Radial Flow Pump Market Size and Forecast 2025 to 2034

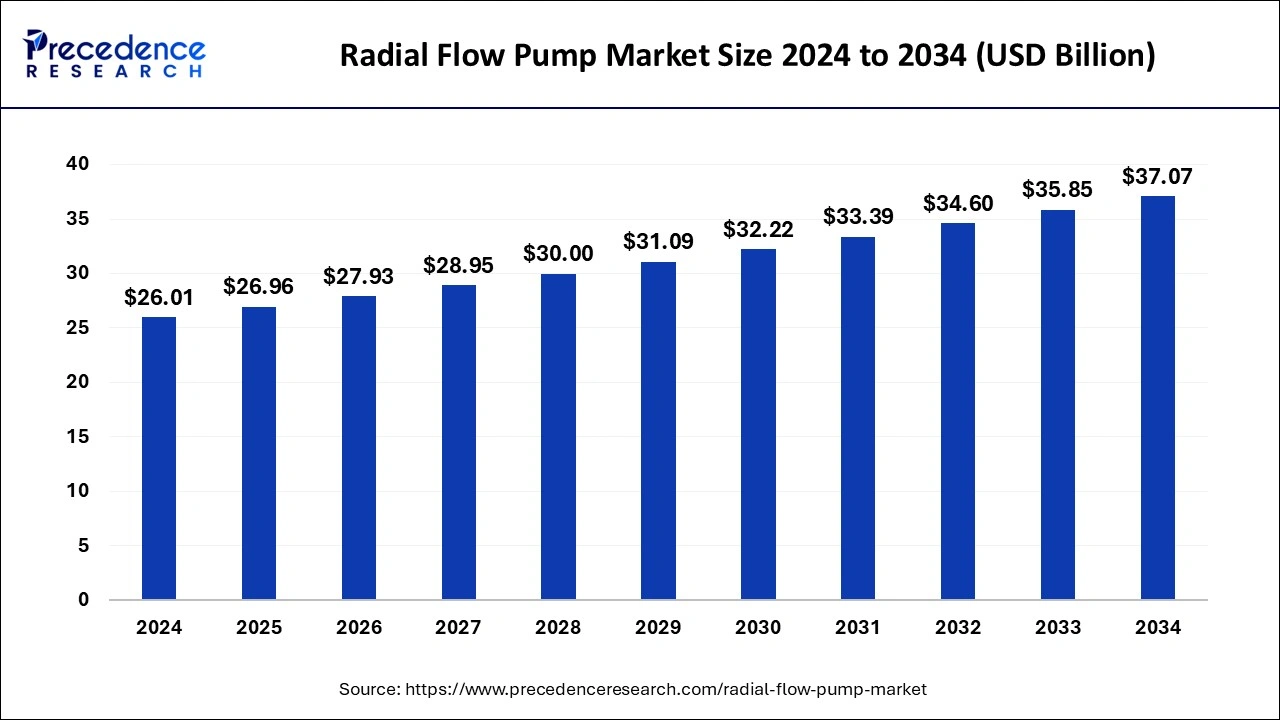

The global radial flow pump market size accounted for USD 26.01 billion in 2024 and is predicted to increase from USD 26.96 billion in 2025 to approximately USD 37.07 billion by 2034, expanding at a CAGR of 3.61% from 2025 to 2034. The radial flow pump market is driven by the necessity of handling fluids under high pressure in several sectors.

Radial Flow Pump Market Key Takeaways

- The global radial flow pump market was valued at USD 26.01 billion in 2024.

- It is projected to reach USD 37.07 billion by 2034.

- The radial flow pump market is expected to grow at a CAGR of 3.61% from 2025 to 2034.

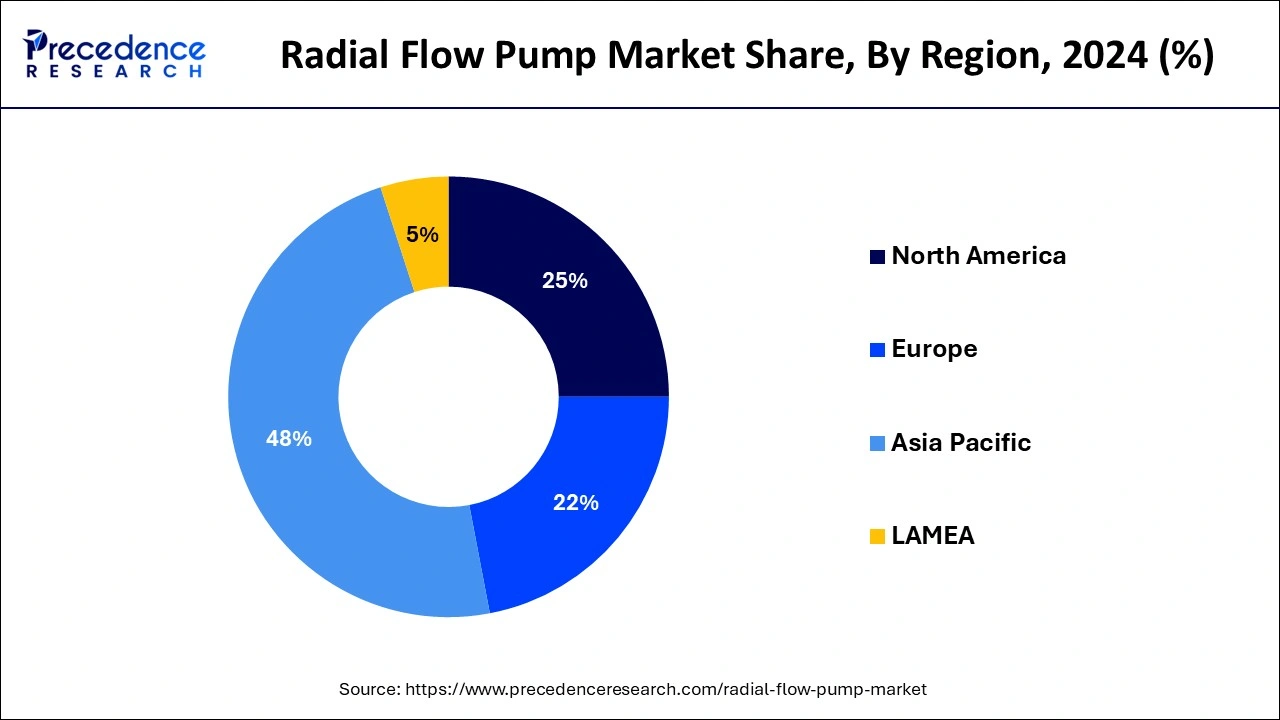

- Asia- Pacific dominated the market with the largest market share of 48% in 2024.

- North America is observed to be the fastest growing region in the market during the forecast period.

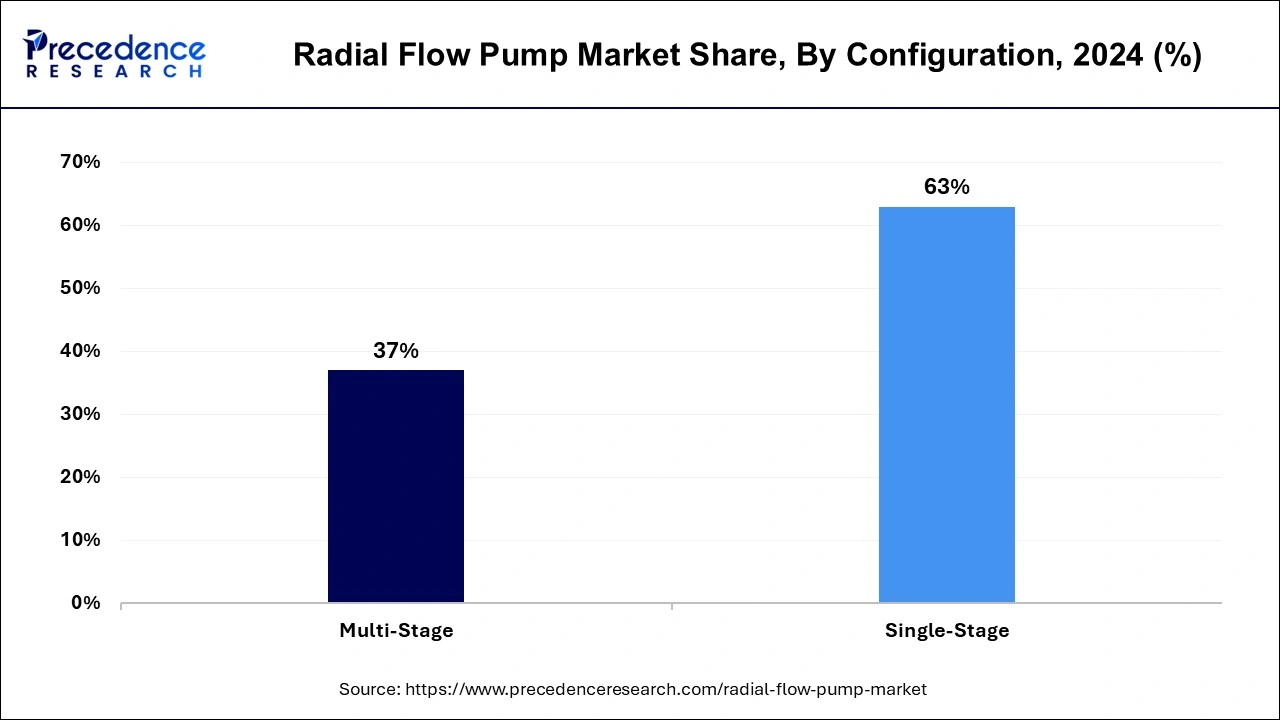

- By configuration, the single stage segment has held more than 63% of market share in 2024.

- By end-use, the agriculture segment has accounted more than 27% of market share in 2024.

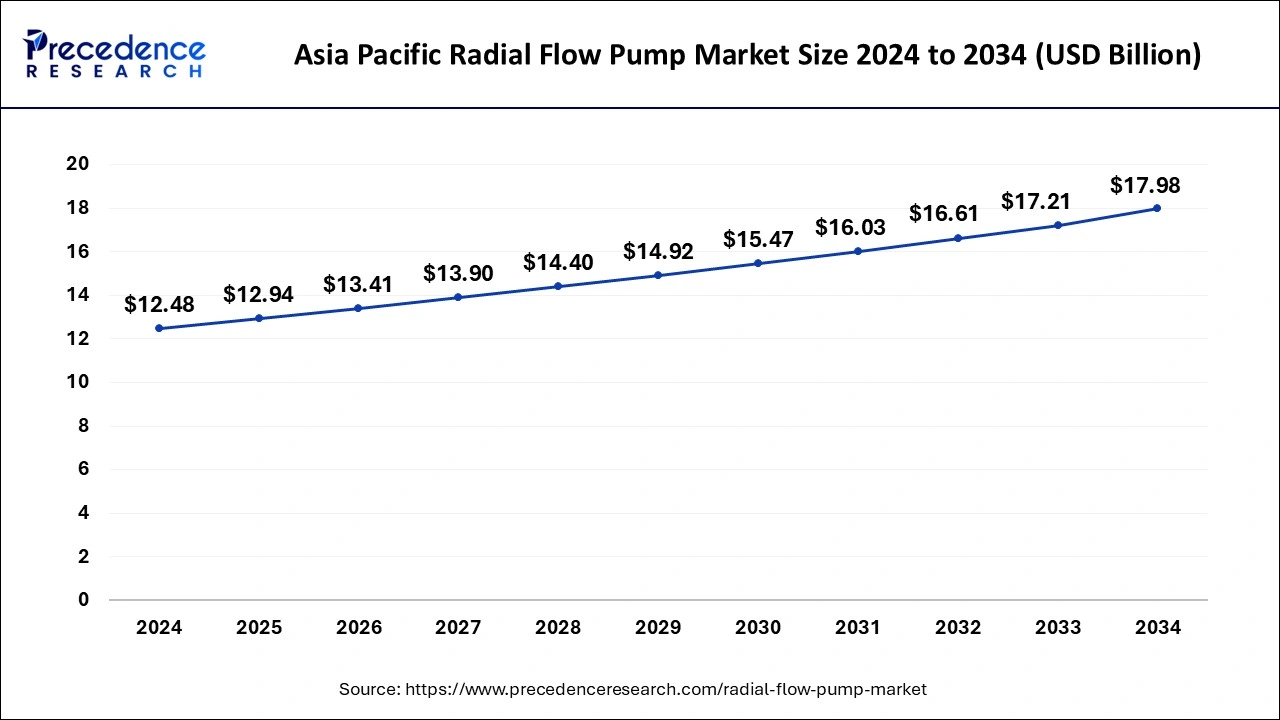

Asia PacificRadial Flow Pump Market Size and Growth 2025 to 2034

The Asia Pacific radial flow pump market size was evaluated at USD 12.48 billion in 2024 and is projected to be worth around USD 17.98 billion by 2034, growing at a CAGR of 3.72% from 2025 to 2034.

Asia-Pacific had the largest share in 2024 in the radial flow pump market and the region is observed to sustain the position throughout the predicted timeframe. Growing the energy infrastructure is important because of the rising demand for energy, especially in emerging nations. This involves the creation of conventional and renewable power plants, which depend on radial flow pumps to perform functions including fluid transfer, circulation, and cooling.

The Asia Pacific region is experiencing rapid industrialization across various sectors, including manufacturing, chemical processing, oil and gas, and water treatment. Radial flow pumps are essential for these industries to transport fluids efficiently in large-scale operations such as manufacturing plants, refineries, and power generation facilities. The growing industrialization in Asia Pacific drives the demand for radial flow pumps, making it the dominant market region.

- In July 2023, after a controversial proposal arising 12 years after the UN's nuclear watchdog approved the Fukushima nuclear disaster, Japan will soon start discharging treated radioactive water into the ocean.

North America is the fastest-growing radial flow pump market during the forecast period. Energy-efficient equipment, particularly pumps, is receiving more attention as worries about environmental sustainability and energy usage grow. When compared to other pump types, radial flow pumps are renowned for their excellent efficiency and low energy usage. Radial flow pumps are becoming increasingly popular in North American companies as they aim to lower operational expenses and carbon impact. There is an increased need for water and wastewater treatment facilities due to urbanization and population growth. Filtration, aeration, and pumping are three standard water treatment procedures that employ radial flow pumps.

Market Overview

Radial flow pumps (also known as centrifugal pumps) are speed pumps in which rotating impellers move varying amounts of water per revolution depending on the rotational speed. This will force the water out at right angles to the shaft, making the pump useful for all emergency stages. It pushes water to the outer edge of a rotating impeller, where the pump body captures the discharged current and the kinetic energy is converted into pressure energy before leaving the pump. When this happens, an area of negative pressure is created at the inlet of the pump chamber, which in turn draws water into the pump.

India has initiated irrigation project, the goal of the Godavari River's Kaleshwaram Lift Irrigation Project at Kaleshwaram, Bhupalpally, Telangana, India, is to effectively use the water resources available for agriculture. Encompassing 13 districts, the 500km (310 miles) project is the largest multi-stage lift irrigation project in the world. It is linked to a 1770km canal network that includes 20 reservoirs and vast subterran tunnels. Some of the most significant water pumps ever constructed are included in it.

Radial Flow Pump MarketGrowth Factors

- Radial pumps are excellent at producing large pressure increases, making them ideal for use in the power generation industries.

- Industries concentrate on increasing production and streamlining procedures. Radial flow pumps, which also enhance pressure and facilitate effective fluid transmission, make this possible.

- Radial flow pumps are necessary for effective water delivery, sewage control, and construction operations due to the growing metropolitan population. The rising demand for construction operations promotes the growth of the market.

- Manufacturers prioritize pumps that can survive harsh operating conditions and provide reliable performance.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 26.96 Billion |

| Market Size in 2024 | USD 26.01 Billion |

| Market Size by 2034 | USD 37.07 Billion |

| Growth Rate from 2024 to 2033 | CAGR of 3.61% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Configuration and End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expansion of oil and gas exploration activities

Successful oil and gas exploration projects depend on optimizing production operations. Radial flow pumps are necessary equipment to maintain optimal reservoir pressure and facilitate the flow of hydrocarbons from the reservoir to the surface. By using radial flow pumps, operators can improve production rates and extend the life of oil and gas fields. Oil and gas companies are pressured to improve profits and minimize environmental impact. Radial flow pumps offer advantages in energy efficiency, reliability, and reduced environmental impact compared to alternative pumping technologies. These factors make them an attractive choice for oil and gas operators looking to optimize their production processes while meeting stringent environmental regulations.

Growing concerns over water scarcity and the need for efficient water management solutions

Hydropower systems use radial flow pumps as essential parts to harness the energy of flowing water to create electricity. Radial flow pumps are needed in hydropower facilities, and demand for these pumps is rising along with the need for renewable energy sources. These pumps aid in producing clean, renewable energy, which advances sustainable development and water management objectives.

Restraint

Lack of skilled professionals

Higher labor expenses are frequently the result of a shortage of skilled workers. Companies might need to invest in specialized training programs or raise compensation to attract and keep qualified pump operators. Due to these extra expenses, businesses may find it more expensive to install radial flow pumps, which could deter them from investing in such machinery.

A shortage of qualified workers may hamper the market expansion to operate radial flow pumps. Industries that view a lack of skilled operators as a significant risk issue may be reluctant to implement radial flow pump technology. This restriction may hinder the radial flow pump market's ability to grow as well as innovation and technological improvements in radial flow pumps.

Opportunity

Advancements in pump technology

Modern radial flow pumps are made with materials and design elements that increase their efficiency. Advances in materials science and manufacturing processes have resulted in radial flow pumps with improved reliability and durability. The use of corrosion-resistant materials, such as stainless steel and high-performance polymers, along with innovative sealing technologies and bearing systems, ensures long-term operational reliability and extended service life for radial flow pumps. These advancements reduce maintenance requirements and downtime, providing cost savings and enhancing the value proposition for customers.

These enhancements make them more economical for end users, leading to increased flow rates and decreased energy use. Pumps that provide better performance while using less power are in high demand as energy efficiency becomes a top priority for many businesses. Such advancements in the pump technology are observed to create lucrative opportunities for the radial flow pump market.

Configuration Insights

The single stage segment dominated the radial flow pump market in 2024. Single-stage radial flow pumps are distinguished by their straightforward construction, which consists of a single impeller rotating inside a volute casing. Their affordability as a solution for various pumping requirements stems from their simplicity, facilitating simpler production, setup, and upkeep. High efficiency is the norm for single-stage pumps, particularly in applications where the required head and flow rate match their capabilities.

Pumps with only one step typically require a less expensive initial outlay of funds than those with many stages. Because of their straightforward design, the pump requires less maintenance over its lifetime, and less money is spent on manufacturing. In addition, their effectiveness in managing head and flow requirements might result in energy savings, ultimately increasing their cost-effectiveness.

The multi-stage segment is the fastest growing radial flow pump market during the forecast period. Applications for multi-stage radial flow pumps are found in many different processes and industries. These pumps are adaptable enough to fulfill the varied demands of many sectors, from power generation and delivery to oil and gas extraction, chemical processing, and water supply and treatment. Global industry diversification and expansion drive demand for pumps that can handle a wide range of fluids and operating conditions, supporting growth.

End-use Insights

The agriculture segment dominated the radial flow pump market in 2024. Water is essential to agriculture since it is used for irrigation. Radial flow pumps are especially well-suited for this purpose because they can effectively carry water over large distances and raise it to higher levels, a necessary skill for irrigation in fields and farms. To increase agricultural output and preserve water supplies, several governments offer subsidies or other forms of encouragement for the adoption of contemporary irrigation methods. This backing increases the need for radial flow pumps in the farming industry.

The construction & building services segment is anticipated to expand in the radial flow pump market during the forecast period. In building projects, energy efficiency, and sustainability are becoming more and more critical. The need for green building technology and solutions is growing as a result. Developers and builders increasingly choose radial flow pumps with high energy efficiency ratings for their projects. The trend toward preventative maintenance and service contracts in the building services and construction industry also fuels demand for premium radial flow pumps. Pumps that are dependable and simple to maintain are preferred by building owners and facility managers because they lower long-term operating expenses and downtime.

The water & wastewater segment shows a significant growth in the radial flow pump market during the forecast period. Global urbanization is increasing, driving up demand for effective wastewater management and water delivery systems. As more people move into metropolitan areas, there is an increasing demand for dependable infrastructure to supply potable water and appropriate wastewater treatment to preserve environmental sustainability.

- In April 2023, The KSB Group created a new radial multi-vane impeller with an open design that can handle untreated wastewater.

Recent Developments

- In June 2023, ZenWTR, the first beverage in the world to be packaged in a bottle made entirely of certified ocean-bound recycled plastic, is pleased to present a redesigned logo demonstrating its dedication to ocean sustainability and preservation. The redesigned brand logo reflects ZenWTR's commitment to providing delicious, ultra-pure vapor distilled water and encouraging good change in the beverage sector.

- In March 2022, CDE unveiled the latest model in their superior water management and recycling system series, the Aqua Cycle A2500 thickener.

Radial Flow Pump Market Companies

- NEC Air Compressors

- KSB SE & Co. KGaA

- EGGER

- Ganga Pumps

- HIFUNI PUMPS PVT. LTD.

- Ruhrpumpen

- Lada Pumps

- Siya Pumps

- Litostroj Power Group

Segments Covered in the Report

By Configuration

- Single Stage

- Multi-Stage

By End-use

- Agriculture

- Construction & Building Services

- Water & Wastewater

- Power Generation

- Oil & Gas

- Chemicals

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting