Permanent Magnet Motor Market Size To Attain USD 91.77 Bn By 2032

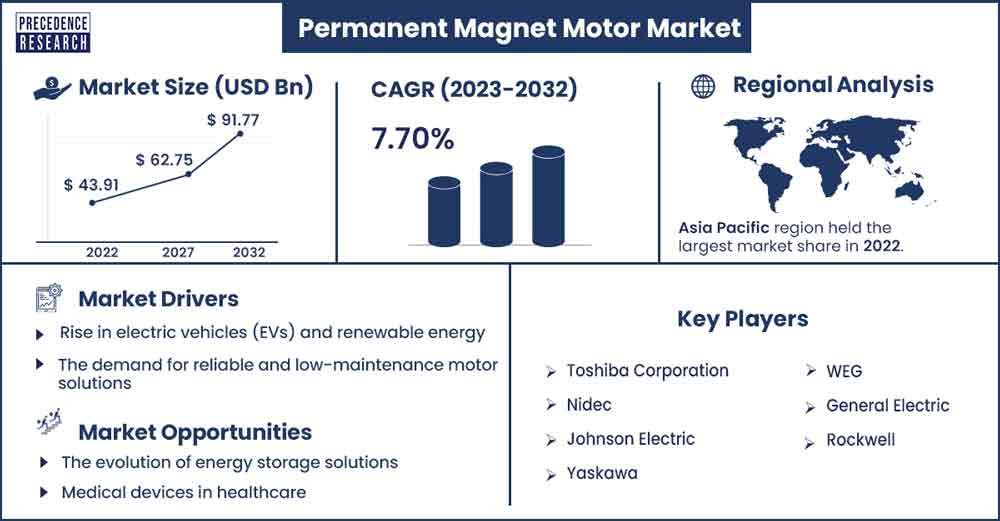

The global permanent magnet motor market size surpassed USD 43.91 billion in 2022 and is projected to attain around USD 91.77 billion by 2032, growing at a CAGR of 7.70% from 2023 to 2032.

Market Overview

A permanent magnet motor, often referred to as a 'permanent motor,' is a type of electric motor characterized by the use of permanent magnets in the rotor. Unlike traditional motors that rely on electromagnetic fields created by winding coils, permanent motors leverage the inherent magnetic properties of permanent magnets for their operation. The core component of a permanent motor is the permanent magnet, which retains its magnetic properties persistently, even when the motor is not powered. This eliminates the need for external power sources to maintain the magnetic field, contributing to the motor's efficiency and reliability.

Permanent motors showcase inherent advantages over traditional counterparts. The elimination of brushes and commutators, common in brushed motors, results in less maintenance and longer operational life. This design also reduces the risk of mechanical failures associated with friction, making permanent motors a durable and reliable choice. Moreover, energy efficiency is a key highlight of permanent motors. Their streamlined design, devoid of brushes and the need for continuous power to maintain magnetic fields, leads to lower energy consumption compared to motors relying on electromagnetic principles. This efficiency aligns with the increasing emphasis on sustainable and energy-conscious technologies in various applications.

The transition to permanent motors is driven by their superior performance characteristics. With lower maintenance requirements, higher durability, and enhanced energy efficiency, these motors find applications in a wide range of industries, from automotive to renewable energy systems. As technological advancements continue, innovations in permanent motor designs, materials, and control mechanisms contribute to their evolving role in meeting the demands of modern electric propulsion systems.

Regional Snapshot

The dominance of Asia Pacific in the global permanent magnet motor market can be attributed to several key factors. Firstly, the robust industrialization and rapid economic growth in countries like China and India have led to increased demand for various applications of permanent magnet motors across industries such as manufacturing, automotive, and electronics. This surge in industrial activities has driven the adoption of efficient electric motors, including permanent magnet motors.

Moreover, Asia Pacific has been at the forefront of technological advancements, with a strong focus on renewable energy and electric vehicle adoption. Permanent magnet motors play a crucial role in these sectors due to their high efficiency and reliability, further contributing to the dominance of the permanent magnet motor market in the region.

North America is the fastest-growing region in the permanent magnet motor market, driven by factors such as a well-established industrial base, advanced technological infrastructure, and a growing emphasis on sustainable practices. The United States, in particular, has seen increased investment in electric vehicles, renewable energy projects, and automation, all of which rely on the efficient performance of permanent magnet motors.

Telecom Analytics Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 47.07 Billion |

| Projected Forecast Revenue by 2032 | USD 91.77 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 7.70% |

| Largest Market | Asia Pacific |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Rise in electric vehicles (EVs) and renewable energy

The global pursuit of sustainable and environmentally friendly technologies drives EVs and renewable energy adoption. Permanent magnet motors offer high efficiency, compact size, and precise control essential attributes for electric drivetrains in vehicles and various renewable energy applications. Within the electric vehicles industry, permanent magnet motors contribute to improved range, energy efficiency, and overall performance. Their compact design is particularly advantageous in accommodating the limited space within electric vehicles.

In renewable energy systems, these motors enhance the efficiency of generators, wind turbines, and other applications. The inherent characteristics of permanent magnet motors align with the goals of reducing carbon emissions and promoting sustainable energy practices, making them integral to the ongoing transformation of the automotive and renewable energy sectors. As the adoption of EVs and renewable energy continues to escalate, the demand for permanent magnet motors is set to grow, reinforcing their crucial role in shaping the future of transportation and sustainable energy solutions.

Reliability and low maintenance

The demand for reliable and low-maintenance motor solutions has positioned permanent magnet motors as advantageous in various applications. By design, these motors feature fewer mechanical components, eliminating brushes and commutators, which significantly reduces wear and maintenance needs. This inherent simplicity enhances their reliability, minimizing the risk of mechanical failures. The absence of these traditional components not only extends the operational life of the motors but also streamlines maintenance procedures. This characteristic proves particularly advantageous across industries, as it translates to increased uptime, lower maintenance costs, and improved overall operational efficiency, making permanent magnet motors a preferred choice for applications prioritizing reliability and reduced maintenance.

Restraint

Financial and regulatory hurdles in adoption

The higher manufacturing costs associated with permanent magnet motors, especially those utilizing rare-earth magnets, pose a significant disadvantage to the permanent magnet motor market. Firstly, in industries with tight budget constraints, the initial cost hurdle can deter the widespread adoption of this technology. For instance, in large-scale manufacturing facilities or infrastructure projects where numerous motors are required, the collective expense of deploying these motors may strain the overall budget, leading decision-makers to opt for more cost-effective alternatives.

The automotive sector, aiming for widespread EV adoption, faces challenges due to the elevated costs of permanent magnet motors. As automakers strive to balance the affordability of electric vehicles with consumer demands, the higher manufacturing expenses associated with these motors can impact the overall cost of EVs. This may impede the broader acceptance of electric vehicles, hindering the transition from traditional internal combustion engines.

Stringent economic considerations, such as developing countries implementing renewable energy solutions and the upfront costs may limit the growth of the permanent magnet motor market. For instance, in off-grid regions where sustainable energy is crucial but budgets are constrained, alternative motor technologies may be favored despite potential long-term benefits offered by permanent magnet motors. Consequently, the cost disparity remains a notable disadvantage, influencing decisions in favor of more economically viable options.

Opportunities

Energy storage systems

The evolution of energy storage solutions, notably batteries, presents a strategic opportunity for the permanent magnet motor market. These motors excel in efficient energy conversion and storage in applications like grid stabilization and backup power. Their precise control and ability to contribute to seamless energy transfer make magnet motors integral components for enhancing the reliability and performance of energy storage systems. As the demand for sustainable energy solutions rises, the versatility of these motors positions them as key enablers in addressing the challenges of energy storage and distribution.

Medical devices in healthcare

Permanent magnet motors offer a distinct advantage in medical devices amid the healthcare industry’s technological advancements. Their compact size, precision, and reliability make them ideal for diverse medical applications. The permanent magnet motor market contributes to the efficiency and accuracy required in critical healthcare settings, from powering imaging equipment with precise movement to facilitating robotic-assisted surgery. As medical technology continues to advance, the adaptability of these motors positions them as crucial components in the development of innovative and sophisticated medical devices, meeting the evolving needs of patient care and diagnostics.

Recent Developments

- In January 2024, Tata launched the Punch.EV in India at an introductory price of Rs 10.99 lakhs. The electric vehicle features a 60kW/114Nm motor, two battery pack options, a 10.25-inch digital driver's display, touchscreen infotainment with wireless CarPlay/Android Auto, automatic climate control, ventilated front seats, sunroof, wireless phone charger, keyless entry, Harman sound system, 360-degree camera, and electric parking brake with auto hold.

- In December 2023, Chinese electric vehicle manufacturer Nio unveiled the luxury electric vehicle, the ET9. Boasting a unique 'executive bridge' interior and a crossover design, the ET9 features innovative technologies like steer-by-wire, rear-steer, and fully active suspension.

- In July 2023, a global motion solution manufacturer unveiled a new series of high torque brushed permanent magnet DC motors, available in 42DI, 52DI, and 63DI sizes with IP54 protection. These motors offer nominal torque up to 0.06Nm, 0.22Nm, and 0.27Nm, respectively. The graphite commutation system enhances motor life, and customization options cater to specific requirements.

Major Key Players

- Toshiba Corporation

- Nidec

- Johnson Electric

- Yaskawa

- WEG

- General Electric

- Rockwell

Market Segmentation

By Type

- PMAC

- PMDC

- Brushless DC

By Power Rating

- Up to 25 kW

- 25–100 kW

- 100–300 kW

- 300 kW and Above

By Magnet Type

- Neodymium

- Samarium Cobalt

- Ferrite

- Others

By Application

- Factory Automation

- Consumer

- Office Automation

- Commercial

- Lab Equipment

- Medical

- Military/Aerospace

By End User

- Industrial

- Automotive

- Textile

- Pulp & Paper

- Aerospace & Aviation

- Electronics

- Robotics

- Food & Beverage

- Chemicals & Petrochemicals

- Others

- Commercial and Residential

- Commercial

- Malls

- Offices

- Banks

- Healthcare

- Others

- Residential

- Commercial

- Others (Defense, Railways)

Buy this Research Report@ https://www.precedenceresearch.com/checkout/1844

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308