Scrubber System Market Size and Forecast 2025 to 2034

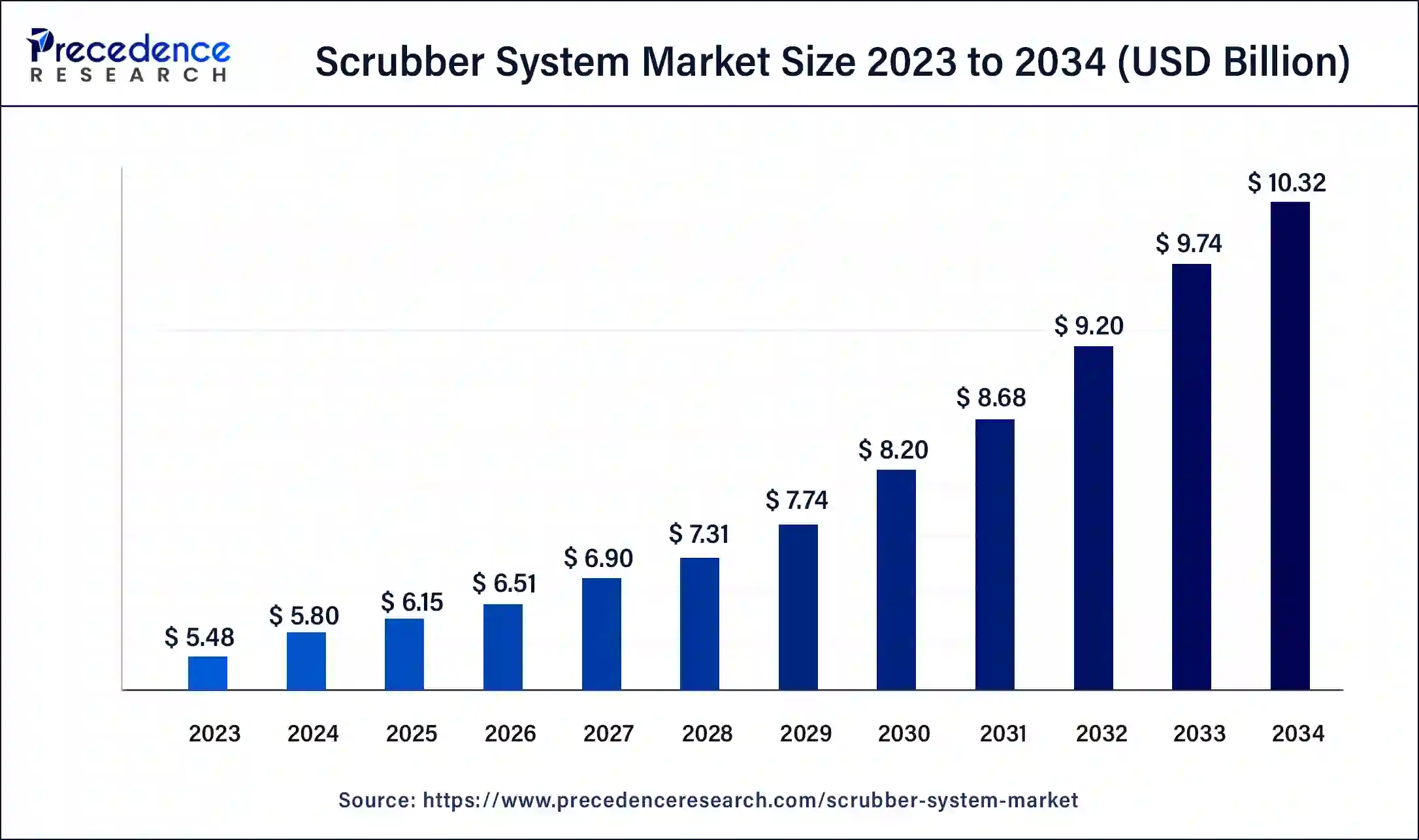

The global scrubber system market size accounted at USD 5.80 billion in 2024 and is anticipated to reach around USD 10.32 billion by 2034, growing at a solid CAGR of 5.93% over the forecast period 2025 to 2034. The increasing demand for scrubber systems demonstrates a global commitment to minimizing environmental impact, safeguarding public health, and complying with strict regulatory standards for air quality.

Scrubber System Market Key Takeaways

- The global scrubber system market was valued at USD 5.80 billion in 2024.

- It is projected to reach USD 10.32 billion by 2034.

- The scrubber system market is expected to grow at a CAGR of 5.93% from 2025 to 2034.

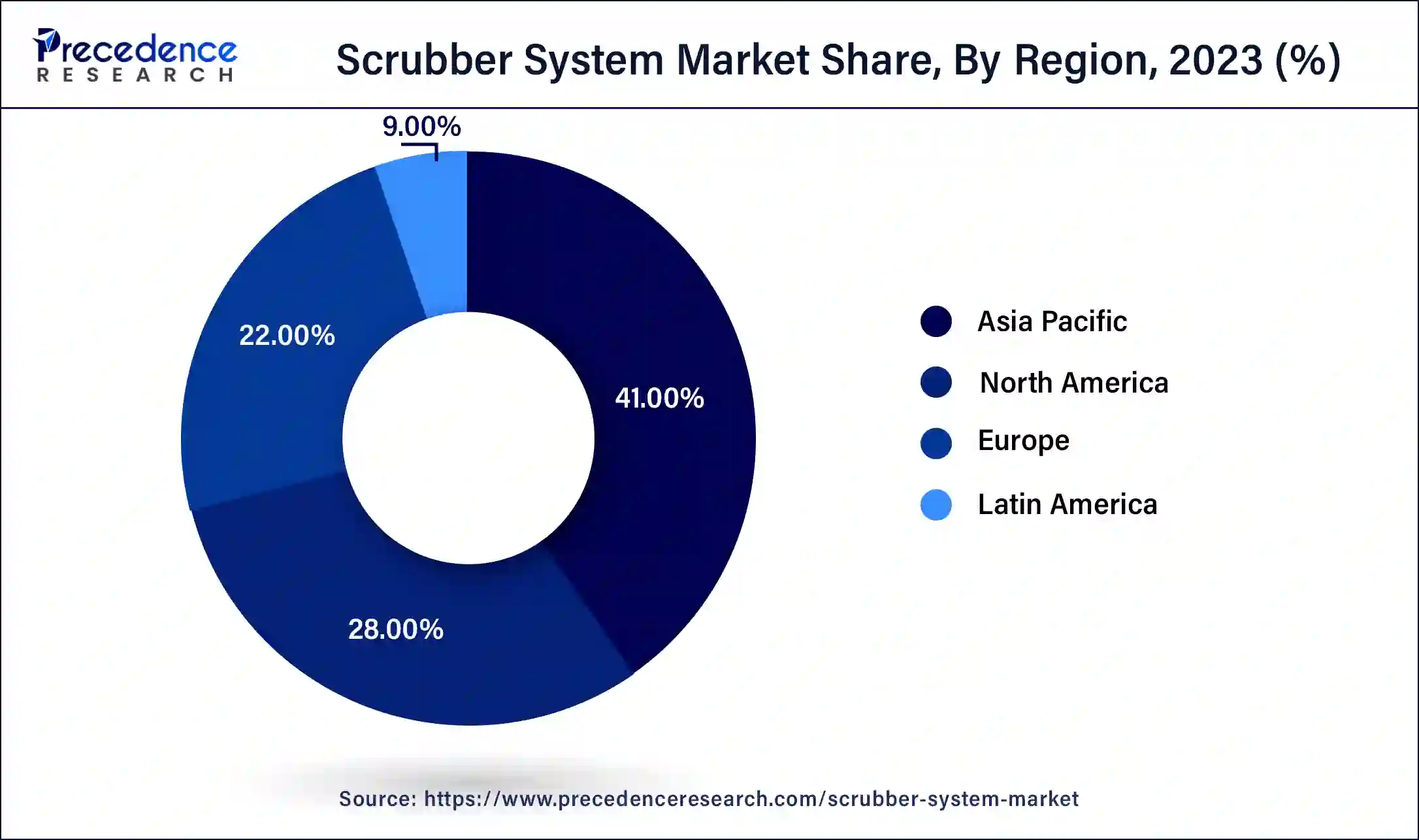

- Asia Pacific dominated the scrubber system market with the largest market share of 41% in 2024.

- North America is expected to expand at a rapid pace in the market during the forecast period.

- By product type, the wet scrubber system segment accounted for the dominating share of the market in 2024.

- By product type, the dry scrubber system segment is expected to witness significant growth in the market during the forecast period.

- By application, the particulate cleaning segment held the largest share of the market in 2024.

- By application, the gaseous/chemical cleaning segment is expected to grow at the fastest rate in the market during the forecast period.

- By end-users, the marine segment accounted for the largest market share of 33% in 2024.

- By end-users, the oil and gas segment is observed to be the fastest-growing in the market during the forecast period.

Impact of AI on the Scrubber System Market

The scrubber system integrates advanced AI-enabled control and monitoring, optimizing EGCS performance with constant refinement. The scrubber system market minimizes losses from fines. Downtime and fuel switching costs through advanced analytics and enhanced monitoring, reducing compliance-related operating expenses.

The IoT is revolutionizing scrubber system maintenance with remote sensors and real-time data transmission, enabling proactive upkeep and minimizing downtime. From advanced designs to AI and IoT integration, the industry adapts to environmental challenges. As industries prioritize emission reduction, scrubber systems play a crucial role in creating a sustainable future. Key benefits include reduced maintenance hours, extended system life, and optimized power consumption through AI analytics. Having an automated system helps you to reduce manpower, accident risks, and equipment hazards.

- In September 2022, SoftBank Robotics Australia unveiled Scrubber 50, developed by Gausium Robotics, at the ISSA Cleaning & Hygiene Expo in Sydney. Scrubber 50 was introduced as a fully automated AI-powered floor cleaning robot featuring a comprehensive array of sensors, including six cameras (3D/2D) and a LiDAR sensor, for fall prevention and collision detection.

Asia Pacific Scrubber System Market Size and Growth 2025 to 2034

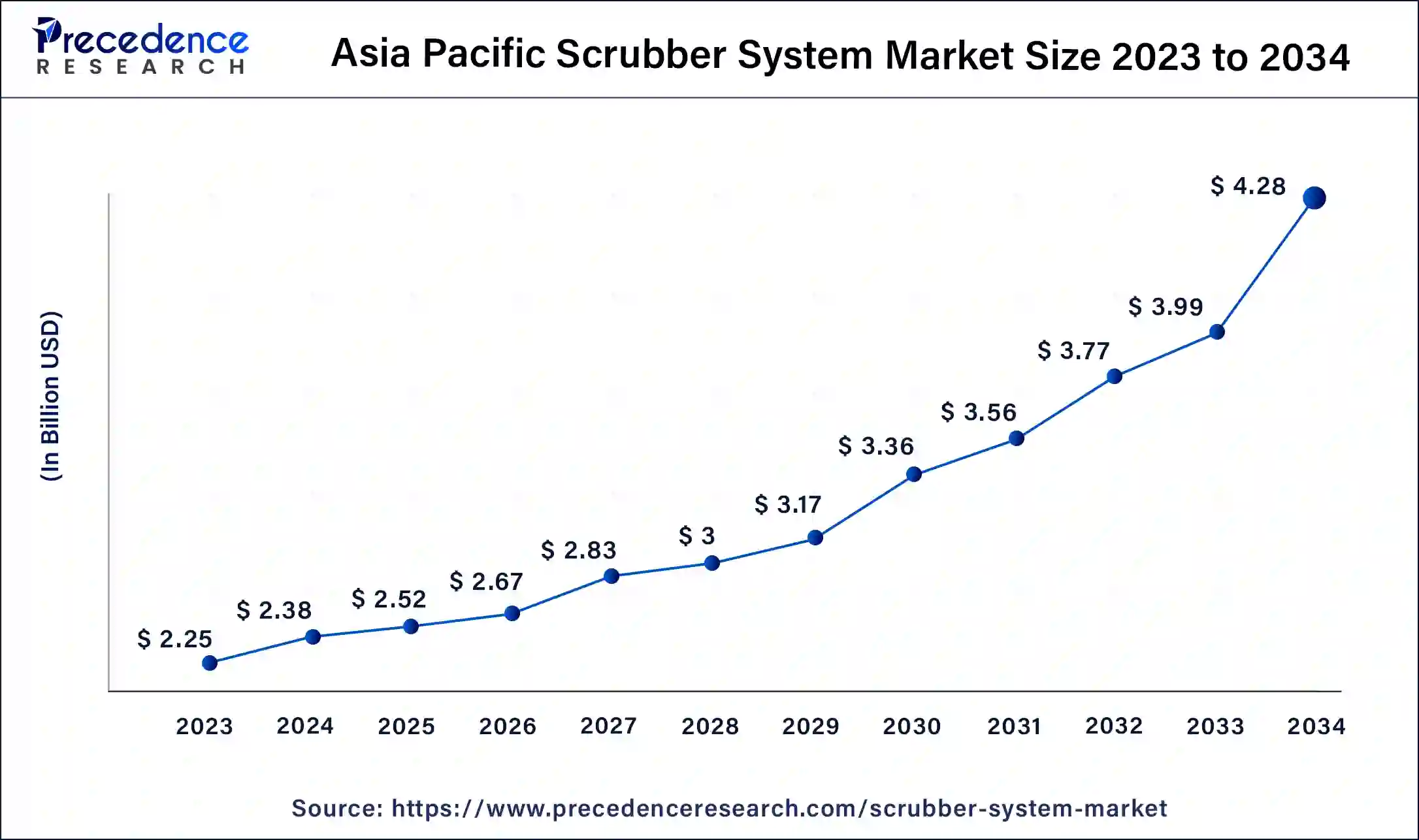

The Asia Pacific scrubber system market size was exhibited at USD 2.38 billion in 2024 and is predicted to reach around USD 4.28 billion by 2034, poised to grow at a CAGR of 6.04% from 2025 to 2034.

Asia Pacific held the leading share of the scrubber system market in 2024 and is observed to witness productive growth during the forecast period. Rapid economic growth and industrialization in Asia Pacific have led to increased demand for raw materials and goods, which are primarily transported via maritime routes. This growth fuels the need for efficient and environmentally friendly shipping solutions, including scrubber systems. There is growing awareness and concern about environmental sustainability in Asia Pacific. These factors collectively contribute to the region's leading position in adopting and advancing the scrubber system market.

- China's State Council released an action plan to enhance air quality as part of its push for high-quality economic development. The plan aims for bluer skies by 2025 through green industrial shifts, cleaner energy, and low-carbon transportation. It targets a 10% reduction in particulate matter 2.5 levels in cities and above by 10 percent by 2025.

- According to NorthStandard, numerous ports and regions have already announced restrictions on the discharge of wash water from open-loop scrubbers. Exhaust gas cleaning systems (EGCS), commonly known as scrubbers, are recognized as an approved means to comply with the IMO 2020 global sulfur cap. In China, specific regulations prohibit discharge in Inland River Emission Control Areas (ECAs), port zones within coastal ECAs, and the Bohai Sea.

North America is observed to expand at a rapid pace in the scrubber system market during the forecast period. Significant growth in the scrubber system market is driven by stringent environmental regulations from agencies like the Environment Protection Agency (EPA), industrial activities, and commitments to improving air quality. In the United States, electricity generation and industrial activities contribute to half of greenhouse gas emissions, primarily CO2 from fossil fuels. These sectors also produce various chemical and acidic waste products. Scrubber systems are well suited for these industries due to their ability to treat contaminants and high levels of air pollutants.

- In April 2024, the European Union parliament revised the law to reduce air pollution in the EU for a clean and healthy environment for citizens and to achieve the EU's zero air pollution vision by 2050. The new rules set stricter 2030 limits and target values for pollutants with a severe impact on human health, including particulate matter (PM2.5, PM10), NO2 (nitrogen dioxide), and SO2 (sulfur dioxide).

Market Overview

Scrubber systems are widely employed in industries for treating exhaust, and vent gases and are an effective method in the inhibition of air pollution. These gases can sometimes contain harmful particles that impact the environment and human health. The scrubber system market solutions are increasingly preferred over traditional methods due to their cost effectiveness and effectiveness in eliminating particulate matter and gases.

Application of scrubbing systems encompasses the removal of particulates, dust, and odors from industrial exhaust and venting systems or residues in continuous or emergency operations of chemical, fertilizer, petrochemical, refinery, pharmaceutical, mining, and other industries. Scrubber systems, including chemical and gas scrubbers, constitute a varied array of devices for controlling air pollution by removing gases and particulates from industrial exhaust streams.

Scrubber System Market Growth Factors

- Stringent carbon emissions norms by oil and gas industries drive the growth of the scrubber system market.

- Growing pollution and particulate matter lead to various environmental and health conditions.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 10.32 Billion |

| Market Size in 2025 | USD 6.15 Billion |

| Market Size in 2024 | USD 5.80 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.93% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Type, Application, Orientation, End-user, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

Stringent government regulation to battle air pollution

Regulation imposed by global entities such as the International Maritime Organization (IMO), the European Union (EU), the U.S. Environmental Protection Agency (EPA), and others aims to reduce environmental impact on both global and local air quality. A primary focus is on lowering sulfur oxide (SOx) emissions, largely from traditional marine fuels with high sulfur content. These rules compel ship designers, owners, and operators to adopt effective measures for SOx compliance. The stringent requirements outlined in regulations like the Clean Air Act (CAA) are driving the demand for the scrubber system market in the maritime sector.

- In August 2022, President Joe Biden signed into law the most robust U.S. climate action to date. The Inflation Reduction Act allocated billions in strategic investment to promote clean energy and climate justice.

Focus on waste management

Scrubbers are vital in waste management, serving to regulate emissions from a variety of sources such as municipal and medical waste incinerators, as well as industrial operations like cement and lime kilns, metal smelters, petroleum refineries, glass furnaces, sulfuric acid plants. They are critical devices that employ gas absorption techniques to extract harmful gases from waste gas streams. Scrubbers are effectively removing acid gases (e.g., HCl, HF, and H2SO4) in industrial waste streams. These capabilities make scrubbers essential solutions driving growth in the scrubber system market for emission control technologies.

Restraint

High installation and operating cost

The scrubber system market faces high costs associated with various factors such as installation, maintenance, operation, and waste disposal. Protection against freezing temperatures poses a significant challenge, leading to increased capital and operational expenses during winter months in the scrubber system market. Waste disposal can also become costlier due to specific handling requirements. Packed bed scrubbers, in particular, face high installation, operational, and wastewater disposal costs compared to other scrubbers. Moreover, ongoing maintenance of packaging material adds to operational costs along with expenses related to pump and fan power and solvent replenishment, influencing investment decisions and operational strategies.

Opportunity

Advancement in scrubber system

Manufacturers of scrubbers are actively developing new and enhanced scrubbing technologies. Another major driver of the global scrubber system market is the requirement to meet stringent carbon emissions norms by the oil and gas industries. Additionally, the necessity to reduce operational expenditures is boosting oil and gas companies to set up advanced scrubbing technology. This is foremost due to a surging number of rigs being deployed around the world. Advancements aim to minimize water, electricity, and chemical usage in scrubbing processes while boosting efficiency and cutting costs. Innovations include automated battery maintenance, customizable features, and size reduction. These changes are being made to address environmental concerns, which are increasing globally.

Product Type Insights

The wet scrubber system segment accounted for the dominating share of the scrubber system market in 2024. Wet scrubbing systems utilize a scrubbing liquid to clean exhaust gases by removing pollutants and dust particles. Wet scrubber systems find extensive use across diverse industrial sectors such as industrial boilers, incinerators, metals processing, chemical production, asphalt production, and fertilizer manufacturing. Wet scrubbers effectively remove pollutants from exhaust gases, achieving a high level of pollutant removal through contact with scrubbing solutions like water or specific reagents. They are effective in removing acids and contaminants from exhaust gases. The purpose of wet scrubbers is to purify vapors and gases to acceptable levels before releasing them into the environment or using them for other purposes.

ERGIL wet scrubbers are particularly effective in treating chemicals such as ammonia from process exhaust air streams.

The dry scrubber system segment is expected to witness significant growth in the scrubber system market during the forecast period. Dry scrubbers offer cost advantages over wet scrubbers due to their simpler design, reduced water consumption, and lower waste processing requirements. Dry scrubbers primarily target acid gases from combustion sources. Generally, this is done by introducing a series of dry reactants to exhaust gas at high speeds. This neutralizes the pollutants in the gas. This versatility and effectiveness in diverse industrial settings underscore why the dry scrubber system is experiencing rapid growth in the scrubber system market.

Application Insights

The particulate cleaning segment held the largest share of the scrubber system market in 2024. Particulate matter (PM) refers to a mixture of solid and liquid droplets suspended in the air. Wet scrubbers are air pollution control devices utilized to eliminate particulate matter and acid gases from waste gas streams at stationary sources. These pollutants are primarily captured through mechanisms such as impaction, diffusion, and interception onto liquid droplets. The scrubber system is widely used to remove particular matters, demonstrating their critical role in environmental stewardship and regulatory compliance.

The gaseous/chemical cleaning segment is expected to grow at the fastest rate in the scrubber system market during the forecast period. Scrubbers have traditionally focused on removing sulfur oxides from stack gases. However, as advancements in control systems continue to evolve, there is a growing trend towards designing scrubbers that can simultaneously remove gases and particulate matter in combustion processes. In a gas treatment system, the principle involves washing waste gases using Rasching rings. This method effectively captures both gas phase pollutants and solid particulates, ensuring cleaner emissions from industrial processes.

End-user Insights

The marine segment accounted for the largest market share of the scrubber system market in 2024. Scrubber technology is a key element in the global maritime industry to reduce sulfur oxide (SOx) emissions from ships. This system can be used to replace conventional fuel oil and help ships comply with international environmental regulations. The marine industry is grappling with the adoption of new technologies and operational standards to meet stringent international, regional, national, and local regulations aimed at reducing exhaust emissions from ships.

The International Maritime Organization (IMO) adopted guidelines on the approval, installation, and use of exhaust gas scrubbers on board ships to ensure compliance with the sulfur regulation. The United Nations Convention on the Law of the Sea also bestows port states with a right to regulate and even ban the use of open-loop scrubber systems within ports and internal waters. Marine air pollution regulations typically require the use of low sulfur fuel to reduce SOx gaseous emissions and the sulfate portion of the particulate matter (PM) emissions.

- In April 2023, Dutch maritime tech firm Value Maritime and Singapore-based ship management company Eastern Pacific Shipping (EPS) completed the world's first CO2 liquid bunkering. The ship was fitted with Value Maritime's filter, approved by the American Bureau of Shipping. This carbon capture and storage (CCS) module separates up to 40% of the CO2 emissions from both main and auxiliary engines, storing it in a battery container onboard.

The oil and gas segment is observed to be the fastest-growing in the scrubber system market during the forecast period. In the oil and gas industry, scrubbers play a crucial role in eliminating impurities like hydrogen sulfide (H2S) and carbon dioxide (CO2) from the gas streams generated during drilling, refining, and processing operations. These impurities pose risks to both workers and the environment, and scrubbers help to reduce the impact of these pollutants.

Scrubber System Market Companies

- Alfa Laval

- Nederman Mikropul

- Wartsila

- Alfa Laval

- Yara Marine

- DuPont

- CECO

- Evoqua

- Verantis

- Fuji Electric

- Croll Reynold

- Fabritech Engineers

- Beltran Technologies

Recent Developments

- In March 2023, Wartsila delivered its first CCS-Ready scrubber systems, designed for Carbon capture and storage capabilities

- In August 2023, Wärtsilä offered carbon capture and storage (CCS) feasibility studies to shipowners and operators, making another milestone in its journey to research, develop, and introduce CCS technologies to the market.

Segments Covered in the Report

By Product Type

- Wet Scrubber System

- Dry Scrubber System

By Application

- Particulate Cleaning

- Gaseous/Chemical Cleaning

By Orientation

- Horizontal

- Vertical

By End-user

- Marine

- Oil & Gas

- Chemical & Petrochemical

- Pharmaceutical

- Glass

- Power Generation

- Metal and Mining

- Food, Beverages, & Agricultural

- Water & Wastewater Treatment

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting