What is the Multi-Effect Evaporators Market Size?

The global multi-effect evaporators market is witnessing strong growth as industries focus on efficient water management, wastewater treatment, and zero liquid discharge systems.The market is growing due to increasing demand for energy-efficient liquid concentration and water recovery.

Multi-Effect Evaporators Market Key Takeaways

- Asia Pacific dominated the multi-effect evaporators market with the largest market share of 34.70% in 2024.

- North America is expected to grow at the fastest rate during the forecast period.

- By flow configuration, the forward feed segment held the biggest market share of 36.80% in 2024.

- By flow configuration, the mixed feed segment is expected to grow at the fastest CAGR during the forecast period.

- By heat recovery technology, the standard steam-based segment captured the highest market share of 44.20% in 2024.

- By heat recovery technology, the mechanical vapor recompression segment is projected to grow at the fastest CAGR during the forecast period.

- By material of construction, the stainless steel segment contributed the maximum market share of 42.90% in 2024.

- By material of construction, the titanium segment is the fastest-growing during the forecast period.

- By application type, the product concentration segment accounted for the significant market share of 34.40% in 2024.

- By application type, the zero liquid discharge segment is projected to grow at the fastest CAGR during the forecast period.

- By end-use industry, the food & beverage segment generated the major market share of 29.80% in 2024.

- By end-use industry, the wastewater treatment segment is expected to grow at the fastest CAGR during the forecast period.

Market Overview

What Is the Multi-Effect Evaporators Market?

The multi-effect evaporator (MEE) market is experiencing robust growth due to the rising demand for sustainable and energy-efficient evaporation solutions in sectors such as wastewater treatment, chemicals, food and beverage, and pharmaceuticals. Businesses are focusing on innovations that enhance process efficiency, reduce operating expenses, and minimize environmental impact. To satisfy the increasing demand for reliable, high-quality outputs in industrial applications, advanced MEE systems are being implemented.

- In August 2024, Myande Group promoted its use of multi-effect evaporators for high-volume wastewater streams, stating these systems are efficient and sustainable solutions for industries aiming to reduce their environmental footprint.(Source: https://www.myandegroup.com)

How Is AI Transforming Operations in the Multi-Effect Evaporators (MEE) Market?

Artificial Intelligence is revolutionizing operations in the multi-effect evaporators market by enhancing energy efficiency, predictive maintenance, and real-time process optimization. AI-driven control systems enable real-time monitoring and adaptive operation, adjusting to variations in wastewater composition with minimal human intervention. This integration leads to reduced energy consumption and operational costs, aligning with the industry's push toward sustainability and efficiency.

- In October 2024, OASK Publishers published a review article by Bahman Zohuri, Artificial Intelligence and Machine Learning Driven Adaptive Control Applications, which explores how AI enhances adaptive control systems across various industries, including industrial process control. This research highlights the shift toward intelligent, data-driven adaptive control, which is directly applicable to optimizing MEE operations in dynamic industrial environments.(Source: https://oaskpublishers.com)

Multi-Effect Evaporators Market Outlook

- Industry Growth Overview: The multi-effect evaporators market is growing because the food and beverage, chemical processing, and wastewater treatment industries are seeing an increase in demand for energy-efficient solutions. Fast industrialization, more stringent wastewater regulations, and the widespread use of these products in textiles and pharmaceuticals have all contributed to Asia Pacific's dominance in consumption. Design and heat recovery technological advancements increase productivity, lower operating costs, and lessen environmental impact, which encourages widespread adoption across industries.

- Sustainability Trends: Eco-friendly evaporator systems with lower energy consumption, a smaller carbon footprint, and increased water recycling efficiency are the focus of businesses. Compliance with environmental regulations is ensured by combining automation, intelligent monitoring, and zero-liquid-discharge (ZLD) capabilities. To improve lifecycle sustainability and cut waste, manufacturers are also employing recyclable and long-lasting materials in their construction.

- Global Expansion: Market players are expanding through strategic partnerships with EPC contractors, local distributors, and industrial facility operators. Joint ventures and acquisitions enable companies to enter emerging markets, while regional manufacturing plants strengthen supply chains and reduce costs. Collaborations with technology providers are driving innovation in heat transfer, vapor recompression, and digital monitoring, thereby enhancing process efficiency and overall productivity.

- Major Investors: Key players include GEA Group, Thermax Limited, Veolia Water Technologies, Swenson Technology, and Saltworks Technologies. Global and regional manufacturers are investing in product innovation, modular evaporator systems, and advanced control technologies to meet the growing demand for industrial wastewater treatment and cater to customers driven by sustainability.

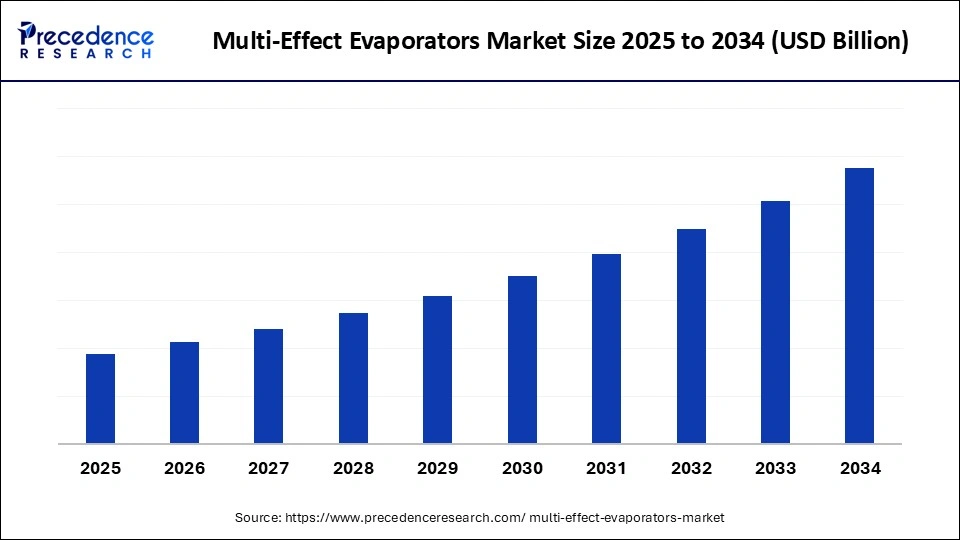

Market Scope

| Report Coverage | Details |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Flow Configuration, Heat Recovery Technology, Material of Construction, Application Type, End-Use Industry, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expansion Across Industrial Sectors

Multi-effect evaporator systems are increasingly being used in wastewater treatment, chemical, food and beverage, and pharmaceutical industries. These systems can swiftly adjust to various processing needs thanks to AI integration, which enhances output quality and operational flexibility across sectors, leading to growth in the multi-effect evaporators market.

Predictive Maintenance and Reduced Downtime

AI analytics in multi-effect evaporator systems can detect early signs of equipment issues, enabling timely maintenance and preventing unexpected downtime. This prolongs equipment life and ensures smoother, more reliable operations. It also reduces maintenance costs and improves safety in industrial plants.

Restraints

High Initial Investment Costs

Advanced multi-effect evaporator systems require substantial capital to set up and install, particularly those that incorporate AI and energy-saving technologies. These systems might be prohibitively expensive for small and medium-sized businesses, which would prevent their widespread adoption. Additionally, in some industries with lower production volumes, the payback period may be longer.

Complexity in Operation and Maintenance

AI-enabled multi-effect evaporators require skilled operators to manage advanced controls, monitor data, and troubleshoot issues. A lack of trained personnel can lead to operational inefficiencies or errors, thereby limiting the benefits of automation. Continuous training is necessary, which adds to operational costs.

Opportunities

Unlocking Growth Horizons in Multi-Effect Evaporators

The multi-effect evaporators market presents significant opportunities driven by the growing demand for energy-efficient and sustainable industrial processes. Rising environmental regulations and increasing focus on wastewater treatment are creating avenues for advanced evaporator technologies. Additionally, industries such as pharmaceuticals, food and beverages, and chemicals are adopting these systems to reduce operational costs and minimize resource consumption. Emerging markets in Asia Pacific and Latin America offer further strong growth potential due to rapid industrialization and stricter environmental regulations.

Segmental Insights

Flow Configuration Insights

Why Did the Forward Feed Segment Dominate the Multi-Effect Evaporators Market in 2024?

The forward feed segment is dominating the multi-effect evaporators market due to its ease of use, low operating costs, and ability to handle large amounts of diluted solutions. Its ability to function effectively with minimal steam consumption has led to its widespread adoption in industries such as the chemical and food processing sectors.

Mixed feed is growing rapidly, as it improves flexibility and adaptability across a range of industries by offering a balanced approach between forward feed and low steam consumption. This has led to its widespread adoption in sectors such as the chemical and food processing industries.

Heat Recovery Technology Insights

What Made the Standard Steam-Based Segment Dominate the Multi-effect Evaporators Market in 2024?

The standard steam-based segment dominates the multi-effect evaporators market, as it enhances flexibility and adaptability across various industries by offering a balanced approach between forward and backward feed systems. Its capacity to maximize energy consumption under varying operating conditions accounts for its increasing uptake. The approach is particularly well-suited for sectors that deal with fluctuating feed concentrations.

Mechanical vapor recompression is experiencing rapid growth in the market as businesses increasingly utilize it to recycle vapor energy, reduce energy expenses, and lower carbon emissions. Stricter environmental regulations, which encourage industries to adopt sustainable solutions, also contribute to its growing popularity. The technology is highly appealing because it guarantees energy savings of up to 90% compared to traditional methods. Its market penetration rate is increasing due to its growing use in zero liquid discharge projects.

Material of Construction Insights

Why Did the Stainless Steel Segment Dominate the Multi-effect Evaporators Market in 2024?

The stainless steel segment dominates the multi-effect evaporators market, as it is the material of choice for the majority of industrial evaporation needs due to its affordability, durability, and corrosion resistance. Its versatility in chemical, pharmaceutical, and food applications strengthens its standing. The material is ideal for delicate applications, such as dairy and beverages, due to its hygienic properties. Its command is reinforced by the rising demand for durable and easily maintained equipment.

Titanium is growing rapidly because it can tolerate harsh operating conditions and has excellent resistance to highly corrosive environments. The rising demand for durable, high-quality equipment is driving its adoption in specialized industries. Although more expensive than stainless steel, titanium has a longer lifespan, resulting in lower overall ownership costs over time. Its quick development is being driven by its growing application in the chemical and high-salinity wastewater treatment sectors.

Application Type Insights

What Made the Product Concentration Segment Dominate the Market for Multi-effect Evaporators in 2024?

Product concentration has dominated the multi-effect evaporators market, as industries such as food, pharmaceuticals, and chemicals heavily rely on MEEs to concentrate raw materials while maintaining product quality. Its ability to enhance production efficiency and reduce processing costs drives higher adoption. The rising demand for ready-to-consume packaged goods has further increased the need for concentration. Growing focus on nutrient retention in concentrated products also strengthens this application's lead.

Zero liquid discharge is growing rapidly as businesses utilize it to meet stringent environmental sustainability and wastewater disposal requirements. It is highly appealing to all sectors due to its ability to reduce industrial effluents while allowing for the reuse of water. In areas with limited water supplies where conservation is essential, the technology is becoming increasingly popular. The adoption of sustainable industrial practices is being further encouraged by government-backed initiatives.

End-Use Industry Insights

Why Did the Food & Beverage Segment Dominate the Multi-Effect Evaporators Market in 2024?

The food & beverage segment is dominating the market due to the extensive need for milk, juices, and other liquid products to be concentrated, guaranteeing a longer shelf life and consistent quality. This dominance is being maintained by rising consumer demand for packaged and processed foods. Strict hygiene and quality standards also encourage the use of MEE systems in this industry. Additionally, its market share is being strengthened by expanding export prospects for processed foods.

Wastewater treatment is growing rapidly, driven by rising environmental regulations and the global push toward water conservation. MEEs are being widely deployed to treat industrial effluents and ensure compliance with zero-discharge norms. Rapid urbanization and industrialization are further boosting demand for efficient wastewater treatment. Industries in high-water-stress regions are increasingly investing in MEE systems to secure sustainable operations.

Regional Insights

What Made Asia Pacific Dominate the Market in 2024?

Asia Pacific is dominating the multi-effect evaporators market, driven by a robust manufacturing base, rapid industrialization, and government water conservation programs. The region's emphasis on low-cost manufacturing encourages widespread adoption even more. The growing pharmaceutical and food processing sectors further contribute to the region's dominance. Asia Pacific leadership is strengthened by favorable policies that promote wastewater recycling.

North America is experiencing rapid growth, driven by stringent wastewater management regulatory frameworks and increasing investments in cutting-edge sustainable technologies. Industry adoption is accelerating due to the growing emphasis on environmentally friendly industrial practices. Additionally, growth is being driven by robust R&D investments in next-generation MEE designs. Collaborations between industries and technology suppliers are also accelerating the shift to environmentally friendly systems.

The U.S. leads the multi-effect evaporator market, driven by industrial demand in the chemical, pharmaceutical, and food sectors. Funding supports R&D and plant upgrades, while investments concentrate on cutting-edge energy-efficient technologies. Policies from governmental compliance and energy efficiency accelerate market expansion.

Country-Level Investments & Funding Trends for Multi-Effect Evaporators Market

| Country | Investment Trends | Funding Trends | Government Initiatives & Policies |

| U.S. | Strong investments in advanced MEE technologies and energy-efficient systems | Funding focused on industrial upgrades and R&D in evaporator efficiency. | Incentives for energy-efficient industrial equipment and environmental compliance programs. |

| Germany | Investments directed toward sustainable and high-performance industrial solutions | Funding supports the adoption of green technologies and zero liquid discharge systems |

Strict environmental regulations and support for sustainable manufacturing. |

| India | Growing investments in manufacturing capacity and industrial expansion. | Funding aimed at energy-efficient and cost-effective evaporation systems |

Government initiatives to promote water conservation and industrial efficiency. |

| UAE | Investments in modernizing food, beverage, and chemical processing plants. | Funding for industrial process optimization and water-saving technologies. |

Policies encouraging sustainable industrial practices and water reuse. |

Multi-effect Evaporators Market Companies

- GEA Group AG – German engineering company offering process technologies including industrial drying, evaporation, and separation systems.

- Alfa Laval – Swedish company specializing in heat transfer, separation, and fluid handling solutions for food, pharma, and industrial markets.

- SPX Flow, Inc. – Provides process equipment such as evaporators, dryers, and mixers for food, chemical, and industrial applications.

- ANDRITZ Group – Austrian technology group supplying separation, drying, and solid-liquid processing systems for multiple industries.

- Bucher Unipektin AG – Swiss company focused on juice processing, drying, and solid-liquid separation equipment for the food industry.

- Veolia Water Technologies – Delivers water and wastewater treatment solutions, including evaporation and crystallization systems.

- Swenson Technology, Inc. – Specializes in custom evaporation and crystallization systems for chemical and industrial processing.

- Dedert Corporation – U.S.-based provider of drying and evaporation technologies, particularly for food and chemical industries.

- Hebeler Process Solutions – Offers drying, thermal processing, and custom-engineered systems for food, chemical, and pharmaceutical markets.

Recent Developments

- In April 2025, Hanpu Technology unveiled high-efficiency MEE systems with AI features for large-scale dehydration, enhancing process reliability and energy efficiency.(Source: https://www.hanputech.com)

- In 2025, Flash Rockwell Technologies introduced the ZeroPoint Evaporator, a portable, skid-mounted, zero-liquid discharge system that treats up to 30,000 gallons of produced water per day by converting it to dry solids using low-pressure flash evaporation powered by waste flare gas.

(Source: https://www.mrt.com)

Segments Covered in the Report

By Flow Configuration

- Forward Feed

- Backward Feed

- Mixed Feed

- Parallel Feed

By Heat Recovery Technology

- Standard Steam-Based

- Thermal Vapor Recompression (TVR)

- Mechanical Vapor Recompression (MVR)

- No Recovery (Direct Condensation / Non-Efficient Systems)

By Material of Construction

- Stainless Steel

- SS 304

- SS 316

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Carbon Steel

- Nickel-Based Alloys

- Inconel 600

- Inconel 625

- Titanium

- Specialty Alloys

- Hastelloy

- Monel

- Tantalum

By Application Type

- Product Concentration

- Food Syrups

- Dairy Concentrates

- Pharmaceutical Extracts

- Chemical Solutions

- Zero Liquid Discharge (ZLD)

- Industrial Wastewater

- Hazardous Effluents

- RO Reject Management

- Solvent or Water Recovery

- Organic Solvent Recovery (Acetone, Methanol)

- Desalination (Brine Reduction)

- Crystallization

- Salt Recovery

- API (Active Pharmaceutical Ingredient) Crystallization

- Volume Reduction

- Sludge Dewatering

- Brine Concentration

By End-Use Industry

- Food & Beverage

- Dairy

- Milk Concentration

- Whey Evaporation

- Sugar Processing (Raw & Refined Sugar Syrup)

- Fruit Juice & Pulp Concentration

- Beverage Manufacturing

- Soft Drinks

- Flavored Syrups

- Malt & Brewing Industry

- Chemicals & Petrochemicals

- Organic Chemicals

- Alcohols

- Acetates

- Acids

- Inorganic Chemicals

- Caustic Soda

- Nitrates

- Phosphates

- Fertilizers

- Urea

- Organic Chemicals

- Ammonium Compounds

- Surfactants and Detergents

- Pharmaceuticals & Biotechnology

- API Manufacturing

- Herbal Extracts

- Antibiotics & Vitamins

- Bioreactor Waste Recovery

- Pulp & Paper

- Black Liquor Evaporation

- Effluent Concentration

- Chemical Recovery Systems

- Textiles

- Dye Wastewater Reduction

- Caustic Soda Recovery

- Textile Sludge Evaporation

- Wastewater Treatment

- Industrial Wastewater

- Common Effluent Treatment Plants (CETPs)

- Zero Liquid Discharge (ZLD) Plants

- High-COD / High-TDS Wastewater

- Oil & Grease-Bearing Wastewater

- Municipal Wastewater Sludge Management

- Dewatered Sludge Evaporation

- Leachate Treatment (from landfills)

- Decentralized STPs with Industrial Mixing

- Industrial Wastewater

- Heavy Metals & Toxic Pollutants Recovery

-

- Battery & Electronics Industry Waste

- Mining & Metallurgical Wastewater

- Chemical Processing Residues

- Hazardous Waste Incineration Scrubber Blowdown

-

- Desalination

- Brine Concentration

- High-Salinity Reject Treatment

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting