding market.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 5.03 Billion |

| Market Size by 2034 | USD 10.08 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 8.03% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, End User,Distribution Channel,and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Type Insights

The global metal and ceramic injection molding market was dominated by the stainless steel segment in 2022. The extensive demand for the stainless steel molded products in the various industries such as automotive, general industries, and aerospace industries have significantly boosted the demand for the stainless steel segment. Moreover, the easy availability of high quality stainless steel and its durability, higher strength, flexibility, and rust resistant properties of the stainless steel has fostered the demand among the end use industries.

On the other hand, the alumina products are estimated to be the fastest-growing segment during the forecast period. The light-weight, durability, strength, flexibility, low cost, and low machinability are the major factors that drive the demand for the alumina products in the electronics and automotive industries. The surging demand for the alumina products in the automotive industry is expected to drive the growth of this segment.

End User Insights

The automotive segment dominated the global metal and ceramic injection molding market in 2020. The massive growth of the automotive industry in the past decades has fueled the growth of the metal and ceramic injection molding market. There is huge demand for the injection molded miniature products in the automotive industry. The complex engine components, locking mechanisms, and electronic systems are made using the metal and ceramic injection molding products, which has significantly contributed towards the growth of this segment in the past few years.

The medial equipment is estimated to be the fastest-growing segment during the forecast period. The growing number of patients owing to the surging prevalence of various chronic diseases across the globe is exponentially driving the growth of the metal and ceramic injection molding market owing to its growing demand for the production of numerous medical equipment.

Metal and Ceramic Injection Molding Market Companies

- Advanced Materials Technologies Pte. Ltd.

- Form Technologies Company

- CN Innovations Holdings Ltd.

- Akron Porcelain & Plastics Co.

- ARC Group Worldwide, Inc.

- Kinetics Climax Inc.

- CMG Technologies

- PSM Industries

- Nippon Piston Ring Co Ltd.

- Abbot Furnace Company

Latest Announcement by Industry Leaders

- In May 2024, the event which include a pavilion showcasing Japan's Metal Injection Molding Industry was announced by the organizers of World PM2024.

Recent Developments

- In October 2024, a new vertically integrated metal injection molding (MIM) service was launched by Biomerics, the vertically integrated medical device contract manufacturer in the interventional device market.

- In October 2024, Osprey HWTS 50 hot work tool steel-based AM, Hot Isostatic Pressing (HIP), and metal injection molding (MIM) was launched by Sandvik.  Osprey HWTS 50 improves the processability in Laser Powder Bed Fusion (L-PBF), lowering the susceptibility of cold cracking compared with conventional H-class hot work tool steels. Typical applications include high-pressure die casting dies, injection molds, and hot forming tools.

Segments Covered in the Report

By Type

- Iron & Steel

- Stainless Steel

- Copper

- Alumina Products

- Zirconia

- Others

By End User

- Aerospace

- Automotive

- Industrial Machinery

- Medical Equipment

- Consumer Goods

- Electronics

- Others

By Distribution Channel

- Online Stores

- Offline Stores

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting