Metaverse in Manufacturing Market Size and Forecast 2025 to 2034

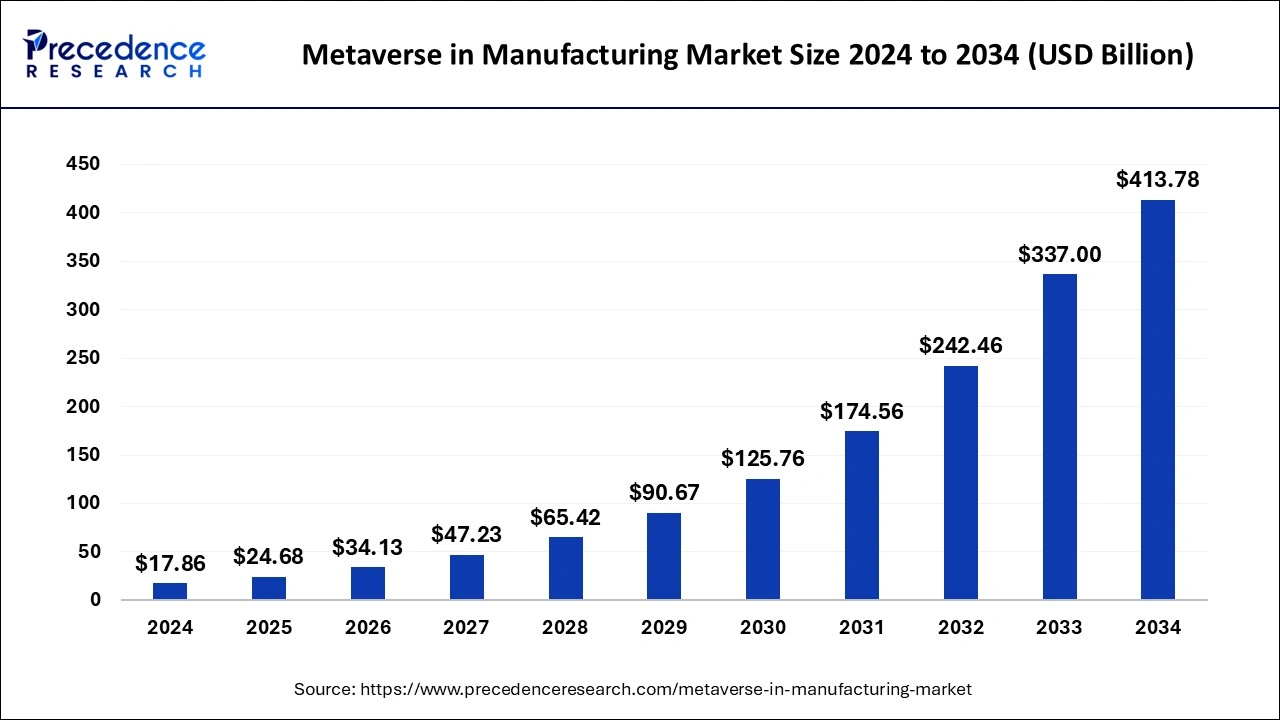

The global metaverse in manufacturing market size was estimated at USD 17.86 billion in 2024 and is predicted to increase from USD 24.68 billion in 2025 to approximately USD 413.78 billion by 2034, expanding at a CAGR of 36.93% from 2025 to 2034.

Metaverse in Manufacturing MarketKey Takeaways

- The global metaverse in manufacturing market was valued at USD 17.86 billion in 2024.

- It is projected to reach USD 413.78 billion by 2034.

- The metaverse in manufacturing market is expected to grow at a CAGR of 36.93% from 2025 to 2034.

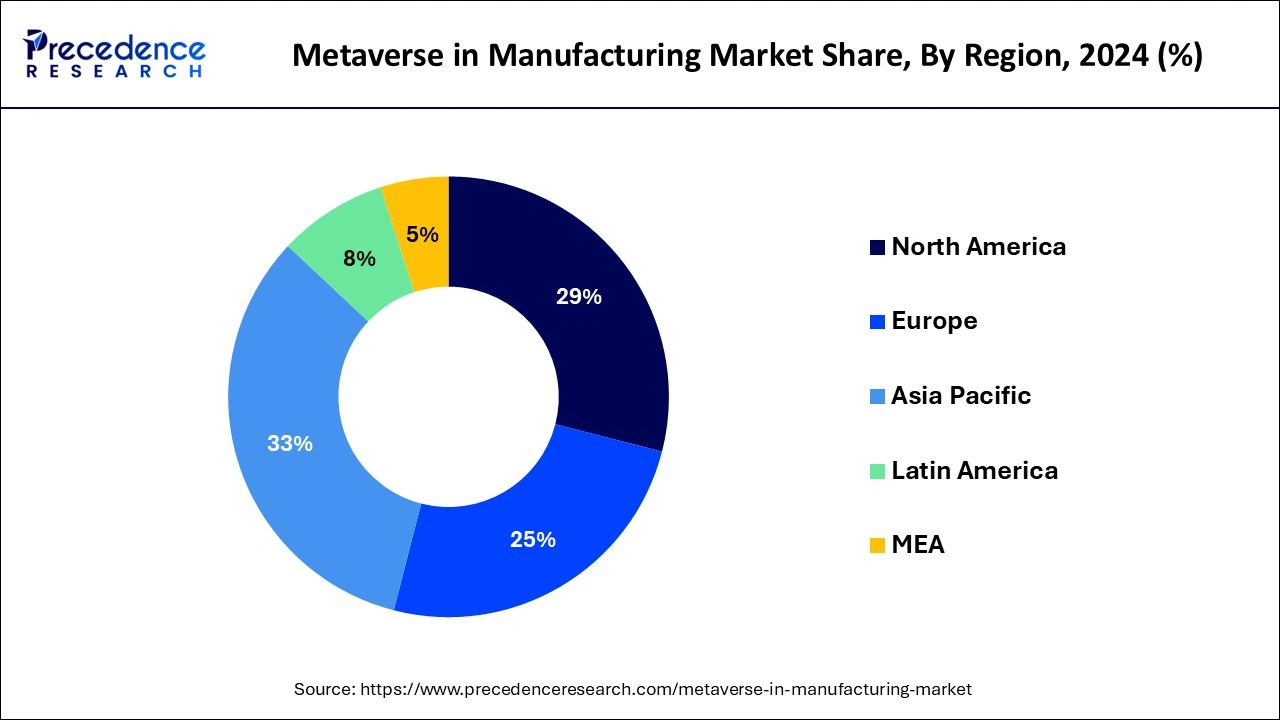

- Asia-Pacific contributed more than 33% of market share in 2024.

- North America is estimated to expand the fastest CAGR between 2025 and 2034.

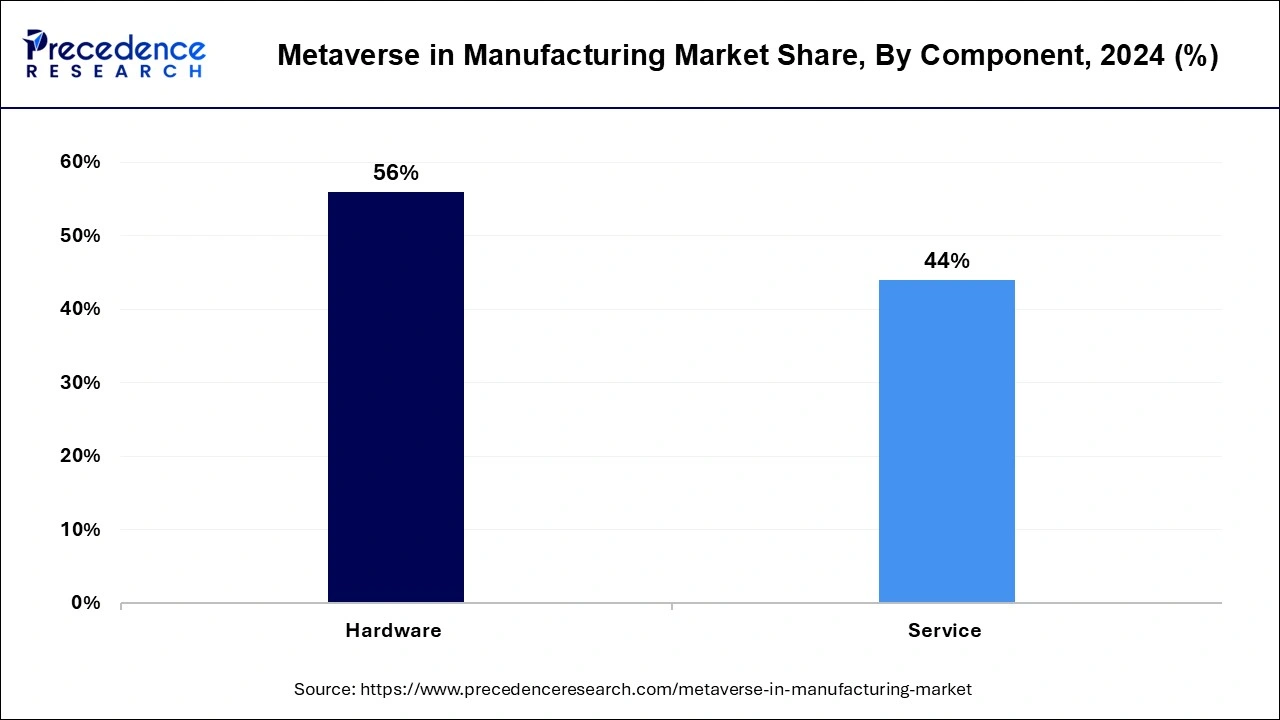

- By component, the hardware segment has held the largest market share of 56% in 2024.

- By component, the service segment is anticipated to grow at a remarkable CAGR of 41.12% between 2025 and 2034.

- By application, the product designing and development segment generated over 24% of the market share in 2024.

- By application, the virtual warehouse segment is expected to expand at the fastest CAGR over the projected period.

- By technology, the VR segment generated over 39% of the market share in 2024.

- By technology, the MR segment is expected to expand at the fastest CAGR over the projected period.

Asia PacificMetaverse in Manufacturing Market Size and Growth 2025 to 2034

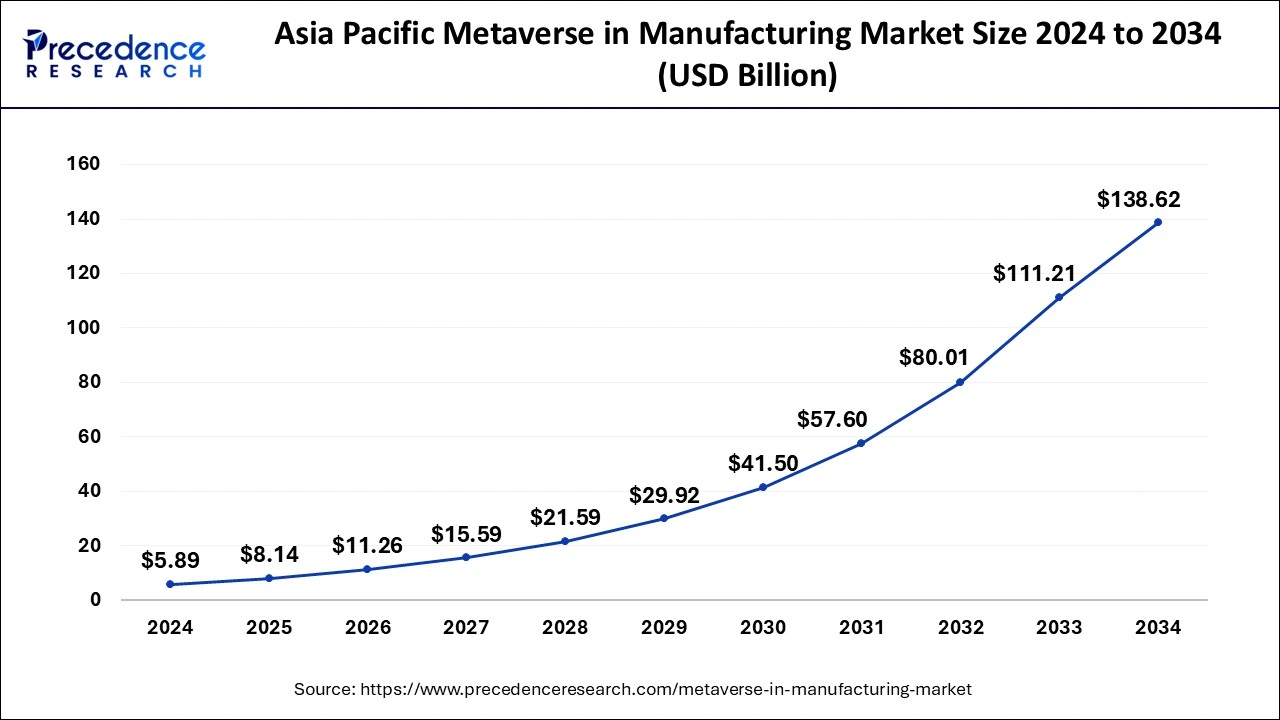

The Asia Pacific metaverse in manufacturing market size was exhibited at USD 5.89 billion in 2024 and is projected to be worth around USD 138.62 billion by 2034, growing at a CAGR of 37.14% from 2025 to 2034.

In 2024, Asia-Pacific held a share of 33% in the metaverse in manufacturing market due to its burgeoning industrial landscape, rapid technological adoption, and robust economic growth. The region's manufacturing sector is embracing digital transformation, driving demand for innovative solutions like the metaverse to enhance productivity and efficiency. Government initiatives supporting Industry 4.0, coupled with a large pool of skilled labor, position Asia-Pacific as a major player in adopting and integrating metaverse technologies, contributing to its substantial market share in the manufacturing sector.

The metaverse in manufacturing is poised for rapid expansion in North America due to its advanced technological infrastructure, widespread digital adoption, and a robust manufacturing sector. With companies increasingly prioritizing digital transformation, the metaverse offers innovative solutions for training, collaboration, and process optimization. The region's favorable regulatory environment, coupled with a strong emphasis on Industry 4.0, positions North America as a key player in adopting metaverse technologies, fostering rapid growth and integration within the manufacturing landscape.

Meanwhile, Europe is experiencing notable growth in the metaverse in the manufacturing market due to a confluence of factors. The region's commitment to Industry 4.0, emphasis on technological innovation, and a robust manufacturing ecosystem drive adoption. European manufacturers recognize the metaverse's potential to enhance productivity, collaboration, and training. Additionally, supportive policies and investments in digital infrastructure contribute to the market's expansion. As companies seek competitive advantages, the metaverse's transformative capabilities position Europe as a significant player in leveraging virtual and augmented reality technologies for manufacturing excellence.

Market Overview

The "metaverse in manufacturing" refers to the integration of augmented reality and virtual reality technologies into the manufacturing industry. In this digital space, manufacturers can create immersive, interconnected environments that enhance various aspects of their operations. Workers can use augmented reality glasses or virtual reality headsets to visualize complex assembly processes, access real-time data, and receive step-by-step instructions, improving efficiency and reducing errors. Collaboration among teams becomes more seamless as individuals from different locations can virtually join the same workspace. Additionally, the metaverse in manufacturing enables the simulation of product prototypes, allowing for thorough testing before physical production. Overall, the metaverse in manufacturing represents a transformative approach that leverages virtual and augmented reality to streamline processes, enhance collaboration, and optimize production in the modern industrial landscape.

Metaverse in Manufacturing Market Data and Statistics

- According to a study by Deloitte, companies adopting metaverse technologies in manufacturing reported up to a 30% improvement in productivity and a significant reduction in operational errors.

- A survey by PwC found that 78% of manufacturing executives believe that metaverse applications facilitate better collaboration among global teams, leading to faster decision-making processes.

- In a report by McKinsey, it was noted that metaverse-based training programs in manufacturing have resulted in a 25% faster skill acquisition among employees, reducing the time required for onboarding.

- The use of metaverse simulations in product design has led to a 20% decrease in prototype iterations, as indicated by a case study from a leading automotive manufacturer.

Metaverse in Manufacturing Market Growth Factors

- The metaverse in manufacturing enables immersive training scenarios, allowing workers to acquire new skills and familiarize themselves with complex machinery and processes in a virtual environment. This leads to a more skilled and adaptable workforce, boosting overall productivity.

- Manufacturers can utilize the metaverse for digital prototyping and simulation, reducing the need for physical prototypes. This accelerates the product development cycle, lowers costs, and allows for more efficient testing of designs, contributing to faster innovation and time-to-market.

- The metaverse facilitates real-time collaboration among global teams. Engineers, designers, and experts from different locations can collaborate seamlessly in a virtual environment, fostering innovation and speeding up decision-making processes across distributed manufacturing networks.

- Metaverse technologies enhance supply chain visibility and coordination. Manufacturers can optimize logistics, reduce lead times, and improve overall supply chain efficiency. This results in cost savings and a more resilient supply chain capable of adapting to dynamic market conditions.

- Metaverse applications leverage augmented reality (AR) for enhanced human-machine interaction. Workers can receive real-time information and guidance through AR devices, improving operational efficiency, reducing errors, and ensuring a safer and more intuitive working environment.

- The metaverse allows manufacturers to create virtual showrooms and interactive product experiences. This personalized engagement with customers enhances brand loyalty and enables manufacturers to gather valuable insights into consumer preferences, leading to the development of tailored and in-demand products.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 36.93% |

| Market Size in 2025 | USD 24.68 Billion |

| Market Size by 2034 | USD 413.78 Billion |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Component, Application, and Technology |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Worker safety and risk mitigation

- Instances of workplace accidents in manufacturing have shown a notable decline of 18% after the introduction of metaverse-based safety training programs, according to a safety audit across multiple manufacturing plants.

Worker safety and risk mitigation play a pivotal role in driving the demand for the metaverse in the manufacturing market. By integrating metaverse technologies, manufacturers can create virtual environments for realistic safety training simulations. This immersive training equips workers with the skills to navigate potential hazards and emergencies, significantly reducing the occurrence of workplace accidents. The ability to simulate dangerous scenarios in a controlled virtual space enhances employee preparedness and responsiveness.

Moreover, the metaverse enables real-time monitoring of worker activities through augmented reality (AR) devices, ensuring compliance with safety protocols. This proactive approach minimizes risks, as supervisors can identify and address potential safety issues promptly. As industries prioritize worker well-being and compliance with stringent safety standards, the metaverse becomes a transformative tool for fostering a culture of safety, ultimately boosting the market demand for its adoption in the manufacturing sector.

Restraint

Regulatory and compliance challenges

Regulatory and compliance challenges pose significant restraints to the market demand for the metaverse in manufacturing. The manufacturing sector is subject to strict regulations governing safety, quality control, and data privacy. Implementing metaverse technologies must align with these standards to ensure legal compliance, but navigating the complex regulatory landscape can be daunting for manufacturers. Meeting compliance requirements often demands meticulous documentation, rigorous testing, and adherence to industry-specific guidelines.

Failure to address these regulatory concerns may result in legal repercussions and financial penalties. Manufacturers, therefore, may hesitate to fully embrace the metaverse until comprehensive regulatory frameworks are established and metaverse solutions are developed with compliance in mind. This regulatory uncertainty acts as a barrier, slowing down the widespread adoption of metaverse technologies in the manufacturing market.

Opportunity

Augmented reality (AR) in maintenance and repairs

Augmented Reality (AR) in maintenance and repairs is a transformative aspect of the metaverse in manufacturing, creating significant opportunities in the market. By overlaying digital information onto the physical world, AR enhances the efficiency and accuracy of maintenance tasks. Technicians equipped with AR devices can access real-time information, step-by-step instructions, and visual cues, reducing the time required for repairs.

- A notable case study by Boeing demonstrated a 25% reduction in assembly time through the implementation of AR technology, highlighting the tangible impact on operational efficiency.

This technology not only streamlines the maintenance process but also contributes to cost savings and minimized downtime. The metaverse's AR applications empower manufacturing companies to improve the skill set of their workforce, enhance equipment reliability, and ultimately drive a more agile and responsive approach to maintenance and repairs. As a result, the integration of AR in maintenance and repairs presents a compelling opportunity for manufacturers to elevate their operational capabilities and deliver more reliable and efficient production processes.

Component Insights

The hardware segment held the highest market share at 56% in 2024. In the metaverse in manufacturing, the hardware component encompasses the physical devices and equipment essential for immersive experiences. This includes augmented reality (AR) glasses, virtual reality (VR) headsets, sensors, and other peripherals. Recent trends indicate a surge in the development of more lightweight, ergonomic, and powerful hardware, enhancing user comfort and overall system performance. The focus on creating user-friendly and technologically advanced hardware is crucial for driving widespread adoption of metaverse technologies in the manufacturing sector, as it directly influences the quality and effectiveness of virtual and augmented reality experiences.

The service segment is anticipated to grow rapidly at a significant CAGR of 41.12% during the projected period. In the metaverse in manufacturing market, the service segment encompasses a range of offerings crucial for the deployment and maintenance of metaverse solutions. This includes consulting, integration, support, and training services. As the market evolves, there is a growing trend towards specialized consulting services to aid companies in formulating effective metaverse strategies. Additionally, demand for training services is rising as manufacturers seek to upskill their workforce for seamless metaverse integration, reflecting the ongoing emphasis on skill development in the industry.

Application Insights

The product designing and development segment has held a 24% market share in 2024. In the metaverse in manufacturing, the product designing and development segment involves utilizing virtual environments for digital prototyping, simulations, and collaborative design processes. This trend leverages the metaverse's capabilities to enhance creativity, reduce time-to-market, and streamline collaboration among geographically dispersed teams. Manufacturers are increasingly adopting metaverse technologies for product design, allowing for real-time iterations and simulations, ultimately optimizing the product development lifecycle. This segment showcases a growing trend towards more efficient and collaborative approaches to product designing within the metaverse in the manufacturing market.

The virtual warehouse segment is anticipated to witness rapid growth over the projected period. In the metaverse in the manufacturing market, the virtual warehouse segment involves creating digital replicas of physical warehouses. This application allows manufacturers to optimize inventory management, track assets, and simulate logistics operations in a virtual environment. The trend in this segment includes the use of virtual warehouses for real-time supply chain visualization, reducing storage costs, and improving overall operational efficiency. The metaverse's virtual warehouse applications enable manufacturers to test and optimize their logistics strategies, leading to more streamlined and responsive warehouse management.

Technology Insights

The VR segment has held a 39% market share in 2024.In the metaverse in manufacturing, the Virtual Reality (VR) segment involves creating simulated environments for immersive experiences. Utilizing VR technology, manufacturers enable workers to undergo realistic training simulations and visualize complex processes. Trends in VR for the metaverse include the adoption of VR headsets for remote collaboration, digital prototyping, and enhanced product design. As manufacturers seek to leverage the metaverse's potential, VR technologies continue to evolve, driving advancements in training, design, and collaborative efforts within the manufacturing sector.

The MR segment is anticipated to witness rapid growth over the projected period. Mixed reality (MR) in the metaverse for manufacturing blends virtual and augmented reality, creating immersive experiences. It seamlessly integrates digital content into the real-world manufacturing environment, enhancing worker interactions with physical objects. A key trend in the MR segment involves its application for hands-on training, allowing workers to practice tasks in realistic virtual scenarios. This technology trend promotes skill development, reduces errors, and contributes to a safer and more efficient manufacturing process within the metaverse.

Recent Developments

- In November 2021, the Korea Advanced Institute of Science & Technology (KAIST) unveiled a groundbreaking initiative – a virtual plastic screw factory within a metaverse environment. This virtual setting allows customers to immerse themselves in the manufacturing process, donning a virtual reality headset to explore the plant and observe operations. The innovative aspect extends to virtual operation of machines, offering users a lifelike experience within a simulated factory environment.

- In January 2022, Hyundai Motor Company and Unity announced a collaborative effort to pioneer a metaverse roadmap and platform for Meta-Factory. This transformative digital-twin factory, rooted in the metaverse, not only optimizes plant operations but also introduces a virtual avenue for creative problem-solving within a dynamic and interactive virtual workspace.

Metaverse in Manufacturing Market Companies

- Microsoft Corporation

- Unity Technologies

- NVIDIA Corporation

- PTC Inc.

- Siemens AG

- Autodesk, Inc.

- EON Reality, Inc.

- Magic Leap, Inc.

- HTC Corporation

- Oculus VR (Facebook Technologies, LLC)

- Samsung Electronics Co., Ltd.

- Alphabet Inc. (Google)

- Varjo Technologies

- Marxent Labs, LLC

Segments Covered in the Report

By Component

- Hardware

- Services

By Application

- Supply Chain Management

- Product Designing and Development

- Factory Landscape

- Virtual Warehouse

- Others

By Technology

- Augmented Reality (AR)

- Virtual Reality (VR)

- Mixed Reality (MR)

- Internet of Things (IoT)

- Artificial Intelligence (AI)

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting