Industrial Metaverse Market Size and Forecast 2025 to 2034

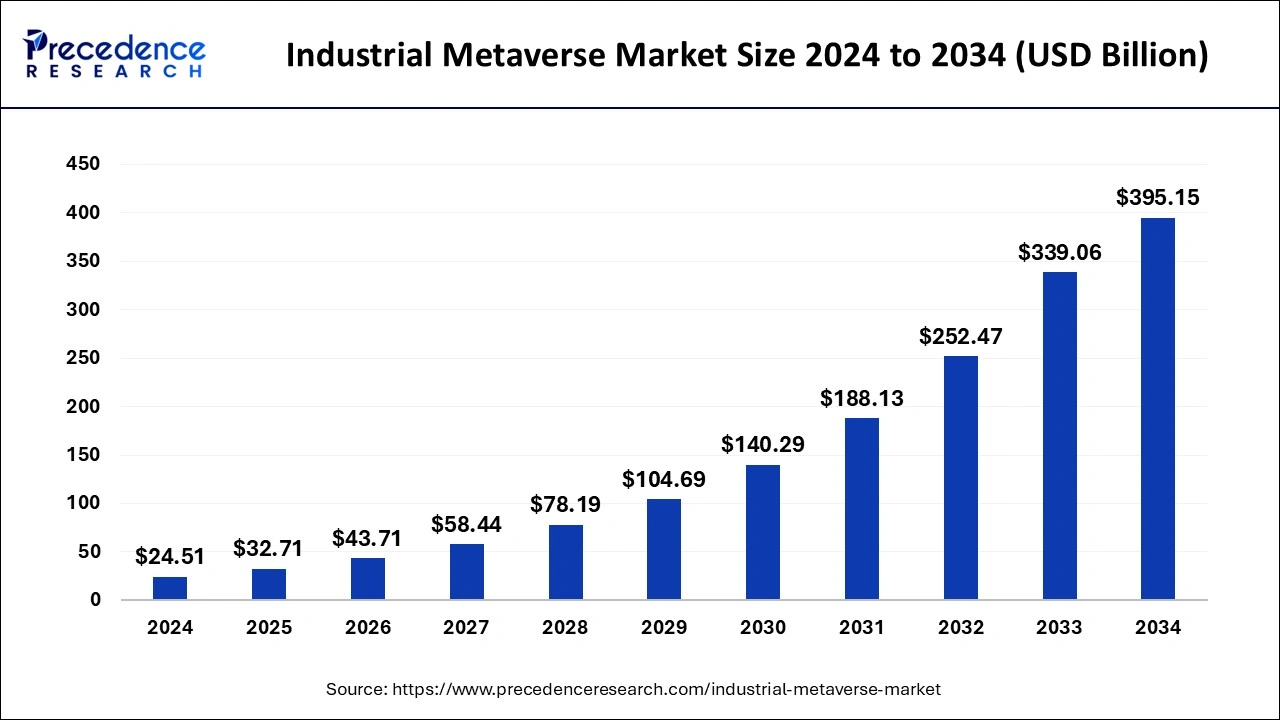

The global industrial metaverse market size was valued at USD 24.51 billion in 2024 and is expected to hit around USD 395.15 billion by 2034, poised to grow at a CAGR of 32.05% from 2025 to 2034.

Industrial Metaverse Market Key Takeaways

- In terms of revenue, the industrial metaverse market is valued at USD 32.71 billion in 2025.

- It is projected to reach USD 395.15 billion by 2034.

- The industrial metaverse market is expected to grow at a CAGR of 32.05% from 2025 to 2034.

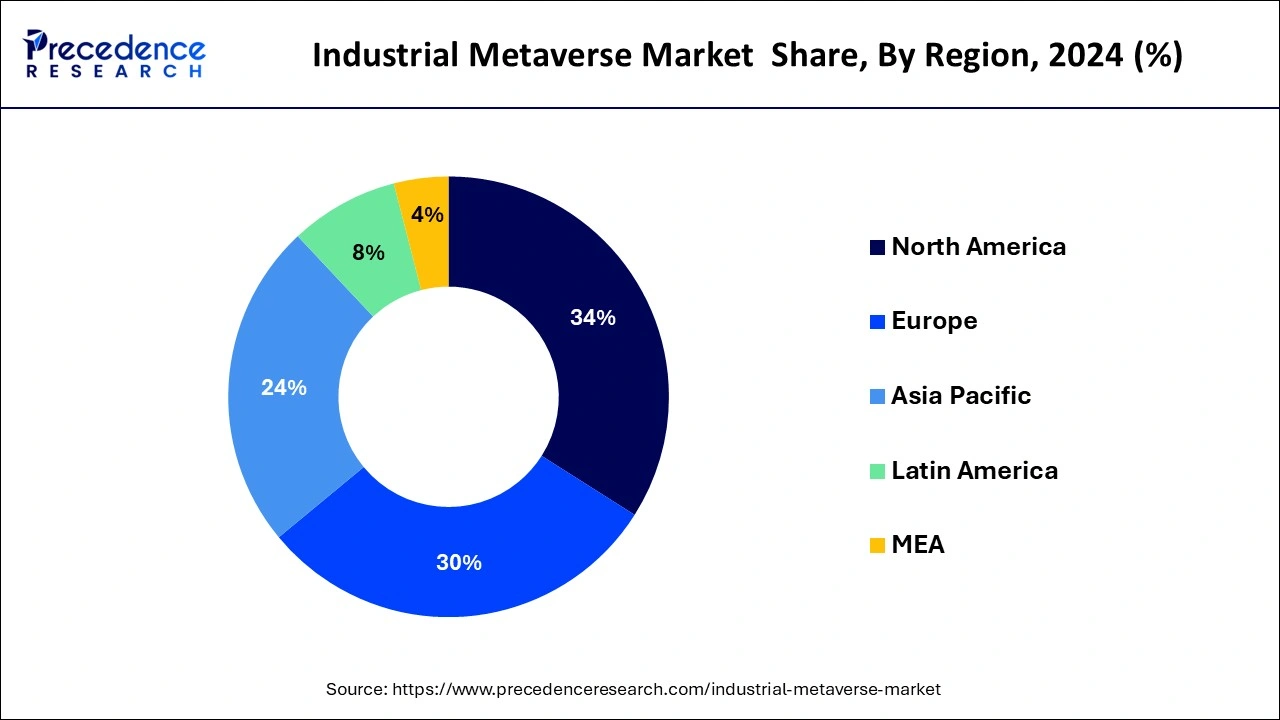

- North America contributed more than 34% of market share in 2024.

- Asia-Pacific is estimated to expand the fastest CAGR between 2025 and 2034.

- By component, the hardware segment has held the largest market share of 43% in 2024.

- By component, the service segment is anticipated to grow at a remarkable CAGR of 36.16% between 2025 and 2034.

- By application, the data visualization & analytics segment generated over 30% of the market share in 2024.

- By application, the maintenance & repair segment is expected to expand at the fastest CAGR over the projected period.

- By technology, the AR segment generated over 42% of revenue share in 2024.

- By technology, the MR segment is expected to expand at the fastest CAGR over the projected period.

- By end-use, the manufacturing segment generated over 27% of market share in 2024.

- By end-use, the automotive segment is expected to expand at the fastest CAGR over the projected period.

U.S. Industrial Metaverse Market Size and Growth 2025 to 2034

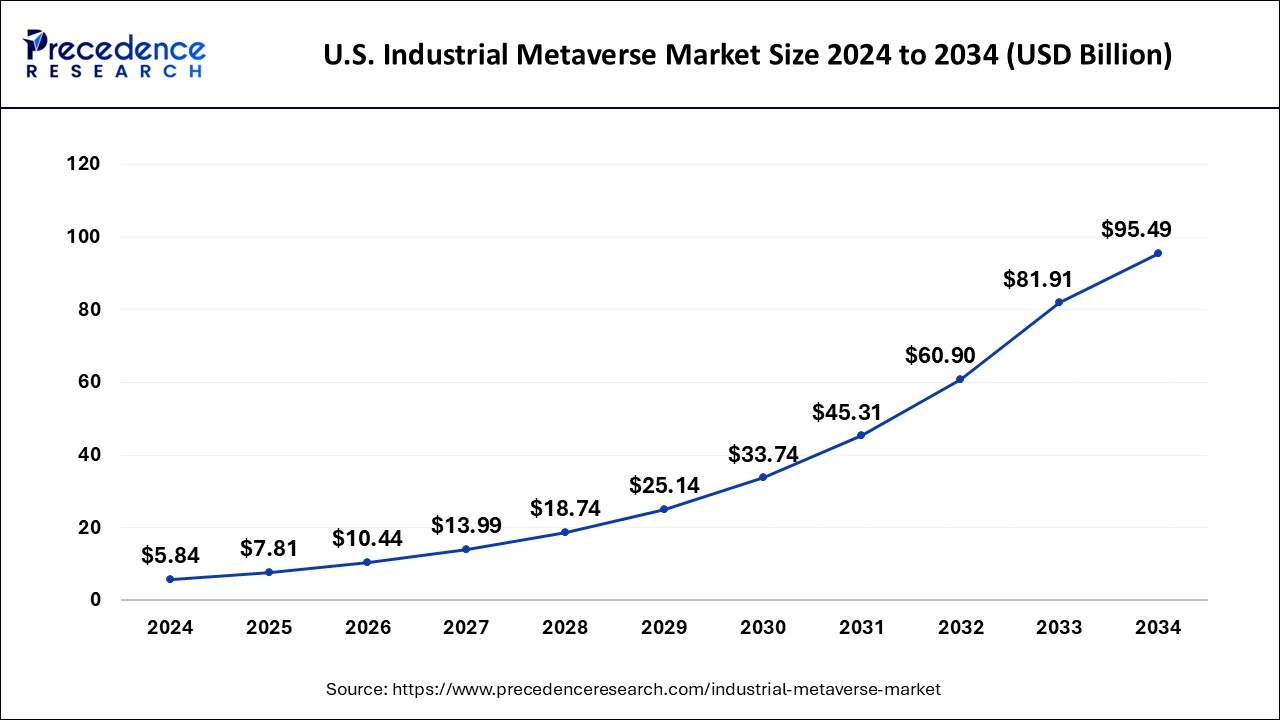

The U.S. industrial metaverse market size was estimated at USD 5.84 billion in 2024 and is expected to reach around USD 95.49 billion by 2034, growing at a CAGR of 32.24% from 2025 to 2034.

North America held a share of 34% in the industrial metaverse market in 2024due to its robust technological infrastructure, widespread adoption of advanced technologies, and a high concentration of key market players. The region's proactive approach to Industry 4.0 initiatives, coupled with significant investments in research and development, has positioned it at the forefront of industrial innovation. Additionally, a mature ecosystem of technology providers, strong collaborations between industry and academia, and a favorable regulatory environment contribute to North America's dominance in driving the growth of the industrial metaverse market.

The presence of the vibrant technology sector in areas like augmented reality and virtual reality helps in the growth of the market. The growing adoption of metaverse technologies for companies' tasks like supply chain management, digital twins, and product design drives the market growth. The strong investment in metaverse technologies and government initiatives to encourage digital transformation in various industries increases demand for the industrial metaverse. The expertise in various areas like data analytics, software development, and digital engineering, and the presence of a highly skilled workforce, increase the implementation of industrial metaverse solutions. The presence of key players like Amazon Web Services, NVIDIA Corporation, and Microsoft drives the overall growth of the market.

The industrial metaverse market in the Asia-Pacific region is set for rapid expansion, driven by its strong technological infrastructure, growing embrace of advanced manufacturing, and a rapidly expanding industrial sector. Leading nations like China, Japan, and South Korea are at the forefront of technological innovation, providing a solid groundwork for the seamless integration of industrial metaverse technologies. Furthermore, the region's dedicated commitment to Industry 4.0 initiatives and the increasing need for digital transformation in the manufacturing sector creates a conducive environment, establishing Asia-Pacific as a pivotal catalyst for propelling the industrial metaverse market forward.

The strong government support through action plans and policy initiatives promotes the development of industrial metaverse solutions. The strong investments in technologies like semiconductors, AI, and 5G increase the development of the industrial metaverse. The robust digital infrastructure, like advanced mobile networks and high-speed internet connectivity in the region, helps in the market growth. The presence of engineers and computer scientists encourages the development of an industrial metaverse solution. The strong investment of foreign and domestic companies in the development of AR and VR software and hardware helps in the market growth. The growing digital transformation and industrial modernization in various industries increase demand for the industrial metaverse, driving the growth of the market.

India is significantly growing in the industrial metaverse market. The technological advancements in AR and VR technologies help in the growth of the industrial metaverse market. The growing expansion of the digital economy and government support for digital transformation increase demand for the industrial metaverse. The growing industrial challenges like digital twins, process optimization, and training increase demand for the industrial metaverse. The growing investment in metaverse startups and industrial expansion contributes to the industrial metaverse market.

Meanwhile, Europe is experiencing notable growth in the industrial metaverse market due to the increased adoption of advanced technologies, strong emphasis on Industry 4.0 initiatives, and a proactive approach toward digital transformation. Companies in the region are leveraging the industrial metaverse for virtualized manufacturing, collaborative design, and enhanced operational efficiency. Furthermore, supportive regulatory frameworks and strategic investments in research and development contribute to the region's prominence in harnessing the potential of the industrial metaverse, positioning Europe as a key player in the evolution of industrial practices.

Market Overview

The industrial metaverse represents an emerging digital terrain that integrates virtual and augmented. The industrial metaverse is a groundbreaking concept that extends the metaverse principles to the industrial realm. It acts as a virtual space where the physical and digital aspects of manufacturing seamlessly blend. This forward-thinking environment empowers manufacturers to generate digital replicas, or "twins," of their actual factories.

Utilizing technologies like augmented reality, virtual reality, artificial intelligence, and the internet of things, the industrial metaverse facilitates the visualization, analysis, and optimization of industrial processes in a collaborative and dynamic virtual setting. This integration of cutting-edge technologies holds the promise of enhancing operational efficiency, encouraging innovation, and advancing sustainability practices across diverse industrial sectors, marking a significant advancement in industrial methodologies.

Industrial Metaverse Market Growth Factors

- Continuous advancements in key technologies such as augmented reality (AR), virtual reality (VR), artificial intelligence (AI), and the Internet of Things (IoT) contribute significantly to the growth of the industrial metaverse market. Innovations in these areas enhance the capabilities of virtualization, simulation, and collaboration within industrial processes.

- The adoption of digital twins, virtual replicas of physical objects or systems, is a key growth factor. Industrial metaverse leverages digital twins to create virtual representations of factories, equipment, and processes, enabling real-time monitoring, analysis, and optimization.

- The global shift towards remote work and training, accelerated by factors such as the COVID-19 pandemic, drives the demand for industrial metaverse solutions. Virtual environments allow for remote monitoring, operation, and training, reducing the need for physical presence on-site.

- Industrial metaverse platforms facilitate improved collaboration and communication among stakeholders, both within and between organizations. This leads to streamlined workflows, increased efficiency, and faster decision-making processes.

- The ongoing Industry 4.0 initiatives, focused on the integration of smart technologies into manufacturing and industrial processes, align closely with the goals of the industrial metaverse. As companies strive for greater automation, data-driven decision-making, and connectivity, the market for industrial metaverse solutions experiences growth.

- Partnerships between technology providers, industrial manufacturers, and other stakeholders play a crucial role in the expansion of the industrial metaverse market. Collaborative efforts lead to the development of comprehensive solutions and drive the adoption of industrial metaverse technologies across various industries.

Major Key Trends in Industrial Metaverse Market

- Integration of Digital Twins for Enhanced Operational Efficiency: Industries are progressively embracing digital twins to develop real-time virtual versions of physical assets, facilitating predictive maintenance, streamlining processes, and minimizing downtime in manufacturing and logistics.

- Merging of AI, AR/VR, and IoT Technologies: The combination of artificial intelligence, augmented and virtual reality, along with the Internet of Things, is improving immersive simulations, enabling real-time data analysis, and fostering remote collaboration, propelling innovation in industrial processes.

- Focus on Sustainability and Resource Efficiency: The industrial metaverse is promoting energy-efficient operations by modeling processes to decrease waste, enhance resource use, and support sustainable manufacturing methodologies.

- Innovations in Workforce Training and Safety: Virtual reality-oriented training programs are being adopted to enhance workforce skills, improve safety measures, and decrease on-site accidents, resulting in better workforce readiness and operational safety.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 32.05% |

| Global Market Size in 2025 | USD 32.71 Billion |

| Global Market Size by 2034 | USD 395.15 Billion |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Component, By Application, By Technology, and By End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Remote work trends

- A PwC survey reveals that 83% of executives consider remote collaboration a permanent change, emphasizing the long-term relevance of virtualized industrial processes.

The surge in remote work trends has become a pivotal driver for the burgeoning demand in the industrial metaverse market. As organizations embrace flexible work arrangements, the need for virtualized industrial processes and remote collaboration intensifies. The industrial metaverse responds to this demand by providing immersive digital environments that enable remote monitoring, operation, and collaboration within industrial settings.

With the global shift toward decentralized workforces, companies seek solutions that enhance connectivity and efficiency, making the industrial metaverse a crucial enabler of seamless virtual collaboration. Moreover, the impact of the COVID-19 pandemic has accelerated the adoption of remote work practices, prompting industries to invest in technologies that bridge physical distances. The industrial metaverse not only addresses the challenges posed by remote work but also enhances the overall resilience and adaptability of industrial operations, fostering a dynamic and interconnected approach to manufacturing and production.

Restraint

Lack of standardization

The lack of standardization poses a significant restraint on the market demand for the industrial metaverse as it hampers interoperability and hinders seamless integration across diverse industrial landscapes. Without universally accepted protocols and guidelines, companies face challenges in adopting cohesive and scalable industrial metaverse solutions. This lack of standardization results in a fragmented ecosystem where different technologies may struggle to communicate effectively, leading to inefficiencies and increased implementation complexities.

The absence of industry-wide standards not only impedes technological integration but also hampers the establishment of best practices and benchmarks. Companies may hesitate to invest in industrial metaverse technologies without clear standards, fearing potential compatibility issues and the need for costly modifications in the future. Standardization efforts are crucial for fostering confidence among businesses, streamlining adoption processes, and promoting the widespread acceptance of the industrial metaverse as a transformative tool for industrial operations.

Opportunity

Enhanced productivity and efficiency

The pursuit of enhanced productivity and efficiency stands as a paramount opportunity in the industrial metaverse market. By leveraging virtual simulations, real-time monitoring, and data analytics, industrial entities can streamline their workflows and achieve unprecedented levels of operational efficiency. The ability to optimize resource utilization, minimize downtime, and implement predictive maintenance through the industrial metaverse translates into tangible cost savings and improved overall productivity.

Furthermore, the industrial metaverse empowers industries to embrace innovative problem-solving and decision-making approaches. The virtualized environment facilitates swift prototyping, testing, and iteration, significantly shortening product development cycles. This acceleration not only fosters innovation but also positions companies competitively in dynamic markets. The profound impact of heightened productivity and efficiency establishes the industrial metaverse as a pivotal player in the advancement of industrial practices, offering substantial economic benefits and fostering a culture of continual improvement within the market.

Component Insights

The hardware segment held the highest market share of 43% in 2024. Within the industrial metaverse market, the hardware segment encompasses the tangible elements forming the bedrock for immersive interactions. This comprises augmented reality and virtual reality headsets, alongside sensors and haptic feedback devices. A notable trend in this sector involves the evolution towards more streamlined and user-centric devices, enhancing accessibility and user comfort in industrial settings. Moreover, continuous enhancements in hardware specifications, including heightened processing capabilities and superior display resolutions, contribute to a heightened level of realism and immersion within the industrial metaverse experience.

The service segment is anticipated to witness rapid growth at a significant CAGR of 36.16% during the projected period. In the industrial metaverse market, the "service" segment encompasses a range of offerings that support the implementation, customization, and maintenance of virtualized industrial solutions. These services often include consultancy, training, and technical support to ensure seamless integration and optimal performance. A notable trend in this segment is the growing demand for specialized consulting services, reflecting the need for tailored guidance in navigating the complexities of adopting and optimizing industrial metaverse technologies, thereby maximizing the value derived from these transformative solutions.

Application Insights

The application, the data visualization & analytics segment has held 30% market share in 2024. The data visualization & analytics segment within the industrial metaverse market pertains to the representation and analysis of complex industrial data in a visual format. This segment involves the use of advanced tools to transform data into meaningful insights, aiding decision-making in real-time. A prominent trend in this segment is the growing demand for intuitive and interactive visualization solutions, enabling industrial stakeholders to interpret data efficiently. As industries increasingly adopt the industrial metaverse, the focus on enhancing data visualization and analytics capabilities is crucial for optimizing processes and improving overall operational efficiency.

The maintenance & repair segment is anticipated to witness rapid growth over the projected period. In the industrial metaverse market, the maintenance and repair segment pertains to leveraging virtual environments for the enhancement of maintenance processes and equipment repair within industrial settings. This involves the utilization of augmented reality and virtual reality for remote diagnostics, real-time monitoring, and training simulations. A prominent trend within this segment is the adoption of digital twins, allowing for accurate virtual representations of machinery, enabling predictive maintenance, and minimizing downtime. This application is increasingly valued for its potential to improve operational efficiency and reduce costs in the maintenance and repair aspects of industrial operations.

Technology Insights

The AR segment has held a 42% market share in 2024. Augmented reality (AR) in the industrial metaverse involves overlaying digital information onto the physical environment, enhancing real-world experiences. In the market, AR trends focus on immersive visualizations, aiding workers in tasks like maintenance, training, and design. As technology advances, AR in the industrial metaverse is evolving to offer more intuitive interfaces, real-time data integration, and enhanced collaboration. The AR segment is pivotal for creating interactive, data-driven virtual environments that optimize industrial processes and empower workers with actionable insights for improved decision-making.

The MR segment is anticipated to witness rapid growth over the projected period. Within the industrial metaverse landscape, Mixed Reality (MR) signifies the convergence of physical and virtual realms, facilitating user interaction with digital content in real-world scenarios. MR seamlessly blends augmented reality (AR) and virtual reality (VR), delivering a dynamic and immersive user experience. A notable trend in the industrial metaverse sphere involves the growing embrace of MR for practical training, remote assistance, and spatial computing applications. This technological shift enhances collaborative efforts and decision-making by overlaying digital information onto the physical environment, reshaping the visualization and execution of industrial processes.

End-use Insights

The manufacturing segment has held a 27% market share in 2024.In the industrial metaverse market, the manufacturing segment pertains to the application of virtualized technologies to enhance processes within manufacturing industries. This involves creating digital replicas of physical factories, utilizing augmented reality, virtual reality, and data analytics for real-time monitoring, simulation, and optimization. Key trends in the manufacturing segment include the adoption of digital twins for precise replication, increased connectivity for Industry 4.0 integration, and the utilization of virtual simulations to improve overall efficiency, ultimately driving advancements in the manufacturing landscape.

The automotive segment is anticipated to witness rapid growth over the projected period. The automotive segment within the industrial metaverse market pertains to the application of virtualized technologies in the automotive industry. This involves creating digital twins of manufacturing facilities, implementing virtual reality (VR) simulations for design and prototyping, and utilizing augmented reality (AR) for maintenance and training purposes. A growing trend in the automotive sector is the virtual operation of manufacturing plants, as exemplified by BMW AG's announcement to operate a new plant virtually in Hungary, showcasing the potential of the industrial metaverse to transform traditional manufacturing processes in the automotive industry.

Industrial Metaverse Market Companies

- Siemens AG

- Microsoft Corporation

- PTC Inc.

- General Electric Company

- Dassault Systèmes

- IBM Corporation

- Unity Technologies

- Schneider Electric

- Rockwell Automation, Inc.

- ABB Ltd

- NVIDIA Corporation

- Honeywell International Inc.

- Bosch Rexroth AG

- Siemens PLM Software

- Alphabet Inc. (Google)

Recent Developments

- In April 2024, Siemens has launched a suite powered by VR and AR that allows for the development of digital twins for manufacturing facilities. This tool enables stakeholders to perform virtual tours, simulate production workflows, and collaboratively design factory layouts, thereby increasing design precision and shortening time-to-market.

- In March 2024, PTC has rolled out HoloWorks 2.0, an enhanced platform that supports AR-based remote assistance. Field technicians can now receive immediate guidance, visualize intricate instructions through AR overlays, and access equipment information while on the move, boosting maintenance productivity and minimizing downtime.

- In February 2024, Microsoft has launched Mesh for Teams, which allows users to create ongoing, shared virtual environments. Industrial teams can now engage in collaborative design workshops, conduct virtual meetings in three-dimensional settings, and track project developments in real-time, thereby improving remote teamwork.

Segments Covered in the Report

By Component

- Hardware

- Software

- Services

By Application

- Product Design & Development

- Virtual Prototyping

- Training & Simulation

- Remote Collaboration

- Maintenance & Repair

- Supply Chain Optimization

- Data Visualization & Analytics

By Technology

- AR

- VR

- MR

By End-use

- Automotive

- Healthcare

- Logistics & Transportation

- Manufacturing

- Energy and utilities

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting